Patents

Literature

92results about How to "Knead fully" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

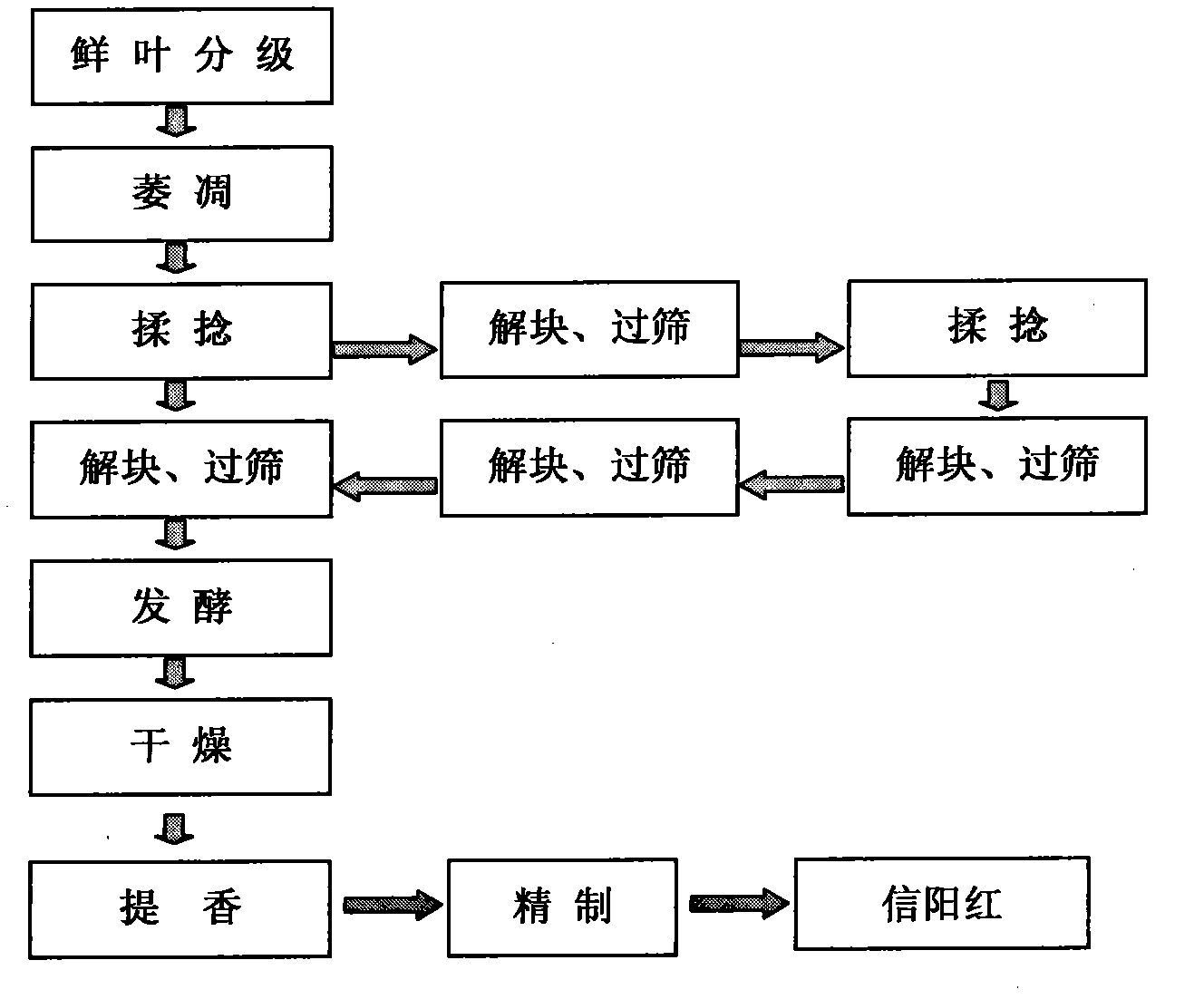

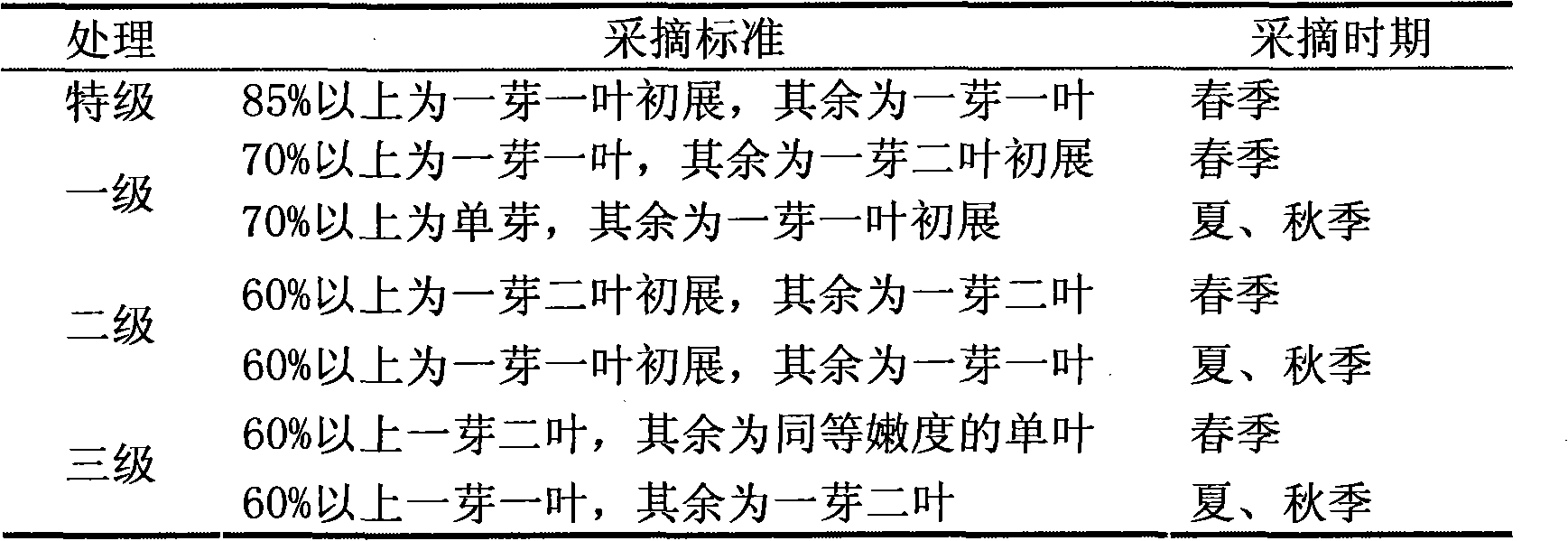

Xinyang red black tea processing technique

The invention relates to a Xingyang red black tea processing technique. The technique comprises the following parameters: wilting temperature: 25-30 DEG C; humidity: 60-70%; wilting time: 6-7 h; twisting machine rotating speed: 55-60 r / min; 2-3 times of twisting, each for 30 min; amount of tea feed: 30-35 kg; unravel machine rotating speed: 35 r / min; sieve pore size: 6#; 2-3 times of unravelling;temperature in a fermentation chamber: 2-7 DEG C; humidity in the fermentation chamber: 96%; tea spread thickness: 10 cm; oxygen supply amount: 5 L / min; fermentation time: 4.5 h; initial drying temperature: 115 DEG C; initial drying time: 20 min; re-drying temperature: 75 DEG C; and re-drying time: 30 min. The processing technique of the invention is unique, and the quality of the made black tea is excellent: the appearance of the product is fat and tender and compact, the peak of the tea is gold and the tea has bright luster; the endoplasm aroma of the tea has rich green flavour; the taste of the tea is mellow and sweet; the tea liquor is brilliantly red; and the root of the tea leaf is soft and green, has many sprouts and a colour of brilliant red.

Owner:信阳市浉河区茶叶办公室

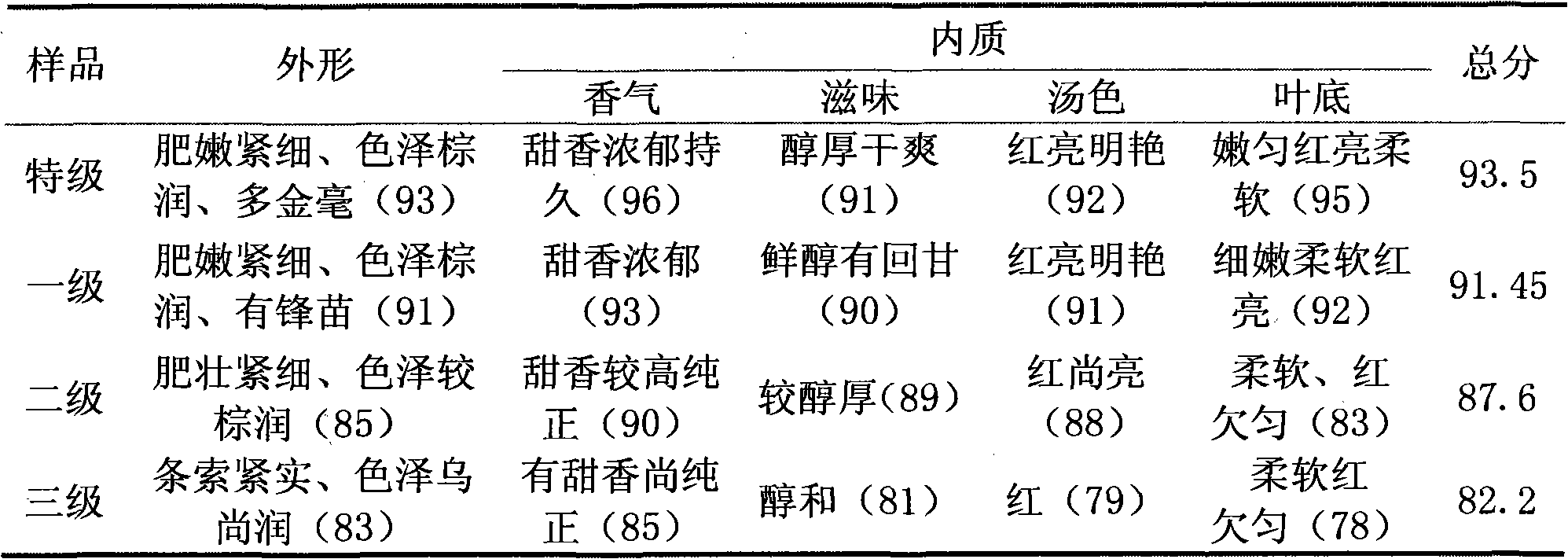

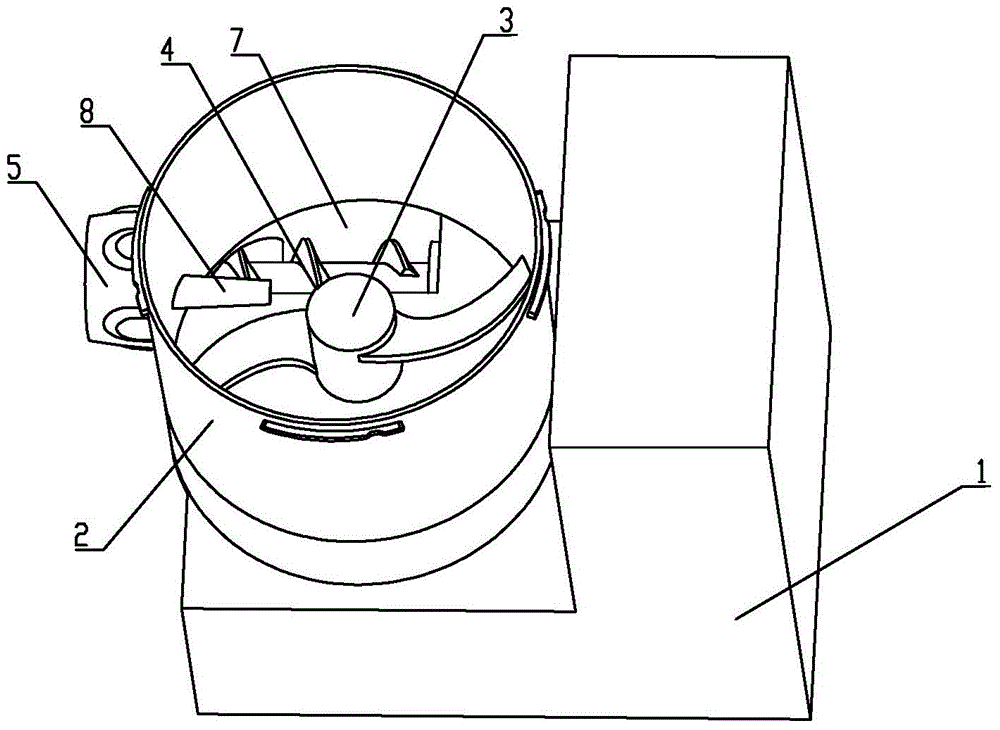

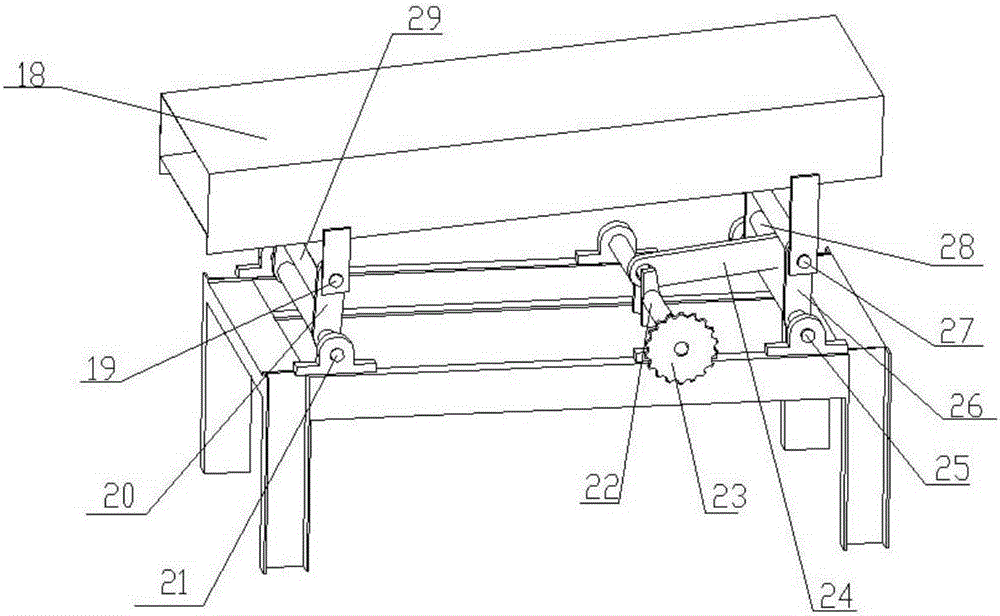

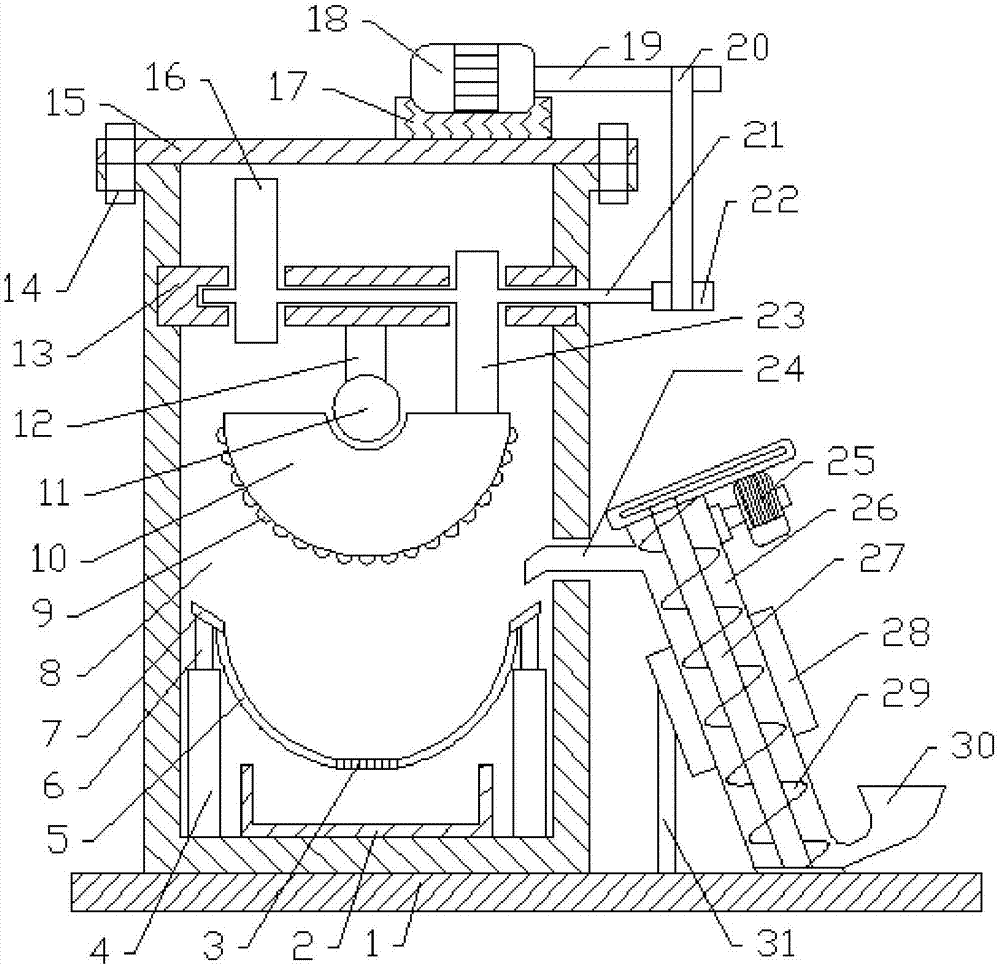

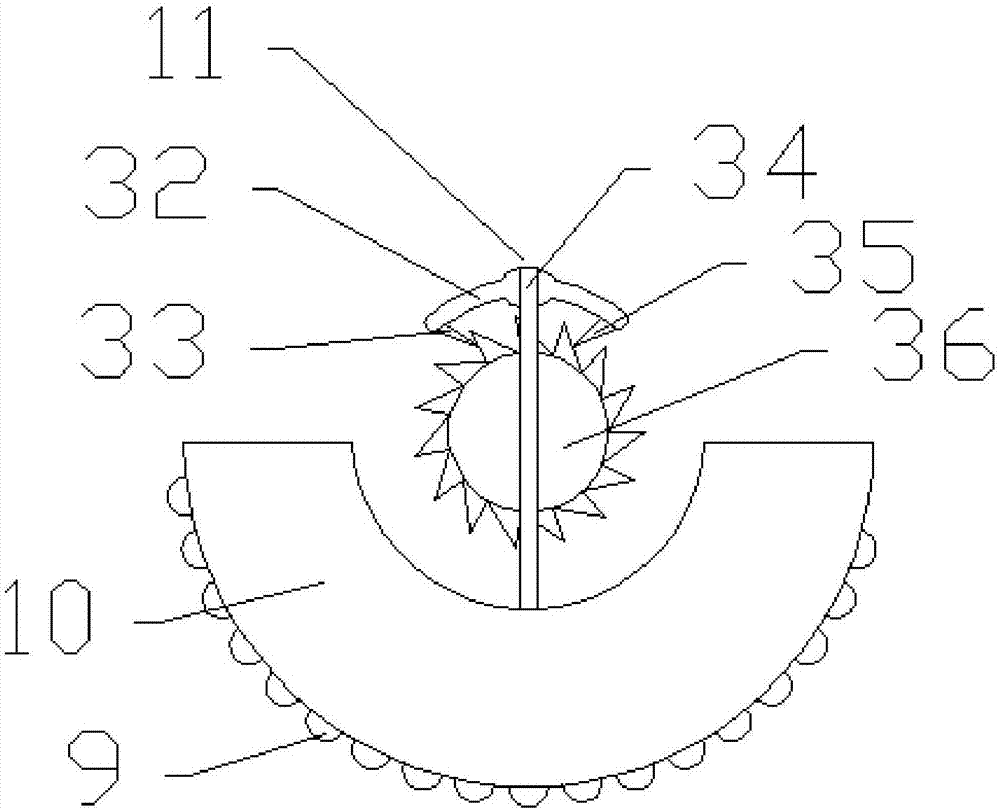

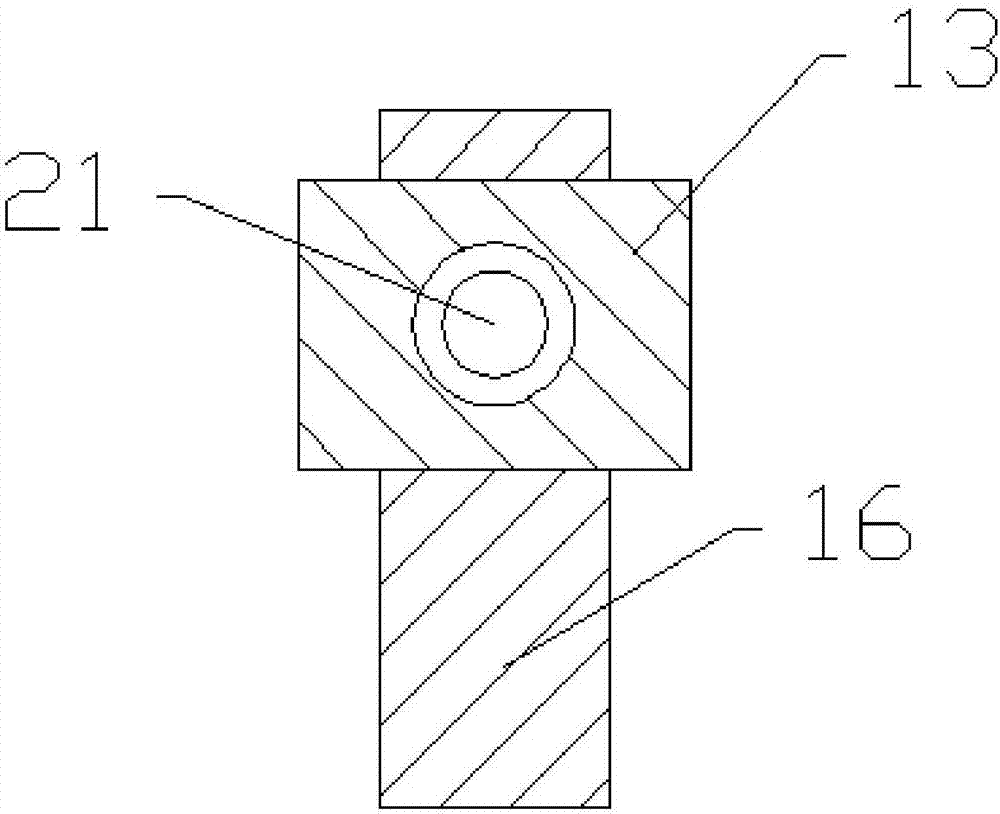

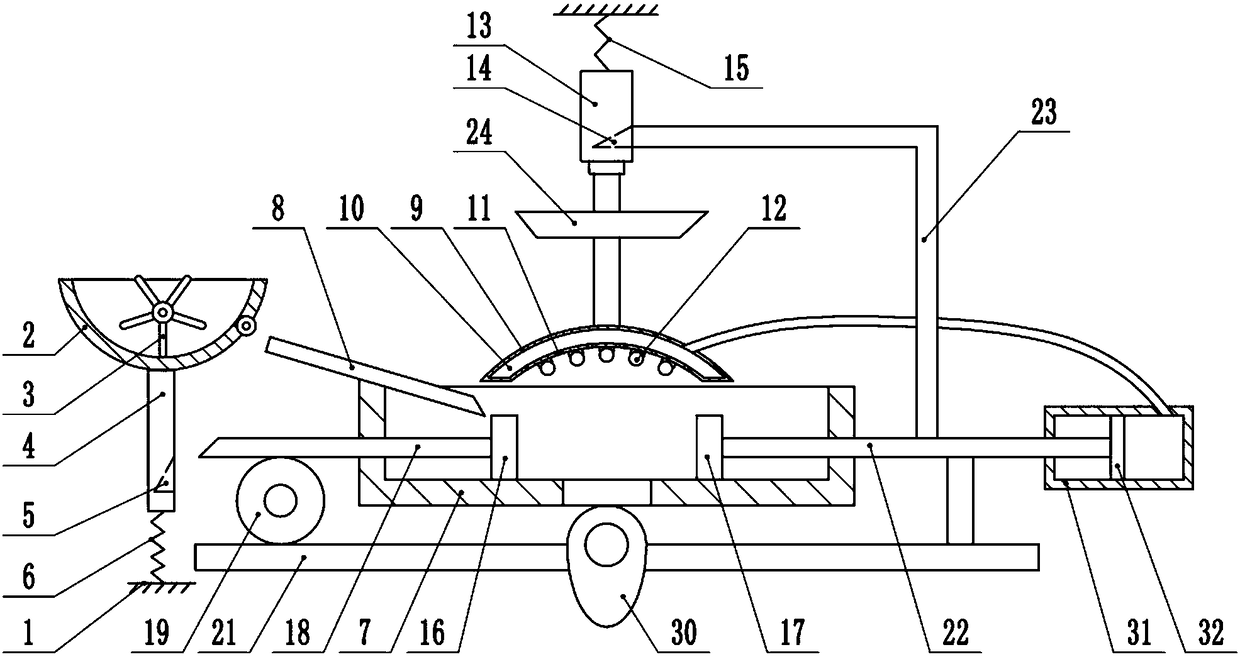

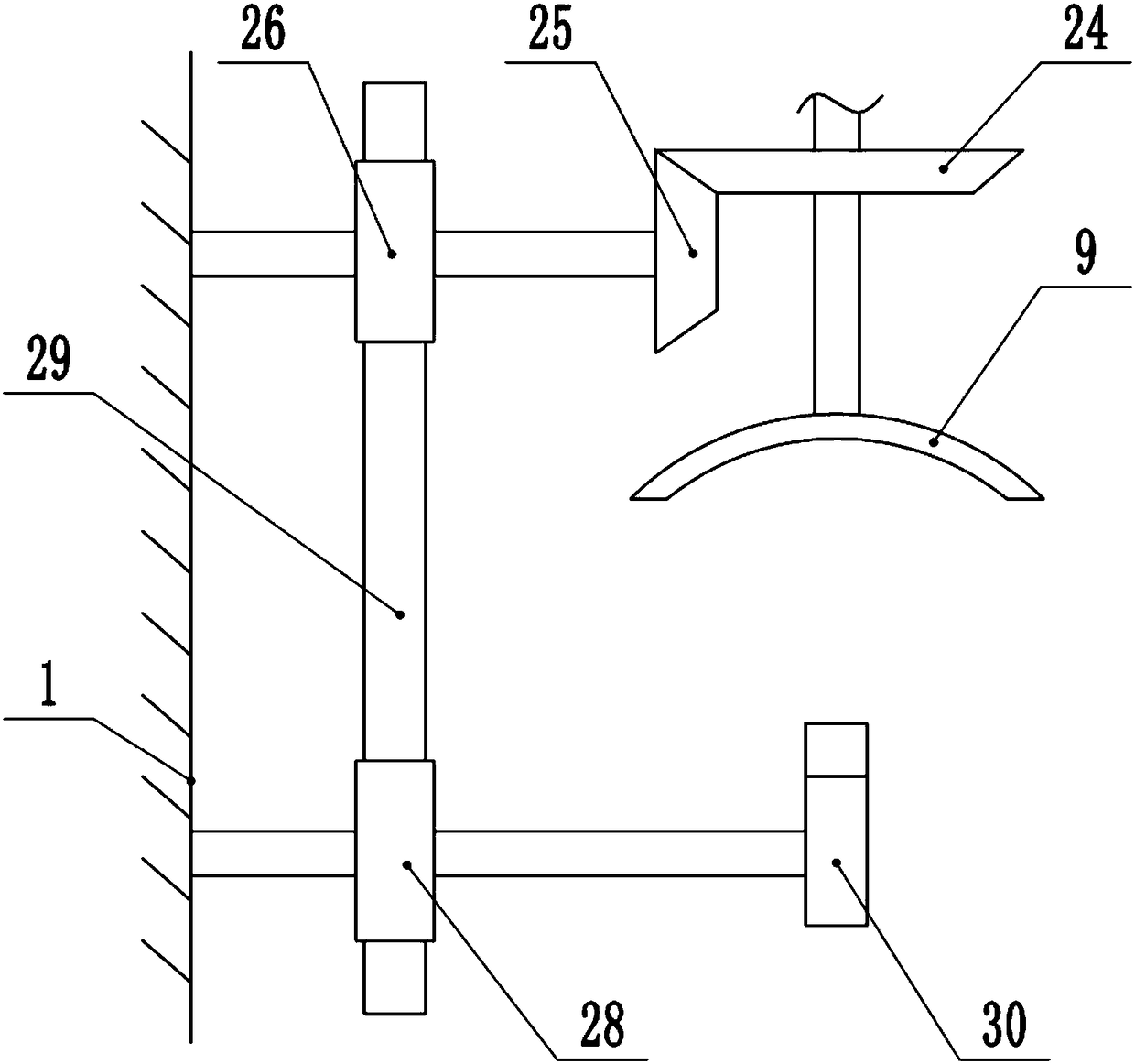

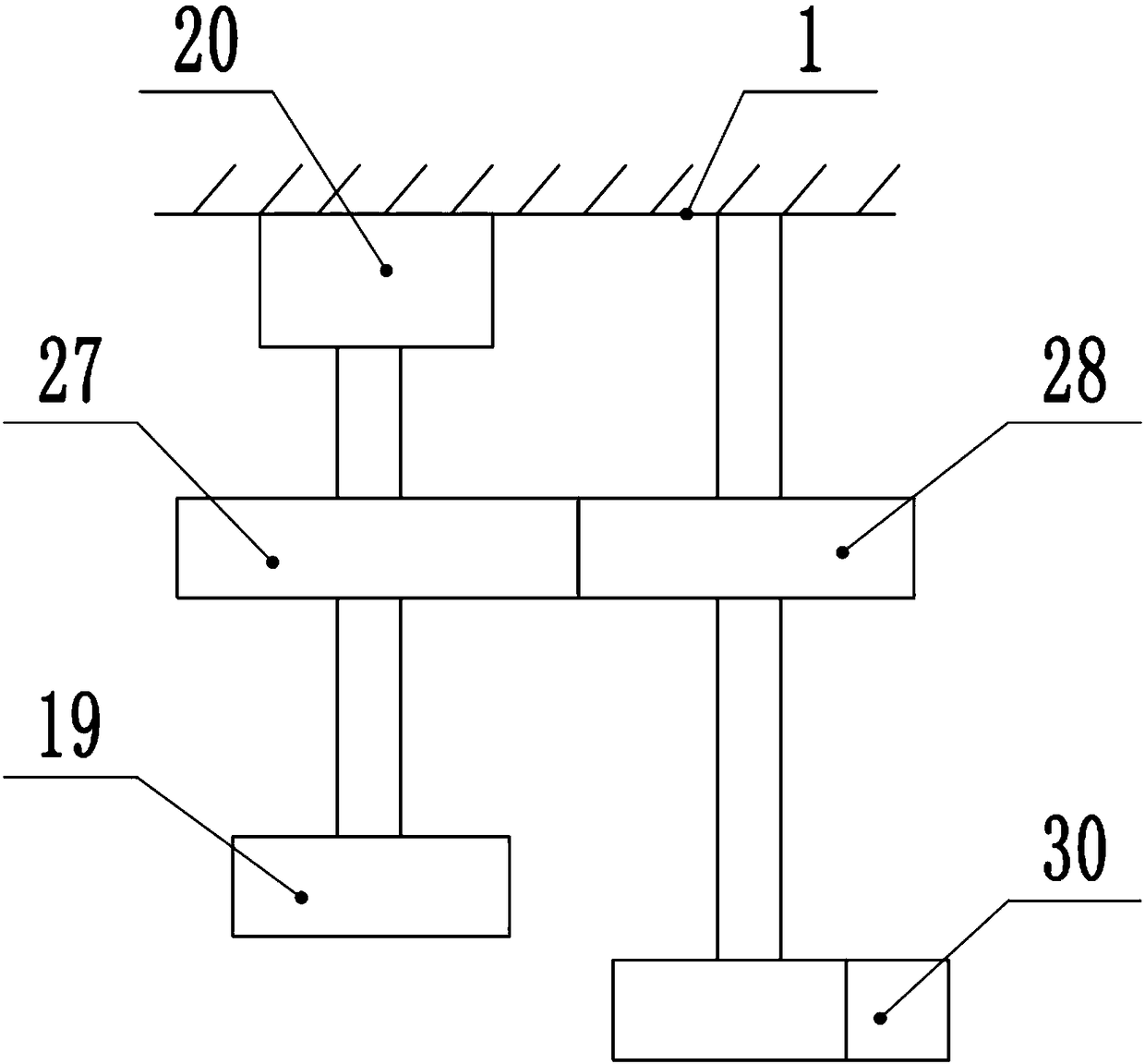

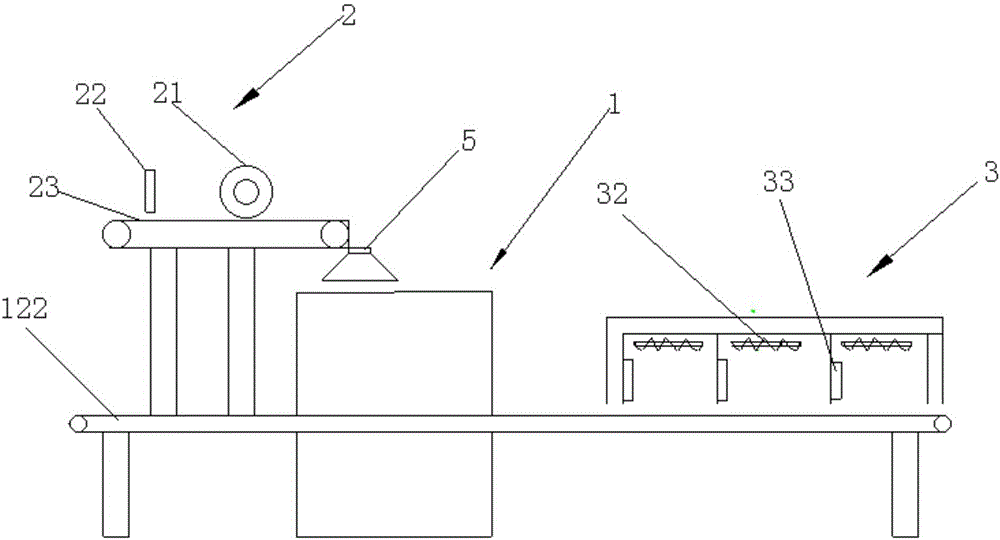

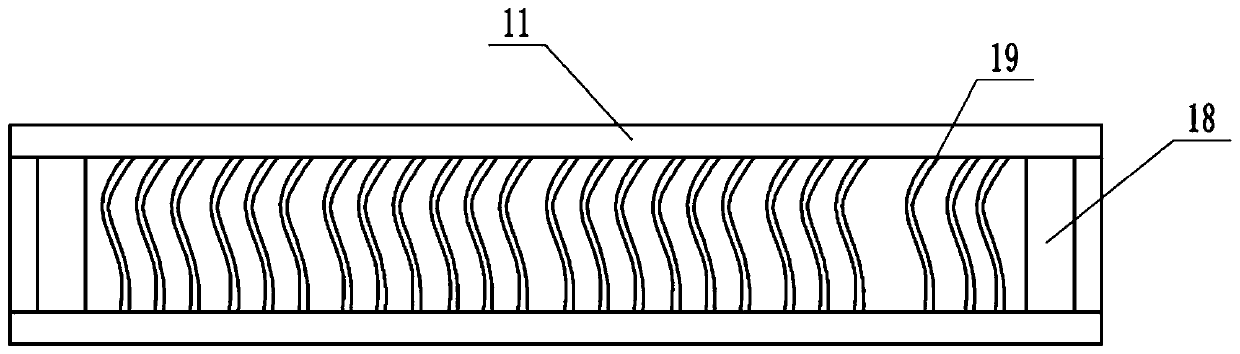

Kneading device of straw kneading machine

InactiveCN105195294AGood kneadingThe kneading device of the kneading machine has a simple structure and is easy to useCuttersGrain treatmentsFixed frameEngineering

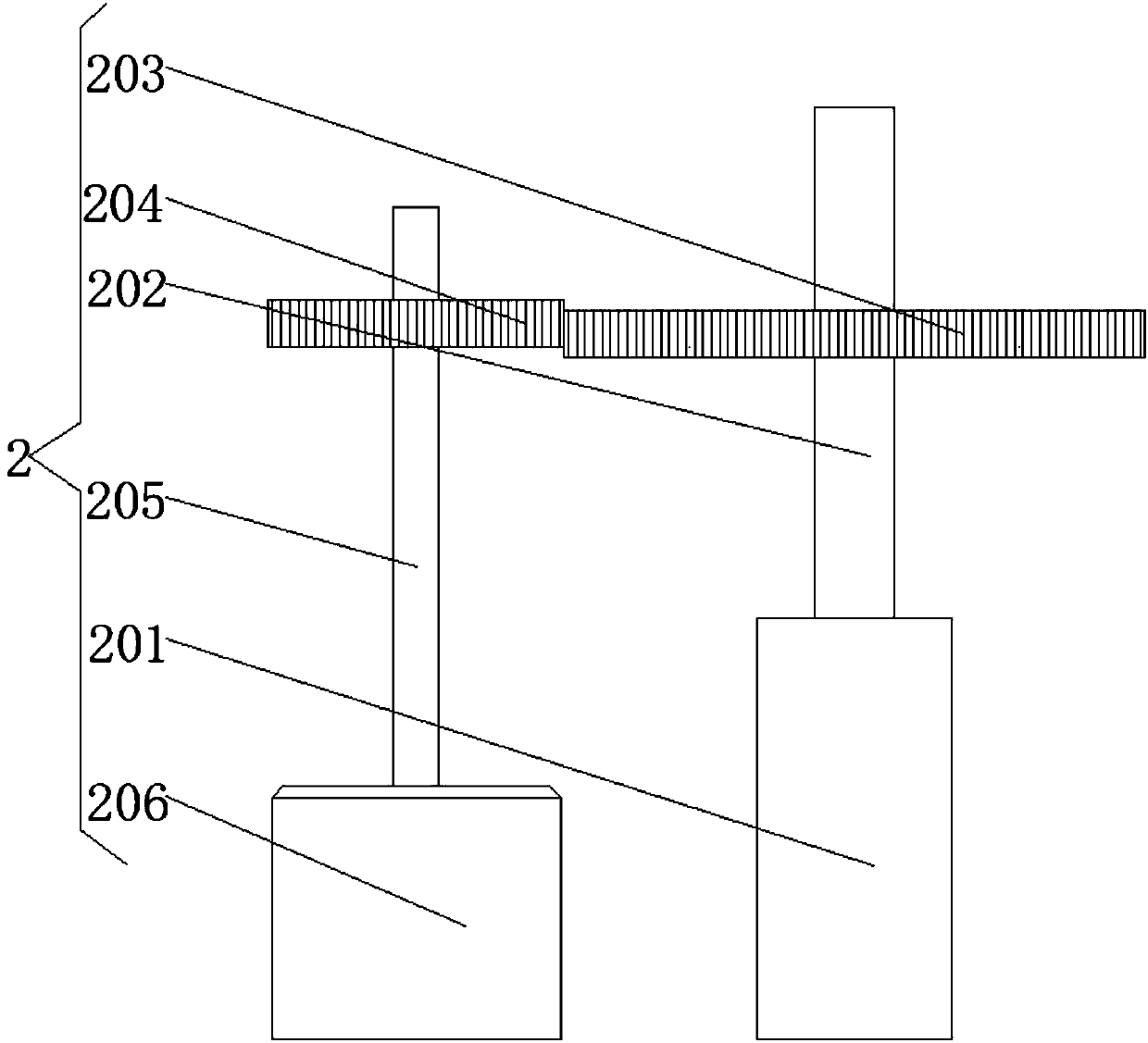

The invention provides a kneading device of a straw kneading machine. The kneading device comprises a bottom plate, a first bracket device, a first air cylinder device, a second air cylinder device, a material collection box, a feeding device, a second bracket device, a third air cylinder device and a crushing device, wherein the bottom plate is provide with a first fixed block; the first bracket device is provided with a first bracket, a second bracket, a first inclined rod and a second inclined rod; the first air cylinder device is provided with a first air cylinder, a first pushing rod, a first pushing plate and a first slide plate; the second air cylinder device is provided with a second air cylinder, a second pushing rod, a third bracket and the like; the feeding device is provided with a feeding hopper, a material collection hopper, a material distribution block, a fixed plate and the like; the second bracket device is provided with a first fixed plate, a second fixed frame, a third inclined rod and the like; the third air cylinder device is provided with a fourth air cylinder, a fourth pushing rod, a sixth bracket and the like; the crushing device is provided with a crushing frame, a rotary wheel, crushing teeth and the like. The kneading device can be used for efficiently kneading straws and crushing the kneaded straws, so that the straws are more fine and smooth.

Owner:蔡旭东

Domestic vertical type noodle maker

ActiveCN104542788AAccelerate the mixing speedImprove mixing efficiencyMixing/kneading with vertically-mounted toolsDough extruding machinesEngineeringExtrusion

The invention discloses a domestic vertical type noodle maker which comprises a base, a stirring cup, a stirring rod, a dough extrusion cylinder, a screw rod, a mold head and a control unit, wherein the base is provided with motors; the stirring cup is connected with the base; the stirring rod comprises a rod body as well as upper stirring teeth and lower stirring teeth which are arranged on the rod body; a dough inlet is formed in the communicating part of the stirring cup and the dough extrusion cylinder; a dough cutting rod is arranged on the inner wall of the stirring cup; the dough cutting rod is positioned between the upper stirring teeth and the lower stirring teeth; the stirring rod rotates to drive the upper stirring teeth and the lower stirring teeth to rotate and mix and stir flour with water to make dough; the dough cutting rod cooperates with the upper stirring teeth and the lower stirring teeth to cut off or tear and deform the dough into dough pieces which are smaller than the dough inlet; when the upper stirring teeth and / or the lower stirring teeth rotate to the dough cutting rod, the projects of the dough cutting rod and the upper stirring teeth and / or the lower stirring teeth in the horizontal direction are at least partially overlapped. By adopting the mode, the effects of no residue, high possibility of dough feeding and high processing efficiency can be achieved.

Owner:JOYOUNG CO LTD

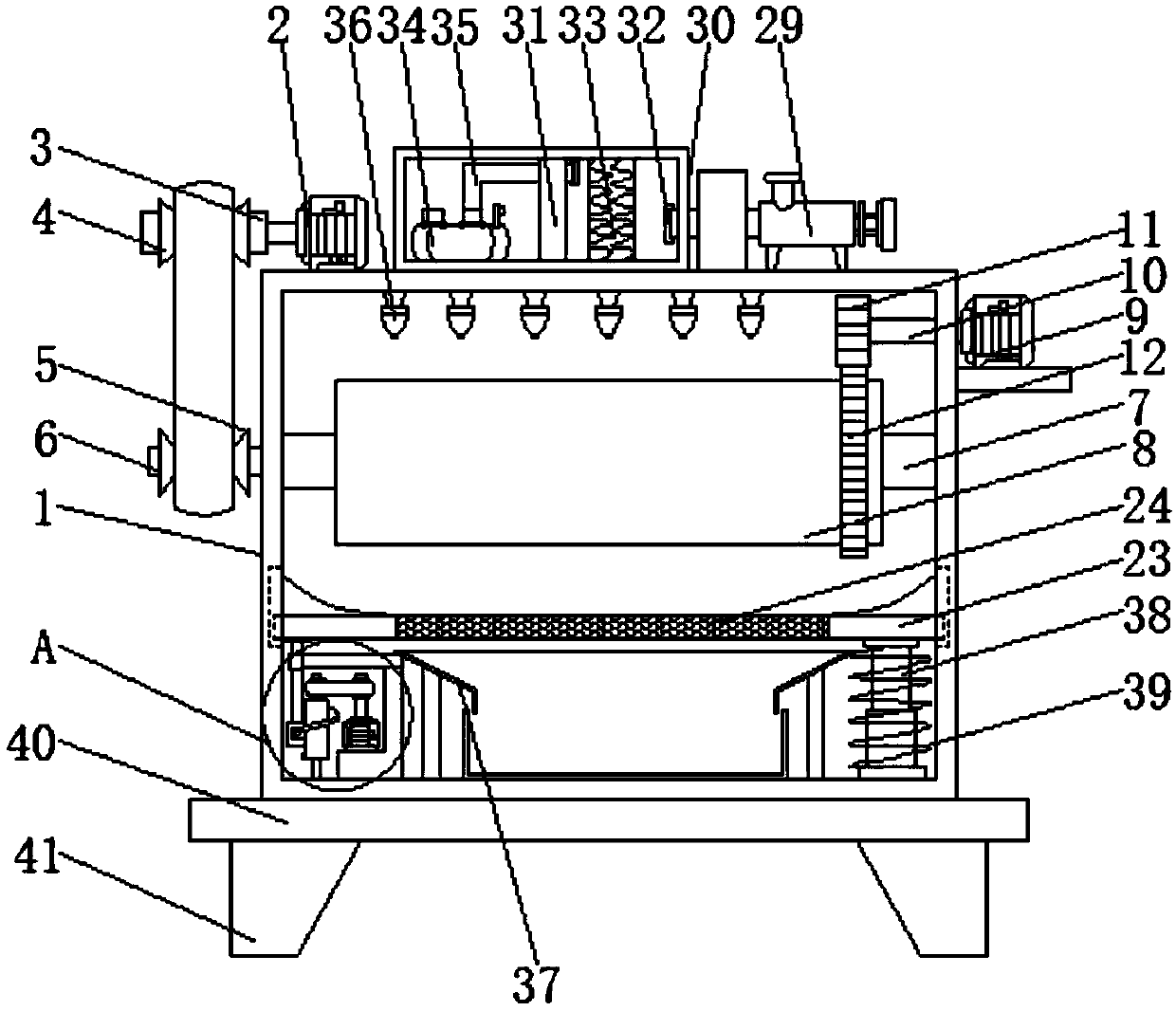

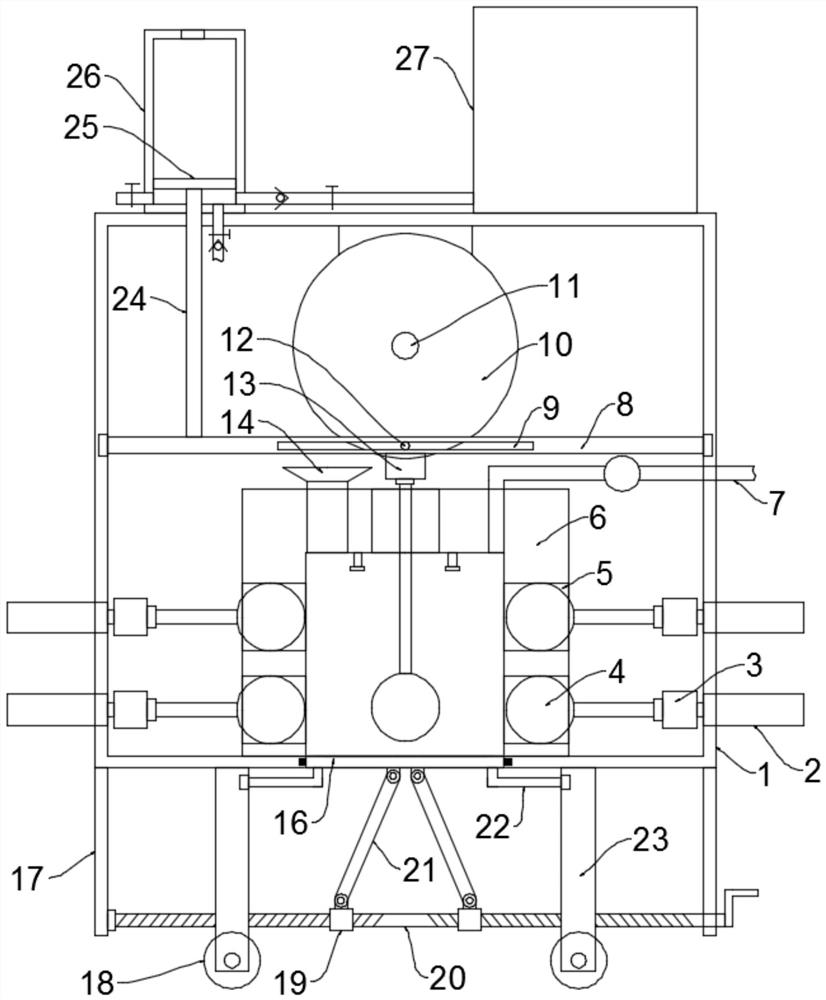

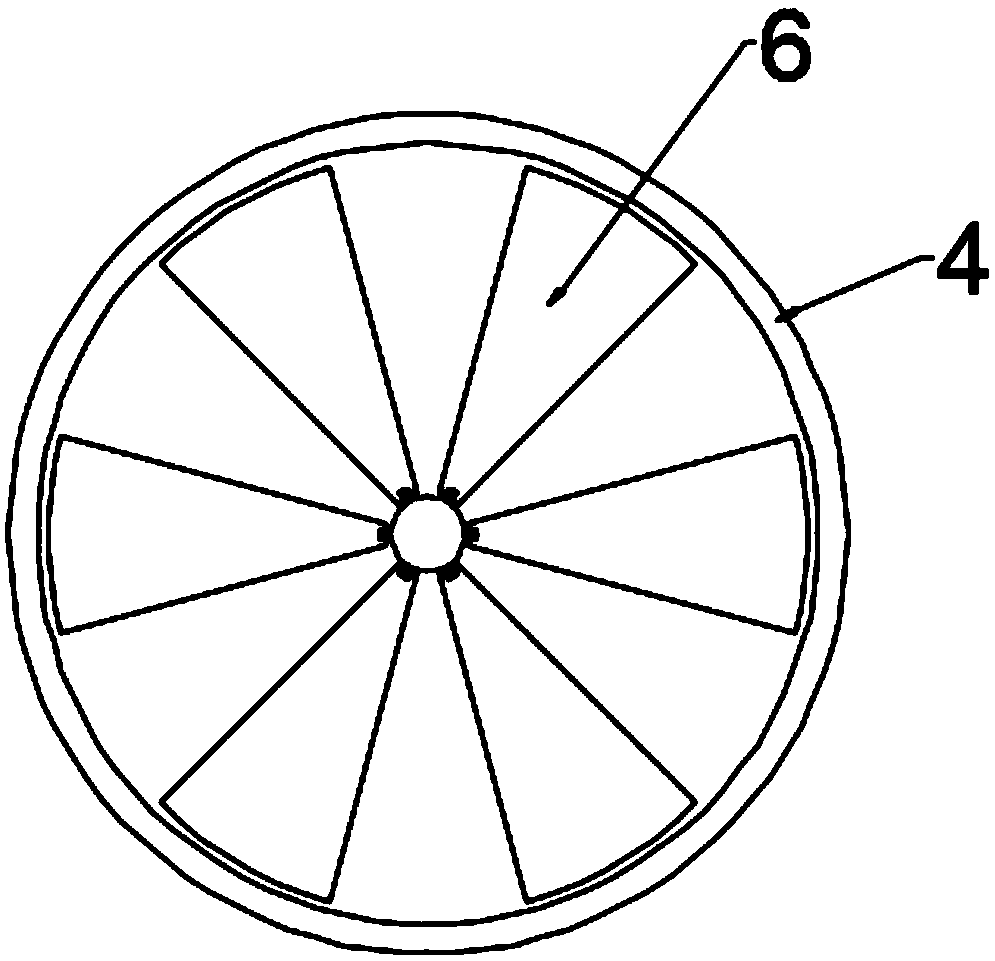

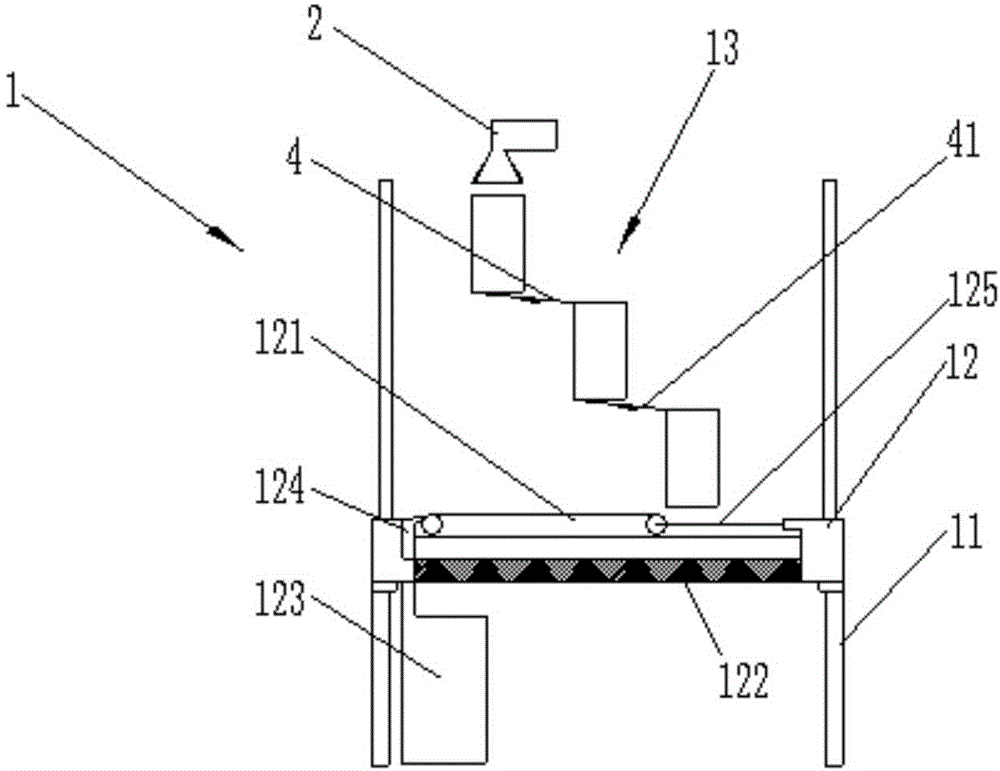

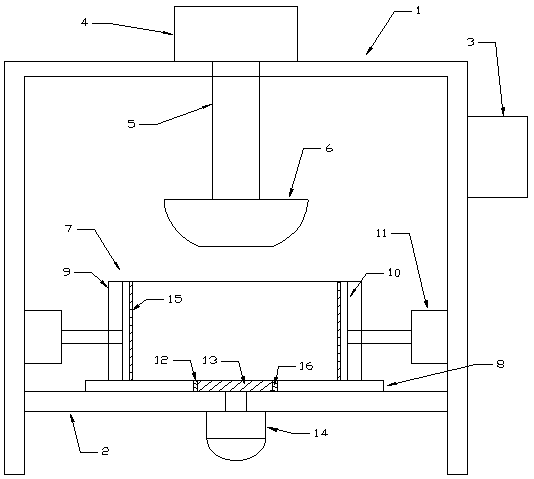

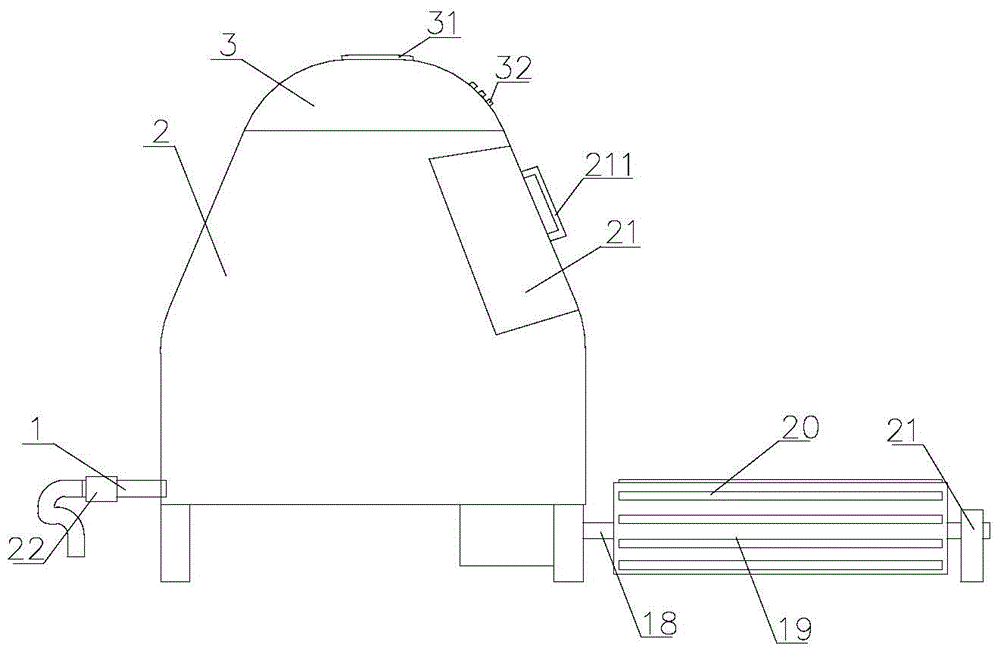

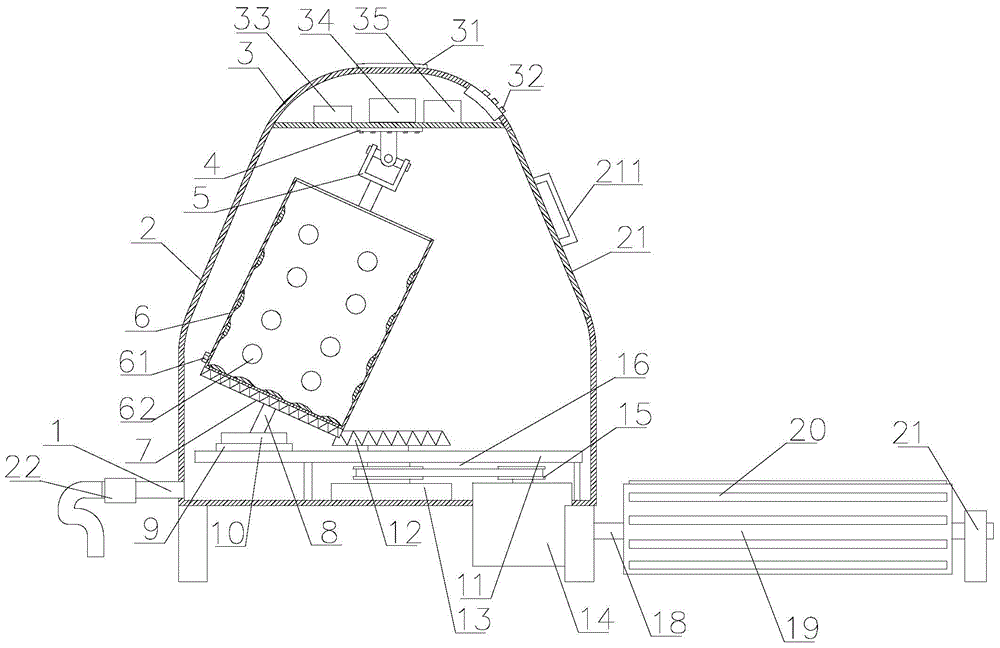

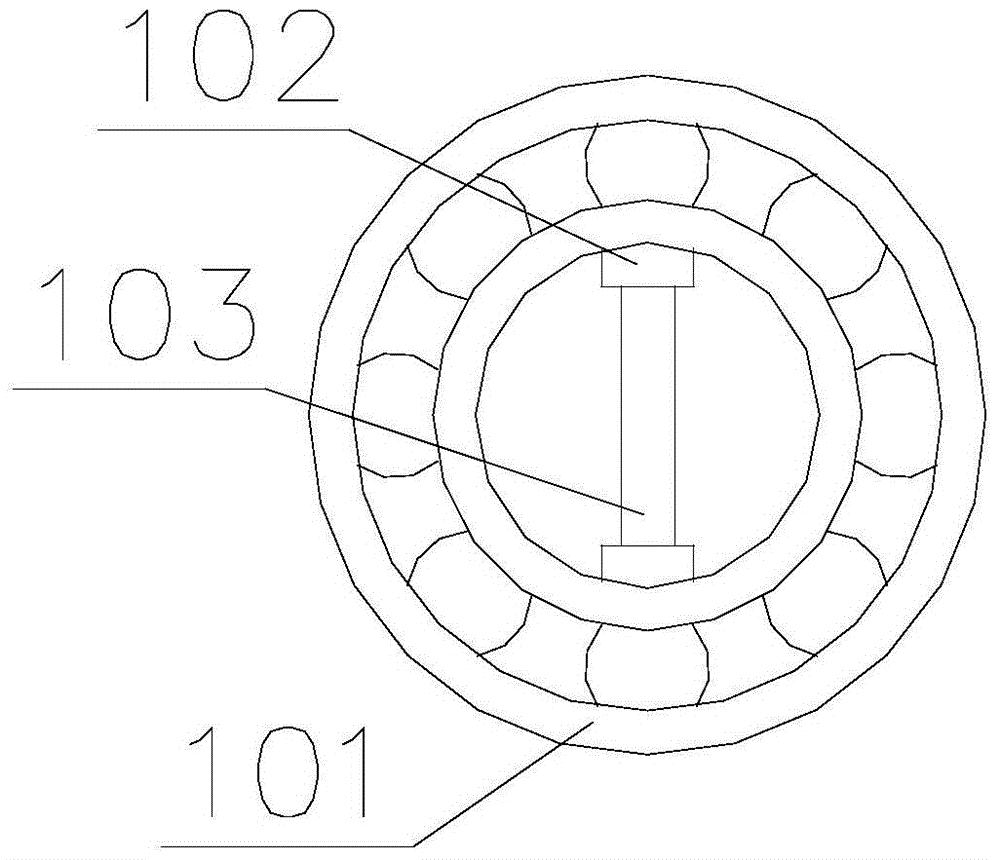

Rolling and screening device with drying function for tea leaves

PendingCN107549355AIncrease productivitySolve screeningSievingPre-extraction tea treatmentRotational axisAgricultural engineering

The invention discloses a rolling and screening device with a drying function for tea leaves. The device comprises a fixed box. A first motor is fixedly connected to the top of the fixed box and the output shaft of the first motor is fixedly connected to a rotary shaft through a coupling; a first belt wheel is fixedly connected to the surface of the rotary shaft; the surface of the first belt wheel is in transmission connection to a second belt wheel through a belt; a rotary shaft penetrates through the middle of the second belt wheel; a rotary column between two sides of the inner wall of thefixed box is fixedly connected to a rotary barrel; and one side of the fixed box is fixedly connected to the second motor through a base. The invention relates to the technical field of tea leaf production. The rolling and screening device with the drying function for tea leaves disclosed by the invention solves the problem that screening and rolling are separated commonly in existing tea leaf production, and realizes an integrated operation of rolling, screening and drying, so that the tea leaf production efficiency is increased, the workload of people is alleviated, and a lot of time of people is saved.

Owner:安吉十万亩白茶有限公司

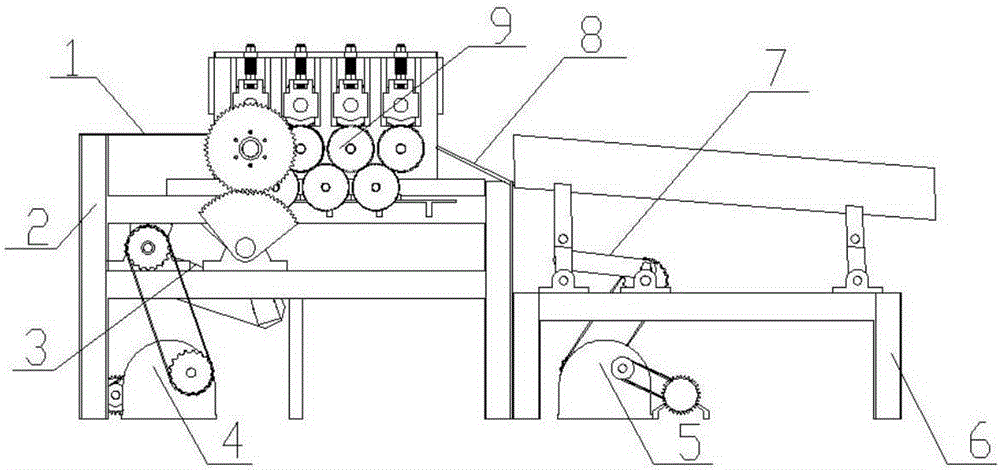

Ramie breaking vibration machine

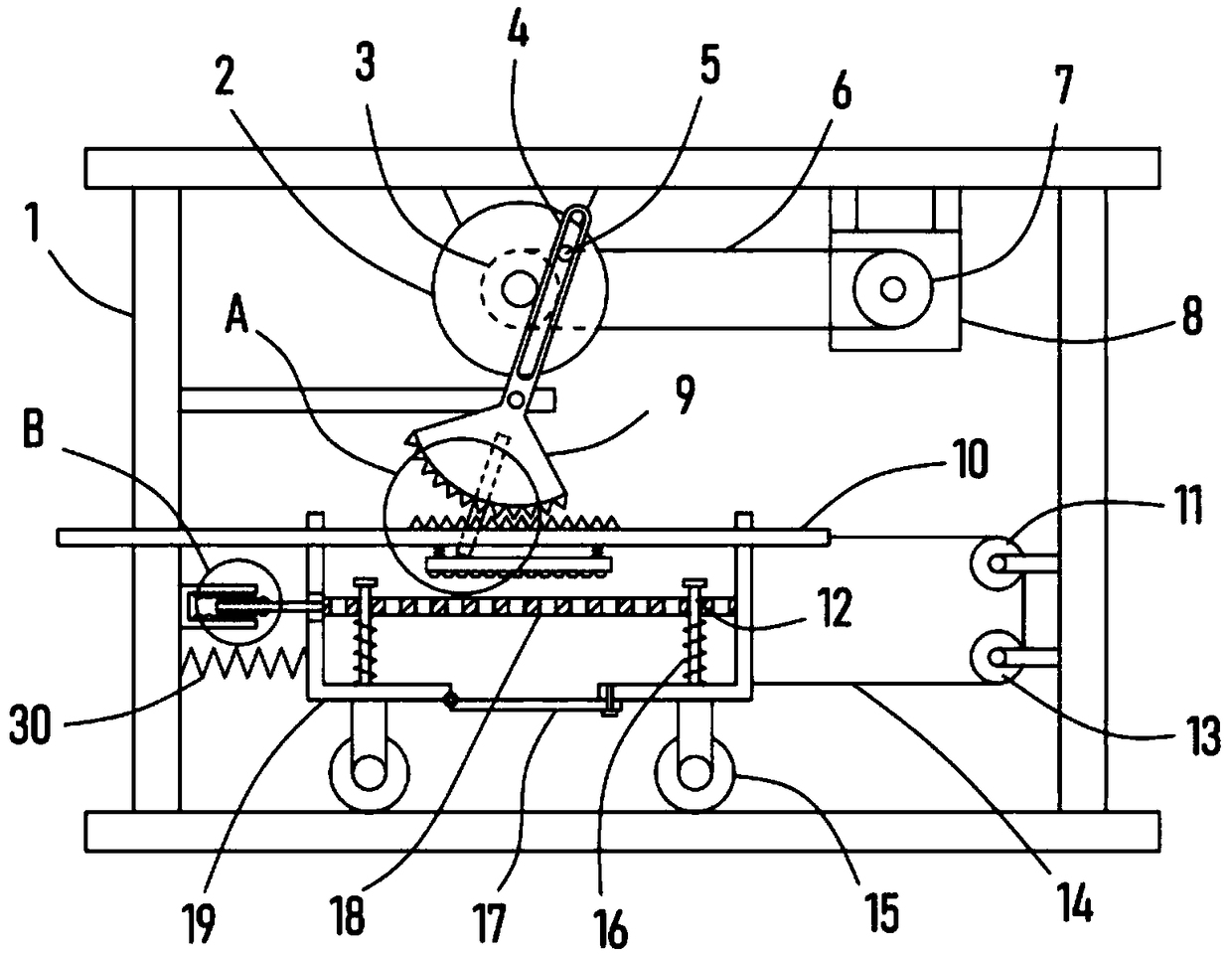

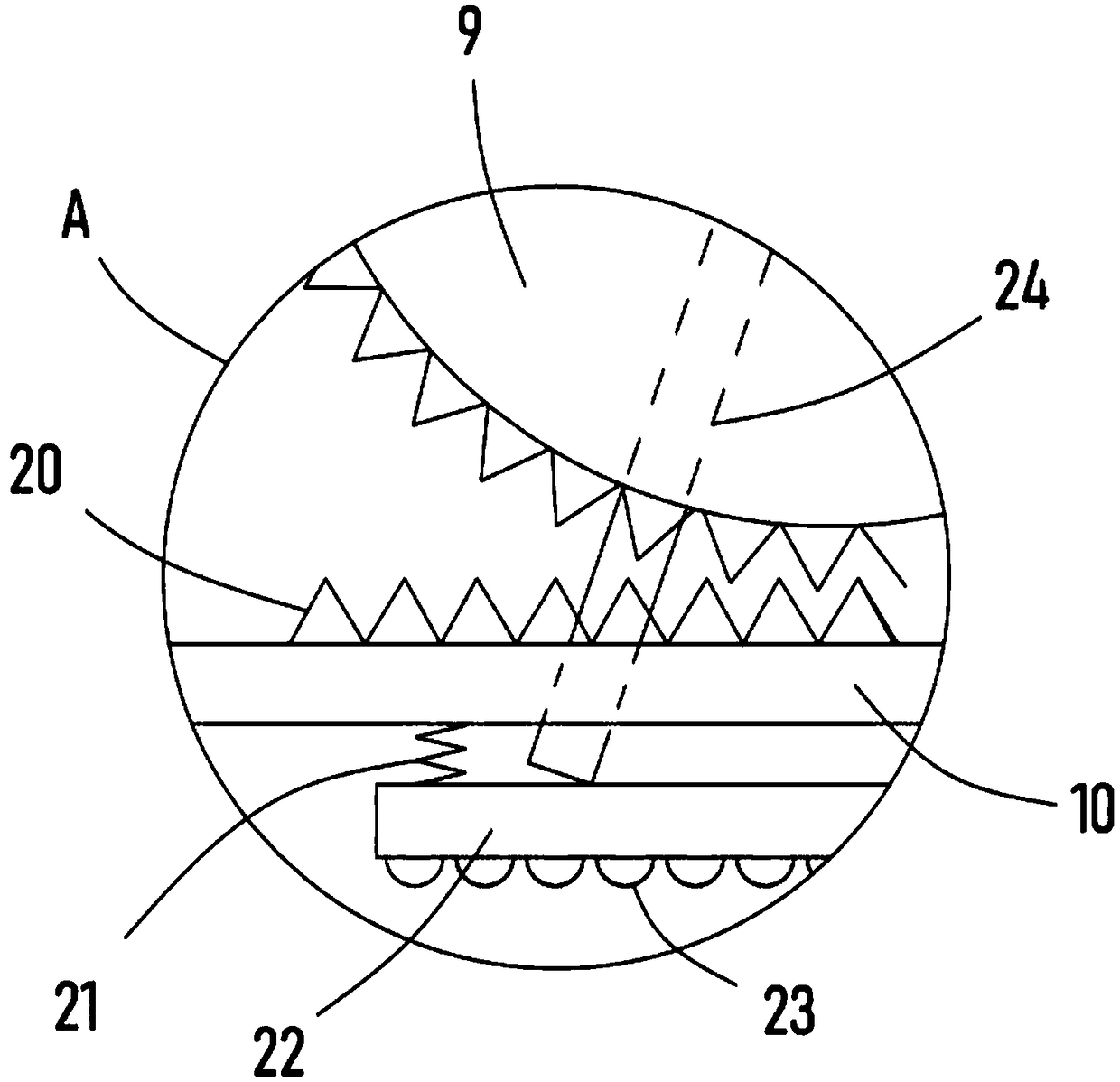

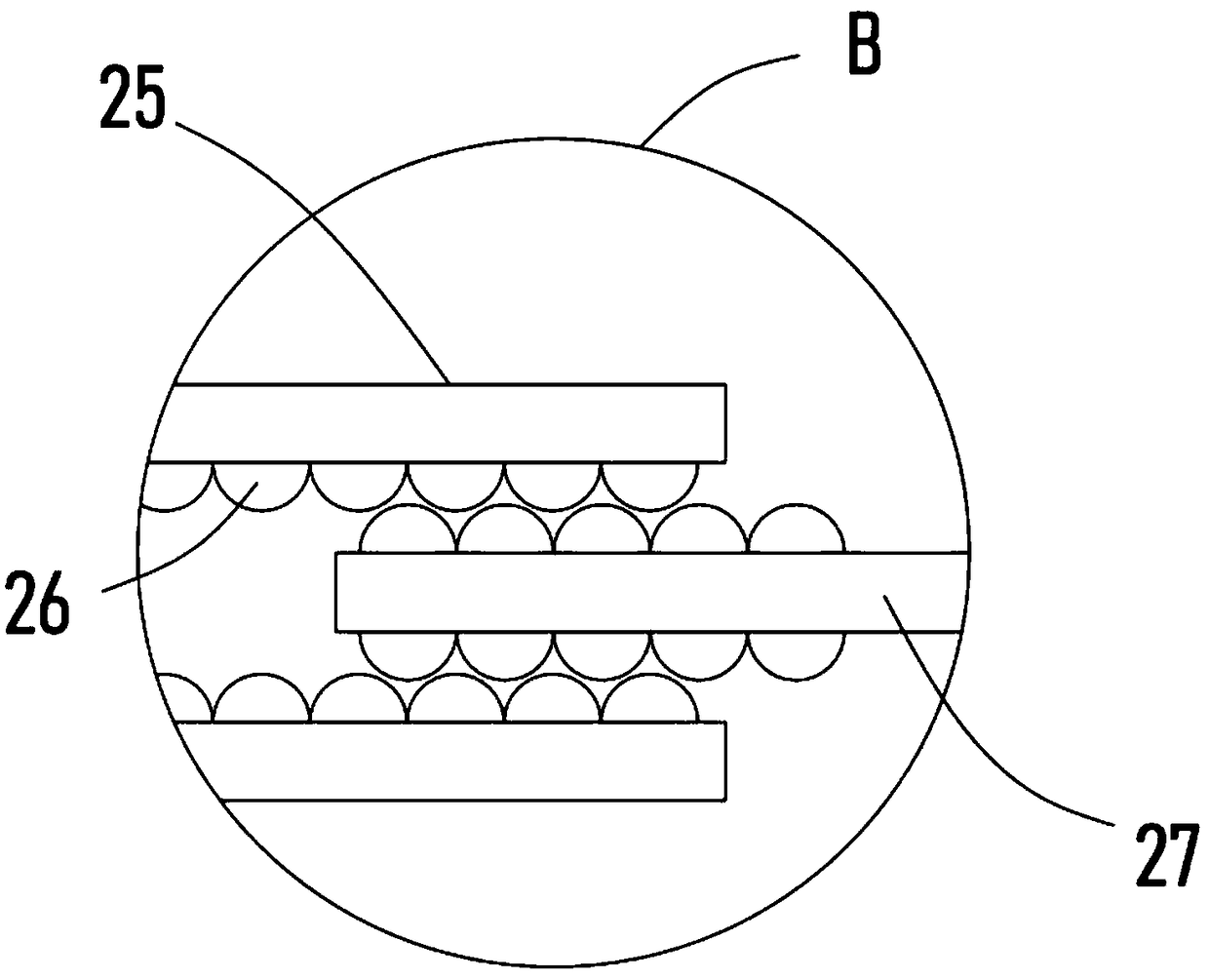

InactiveCN105821484AKnead fullyFacilitate automatic control of productionMechanical fibre separationEngineeringEnergy consumption

The invention relates to a ramie breaking vibration machine. The ramie breaking vibration machine comprises a first rack, a second rack, a first power unit, a second power unit, a ramie input curtain, a crank rocker unit, a vibration unit, a ramie output curtain and a breaking roller set unit, wherein the ramie input curtain, the crank rocker unit, the ramie output curtain and the breaking roller set unit are arranged on the first rack; the crank rocker unit is located at the front end of the first rack; the first power unit is connected with the crank rocker unit located at the front end of the first rack through a chain; the crank rocker unit is connected with the breaking roller set unit located on the first rack through a gear; the ramie input curtain and the ramie output curtain are arranged at the front and rear ends of the breaking roller set unit, respectively; the second rack is located at the rear end of the first rack; the first rack and the second rack are mounted on the same plane; the second rack is provided with the vibration unit; and the second power unit is located under the second rack and is connected with the vibration unit through a chain. The ramie breaking vibration machine is simple in structure, reliable in transmission, small in energy consumption and high in efficiency.

Owner:WUHAN TEXTILE UNIV

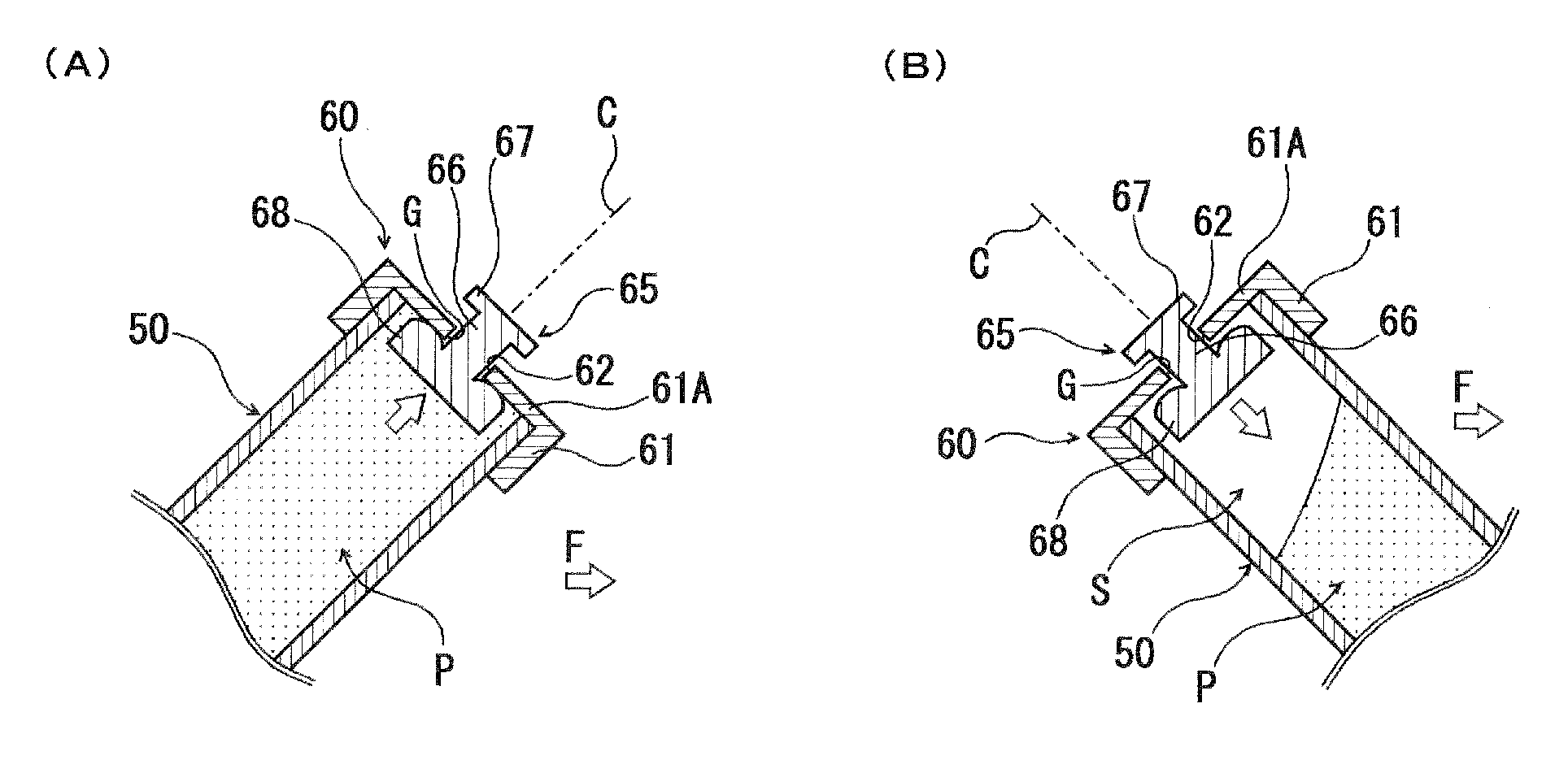

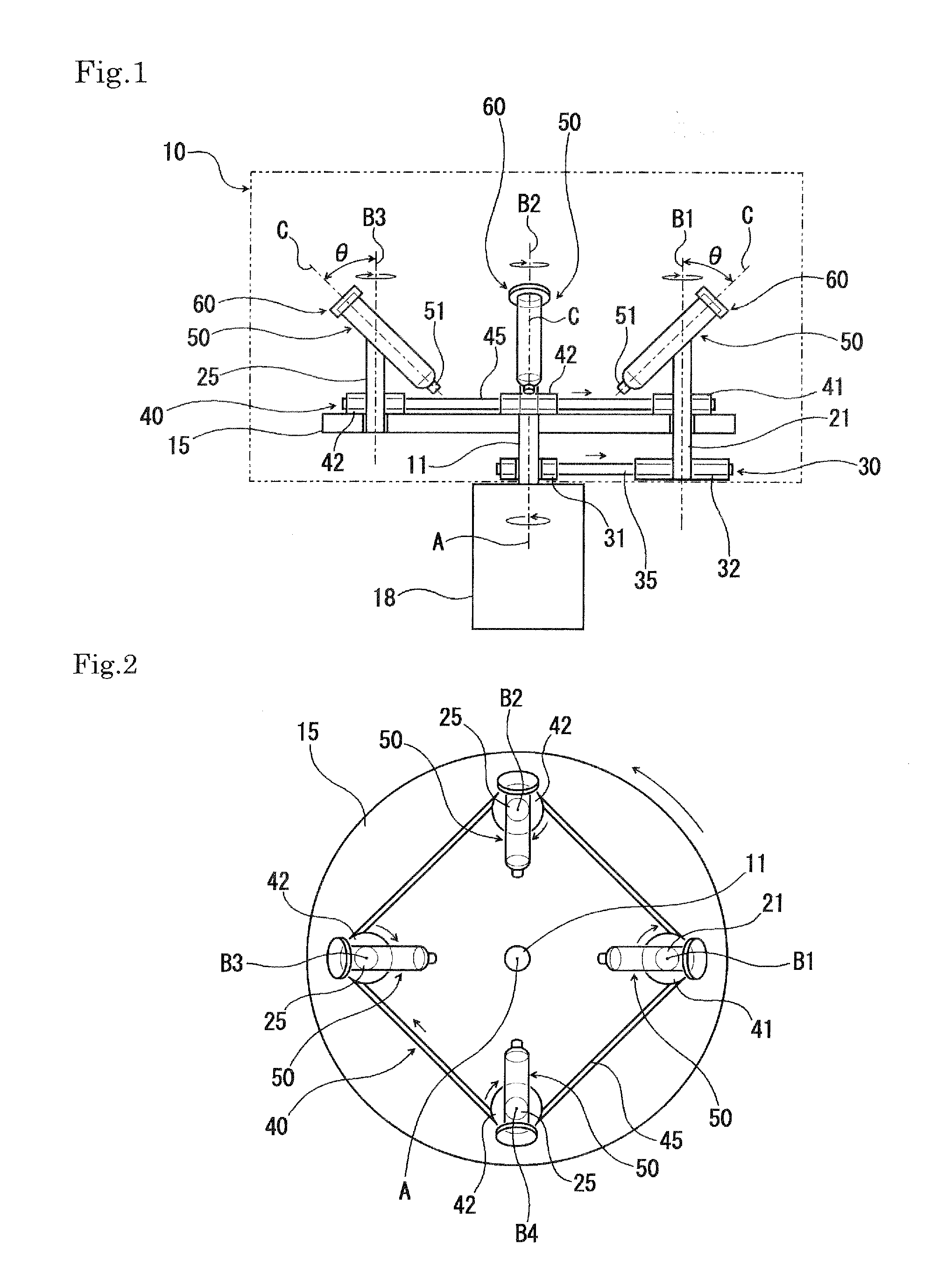

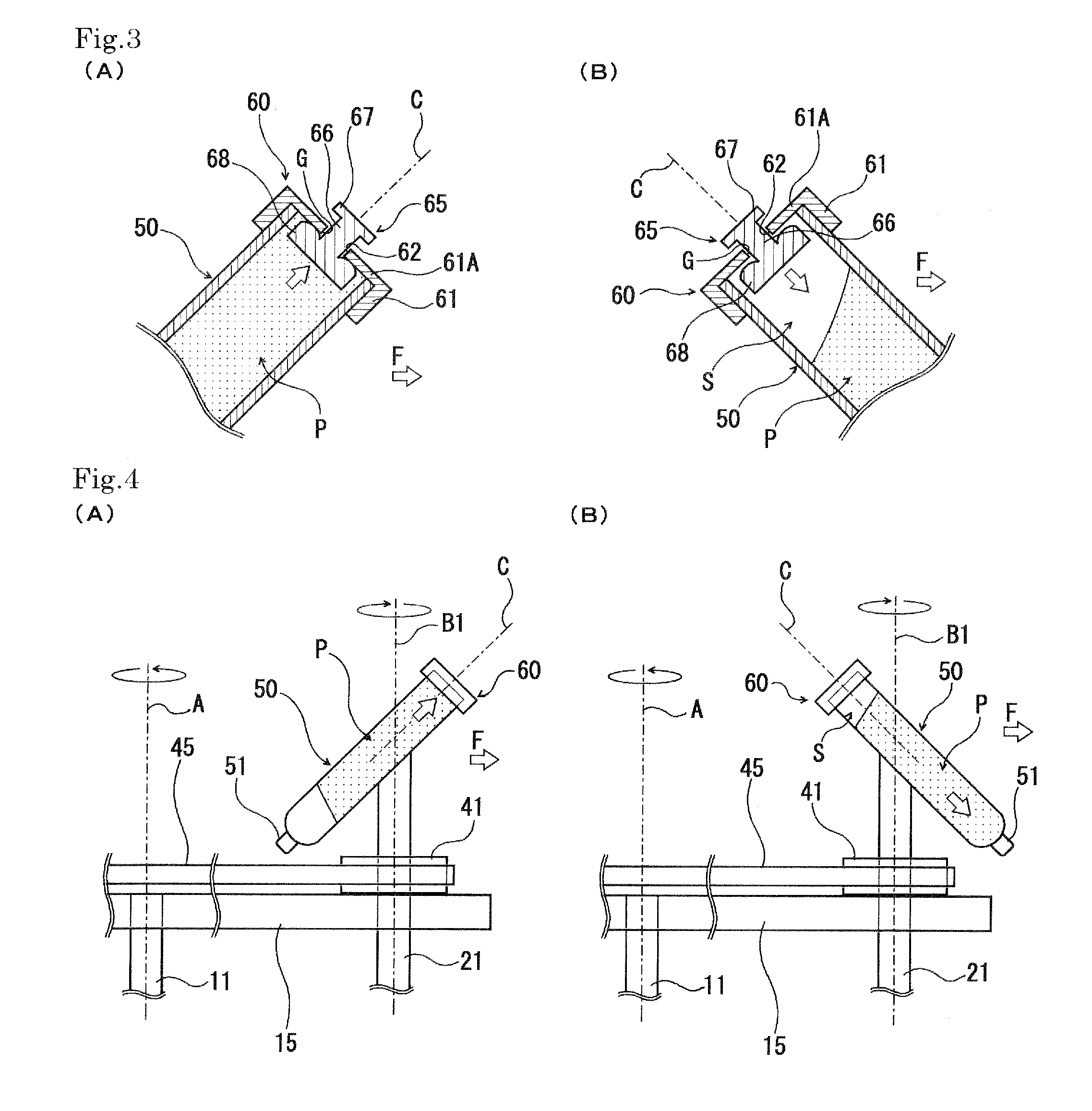

Vacuum kneading and deaerating device

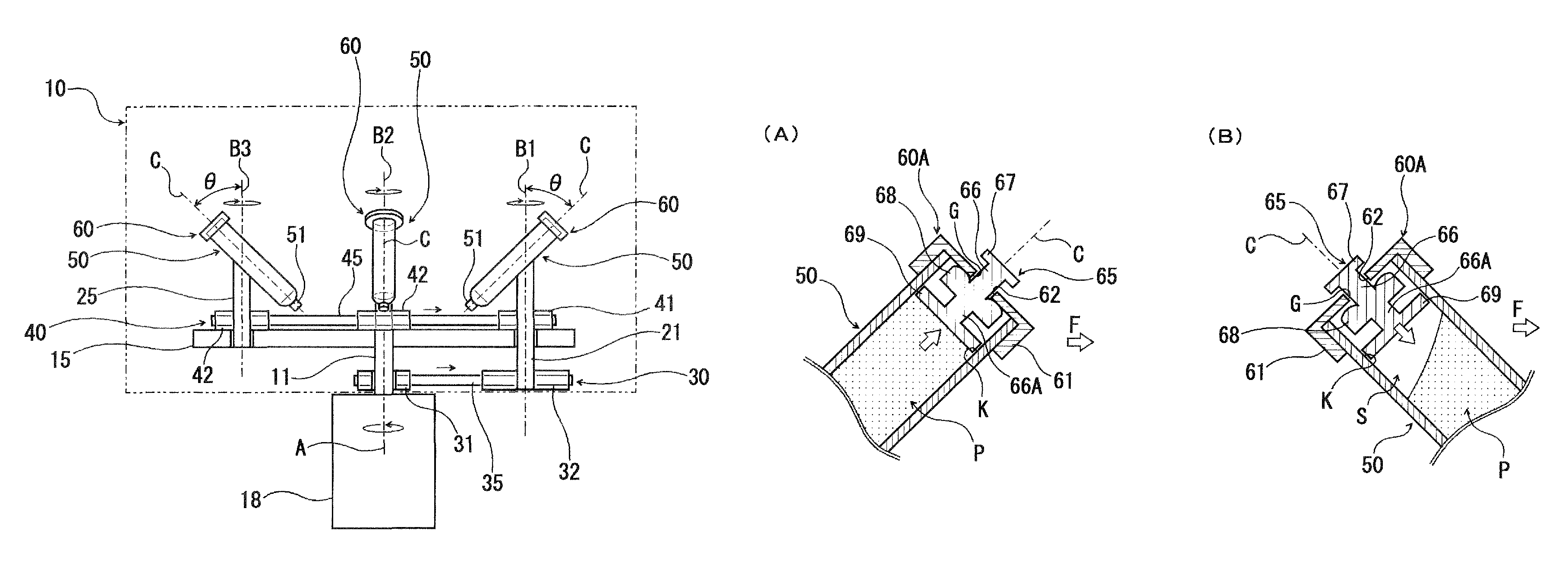

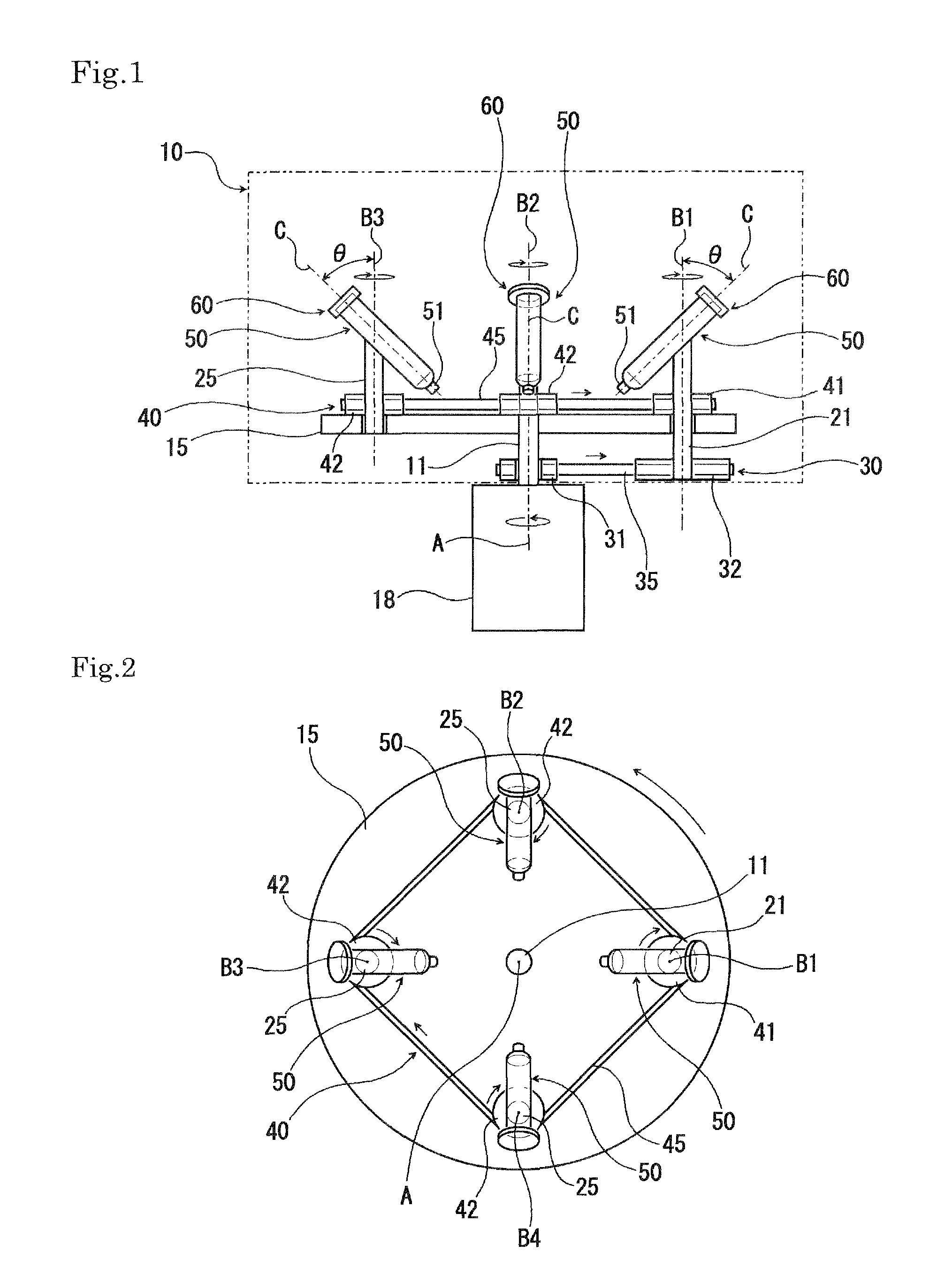

ActiveUS20120106288A1Knead fullyImprove efficiencyRotating receptacle mixersShaking/oscillating/vibrating mixersRotational axisCentrifugal force

Disclosed is a vacuum kneading and deaerating device capable of conducting an uniform and sufficient kneading treatment and a sufficient deaerating treatment with a high efficiency for a paste material contained in a cylindrical paste container.This vacuum kneading and deaerating device is equipped with a rotating body for revolution, which is provided in a chamber held under a closed or pressure-reduced condition and rotated in a horizontal plane around a basic driving rotation axis, a container holding means which is provided in the chamber rotationably on an operating rotation axis parallel to the basic driving rotation axis in a revolution edge portion of the rotating body for revolution and detachably holds a paste container in a state that a central axis of the paste container obliquely intersects the operating rotation axis, and a driving mechanism for rotating the rotating body for revolution and the container holding means, wherein a deaeration valve for opening an internal space of the paste container to an internal space of the chamber by the action of centrifugal force attending on the revolution and rotation of the paste container, or a paste material-impermeable and gas-permeable membrane is provided in an opening portion of the paste container for placing the paste material.

Owner:MARUKOMU

Process for preparing honeyed black tea

InactiveCN105309655AShorten withering timeSpread evenlyPre-extraction tea treatmentBrilliant RedBlack tea

The invention discloses a process for preparing honeyed black tea. The process comprises the following steps: 1, fresh leaf picking; 2, withering, 3, rolling in three times, 4, primary fermentation: putting rolled leaves into a fermentation tank, keeping the temperature to be 26-29 DEG C, conducting spraying fermentation, keeping the humidity to be 90-92%, automatically turning once every 15 min, adding honey water in a spraying manner before turning, and automatically stopping turning after uniform mixing, wherein the fermentation time is 3 h; 5, drying: drying by adopting a drying machine, wherein the drying temperature is 40-50 DEG C, the air speed is 1 m / s, and the drying time is 2-3 h; 6, secondary fermentation: putting the dried tea leaves in a ventilated fermentation room for storage for 3-4 d, and conducting secondary fermentation under the natural condition; 7, aroma extraction. The prepared black tea is brilliant red and bright in tea color and has a strong honey aroma.

Owner:GUANGXI ZHAOPING NINGXIANGCUI TEA FACTORY

Vacuum kneading and deaerating device

ActiveUS8534906B2Knead fullyImprove efficiencyRotating receptacle mixersShaking/oscillating/vibrating mixersCentrifugal force

A vacuum kneading and deaerating device has a rotatable body provided in a chamber held under a closed or pressure-reduced condition, and which is rotated in a horizontal plane around a basic driving rotation axis. A container holder is provided in the chamber rotationably on an operating rotation axis parallel to the basic driving rotation axis in a revolution edge portion of the rotatable body, and detachably holds a paste container such that a central axis of the paste container obliquely intersects the operating rotation axis. A driving mechanism rotates the rotating body and the container holder. A deaeration valve for opening an internal space of the paste container to an internal space of the chamber by the action of centrifugal force attending on the rotation of the paste container, or a paste material-impermeable and gas-permeable membrane, is provided in an opening portion of the paste container.

Owner:MARUKOMU

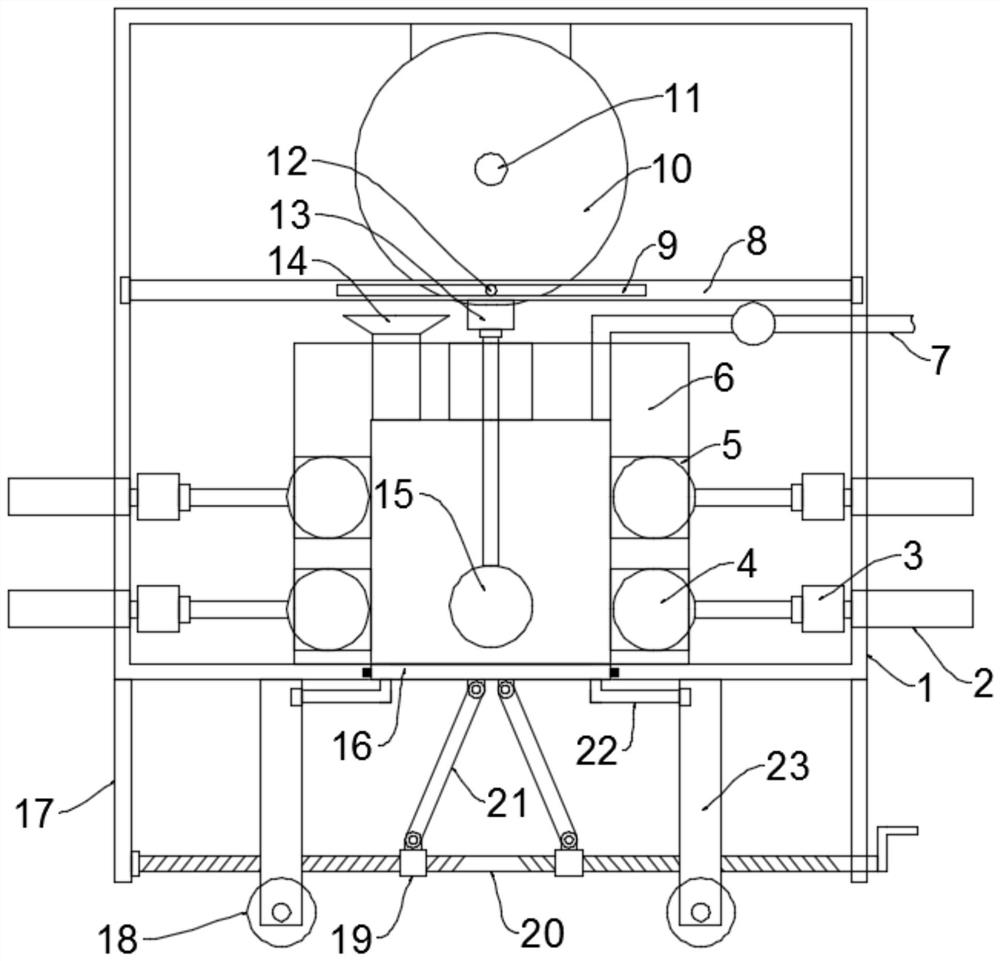

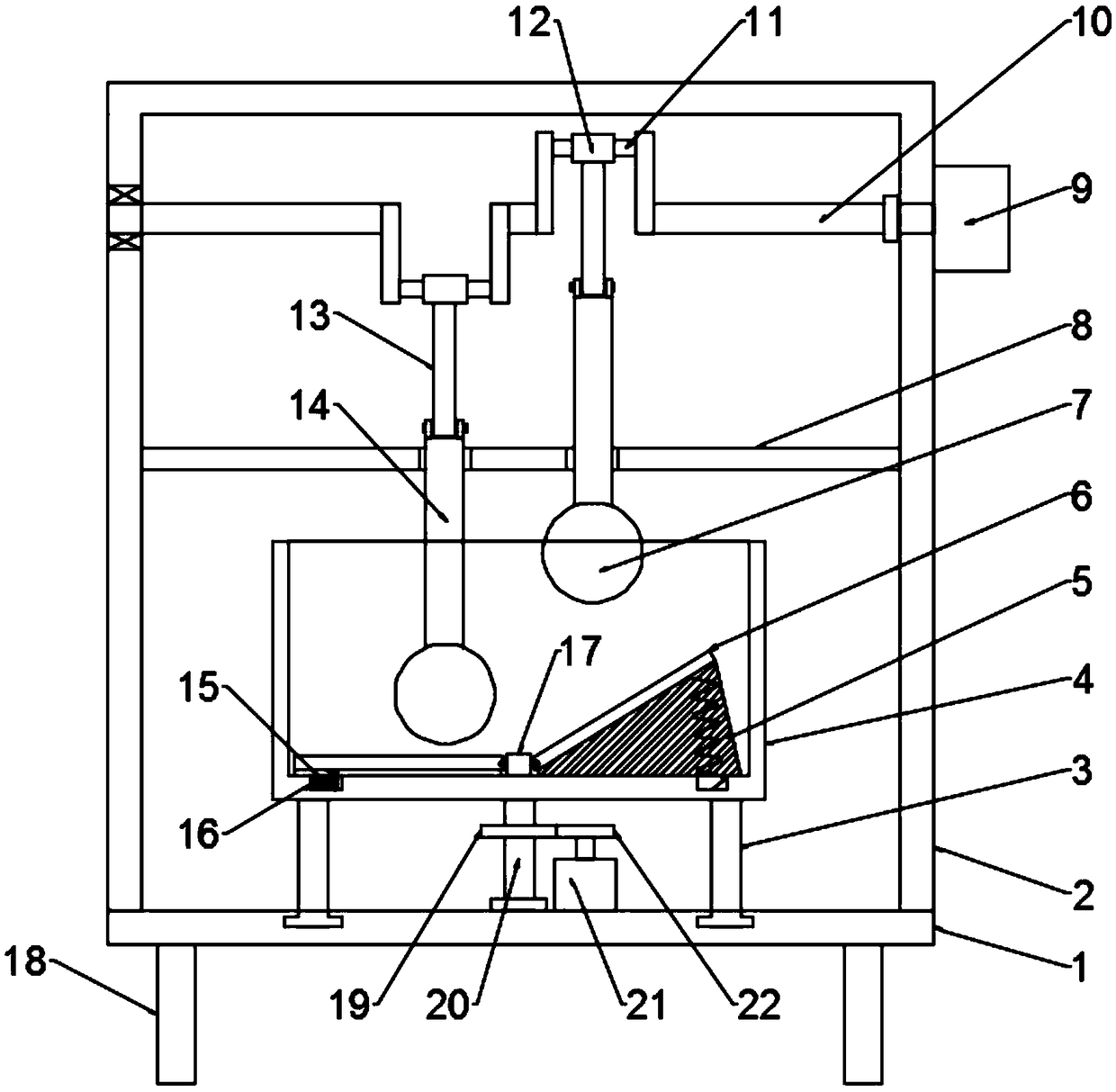

Flour processing device in agricultural production

InactiveCN112450232AKnead fullyAvoid wastingMixing/kneading structural elementsHollow article cleaningAgricultural scienceReciprocating motion

The invention discloses a flour processing device in agricultural production, relates to the field of agriculture, and mainly aims to solve a problem that an existing device is easy to stick flour tocause waste. The flour processing device comprises a box body, a dough kneading unit and a cleaning assembly, the dough kneading unit comprises a dough kneading cover and a dough kneading mechanism, the dough kneading cover is fixedly arranged at a bottom of an inner cavity of the box body, the dough kneading mechanism comprises a third motor, a main dough kneading ball, a driving mechanism used for driving the third motor to reciprocate, second motors, electric push rods, auxiliary balls and air bags, the cleaning assembly comprises spray heads and a water supply unit used for supplying waterto the spray heads and is provided with a dough kneading unit, repeated and sufficient dough kneading is conducted through a movement cooperation of a main ball and auxiliary balls, meanwhile, the main ball and the auxiliary balls are extruded through the air bags, flour adhering to the main ball and the auxiliary balls is scraped off, sufficient dough kneading is guaranteed, and meanwhile wasteis avoided.

Owner:佘衎

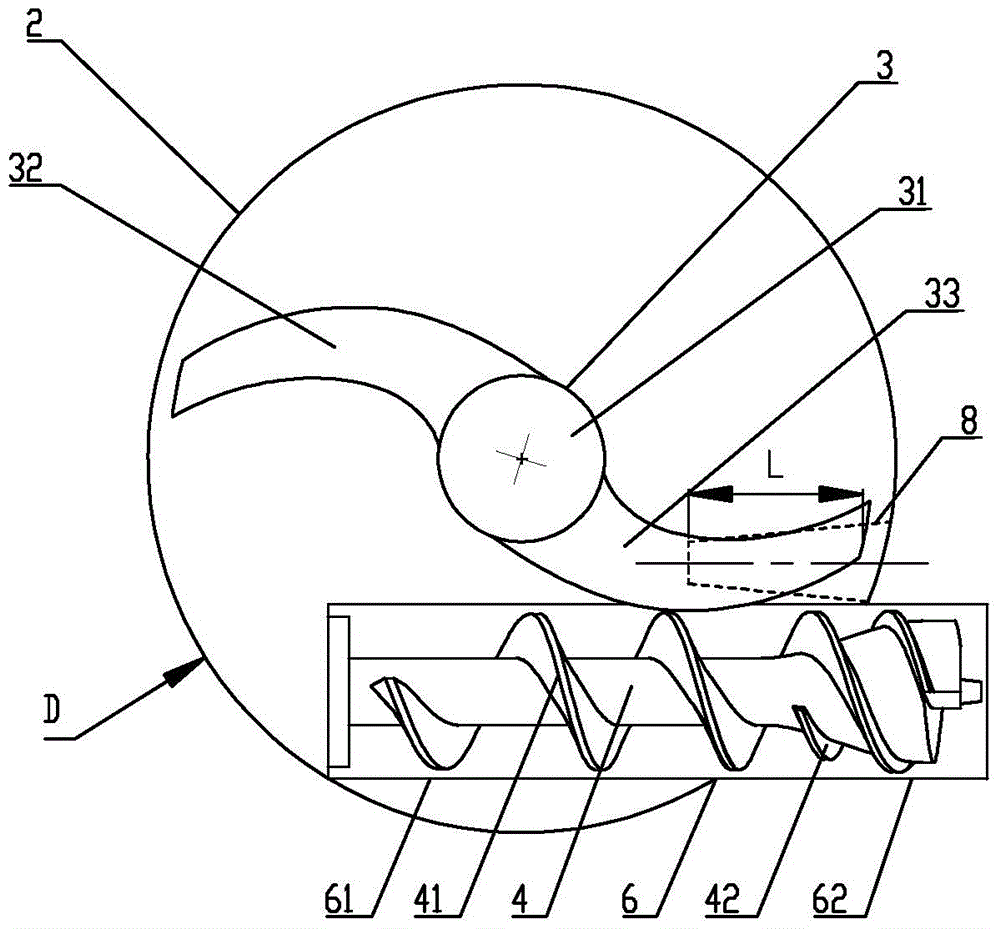

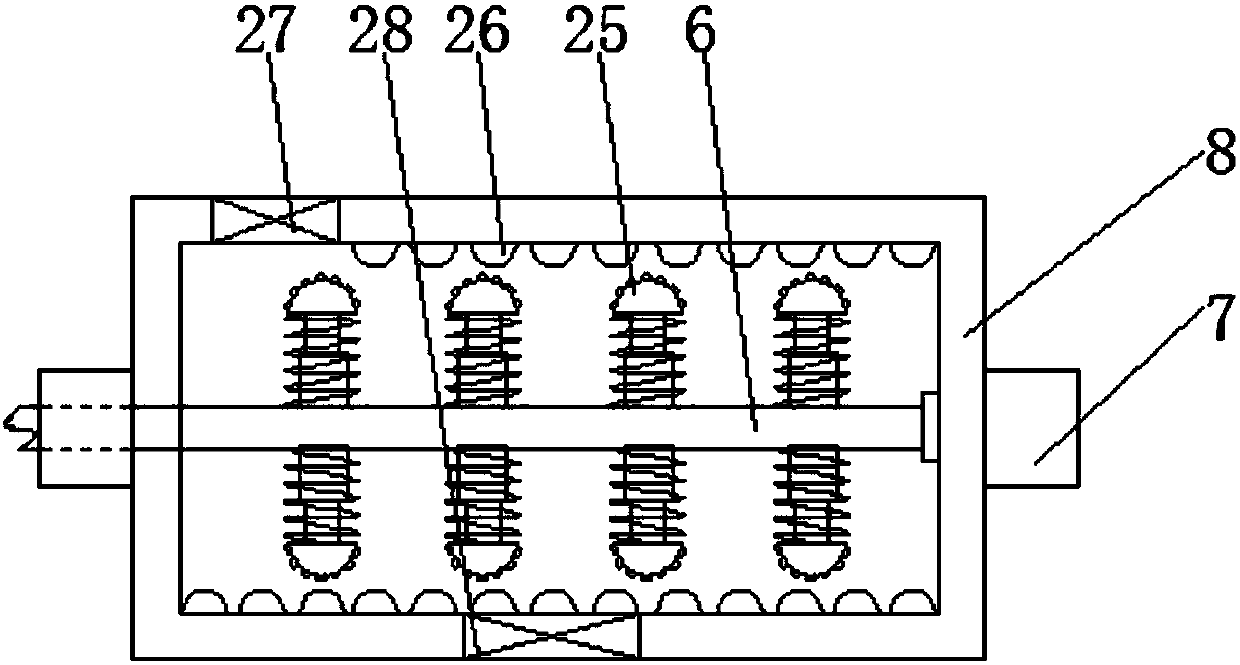

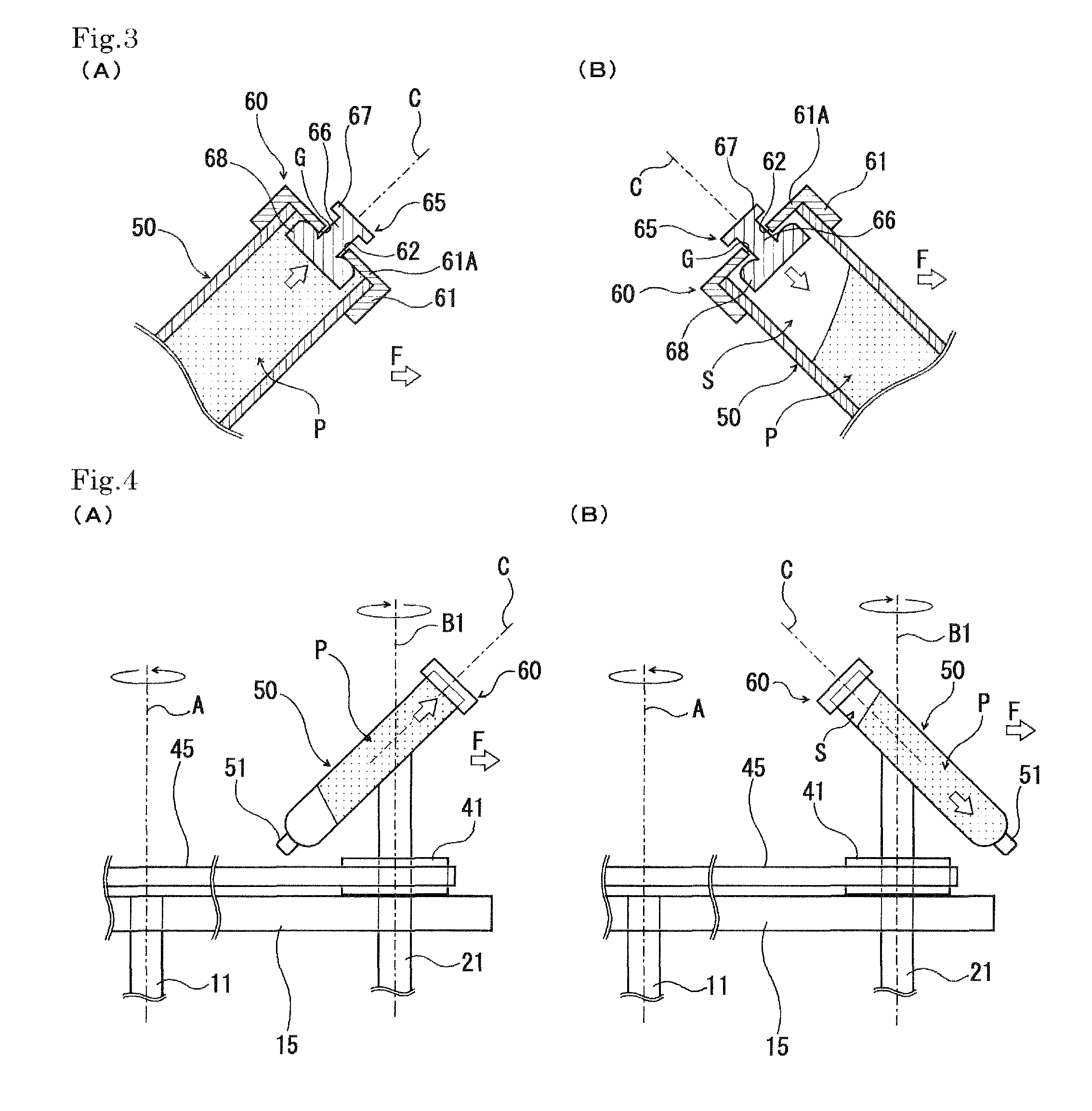

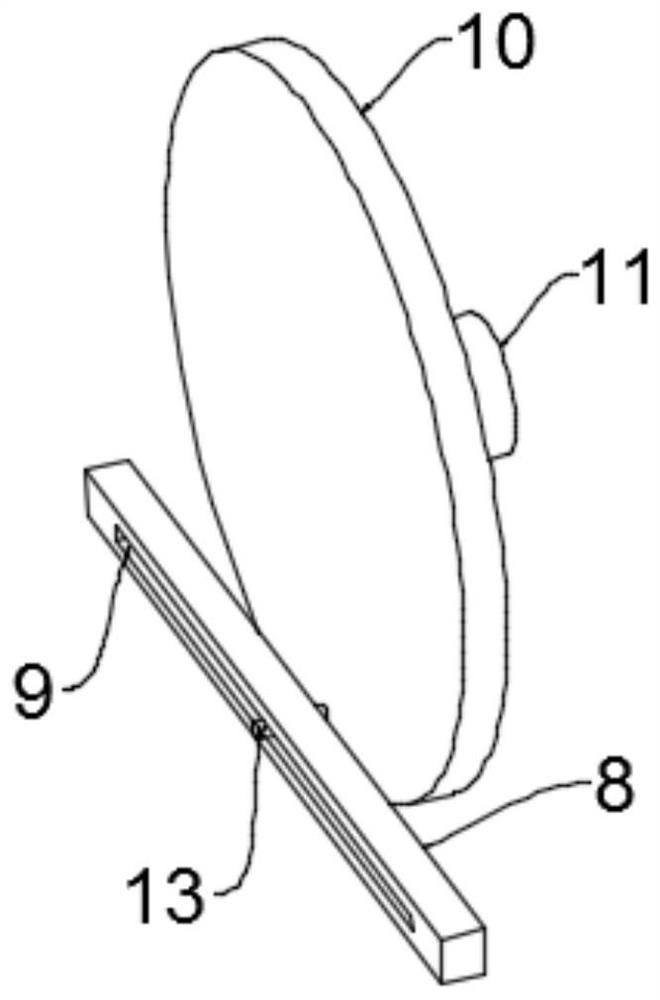

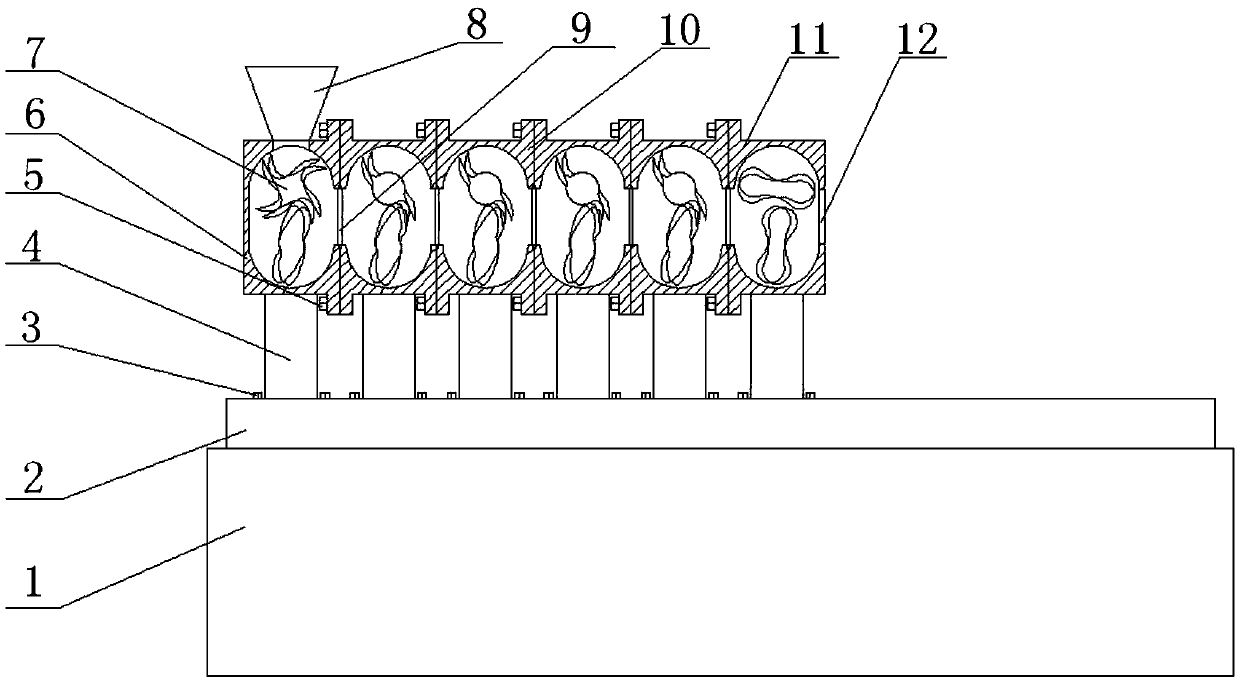

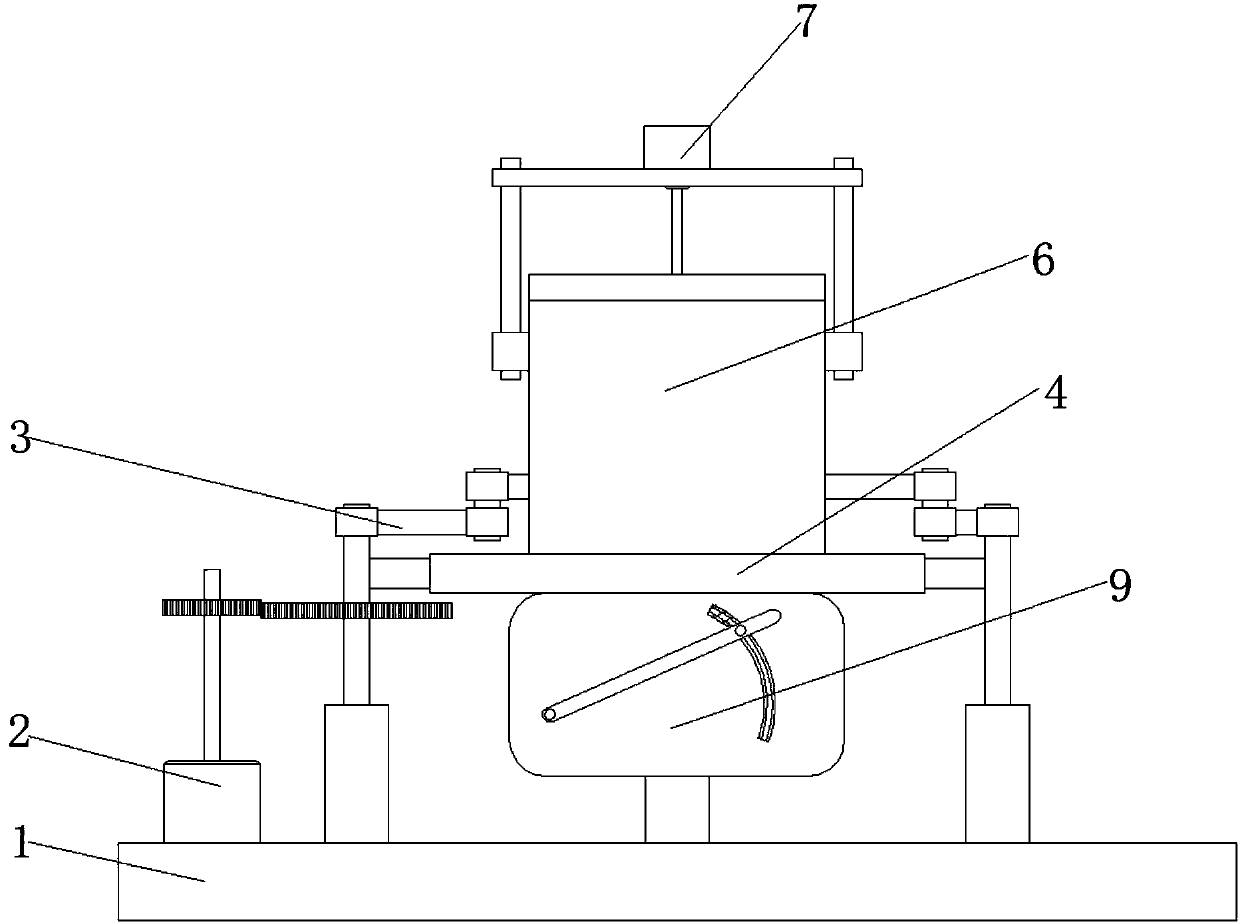

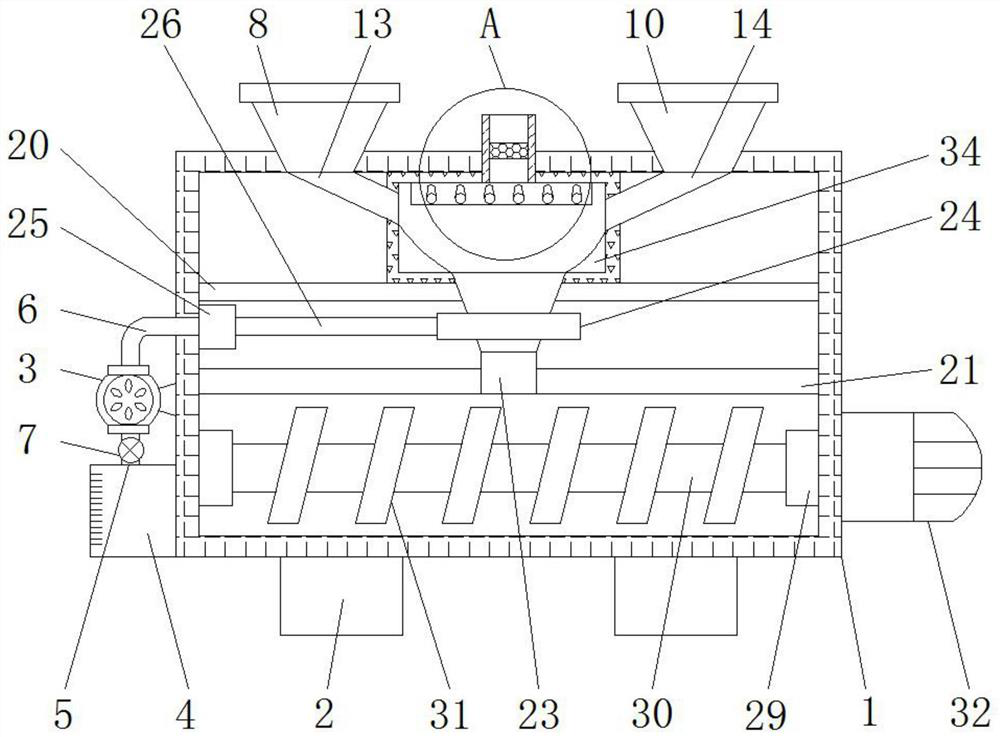

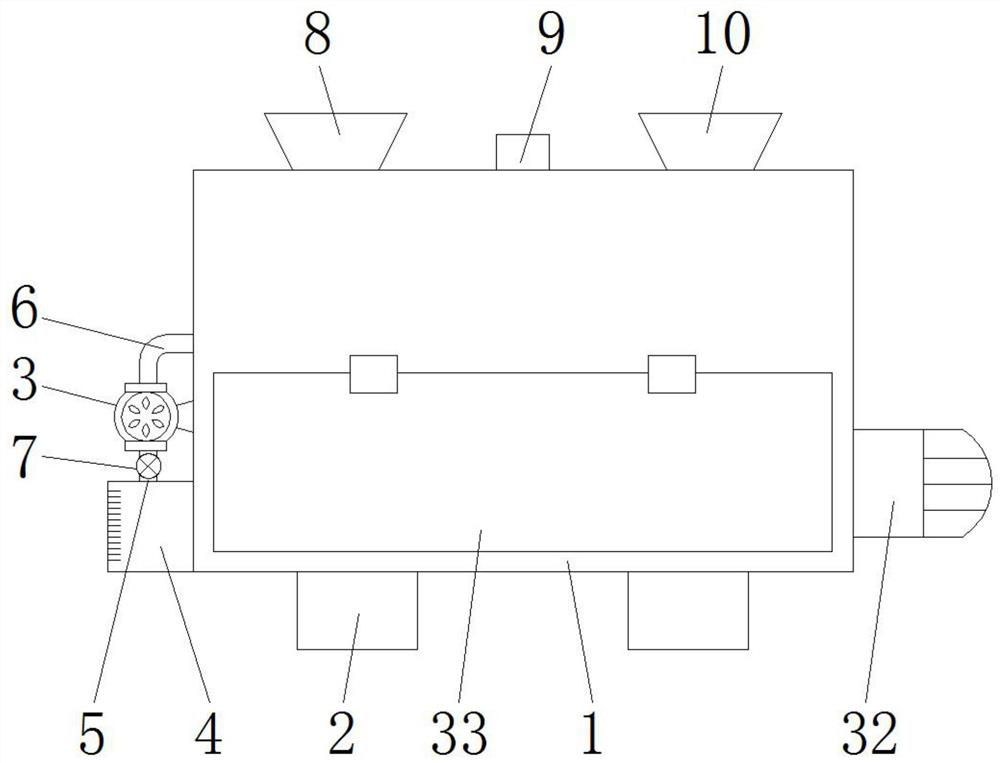

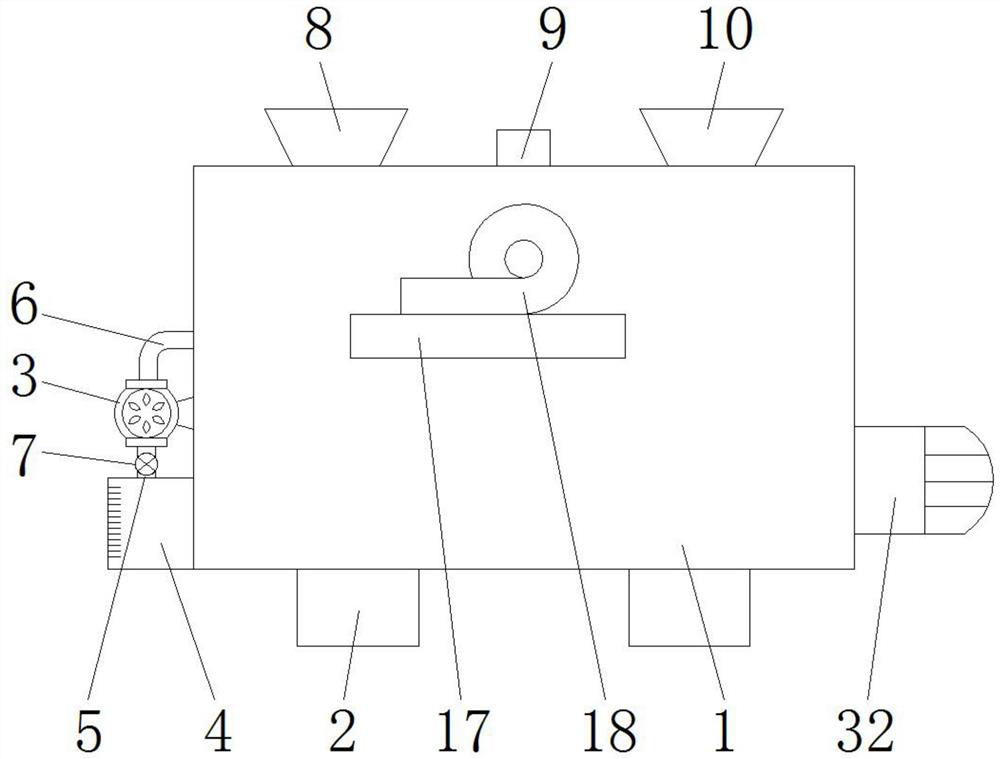

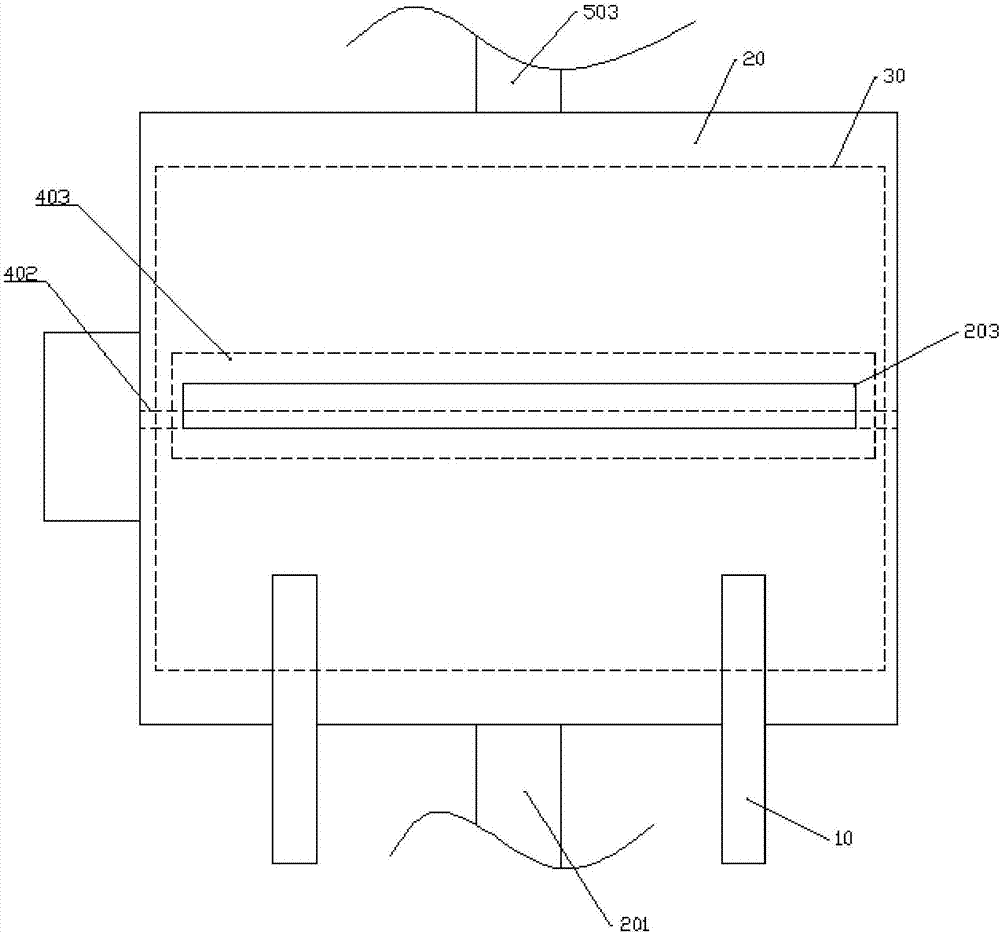

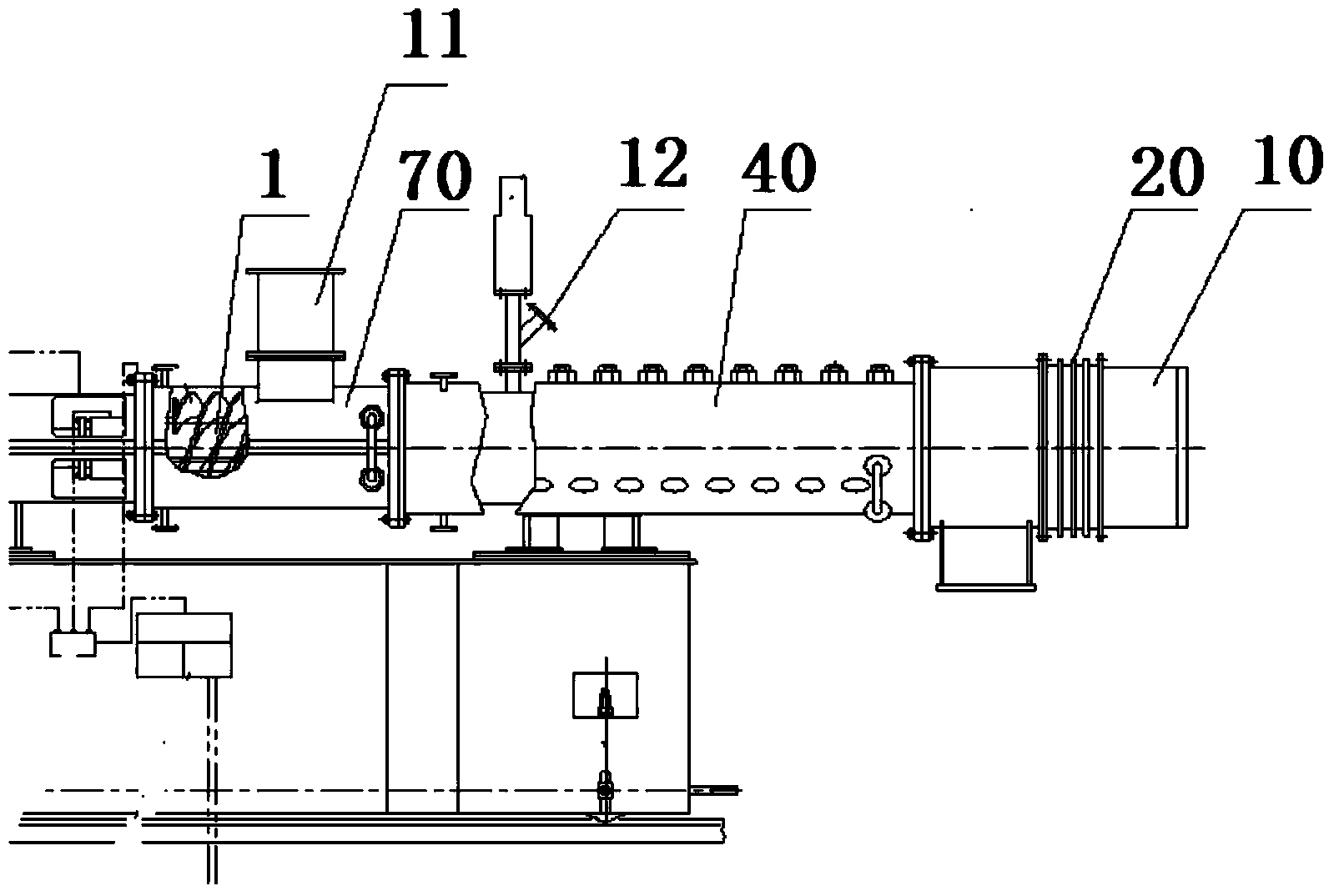

Modularized multi-chamber continuous kneading machine

The invention discloses a modularized multi-chamber continuous kneading machine which can be applicable to high-solid-content composite materials. The equipment is flexible, and kneading is full. Thedevice comprises a hopper 8, chambers 6, paddles 7, a sieve plate 9, connecting screws 5, a support 4, a guide rail 2, fastening screws 3 and a base 1. Each paddle is driven independently, larger torque is provided, the number of the chambers arranged in a series-connection manner is changed to adapt to materials with different solid contents, the stay time of the materials is adjusted, by means of counter rotating of the paddles, the materials are pushed in the tangential direction while being kneaded, and continuous flowing of the materials among the chambers is achieved. According to the machine, the defects of an existing screw continuous kneading technology, a double-rotor continuous mixing technology, a multi-chamber continuous kneading technology and the like are made up, the kneading ability of the kneading equipment is improved, flexibility is higher, autonomy is higher, and the application range of the equipment is expanded.

Owner:XIAN MODERN CHEM RES INST

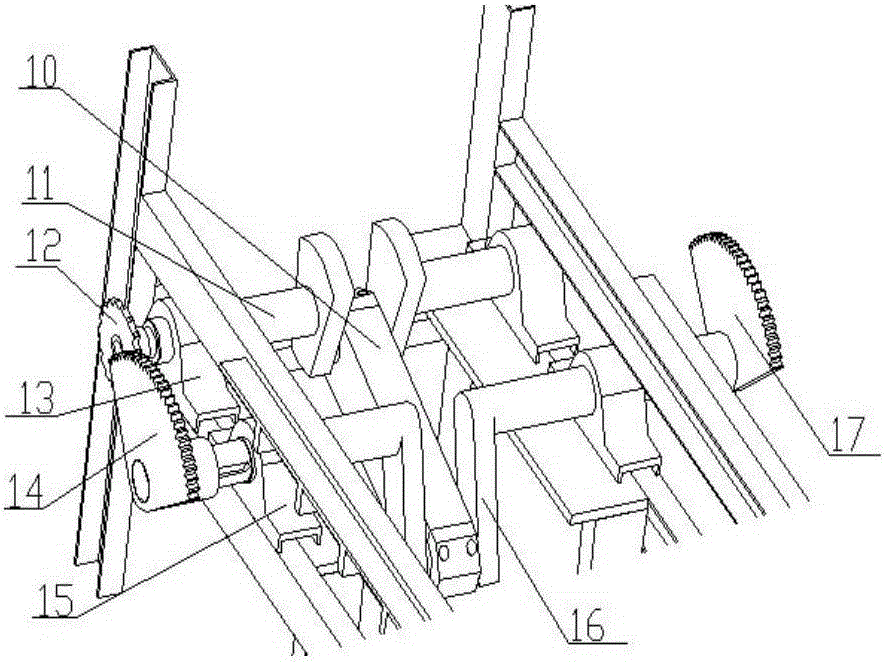

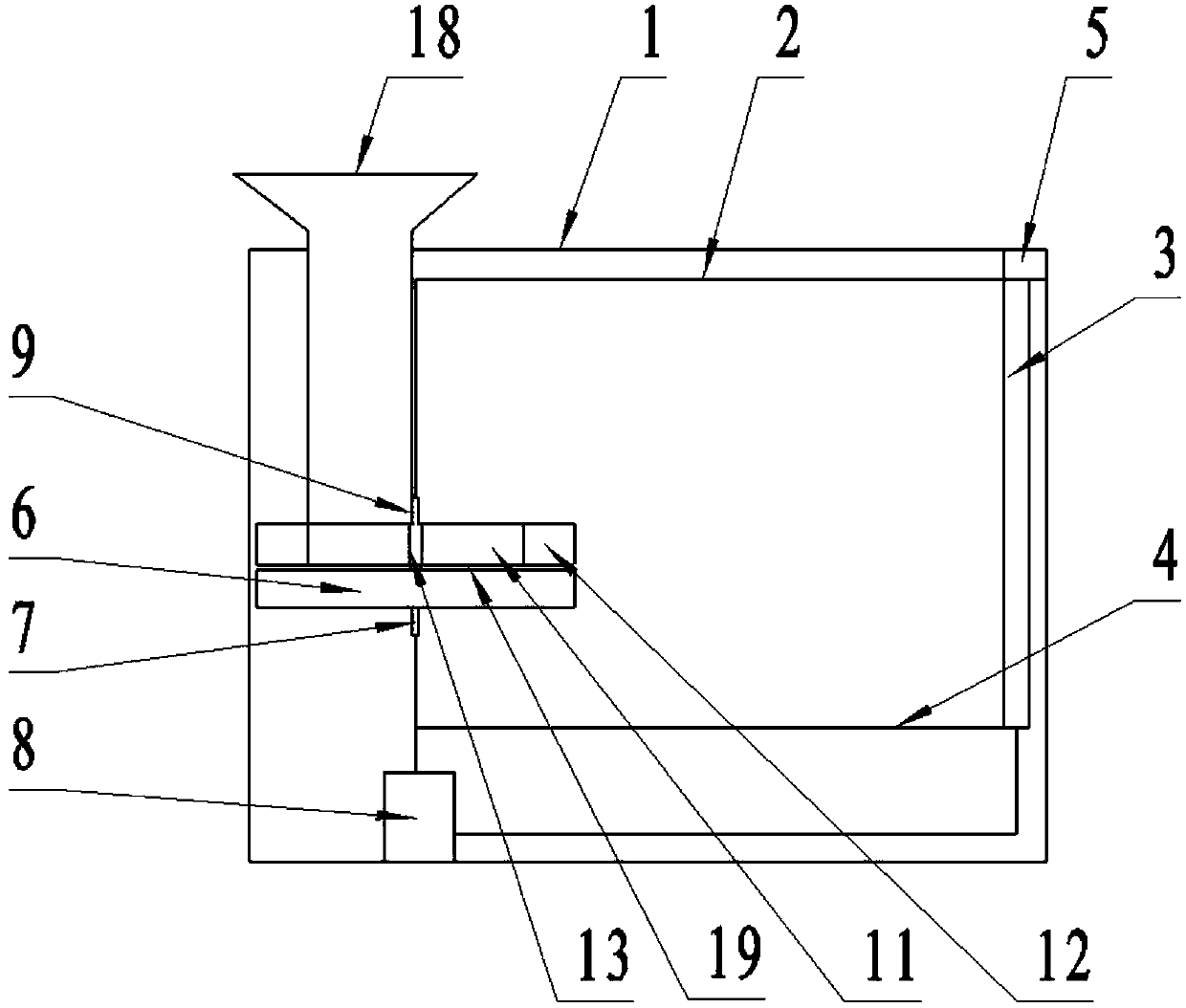

Crank type continuous dough kneading device for flour processing

InactiveCN108967459AImprove kneading efficiencyGood kneadingMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsGear wheelEngineering

The invention discloses a crank type continuous dough kneading device for flour processing. The crank type continuous dough kneading device comprises a bottom plate, a dough kneading frame, an installation frame, a rotary shaft, a gear, an incomplete gear, a first motor, an installation rod, fan-shaped collecting plates, springs, a second motor, a crank, a rod journal, a sleeve, a connection rod,a movable rod and two dough kneading balls. The crank type continuous dough kneading device is provided with the second motor, the crank, the rod journal, the sleeve, the movable rod, the dough kneading balls and the fan-shaped collecting plate, the two dough kneading balls knead dough continuously, the dough kneading efficiency is high, when the dough kneading balls move upwards, the corresponding fan-shaped collecting plates rotate upwards under the effects of springs, the dough is collected, so that dough kneading for the next time is facilitated, the dough can be further kneaded more sufficiently and uniformly, the dough kneading efficiency is improved, the first motor, the incomplete gear and the gear are arranged to intermittently drive the dough kneading frame to rotate a certain angle, so that the dough kneading balls can knead and press the different parts of the dough, thus dough kneading is more sufficient, and the dough kneading speed is increased.

Owner:CHANGSHA FENGYING MACHINERY TECH CO LTD

Breakage-proof tea processing device

InactiveCN112273478AScientific and reasonable structureSafe to usePre-extraction tea treatmentHollow article cleaningHorticultureEngineering

The invention discloses a breakage-proof tea processing device. A connecting support is welded to one side of the top end of a mounting support, a fixation tank is welded to the top end of the connecting support, a feeding port is welded to the top of one side of the fixation tank, a discharging pipe is fixedly connected to the middle of the bottom end of the fixation tank, and the top, corresponding to the internal position of the fixation tank, of the discharging pipe is clamped with a fixation screen cylinder; according to the present invention, with the downward pressing of a lifting roundplate, the tea leaves in the fixation screen drum are compact, and the gap between the tea leaves is reduced, such that the water loss speed of the tea leaves during the fixation process is effectively reduced, and the charring phenomenon of the tea leaves with the low water content is avoided; the breakage-proof tea processing device ensures that the tea leaves after fixation still have sufficient moisture, ensures that the tea leaves on the inner and outer rings of the fixation screen cylinder can be uniformly heated, and can discharge surplus water vapor accumulated in the fixation tank during next pressing, optimizes the fixation process of the tea leaves, ensures high-quality fixation of the tea leaves, and improves the fixation quality of the tea leaves.

Owner:韦世林

Tea leaf processing kneading device

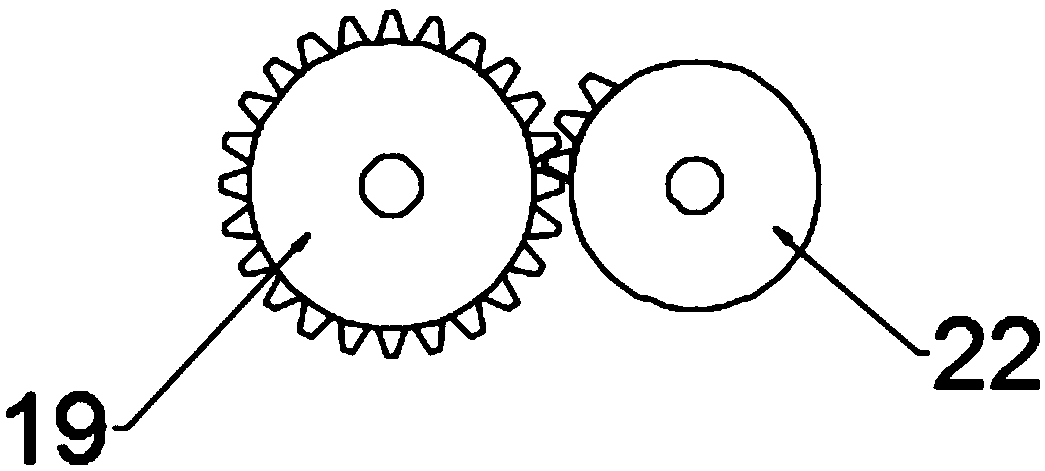

InactiveCN107396990AIncrease delivery speedImprove rolling efficiencyPre-extraction tea treatmentGear wheelEngineering

The invention discloses a tea processing and rolling device, which comprises a base; a kneading box is fixed on the left side of the upper surface of the base; the left and right inner walls of the kneading box are connected to cross bars; the inside of the cross bar is embedded with a rotating shaft; The rotation axis runs through the left movable hammer and the right movable hammer; the lower surface of the cross bar is connected to the connecting rod in the middle; the spherical body is fixed below the connecting rod; the gear is installed inside the spherical body; the gear escapement is installed above the gear The cycloid is fixed on the gear escapement; the lower end of the cycloid connects with the swing ball; the kneading pot is installed directly below the swing ball; the right side of the kneading box is inclined to fix the screw feeder; the screw feeder of the screw feeder The discharge port is welded on the left side and the feed hopper is welded on the right side; the discharge port runs through the right wall of the kneading box; the invention has simple structure, convenient operation, high working efficiency and sufficient kneading.

Owner:贵州云顶茶叶有限公司

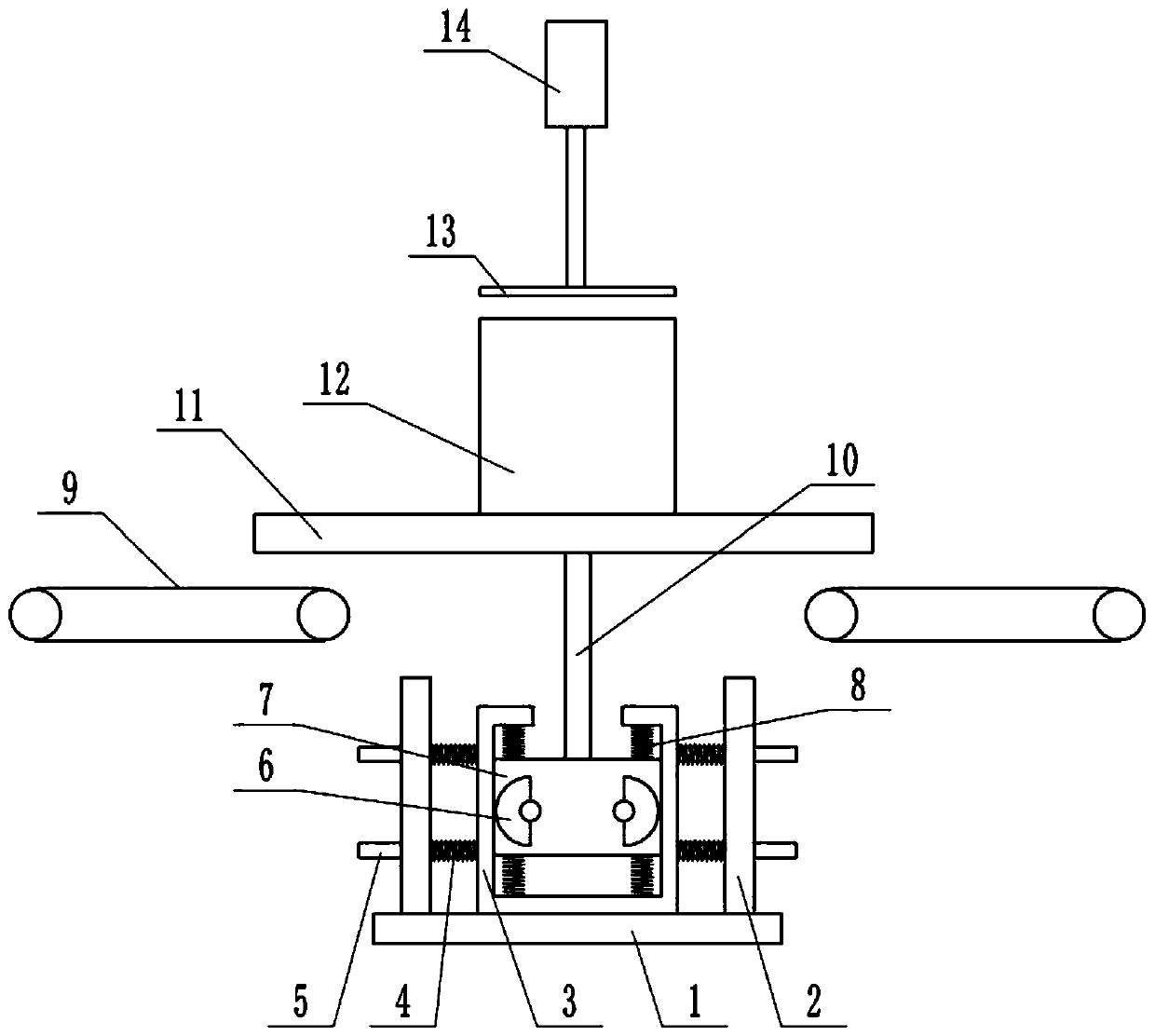

Garlic clove splitting device with screening function

InactiveCN109105931AIncrease displacementKnead fullySievingScreeningRelative displacementDrive motor

The invention discloses a garlic clove splitting device with a screening function and relates to the garlic processing machinery technology field. The device comprises a support framework. A driving motor is fixedly arranged in the support framework. A splitting box is arranged in the support framework. A screening plate is horizontally arranged in the splitting box. The lower portion of a transmission plate is provided with a rubbing plate. The bottom of the rubbing plate is uniformly and fixedly provided with several rubbing bumps. Several telescopic springs are fixedly installed between therubbing plate and the transmission plate. The upper surface of the transmission plate is fixedly provided with a spur rack. A sector gear is engaged with the upper portion of the spur rack in a swingmode. The back side of the sector gear is fixedly provided with a transmission rob which abuts against the rubbing plate. In the invention, through the swinging of the transmission rob, the rubbing plate is used to rub garlic on the screening plate, and simultaneously, because of the transverse relative displacement of the splitting box and the transmission plate, the relative displacement of therubbing plate to the screening plate is greatly increased, the rubbing plate can be used to fully rub the garlic, and the splitting efficiency of the garlic is greatly improved.

Owner:CHANGSHA FENGYING MACHINERY TECH CO LTD

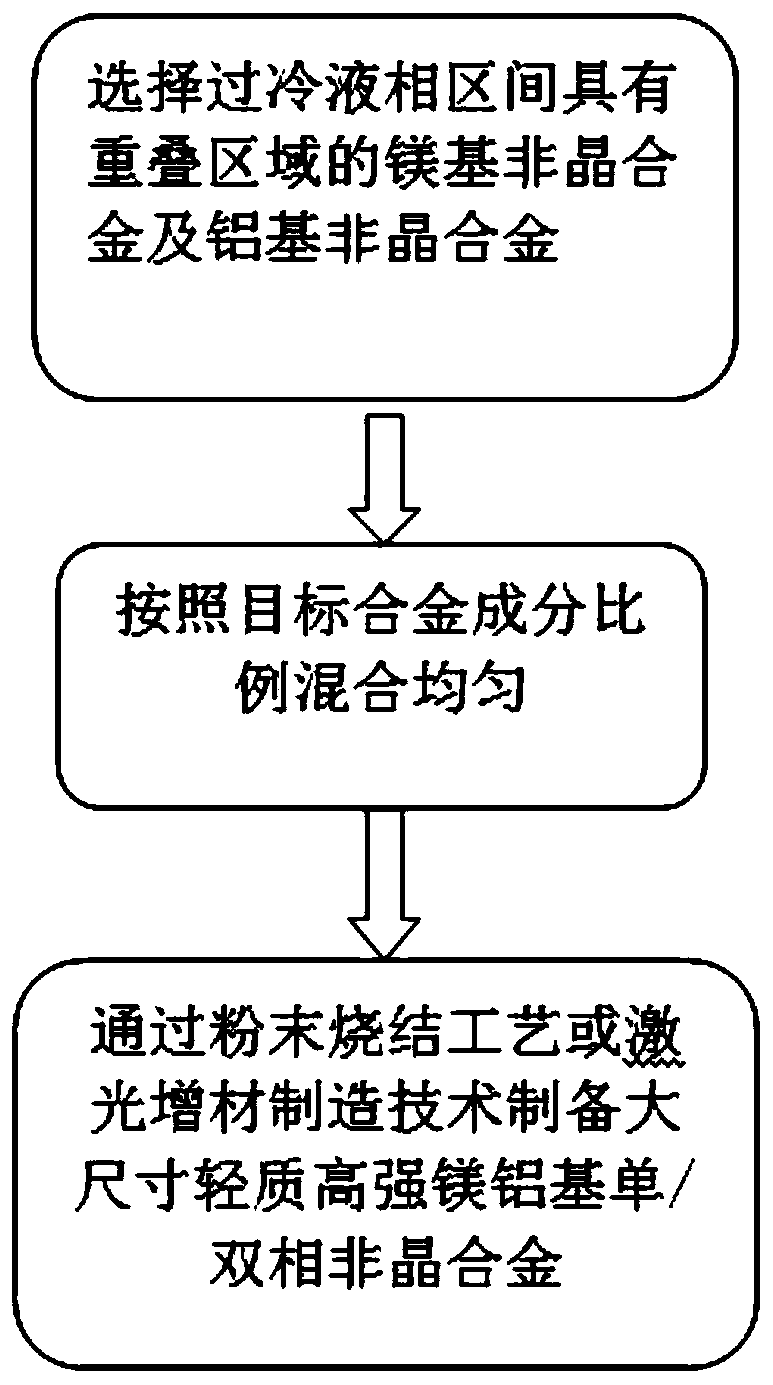

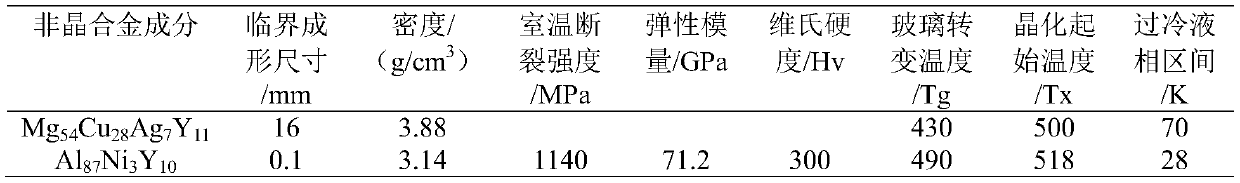

Preparation method for large-dimension light magnesium-aluminum based amorphous alloy

ActiveCN110724885AHigh strengthGood plasticity at room temperatureLaser additive manufacturingAlloy composition

The invention belongs to the field of amorphous alloys, and particularly relates to a preparation method for a large-dimension light magnesium-aluminum based amorphous alloy. The preparation method comprises the following steps: weighing powered magnesium based amorphous alloy and aluminum based amorphous alloy according to a target alloy component proportion, and uniformly mixing the magnesium based amorphous alloy with the aluminum based amorphous alloy to obtain magnesium-aluminum based amorphous alloy mixed powder; enabling a super-cooling liquid phase zone of the magnesium based amorphousalloy to be superposed with a super-cooling liquid phase zone of the aluminum based amorphous alloy; and preparing magnesium-aluminum based amorphous alloy through a powder sintering process or a laser additive manufacturing technology. The preparation method utilizes aluminum based amorphous alloy as a toughening phase to improve room-temperature plasticity of the magnesium based amorphous alloyor utilizes magnesium based amorphous alloy as a reinforcing phase to improve strength of the aluminum based amorphous alloy; and large-dimension light high-strength magnesium-aluminum based amorphous alloy is prepared by the powder sintering process or the laser additive manufacturing technology, so that the technical problem that the prepared composite material is not high in performance as relatively great difference exists between a crystal second phase and an amorphous matrix internal structure, deformation mode difference is relatively great, and interface metallurgical bonding is difficult is solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Tea leaf fixation equipment

Owner:贵州省凤冈县翠巅香生态茶业有限公司

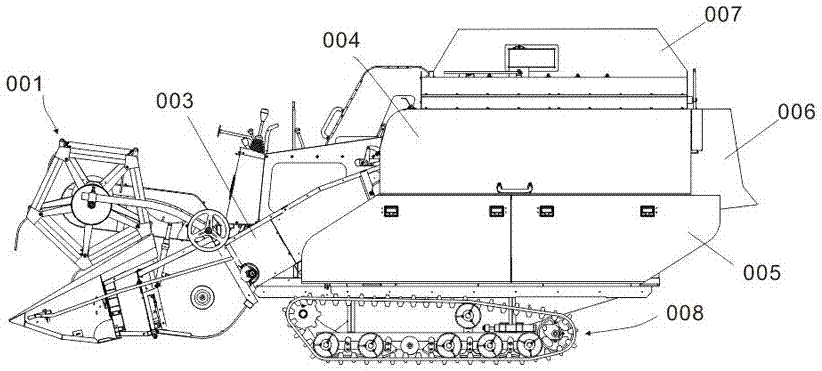

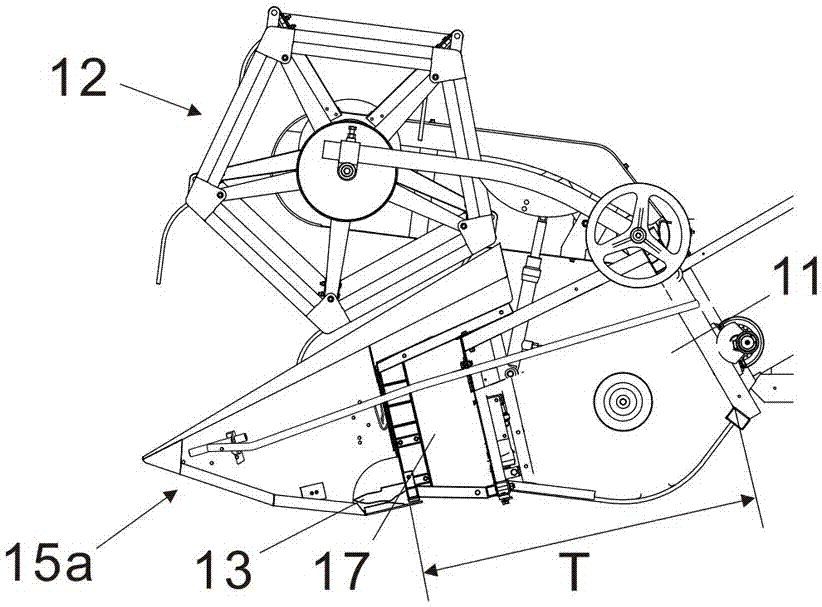

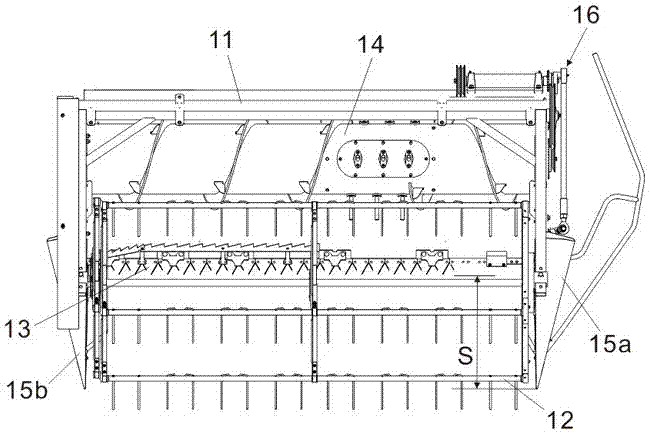

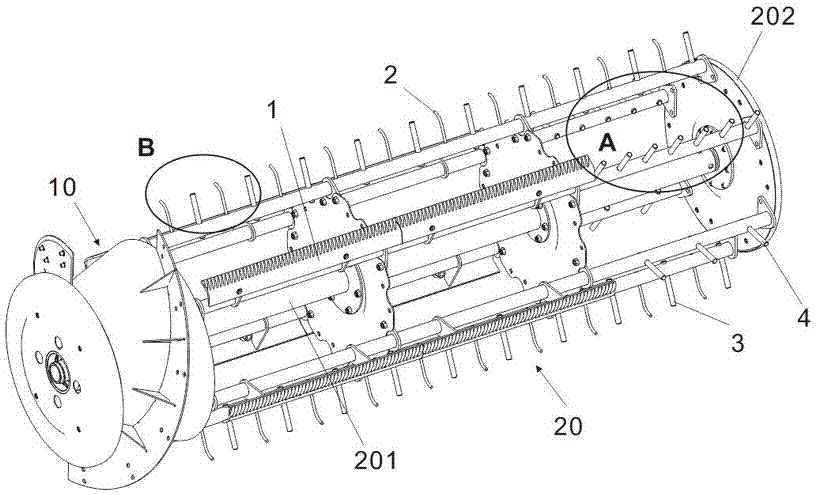

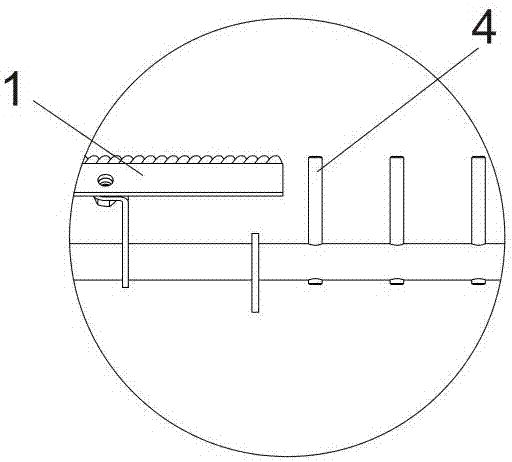

Combined harvester for cereals

ActiveCN107371572AReduce the difficulty of cleaningPowerful rubMowersThreshersAgricultural engineeringThreshing

The invention discloses a combined harvester for cereals, and belongs to the field of crop harvesting. The combined harvester comprises a cutting table, a threshing separation part and a cereal cleaning part. The threshing separation part comprises threshing rollers distributed in a longitudinal axial flow threshing manner. An open type rear cylinder of each threshing roller comprises a roller shaft coaxially connected with a closed conical front cylinder, flanges connected with two ends of the roller shaft, and a plurality of threshing toothed rods circumferentially arranged on the roller shaft and connected with the flanges; each of some threshing toothed rods is provided with a rasp-bar toothed rod and a plurality of grass discharge teeth, and each of some threshing toothed rods is provided with a combined toothed rod and a plurality of grass discharge teeth; the combined toothed rod is composed of a plurality of threshing teeth and a plurality of arc-shaped elastic teeth alternatively arranged at intervals; the cereal cleaning part comprises a volute centrifugal fan adopting arc blades, and a reciprocating vibration sieve with a dual-layer mesh grid and a straw walker. The combined harvester provided by the invention effectively controls dropping of rice spikes of the cutting table, and is long in threshing time, large in separation area, reduced in collection of green stems and leaves sticking on sieve, convenient to dismount and mount, and strong in cleaning capacity.

Owner:XINGGUANG AGRI MACHINERY

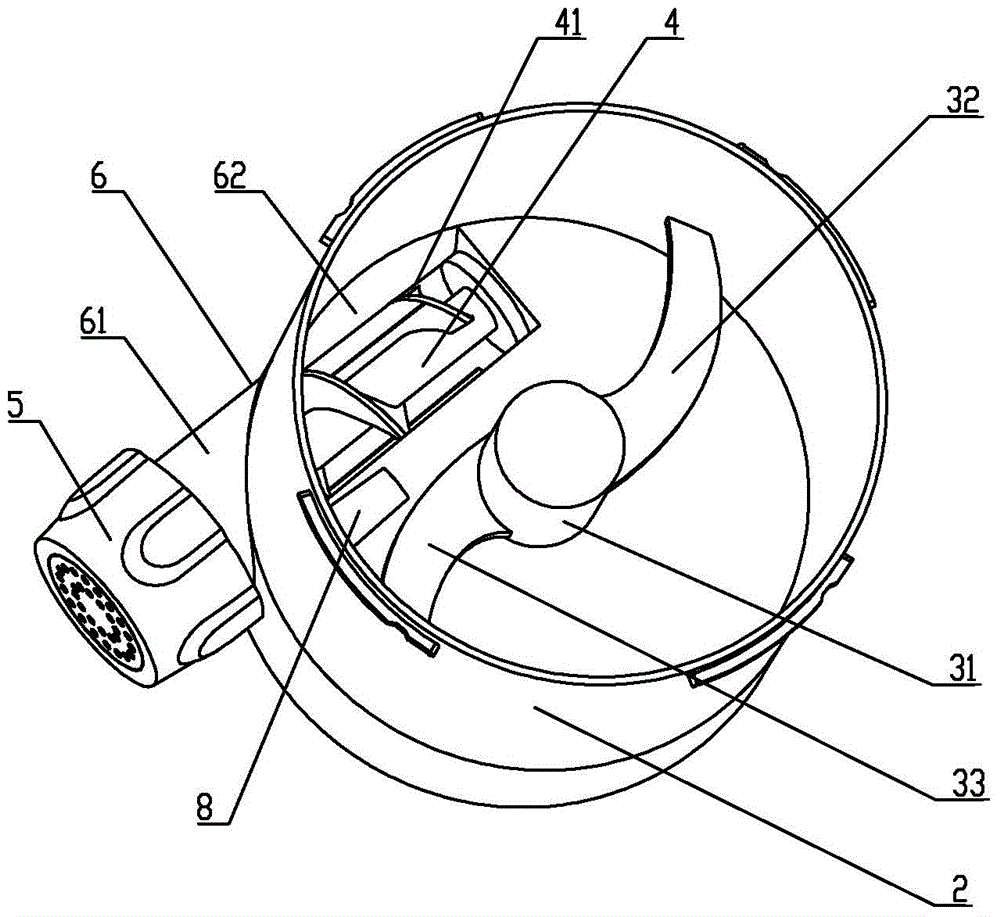

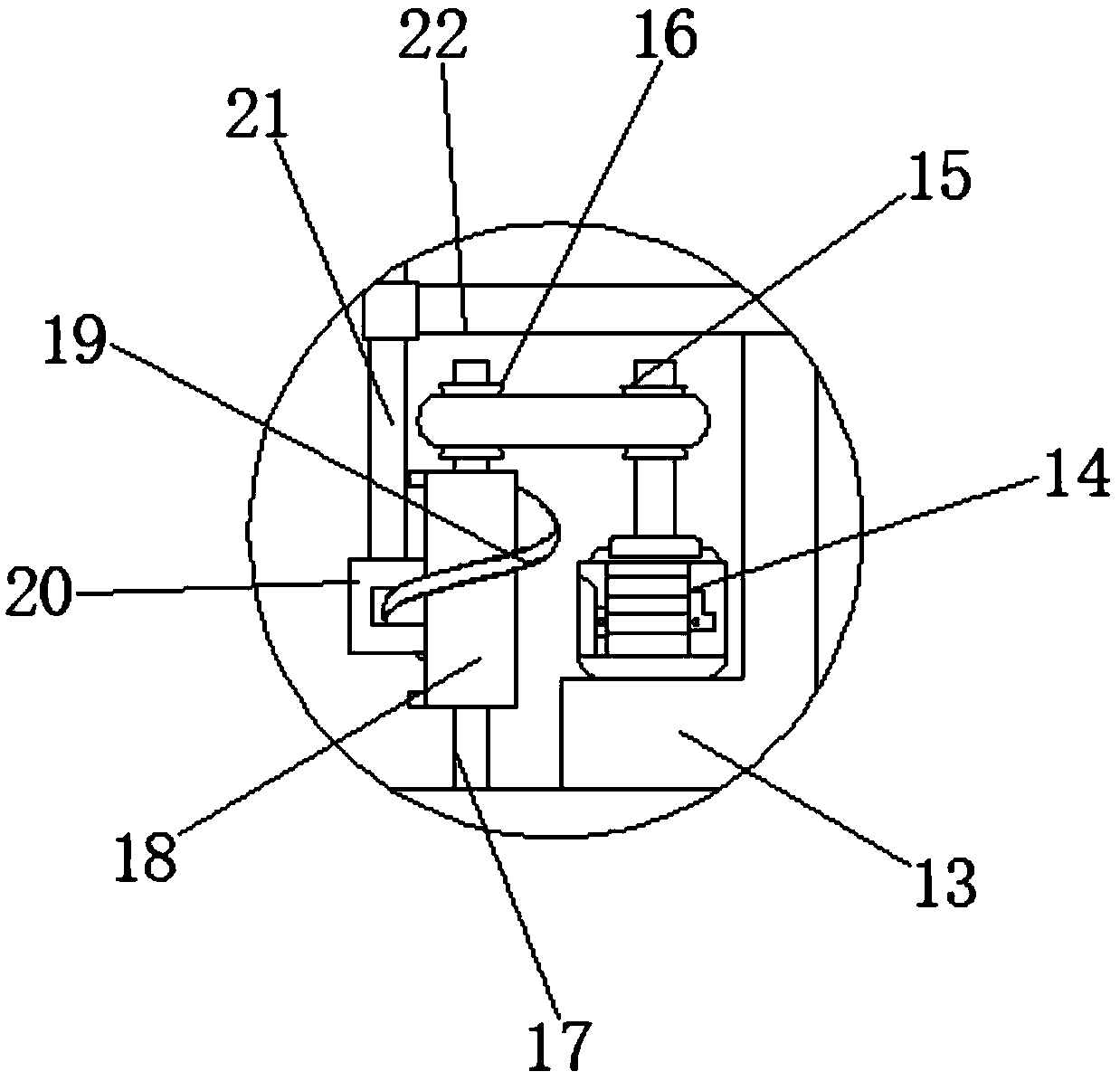

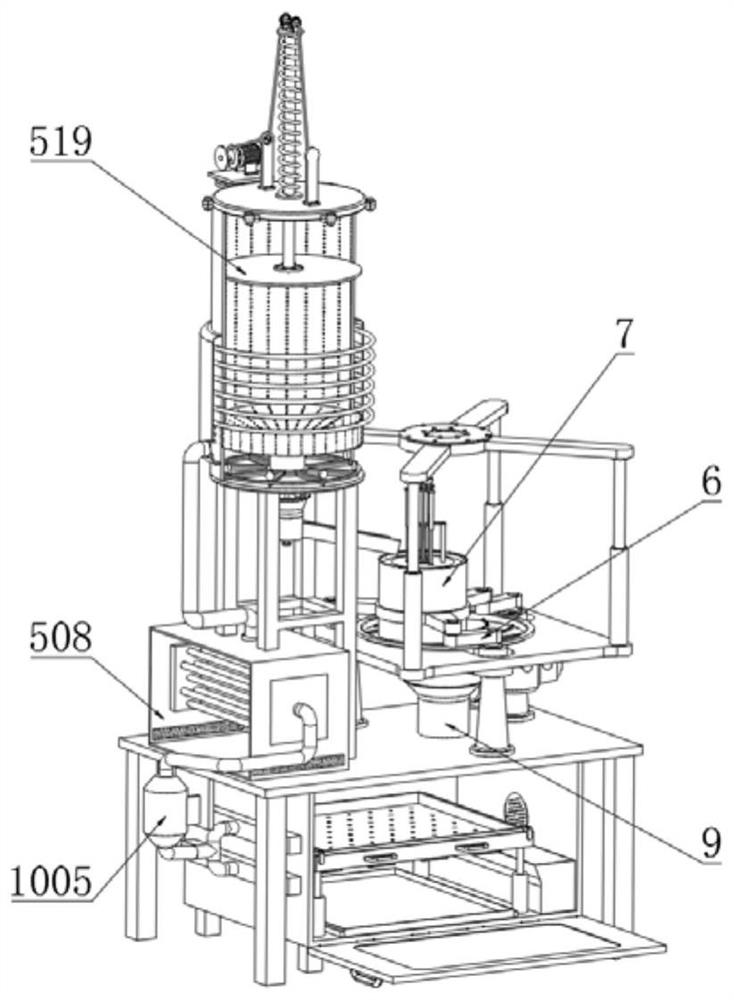

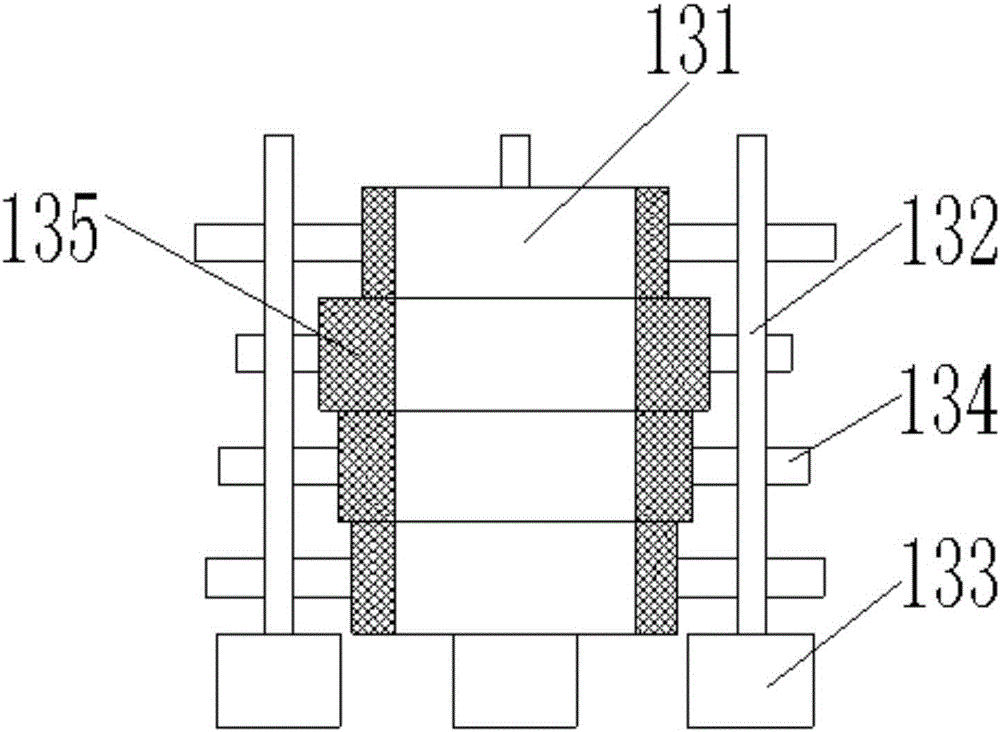

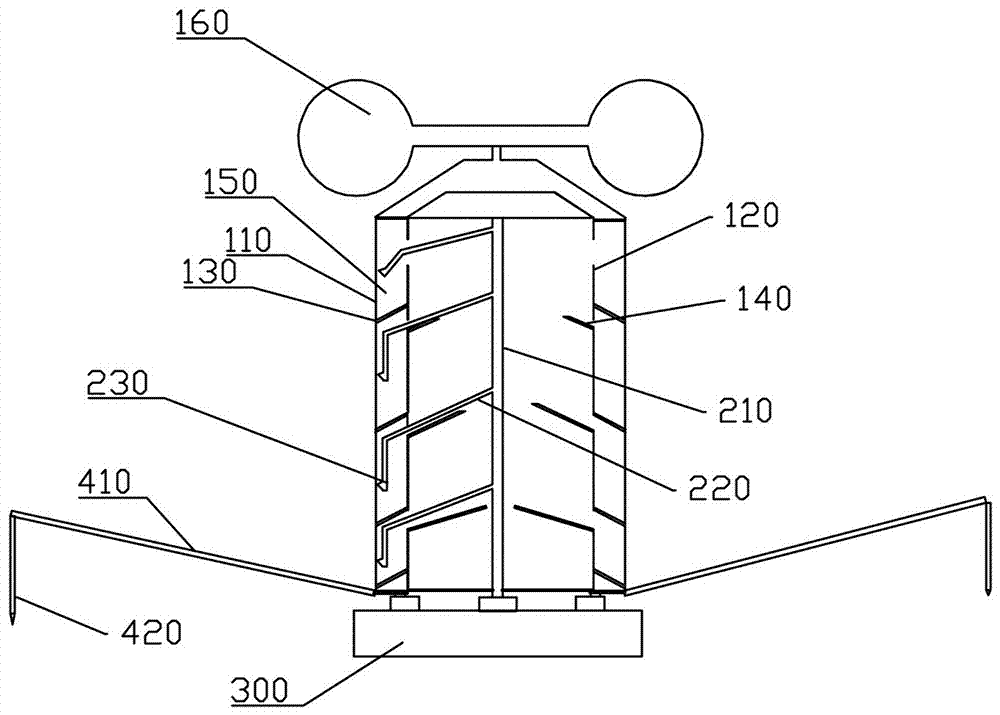

Automatic impending twisting unit

ActiveCN106417726AImprove qualityBroken tea rate is lowPre-extraction tea treatmentRubber ringDrive motor

The invention relates to an automatic impending twisting unit. The automatic impending twisting unit comprises a twisting mechanism, a feeding mechanism and a drying mechanism, wherein the twisting mechanism comprises a drum; the drum comprises a plurality of rotating barrels which are successively connected with each other in a clamped manner in the up-down direction and rotate independently; an opening of the upper end of each rotating barrel is positioned below a discharging opening of the feeding mechanism; a rubber ring sleeves the outer surface of each rotating barrel; a rotating shaft is positioned on the peripheries of the rotating barrels; a plurality of rotors with different diameters sleeve the rotating shaft and correspond to the rotating barrels; the rotors are abutted to outer side surfaces of the rubber rings with different thicknesses; the rotating shaft is connected with a driving motor; the driving motor is connected with a controller via electric signals; a plurality of air blades are vertically arranged on the inner wall of each rotating barrel; a main conveying belt is arranged below the drum; the twisting mechanism and the drying mechanism are successively positioned in the feeding direction of the main conveying belt; and the drying mechanism is positioned above the main conveying belt.

Owner:福建省麒麟山茶业发展有限公司

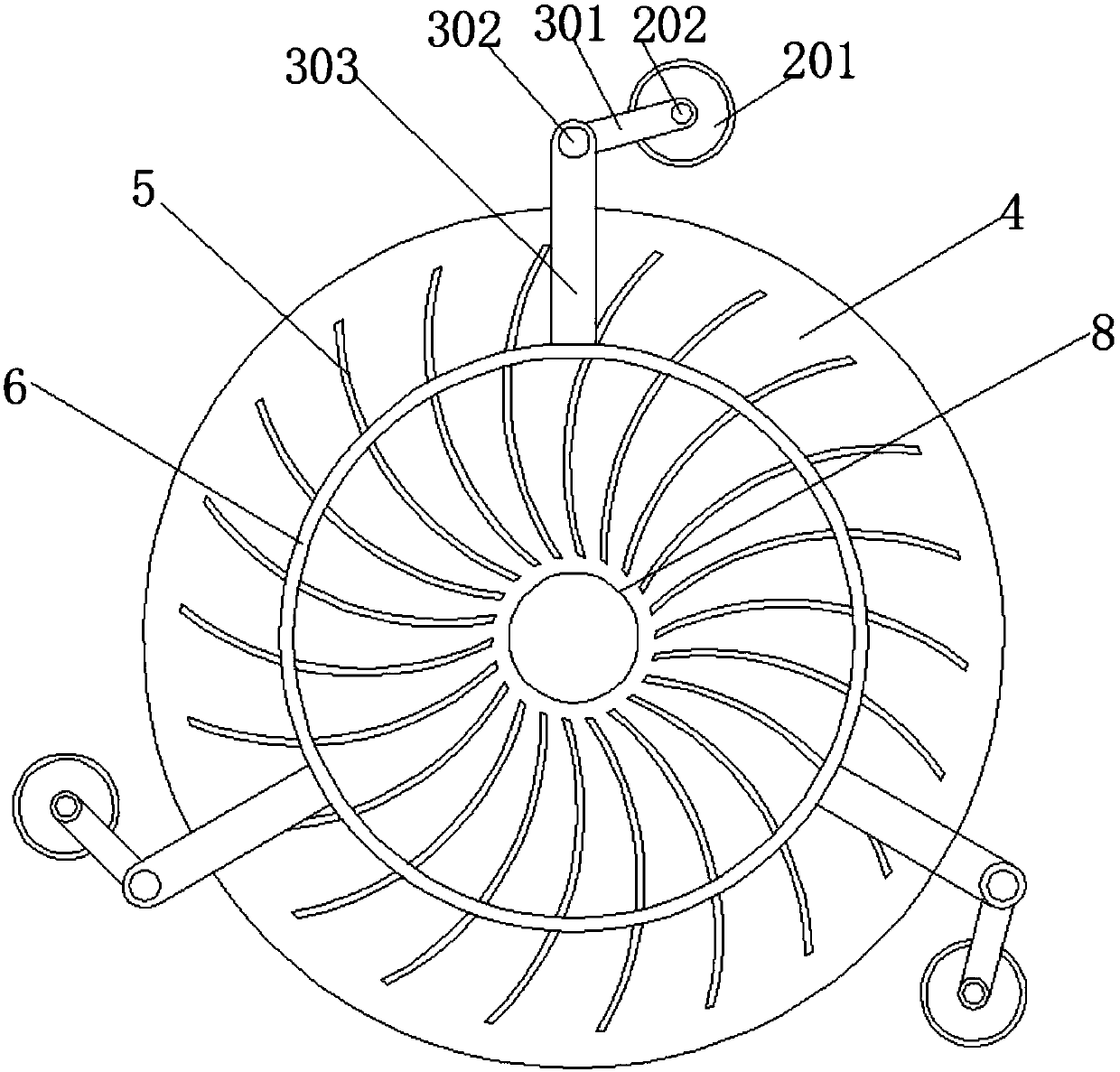

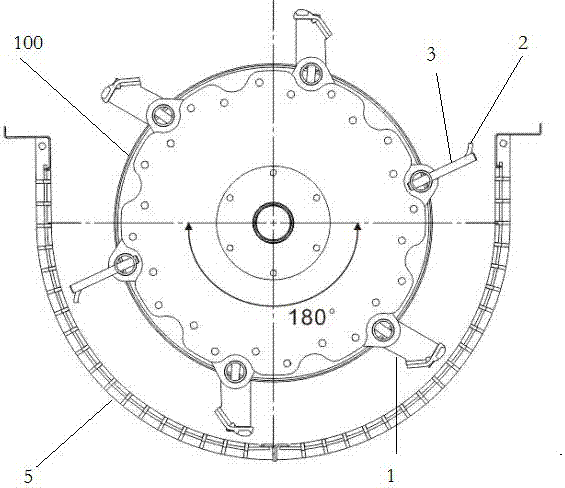

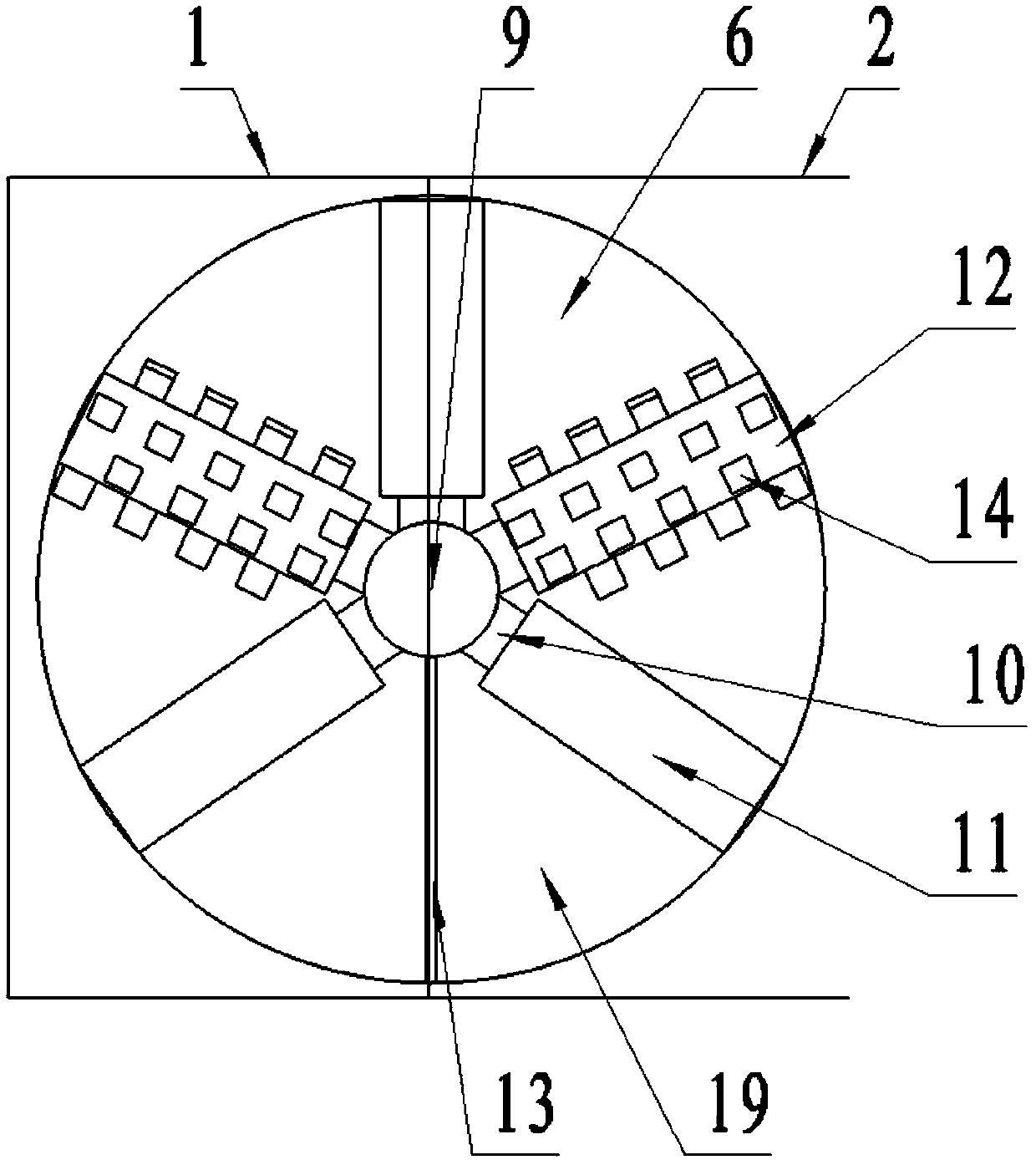

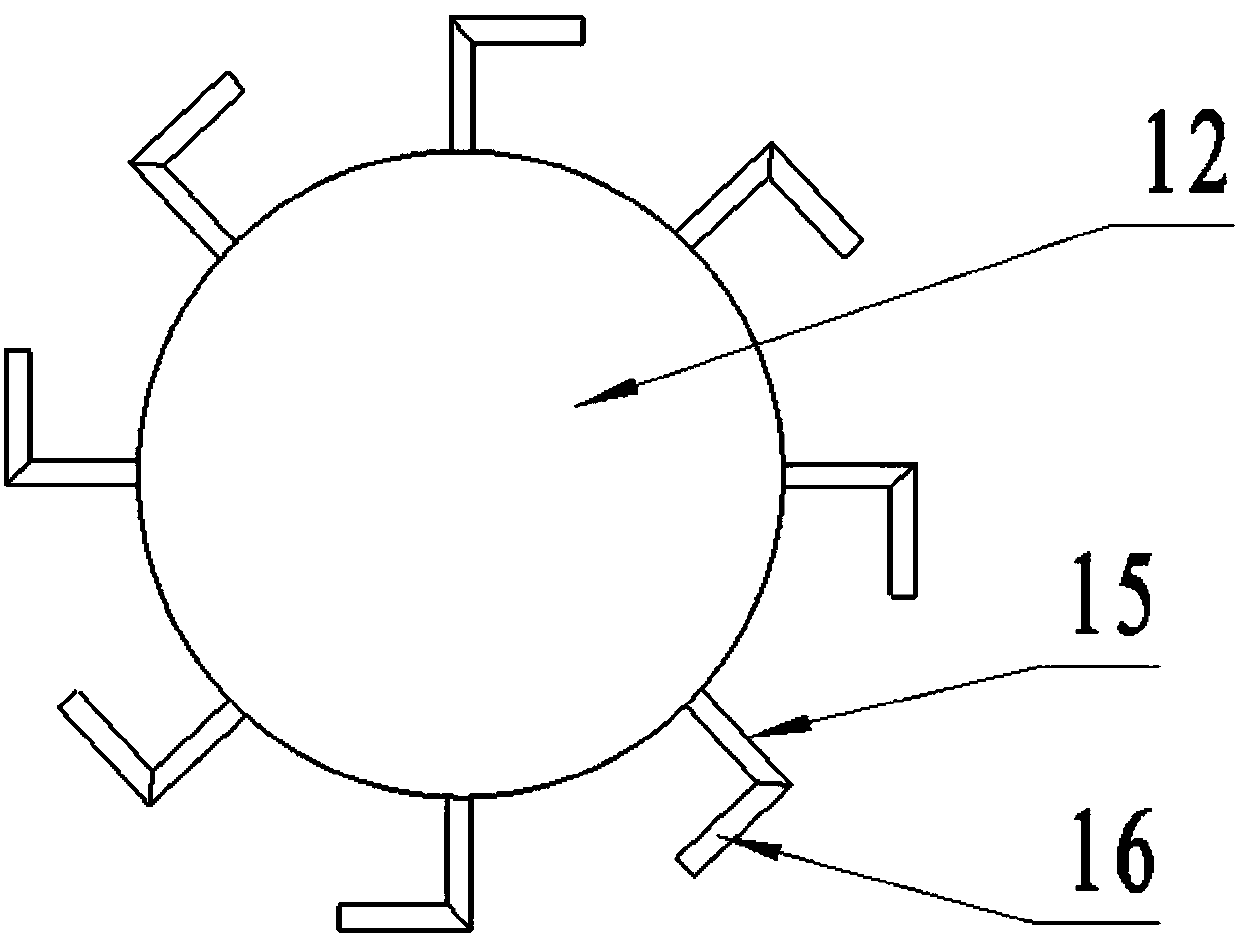

Rolling machine for tea leaf

InactiveCN107927226AHigh output effectPlay a buffer rolePre-extraction tea treatmentEngineeringTea leaf

The invention relates to the technical field of processing equipment for tea leaves, and further discloses a rolling machine for a tea leaf. The rolling machine comprises a circular plate, wherein thetop of the circular plate is fixedly connected with drive mechanisms; the quantity of the drive mechanisms is three; moreover, the three drive mechanisms are symmetrically arranged by using the center of the top of the circular plate as a symmetric center; the tops of the drive mechanisms are fixedly connected with rotating mechanisms; moreover, a rolling disc is fixedly connected among the threerotating mechanisms; the bottom of the inner wall of the rolling disc is fixedly connected with convex edges; the convex edges are of arc-shaped structures; the quantity of the convex edges is thirtythree. According to the rolling machine, as the tea leaf is influenced by sole weight in a process of falling from a circular groove, a slide block is enabled to slightly move on an arc-shaped rod; moreover, by utilizing the elastic action of a telescopic spring, a strip rod is enabled to rotate by using a rotating shaft as a center of a circle; moreover, the buffer action is realized; a discharge effect of a moving-out mechanism is enabled to be better, and the buffer effect is achieved.

Owner:ZHEJIANG XINCHANG TUANFENG MACHINERY

Natural rosin black tea production process

The invention discloses a natural rosin black tea production process. The natural rosin black tea production process comprises the following steps: fresh leaf picking; withering; rolling by the three-step method; fermentation for 8-10 h in a fermentation room at the temperature of 25-30 DEG C and the humidity of 90-95 percent; primary drying; secondary fermentation; secondary drying till the water content of tea leaves is 10-12 percent; primary mixing of tea leaves and pine needle by performing repeated multi-layer stacking according to the weight ratio (pine needles to the tea leaves) of (1-2):6 in such a way that the tea leaves and the pine needle are placed layer by layer; third-time fermentation; third-time drying. After a natural rosin black tea produced by the method is brewed, the tea soup is red and bright, has a unique fresh rosin flavor and can meet the many-flavor demands of tea lovers.

Owner:GUANGXI ZHAOPING NINGXIANGCUI TEA FACTORY

Threshing device of millet combine harvester

ActiveCN107396700ASimple structureEasy to assemble and disassembleThreshersConical tubeAgricultural engineering

The invention discloses a threshing device of a millet combine harvester, and belongs to the technical field of crop harvesting. The threshing device of the millet combine harvester provided by the invention comprises a threshing roller, a threshing roller top cap which is arranged on the threshing roller, lattice concave boards which are arranged below the threshing roller, wherein the threshing roller comprises a closed conical front tube and an opened back tube; the opened back tube comprises a roller shaft which is coaxially connected with the closed front conical tube, amplitude discs which are connected to two ends of the roller shaft and a plurality of threshing toothed bars which are uniformly distributed on the roller shaft and connected to the amplitude discs; each of parts of the plurality of threshing toothed bars is equipped with a rasp-bar toothed bar and a plurality of grass discharging teeth, and each of parts of the plurality of threshing toothed bars is equipped with a combined toothed bar and a plurality of grass discharging teeth; and each combined toothed bar consists of a plurality of threshing teeth and a plurality of arc elastic teeth which are arranged alternately at intervals. The threshing device of the millet combine harvester provided by the invention has a simple structure, takes rolling and grinding as the main functions, has a certain brushing function, and effectively reduces screen sticking by green stems and leaves.

Owner:XINGGUANG AGRI MACHINERY

Dough making device for chocolate cake body

InactiveCN111727990AWell mixedUniform sprayMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsChocolate cakeEngineering

The present invention discloses a dough making device for a chocolate cake body. The dough making device for the chocolate cake body comprises a box body, two symmetrical supporting legs are fixedly arranged at a bottom part of the box body, a water pump is fixedly arranged at a middle part of a left side surface of the box body through a machine seat, a water cylinder is fixedly arranged at a bottom part of the left side surface of the box body, a bottom part and a top part of the water pump respectively communicate with a water inlet pipe and a water outlet pipe, a bottom part of the water inlet pipe extends inside of the water cylinder, besides, a flow regulating valve is arranged on the water inlet pipe, a first material hopper, an air outlet pipe and a second material hopper are successively arranged at a top part of the box body from left to right, a sponge block is arranged in the air outlet pipe, a mixing box is fixedly arranged on an inner top wall of the box body, a first material discharging pipe is arranged between a left end of the mixing box and the first material hopper, a second material discharging pipe is arranged between a right end of the mixing box and the second material hopper, a bottom part of the air outlet pipe penetrates and extends inside the mixing box, and an air collecting box is fixedly arranged on an inner wall of a back surface of the mixing box, and air blowing pipes are arranged at a front surface of the air collecting box. The dough making device mixes raw materials, auxiliary materials and water, then stirs the mixture and rapidly formsthe mixture.

Owner:怀宁县洪铺镇永和食品厂

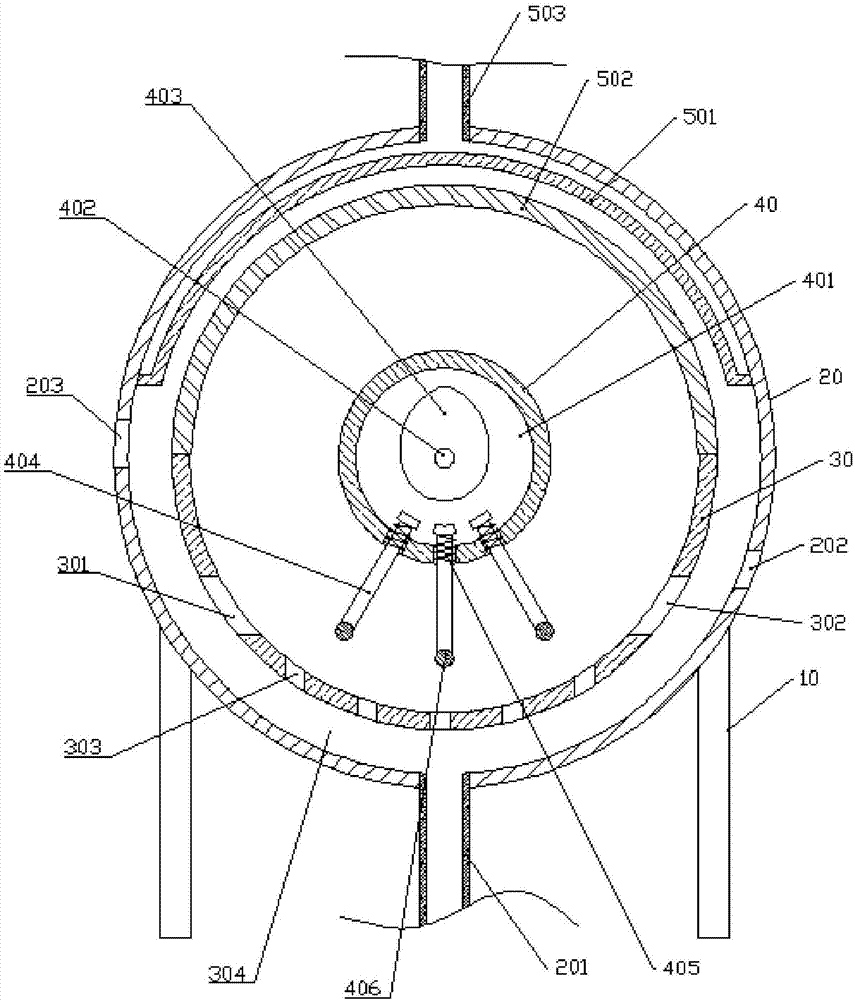

Cloth boiling and dyeing device

ActiveCN107988749AEasy to dipKeep it straightTextile treatment containersSucessive textile treatmentsEngineeringWater pipe

The invention relates to the field of cloth processing, in particular to a cloth boiling and dyeing device. The device includes an outer cylinder, a water inlet pipe, an inner cylinder, a fixing shaft, a first electric heat wire and an air outlet pipe; the outer cylinder and the inner cylinder are sequentially, coaxially and fixedly installed on the fixing shaft from outside to inside, and the outer cylinder and the inner cylinder form a dye cavity; the outer wall of the outer cylinder is fixedly connected with a machine frame, the upper end of the water inlet pipe is communicated with the lower side of the outer cylinder, the side face of the inner cylinder is provided with a first inlet and a first outlet which are communicated with the inner cylinder, and the first inlet and the first outlet are formed in the two sides of the vertical diameter of the cross section of the inner cylinder; the outer cylinder is provided with a second outlet near the first outlet, the outer cylinder isprovided with the second outlet near the first inlet, the first electric heat wire is fixedly installed on the inner wall of the upper side of the outer cylinder, the air outlet pipe is communicated with the upper side of the outer cylinder, and the air outlet pipe is communicated with the air inlet pipe. According to the scheme, the situation that cloth generates wrinkles in the dyeing process can be avoided.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

Efficient practical kneader

InactiveCN108719372AEasy kneadingEasy to kneadDough homogenizationHydraulic cylinderArchitectural engineering

The invention discloses an efficient practical kneader, comprising a frame, and a support plate at the lower portion of the frame. An electric hydraulic cylinder is arranged at the top of the frame; the output end of the electric hydraulic cylinder is connected with a hammerhead via a connection rod; a hammer trough is arranged right below the hammer trough; the hammer trough includes a bottom plate arranged on the support plate, two fixed plates arranged on the two parallel sides of the bottom plate, and two moving plate arranged on the other two parallel sides; the outer sides of the movingplates are connected with electric push bars mounted at the lower portion of the frame; the geometric center of the bottom plate is provided with a mounting hole; a rotating plate is disposed in the mounting hole; a rotating motor is disposed at the bottom of the support plate. The efficient practical kneader is simple in structure and reasonable in design, replaces manual kneading via mechanicaloperation, enables automatic kneading to be facilitated and labor intensity to be reduced, has improved kneading efficiency, and can prevent pollution of dough caused by manual kneading.

Owner:SICHUAN XIONGJIAN IND

Tea leaf processing technique

InactiveCN107080007AQuality improvementImprove qualityPre-extraction tea treatmentClimate change adaptationOxygenase activityBud

The invention discloses a tea leaf processing technique, comprising the following steps: selecting and picking fresh, tender and strong three leaves with one bud; spreading the picked tea leaves uniformly on a bamboo sieve for cooling; standing the cooled tea leaves indoors; pouring the stood tea leaves into a bamboo rocking machine for rocking; killing the rocked tea leaves in a killing pot; rolling the killed tea leaves in a rolling machine, lightly rolling for 10-12 minutes, heavily rolling for 5-8 minutes, and then lightly rolling again for 18-20 minutes; shaping the rolled tea leaves in a tea leaf shaper; drying the shaped tea leaves in a dryer; disinfecting the dried tea leaves; and packaging the tea leaves in a vacuum condition. According to the tea leaf processing technique, the killing environment is scientifically and reasonably improved, the activity of oxidase in fresh tea leaves is better destroyed and passivated, enzymatic oxidation of tea polyphenols and the like in fresh leaves are inhibited, and partial moisture in fresh leaves is evaporated, so the tea leaves are softened and convenient for rolling and shaping, formation of good aroma is promoted, and the processing quality of tea leaves is improved.

Owner:贵州博联茶业股份有限公司

Controllable-temperature tea stir-frying machine capable of fully rolling tea leaves

The invention relates to a controllable-temperature tea stir-frying machine capable of fully rolling tea leaves, which comprises an outer furnace body, an inner furnace body, a tea rolling device anda heater, wherein the inner furnace body is embedded and fixed in the outer furnace body, an opening is opened on one side of the inner furnace body, the tea rolling device is located between the outer furnace body and the inner furnace body through the opening with a half position, and the other half position is located in the inner furnace body, the tea rolling device comprises a rolling platform and a plurality of rolling ends on the rolling platform, a sieve tray is arranged under the tea rolling device in the inner furnace body, the heater is connected with a temperature sensor, and a temperature display is provided on the temperature sensor. The rolling platform in the tea rolling device cooperates with a plurality of rolling ends to carry out the rolling of the tea leaves, so as toavoid the incomplete rolling of the tea leaves when the rolling end is used for rolling the tea leaves, the plurality of the rolling ends can improve the effect of the tea leaves, so that the tea leaves are fully rolled, and the working efficiency of the tea stir-frying machine and the final taste of the tea are improved.

Owner:谷约飞

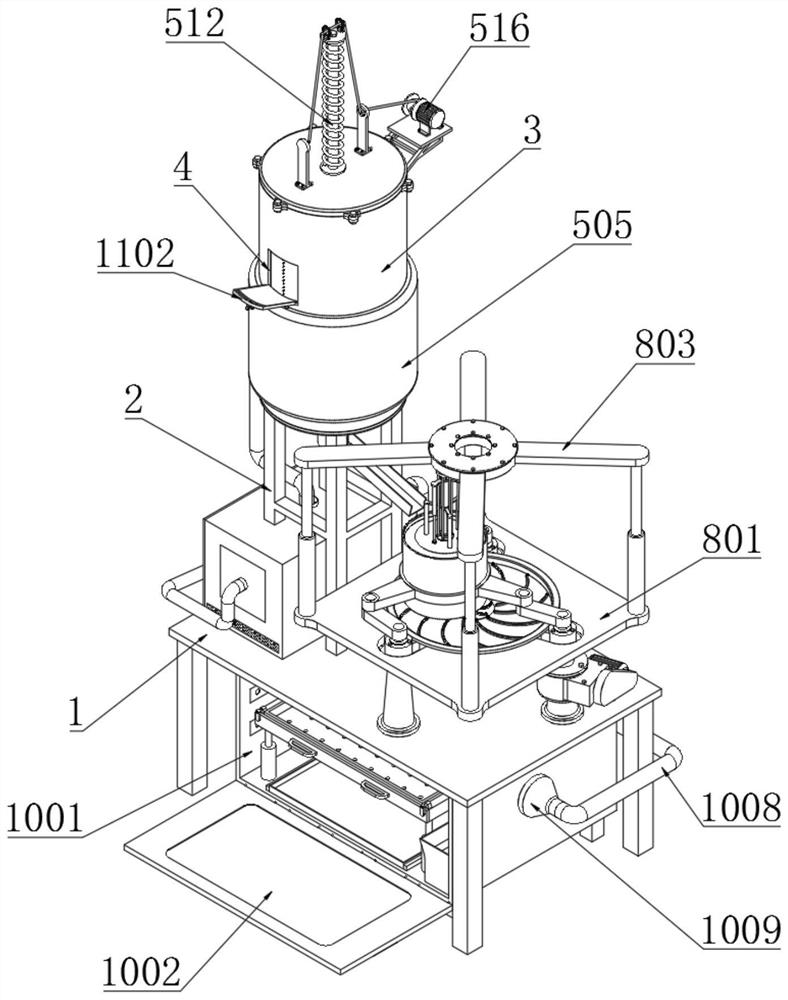

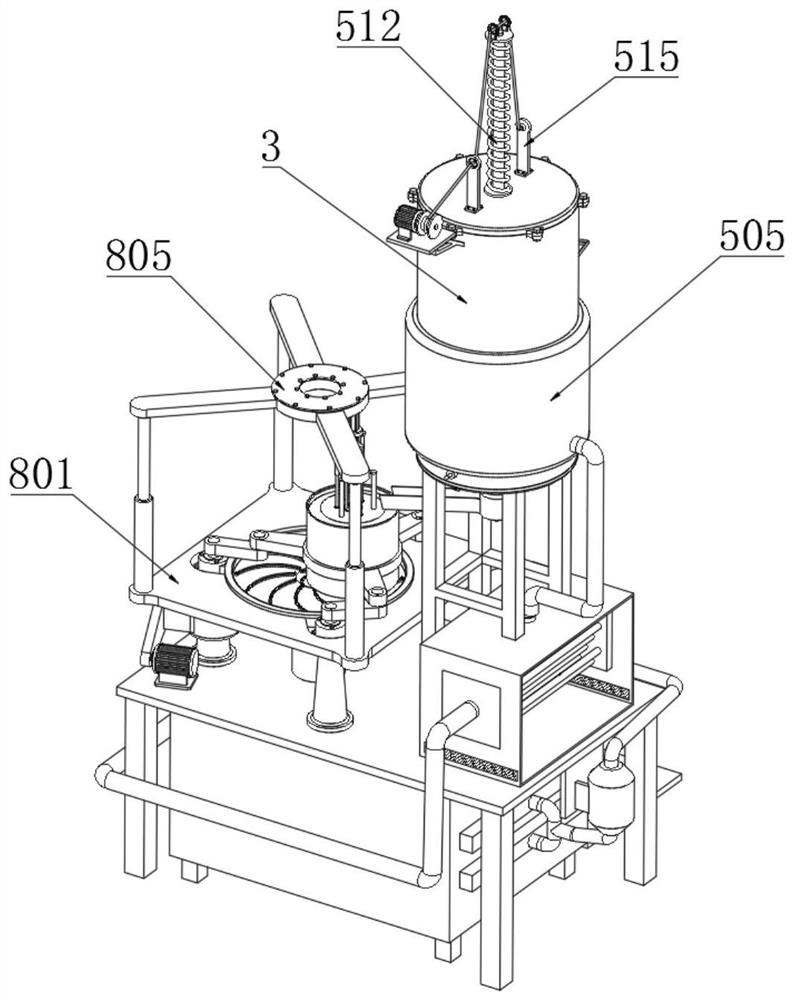

Tea airing equipment

The invention relates to automatic equipment used in a withering step of a tea making procedure and particularly relates to tea airing equipment. The tea airing equipment comprises a mounting seat, a cylinder, a stirring mechanism and a protecting sleeve, wherein the cylinder is rotatably connected to the mounting seat, a plurality of tea airing cavities are formed among an outer cylinder shell, an inner cylinder shell and partition boards and are provided with tea inlets and tea outlets, the tea inlets are connected with tea inlet trays, tea outlet doors are arranged at the tea outlets, and wind wheels are fixed at the top of a cylinder frame; and the stirring mechanism is arranged in the inner cylinder shell and comprises support rods, a plurality of connecting rods and stirring shovels, the support rods are fixed in the center of the mounting seat, one ends of the connecting rods are fixedly connected to the support rod, the other ends of the connecting rods are connected with the stirring shovels, and the stirring shovels stretch into the tea airing cavities. According to the tea airing equipment, the problem the tea leaves are easily contaminated by dust during withering is solved; and a tea airing device which is relatively closed and easy to collect is provided.

Owner:凤冈县凤鸣春茶业有限公司

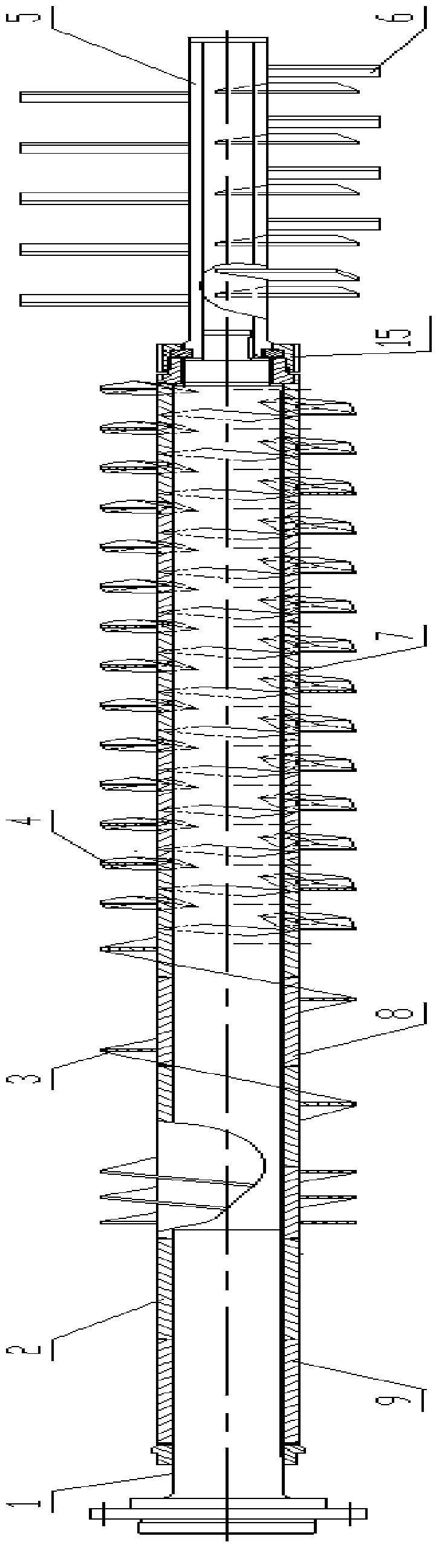

Pre-reactor main shaft spiral system for hydrogen fluoride

ActiveCN104071752AExtended service lifeWith safety technical levelFluorine/hydrogen-fluorideFailure rateHydrogen fluoride

The invention discloses a pre-reactor main shaft spiral system for hydrogen fluoride. Fluorite charging section blades are welded on a fluorite charging section shaft sleeve; reaction section blades are welded on a reaction section shaft sleeve; extension section blades are welded on an extension section shaft; the length is greater than 5 meters; the extension section blades, fluorite charging section blades and reaction section blades are respectively welded with a stellite alloy in an overlay welding mode; the pitch between the reaction section blades and the blades at the acidification port is increased; a 130-145mm-long spiral short section is added to the tail end of the main shaft, so that the acidification port deviates from the spiral junction surface by 180-200mm; the fluorite charging section blades and fluorite charging section shaft sleeve are made of the same material; and the reaction section blades and reaction section shaft sleeve are made of the same material; and the extension section blades and the extension section shaft are made of the same material. The system has the advantages of sufficient reaction, no blocking, no material return, favorable abrasion resistance, low failure rate, long equipment life and high yield, and is suitable for delivering slurry and lumping materials as well as high-abrasion materials.

Owner:沈阳派司钛设备有限公司

Manpower foot-operated type dual-rotation laundry device

The invention discloses a manpower foot-operated type dual-rotation laundry device. The laundry device comprises a power input shaft, a foot-operated rotating cylinder, anti-slip strips, an input shaft support, a water pump, a water guiding pipe, a central fluted disc, a rotary disc seat, a gearbox, a belt wheel and a belt. The water guiding pipe is arranged at the lower portion of a main shell; the water pump is mounted on the water guiding pipe; the input shaft support is arranged on the right side of the main shell; the power input shaft is arranged on the side portion of the gearbox; the other end of the power input shaft is fixedly mounted on the input shaft support; the foot-operated rotating cylinder is arranged on the power input shaft; the diameter of the foot-operated rotating cylinder is 300-500 mm; 10-30 anti-slip strips are arranged on the surface of the foot-operated rotating cylinder; and the vertical section of each anti-slip strip is rectangular. According to the invention, the noise of a whole washing process can be reduced, clothes can be fully rubbed, and the power is input by a user, so that the user can do physical exercises, energy waste can be reduced, environment pollution can be reduced, and the laundry device is more environment-friendly.

Owner:湖州佳灏信息技术有限公司

Rolling mechanism for enzyme deactivation of tea leaves

PendingCN110800830AReduce weightEasy to movePre-extraction tea treatmentClassical mechanicsElectric machinery

The invention relates to the field of tea processing, in particular to a rolling mechanism for enzyme deactivation of tea leaves. The rolling mechanism comprises a machine frame, a rolling barrel anda pressing disc, wherein the rolling barrel is fixedly connected with the machine frame, two vertical plates are fixedly connected with the machine frame, a moving frame is arranged between the two vertical plates, the left and right two sides of the moving frame are fixedly connected with sliding rods, the sliding rods are horizontally connected with the vertical plates in a sliding manner, firstcompression springs are connected between the left and right two sides of the moving frame and the vertical plates, a vibration block is vertically connected in the moving frame in a sliding manner,second compression springs are connected between the upper and lower two sides of the vibration block and the moving frame, motors are fixedly connected with the vibration block, eccentric blocks areconnected with the motors, a vertical rod is fixedly connected with the vibration block, the top of the vertical rod is fixedly connected with a rolling plate located below the rolling barrel, and twoends of the rolling plate are provided with material outlets. The solution improves the rolling degree of tea leaves, and makes the tea leaves be more fully rolled.

Owner:贵州省凤冈县浪竹有机茶业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com