Patents

Literature

97results about How to "Knead evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

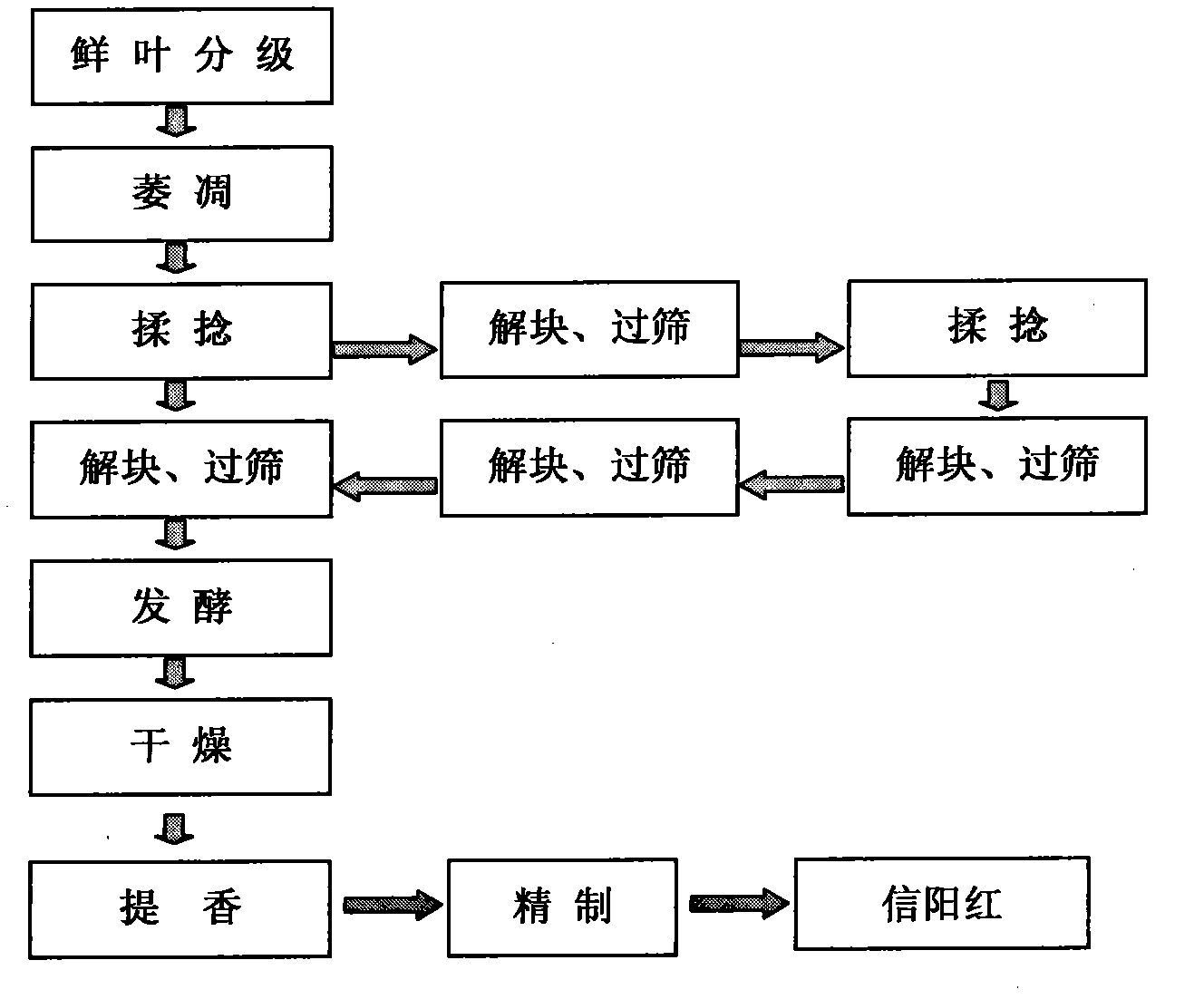

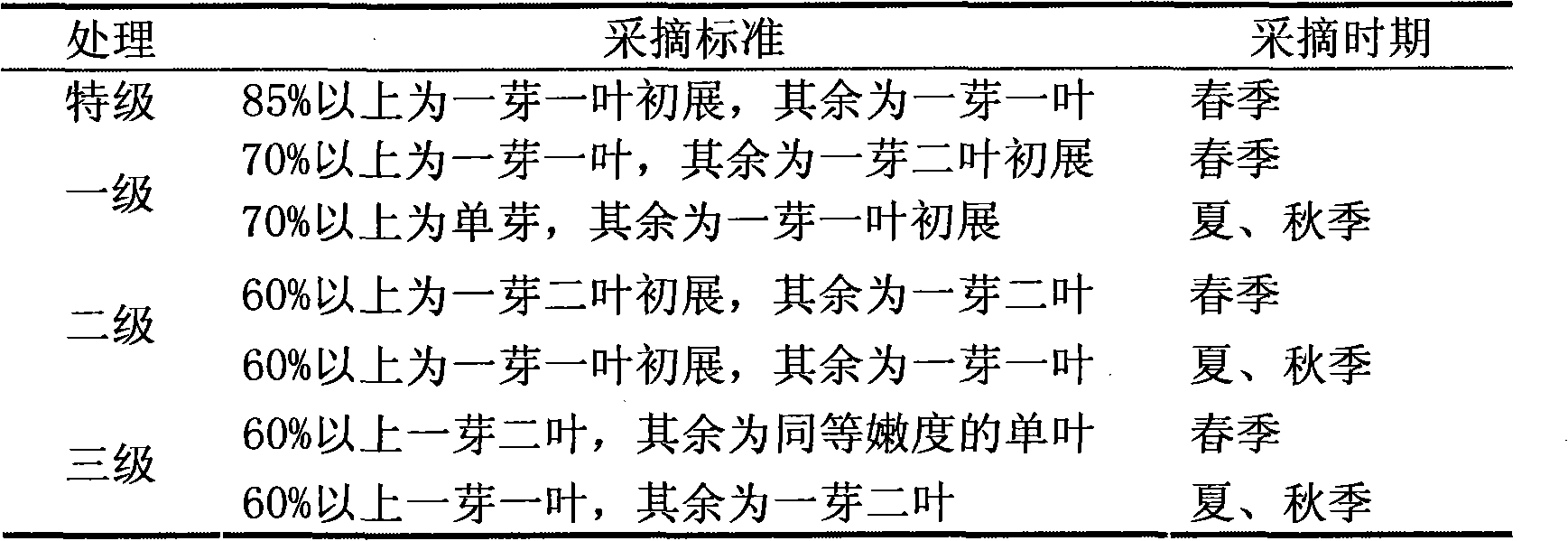

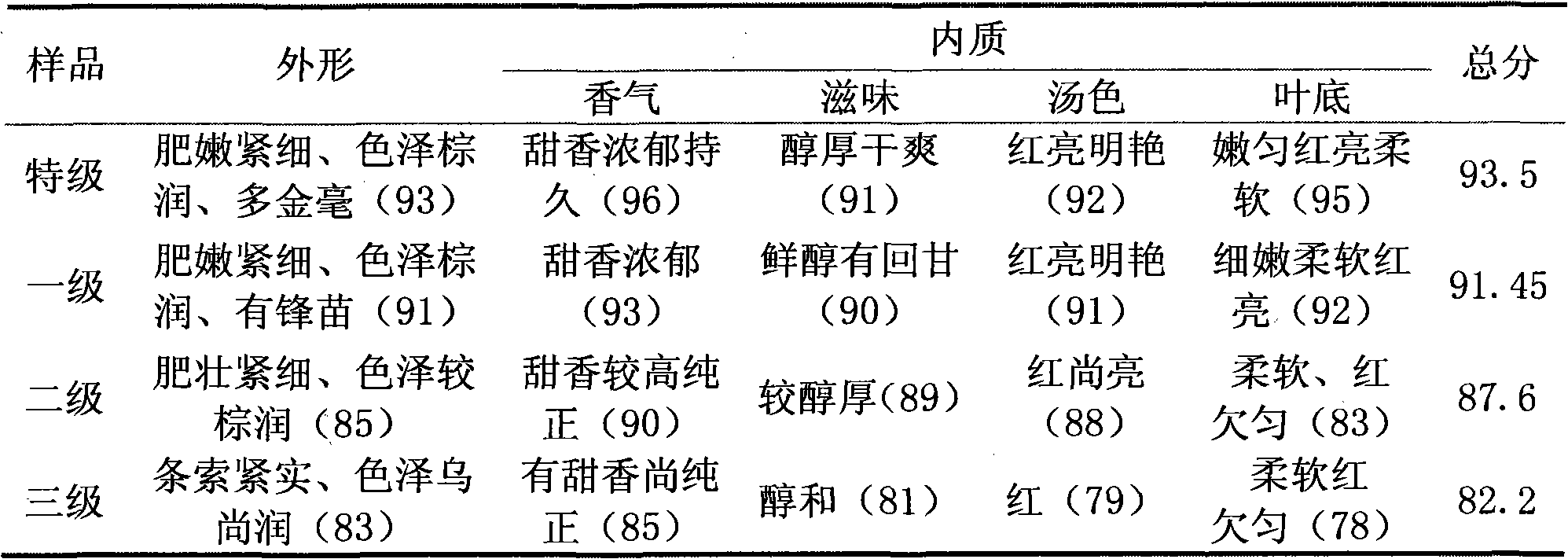

Xinyang red black tea processing technique

The invention relates to a Xingyang red black tea processing technique. The technique comprises the following parameters: wilting temperature: 25-30 DEG C; humidity: 60-70%; wilting time: 6-7 h; twisting machine rotating speed: 55-60 r / min; 2-3 times of twisting, each for 30 min; amount of tea feed: 30-35 kg; unravel machine rotating speed: 35 r / min; sieve pore size: 6#; 2-3 times of unravelling;temperature in a fermentation chamber: 2-7 DEG C; humidity in the fermentation chamber: 96%; tea spread thickness: 10 cm; oxygen supply amount: 5 L / min; fermentation time: 4.5 h; initial drying temperature: 115 DEG C; initial drying time: 20 min; re-drying temperature: 75 DEG C; and re-drying time: 30 min. The processing technique of the invention is unique, and the quality of the made black tea is excellent: the appearance of the product is fat and tender and compact, the peak of the tea is gold and the tea has bright luster; the endoplasm aroma of the tea has rich green flavour; the taste of the tea is mellow and sweet; the tea liquor is brilliantly red; and the root of the tea leaf is soft and green, has many sprouts and a colour of brilliant red.

Owner:信阳市浉河区茶叶办公室

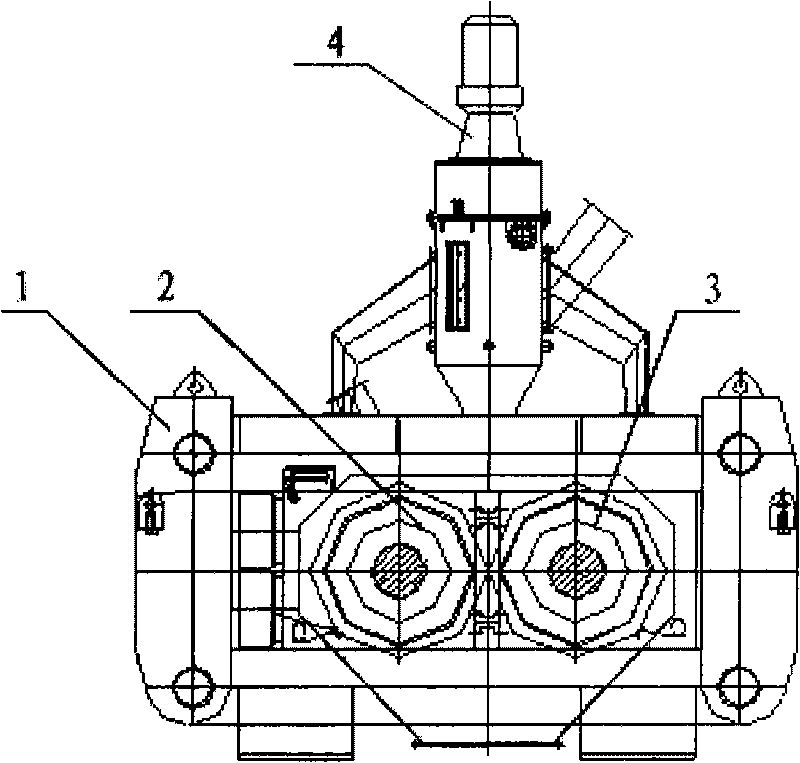

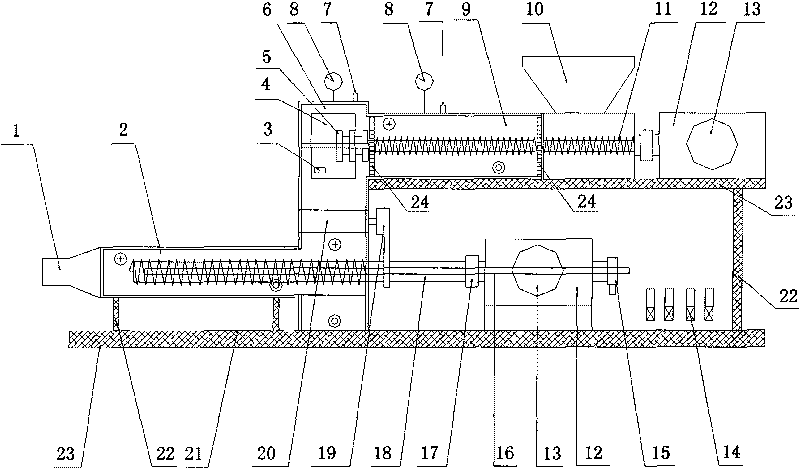

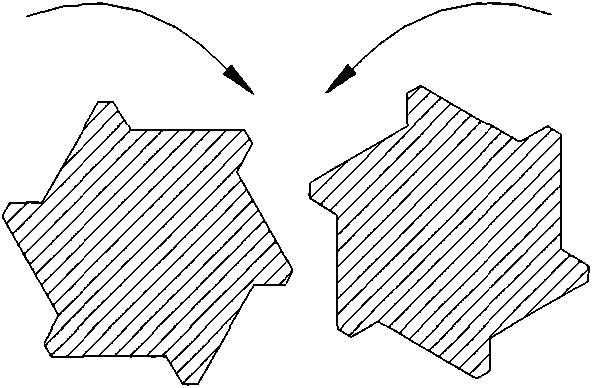

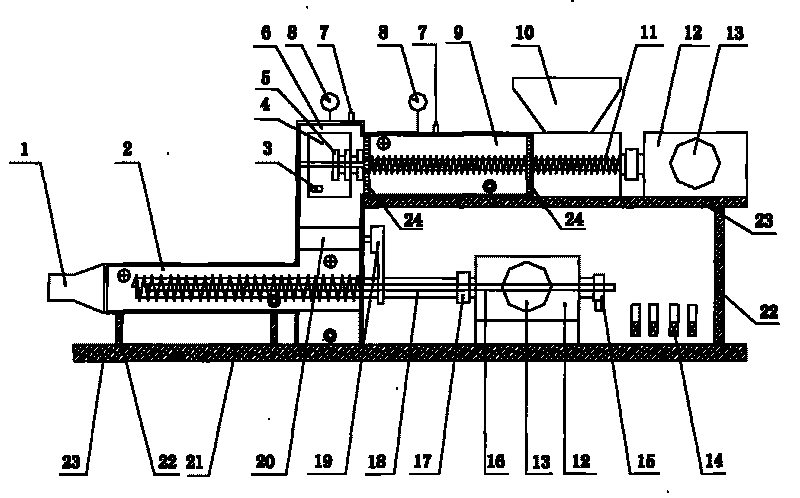

Pulverized coal molding method without binding agent and double-roller molding machine suitable for method

InactiveCN101722669AMeet shipping requirementsMeet industrial application requirementsShaping pressWater contentCircular surface

The invention provides a pulverized coal molding method without binding agent, which comprises the following steps of: 1. screening pulverized coal with the granularity of not more than 6mm by a screening device, carrying out drying dehydration processing on the pulverized coal and controlling the water content to be 2-15 percent; 2. forcibly compressing and feeding the pulverized coal obtained in the step 1 into a seam between double rollers of a double-roller molding machine by a feeding machine; and 3. running the double-roller molding machine, continuously rotating the double rollers of which at least one roller circular surface is distributed with pits and compacting and molding molded coal by the pits. The invention also provides the double-roller molding machine which is suitable for the method. The invention solves the problem of pulverized coal molding without binding agent of weak caking coal and non-caking coal, such as low-order bituminous coal, middle and old aged lignite, and the like.

Owner:CHNA ENERGY INVESTMENT CORP LTD +4

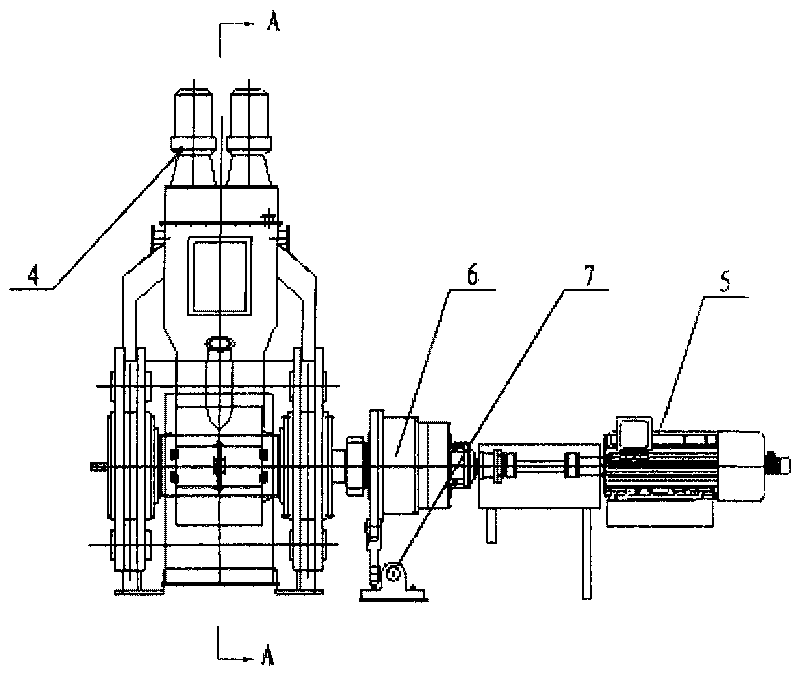

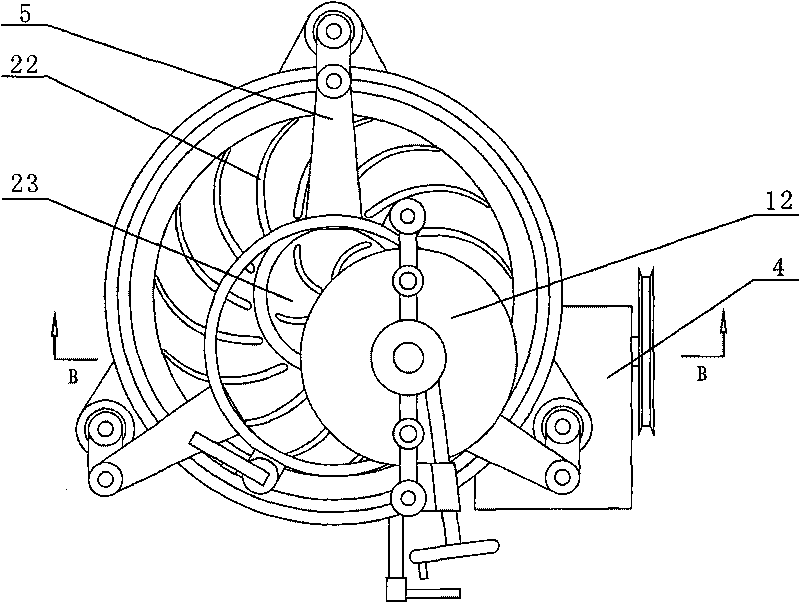

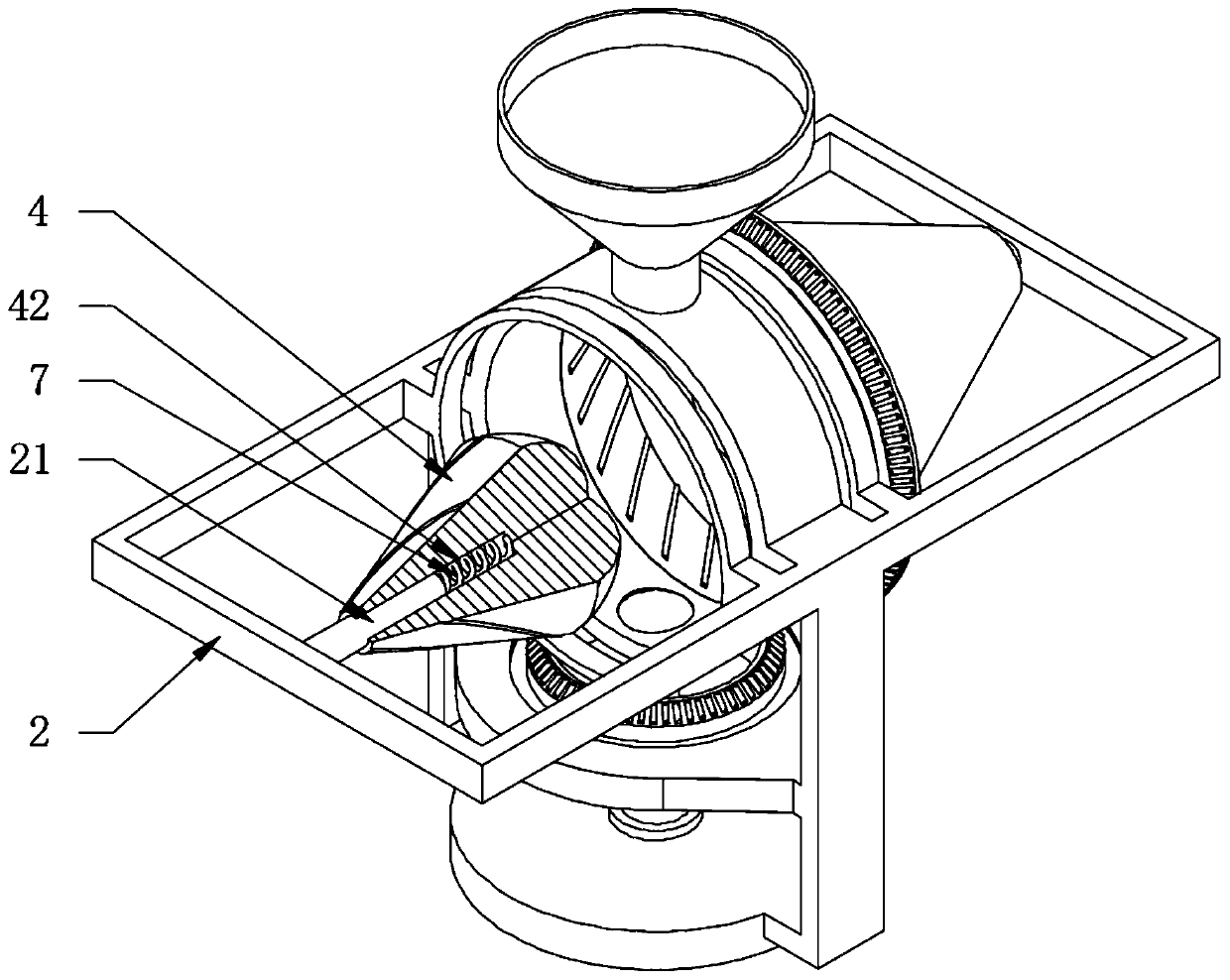

Novel tea knead entwist machine

The invention discloses a novel tea knead entwist machine and relates to tea processing machineries. The circular movement of the knead entwist device above the knead entwist plate can be realized by connecting the knead entwist device with a crank rocker mechanism; and the tailor-made knead entwist plate matches with the screw cover in the knead entwist device. The stripping tea rate of the tea is high, broken tea is little, and the broken tea generated in production can be separated from the mature tea automatically, thus improving tea grade and increasing production efficiency.

Owner:WUFENG TIANCHI TEA MACHINERY

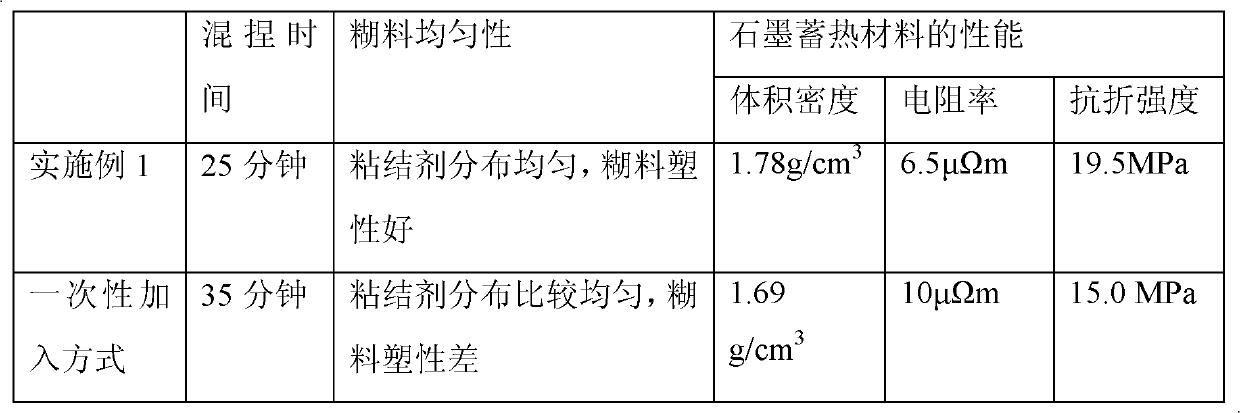

Heat accumulation and energy storage graphite material for solar thermal power generation and preparation method thereof

ActiveCN101948675AImprove thermal conductivityImprove heat storage capacityHeat-exchange elementsCooking & bakingThermal expansion

The invention relates to a heat accumulation and energy storage graphite material for solar thermal power generation and a preparation method thereof. The performance parameters of the graphite material meet the following requirements that: volume density is more than or equal to 1.75 g / cm<3>; electrical resistivity is less than or equal to 7.5 mu ohm m; ash content is less than or equal to 0.2 percent; rupture strength is more than or equal to 18.5 Mpa; elastic modulus is less than or equal to 8.8 Gpa; and thermal expansion coefficient is less than or equal to 2.0*10<-6> / DEG C<-1>. The graphite material of the invention has the advantages of high thermal capacity, high heat conductivity, long service life, low cost and the like. In the preparation method, the focusing solar thermal power generation and heat accumulating material is prepared from raw materials by the steps of sieving, burdening, kneading, airing, vibration molding, baking, soaking, secondary baking, graphitizing and machining.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

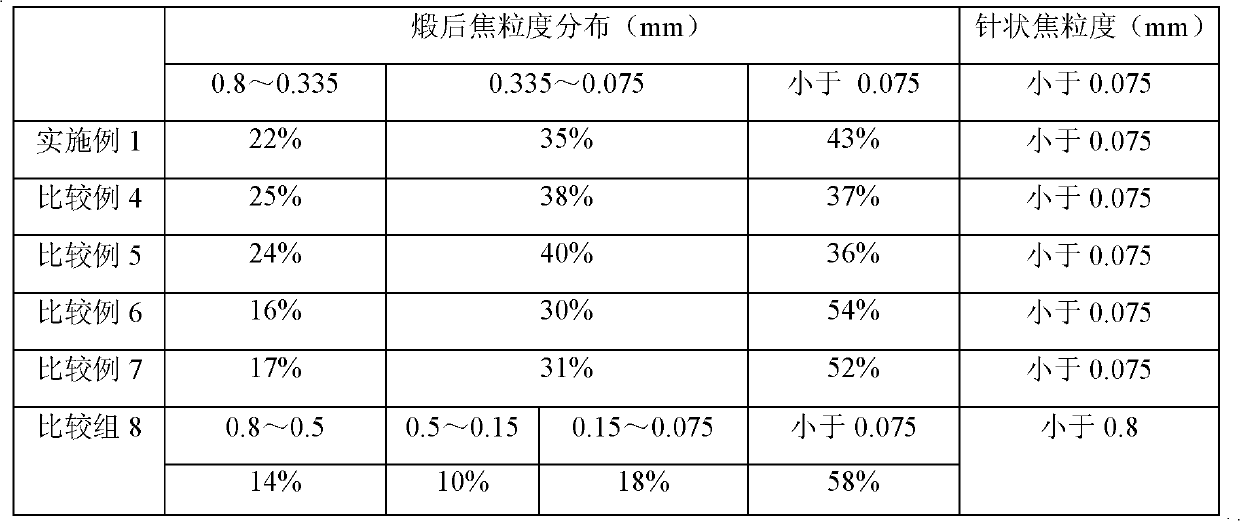

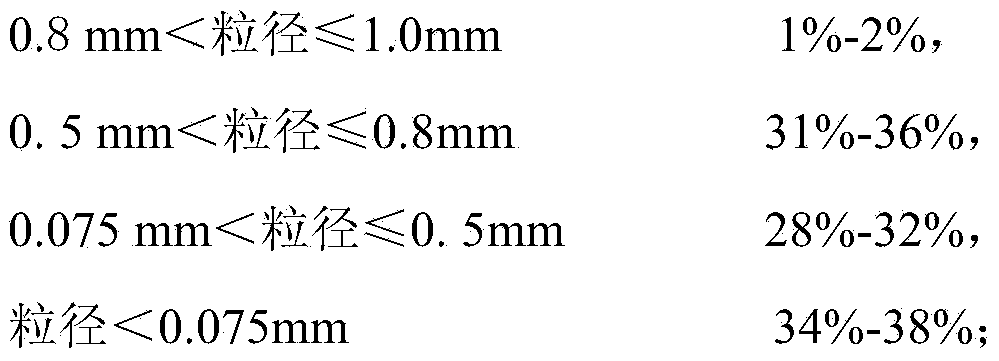

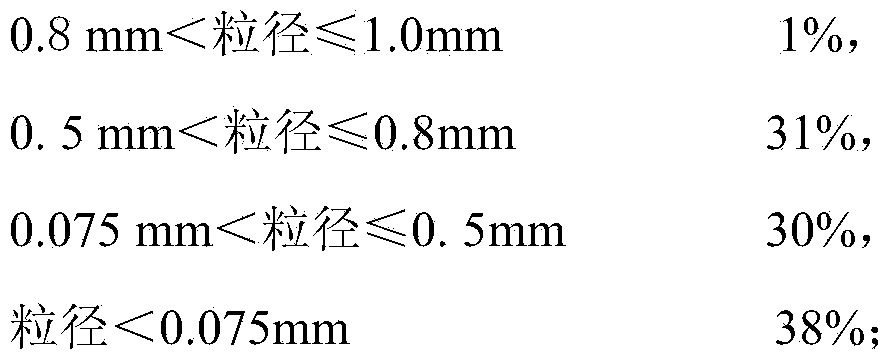

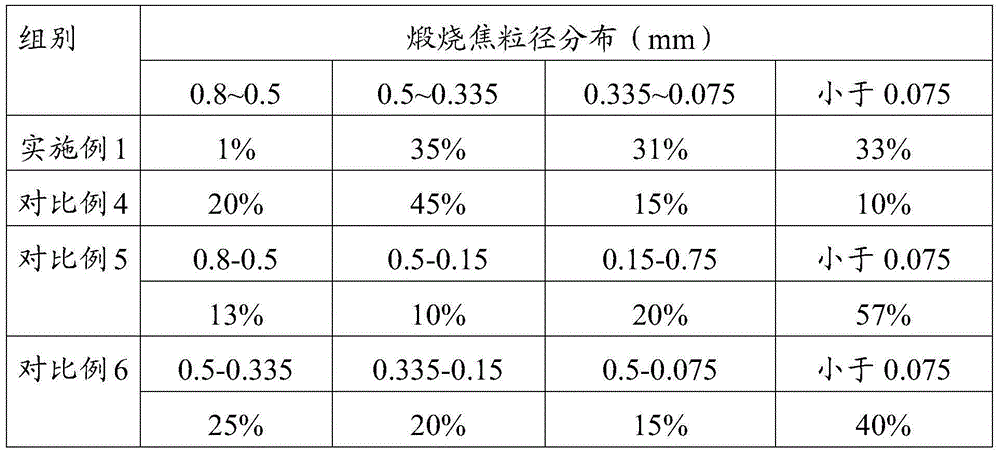

Graphite material for continuous casting mold and preparation method thereof

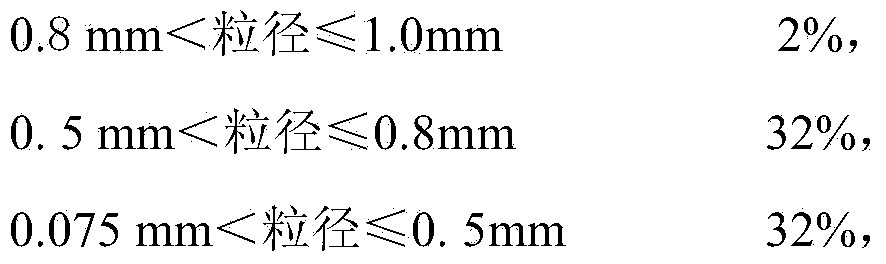

The invention relates to a preparation method of a graphite material for a continuous casting mold. The preparation method comprises the following steps: crushing, screening and burdening calcined coke, adding mid-temperature pitch, and carrying out mixing, molding, primary roasting, primary dipping, secondary roasting, secondary dipping, third roasting and graphitizing to obtain the product, wherein the particle size range and the content of the calcined coke are that the calcined coke with the particle size which is smaller than or equal to 1.0mm and greater than 0.8mm accounts for 1-2%; the calcined coke with the particle size which is smaller than or equal to 0.8mm and greater than 0.5mm accounts for 31-36%; the calcined coke with the particle size which is greater than 0.075mm and smaller than or equal to 0.5mm accounts for 28-32%; the calcined coke with the particle size which is smaller than 0.075mm accounts for 34-38%; the mixing is divided into dry blending and wet blending; the wet blending comprises the following processes: firstly heating the mid-temperature pitch to 180-230 DEG C, carrying out heat preservation and stirring for 30-60 minutes, and then adding the mid-temperature pitch to aggregate twice to knead, wherein the kneading temperature is 140-150 DEG C.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

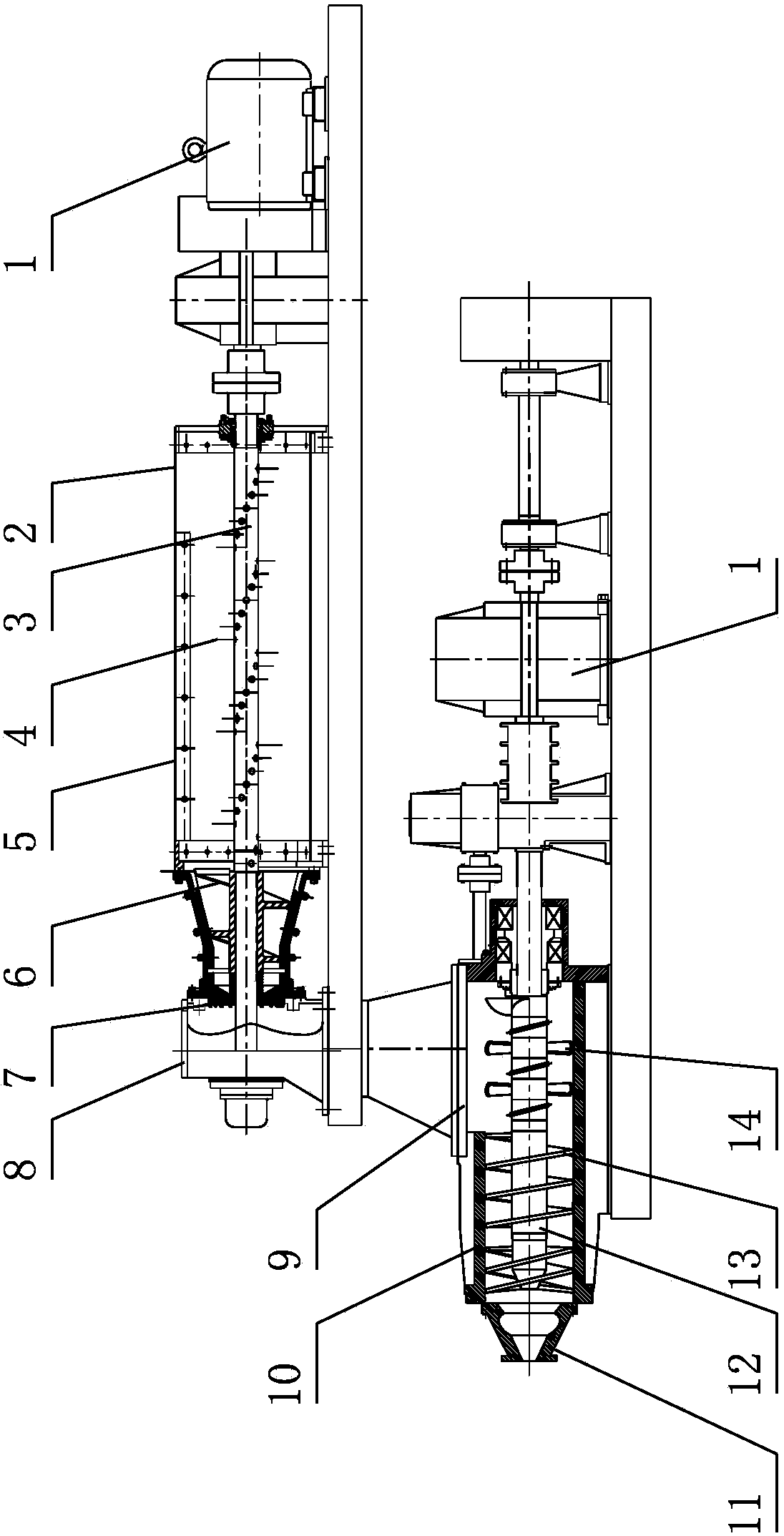

Honeycombed ceramic slurry water cooling vacuum refiner

The invention provides a honeycombed ceramic slurry water cooling vacuum refiner, comprising a slurry feed cylinder, slurry stirring shafts with helical blades, a vacuum chamber, a pumping hole, two kneading rollers, a photoelectric control device, a transmission mechanism, a hollow extruding shaft with helical blades, a slurry discharge cylinder, a fence which has section area close to and slightly smaller than the slurry feed cylinder, a cooling water device, a frame, a speed reducer and a variable-frequency motor, wherein the front end of the slurry stirring shafts with helical blades is provided with a slurry scraping knife. The slurry feed cylinder consists of two cylinders which are communicated, the section plane of the slurry feed cylinder is in a shape of a lying 8, and is communicated in the middle; the outlet end of the slurry feed cylinder is provided with the fence and the pumping port to form primary vacuum area; one slurry stirring shaft with the helical blade extends into each single cylinder, and is supported by a bearing with a seal ring; a bearing at the front end of the slurry stirring shaft is provided with a plurality of slurry scraping knives consisting of crossed blades; the fence is arranged at the outlet of the slurry feed cylinder; the upper end of the vacuum chamber is provided with the pumping port to ensure the vacuum chamber and the slurry discharge cylinder to form a secondary vacuum area; the lower part of the vacuum chamber is provided with two kneading rollers which are engaged with each other; the slurry outlet on the front part of the slurry discharge cylinder is a cone with narrowing opening.

Owner:NANJING KERUI SPECIAL CERAMICS +1

Preparation method of hydrodemetalization catalyst for heavy oil

ActiveCN103785396AHigh activityKnead evenlyMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsBoehmiteFuel oil

The invention discloses a preparation method of a hydrodemetalization catalyst for heavy oil. The method includes the following steps: weighing a certain amount of a pseudo-boehmite dry glue powder; evenly mixing the powder with a amount of a peptizator and an extrusion aid; then adding an appropriate amount of ammonium bicarbonate solution to the above materials; kneading the materials into a plastic body; extruding the plastic body into a strip shape; treating the molded material with hot water in a sealed container and roasting to obtain an alumina carrier; and loading active metal components Mo and Ni by using the alumina as a carrier through an impregnation method to prepare the hydrodemetalization catalyst for heavy oil. The hydrodemetalization catalyst for residuum prepared by the method has high activity and good stability, and is suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

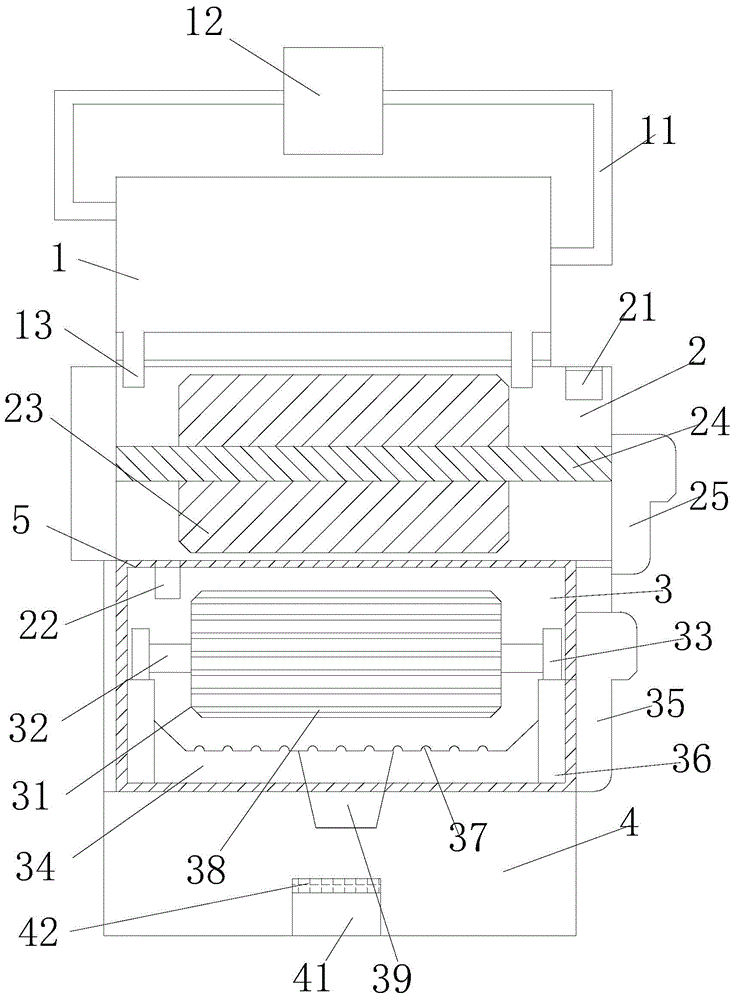

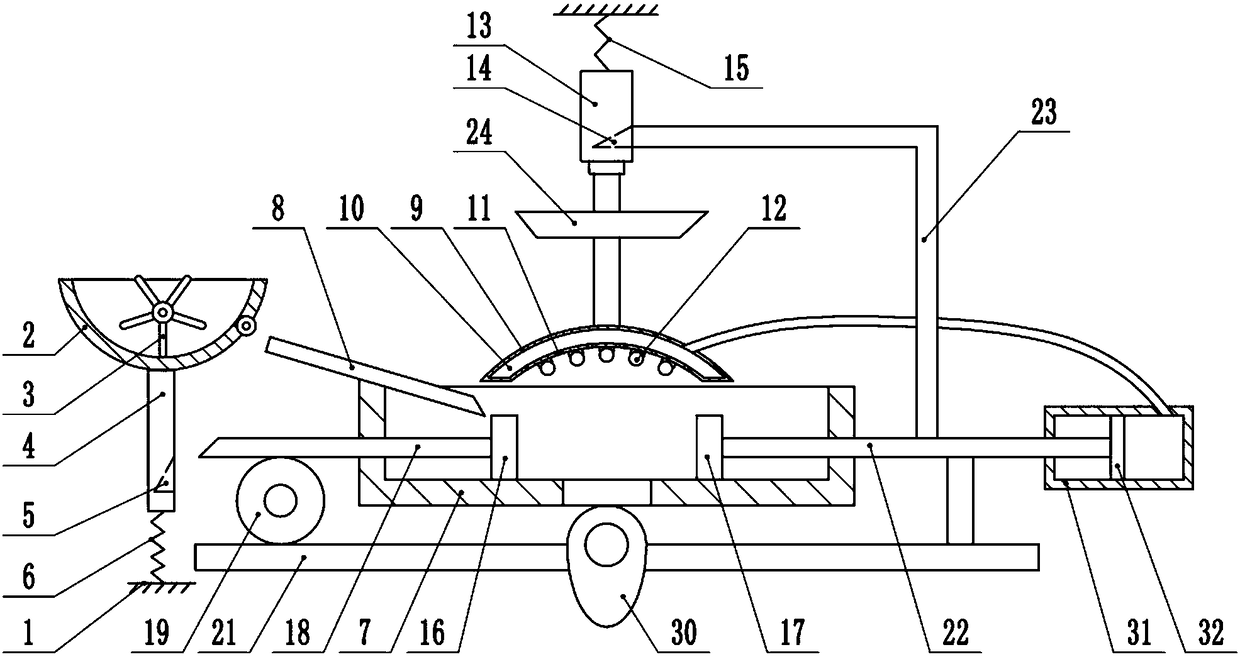

Tea leaf fixation and rolling integrated device

InactiveCN104543053AQuality assuranceImprove qualityPre-extraction tea treatmentCombustion chamberDrive shaft

The invention discloses a tea leaf fixation and rolling integrated device. The tea leaf fixation and rolling integrated device comprises a hot-blast furnace, a fixation device, a rolling device and a combustion chamber, wherein the hot-blast furnace is arranged at the upper end of the fixation device, air outlet pipes are arranged at two sides of the hot-blast furnace and are connected with an air blower, an air inlet pipe is arranged at the lower end of the hot-blast furnace, a rotating shaft is arranged inside the fixation device, a leaf guide plate is arranged on the rotating shaft, the rotating shaft is connected with a No. 1 motor, a feed opening is formed in the upper end of the fixation device, a discharge opening is formed in the bottom of the fixation device, the rolling device comprises a roller, a connecting bracket, a No. 2 motor, a rolling groove and a driving shaft, the roller is fixedly connected with the driving shaft, the driving shaft is hinged to a telescopic screw rod, the telescopic screw rod is arranged on the connecting bracket, the rolling groove is formed right below the roller, a layer of heat conduction plate is arranged on the periphery of the rolling device, and the combustion chamber is arranged at the lower end of the heat conduction plate. According to the tea leaf fixation and rolling integrated device disclosed by the invention, the hot-blast furnace, the fixation device, the rolling device and the combustion chamber are arranged to form an integrated structure, so that the processing efficiency can be greatly improved, and the processing cycle of tea leaves can be shortened.

Owner:新昌县小将镇乌牛岗家庭农场

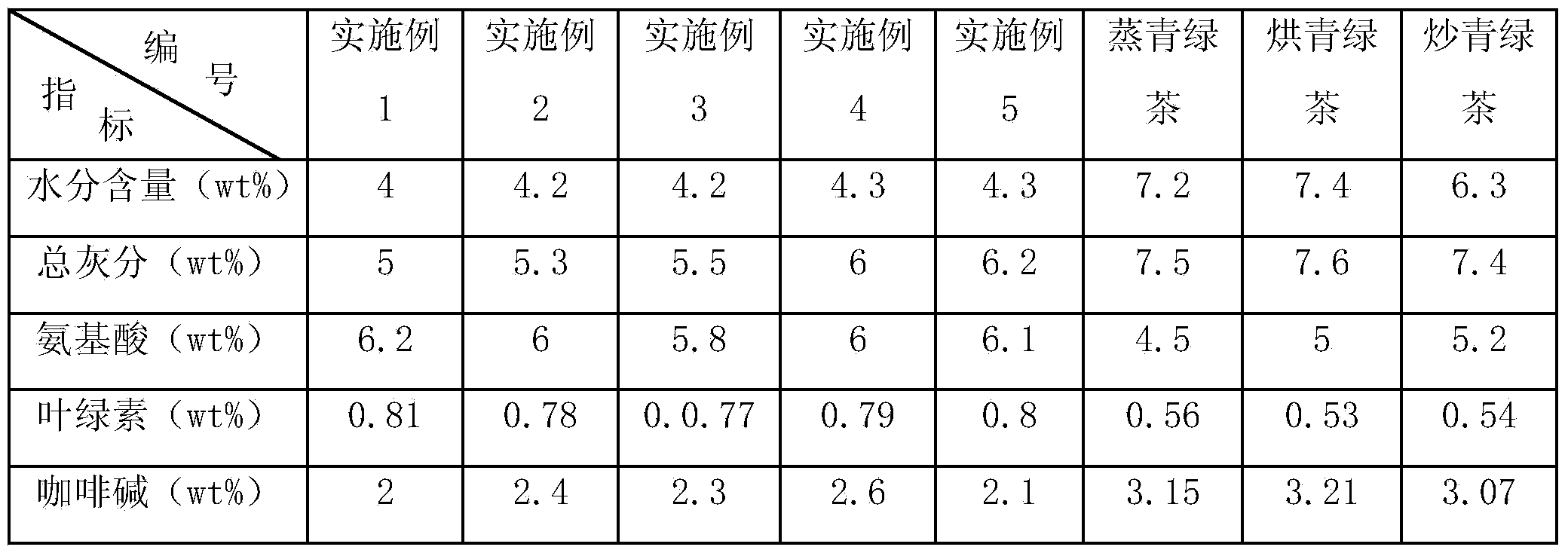

Green tea and preparation process thereof

The invention relates to green tea and a preparation process thereof, and belongs to the field of green tea processing. The preparation process of green tea comprises the following steps: picking fresh tea leaves; steaming; air-cooling; threshing; twisting roughly; kneading; twisting intermediately; frying by means of roller; and then drying. According to the preparation process, the steaming mode is performed to give the green tea with the quality characteristics of special three greens of steamed tea, namely, dark-green dry tea, light-green tea water, and blue-green tea bottom; the process of frying by means of roller is performed at low temperature, thereby greatly preventing chlorophyll from being damaged, enabling a tea bar to be compact, and improving the thickness of flavor; the traditional drying process overcomes the problems that steamed tea has a strong smell and also has the smell of green grass and strong acrid odor, and the flavor of castanea mollissima and mellow and fresh taste are generated.

Owner:四川嘉竹茶业有限公司

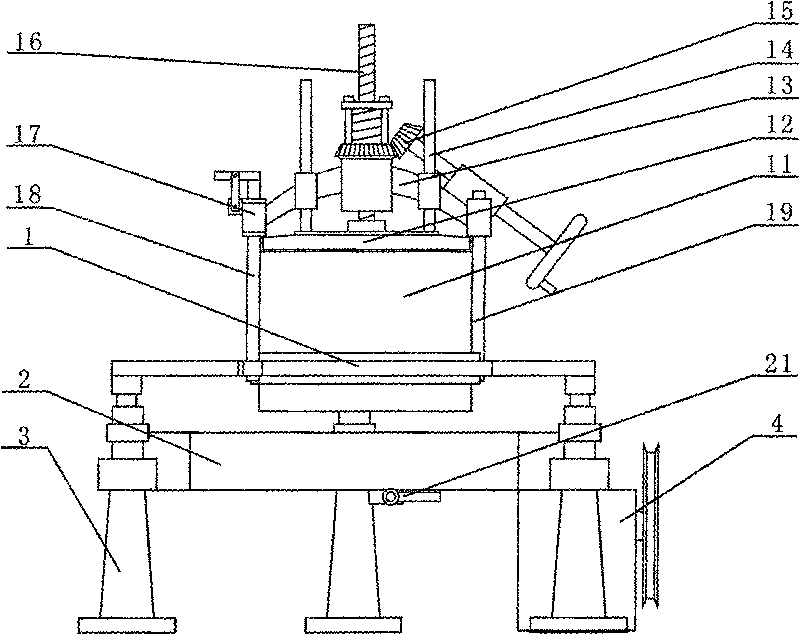

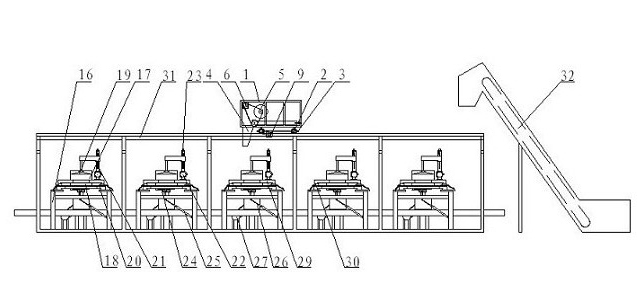

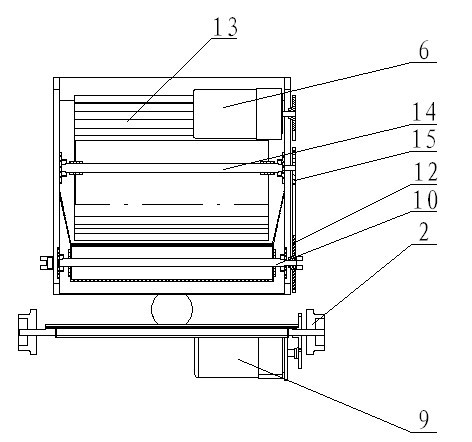

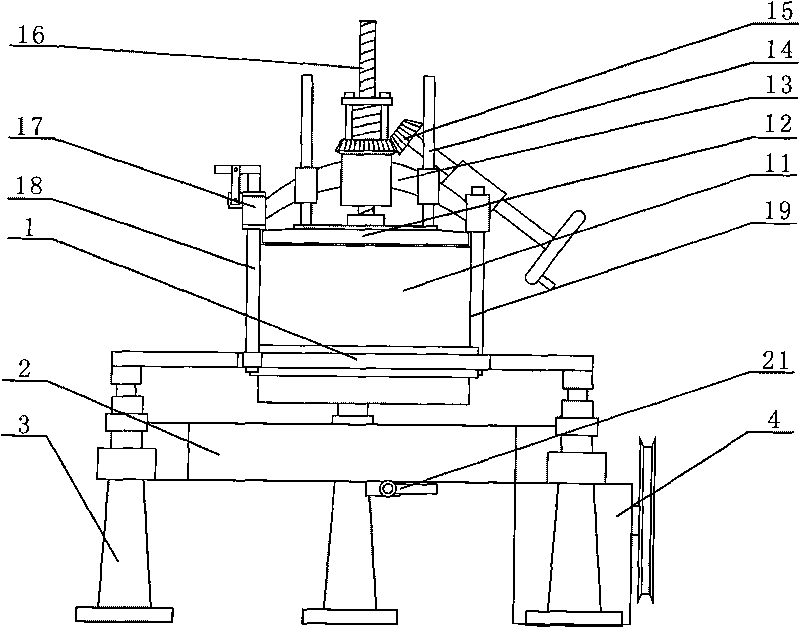

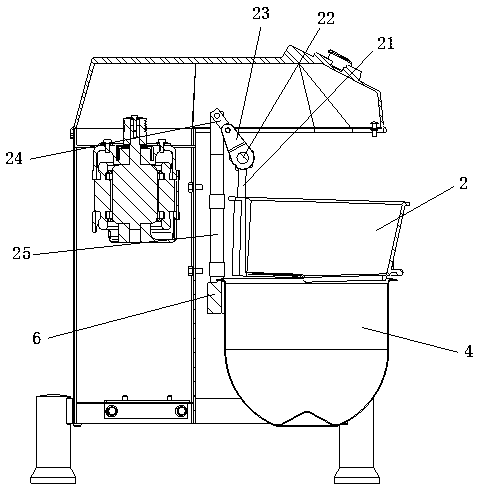

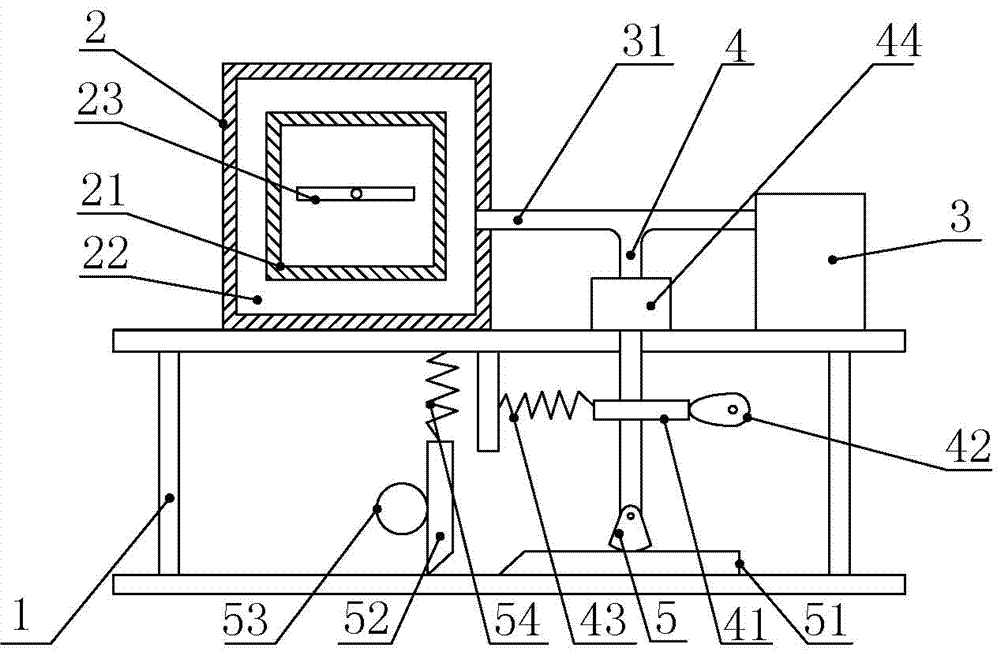

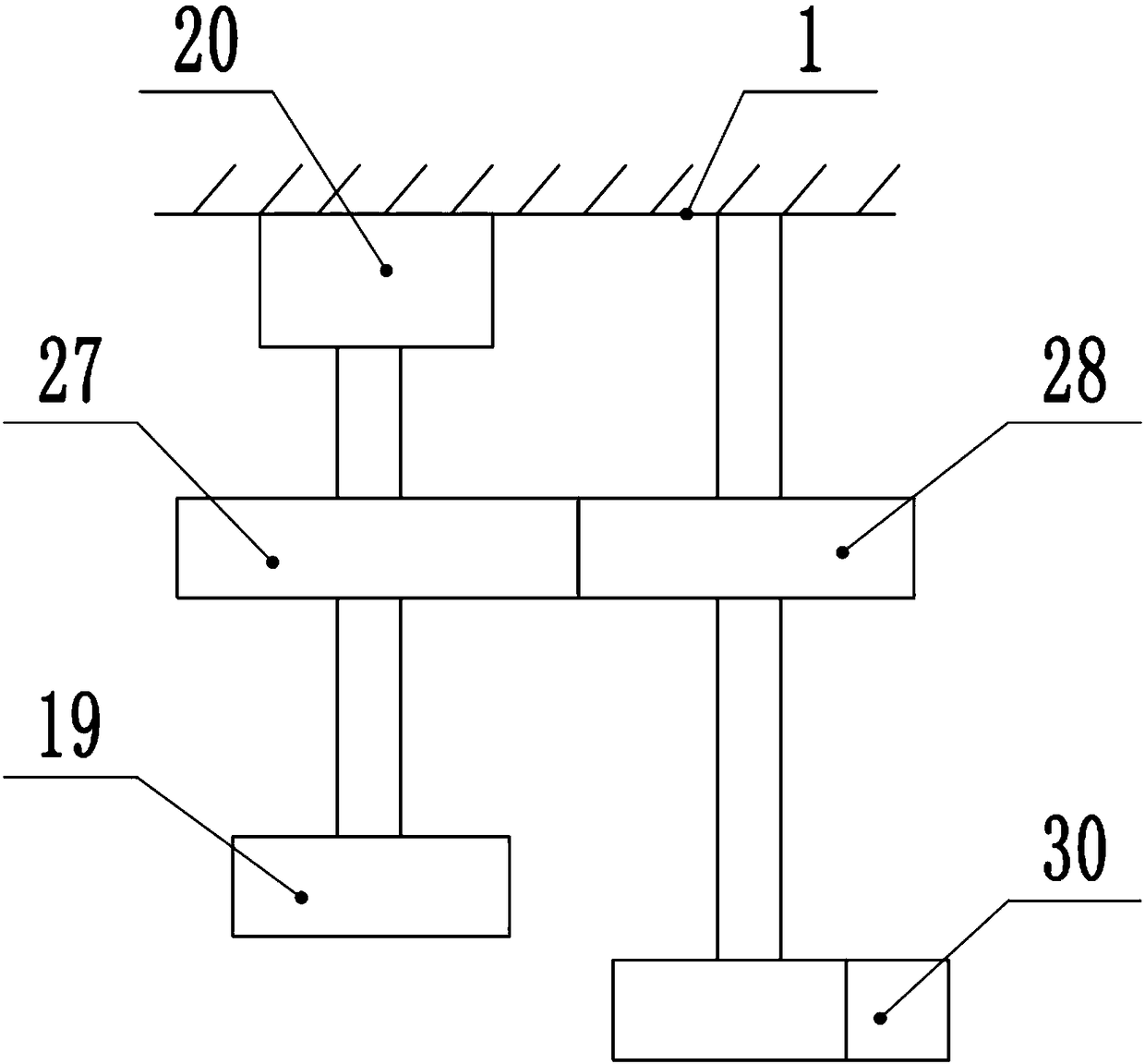

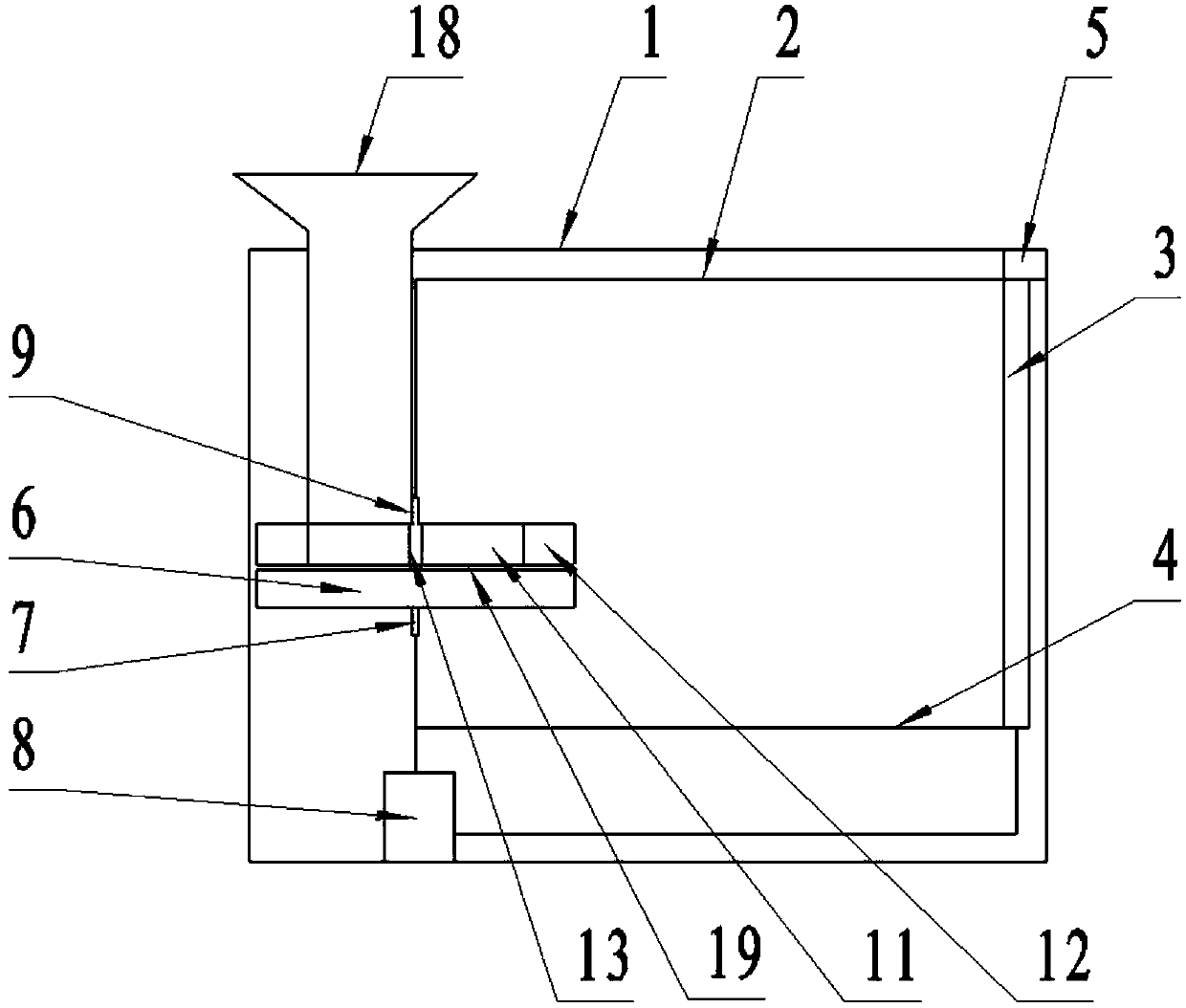

Automatic feeding device and kneading device for tea leaves

InactiveCN101884355ASave operating procedures and timeExact pressurePre-extraction tea treatmentTurning framesElectric machinery

The invention discloses an automatic feeding device and a kneading device for tea leaves, wherein the automatic feeding device for the tea leaves comprises a charging box for accommodating the tea leaves; a lower end face of the charging box is provided with a frame with a wheel for walking on a rail and a discharge outlet for discharging; the discharge outlet is provided with a discharge hopper;a tea leaf transportation mechanism is arranged at the bottom of the charging box, and a leaf distributing machine is arranged above the tea leaf transportation mechanism; and both the tea leaf transportation mechanism and the leaf distributing machine are connected with a motor, which is arranged on the charging box, through a chain. The kneading device for the tea leaves comprises a stander, a power transmission mechanism for controlling the rotation of a kneading barrel, a kneading disc which is arranged below the kneading barrel, a pressure mechanism for controlling the pressure of a gland, and a material unloading device; and an edge of the kneading disc is provided with a blowing device for cleaning remainders in the kneading disc. The automatic feeding device and the kneading device for the tea leaves have the advantages of ingenious conception, simple structure and high degree of automation; and by using the two devices, the tea leaves can be weighed, fed, discharged automatically, unloaded and kneaded uniformly, so that the work efficiency is improved greatly.

Owner:CHONGQING ACAD OF AGRI SCI

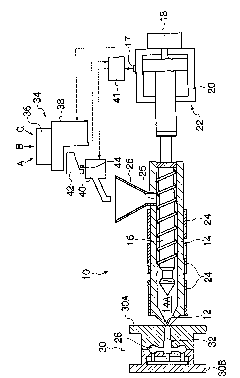

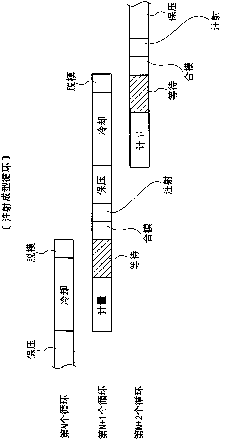

Injection molding method

An injection molding method including a measuring step for measuring an amount of the molding material by storing a molding material fed into a cylinder of an injection molding apparatus in a tip of the cylinder by rotation of a screw and stopping a rotation of the screw after the screw is retracted to a measurement set position by a pressure from the stored molding material itself. The measuring step comprises: setting a back pressure to be applied on the screw, to a predetermined value; setting a rotation speed of the screw to a constant rotation speed within a predetermined range; and adjusting a feeding speed of the molding material to a predetermined time so that the measuring time is controlled irrespective of the rotation speed of the screw and the back pressure set value.

Owner:FUJIFILM CORP

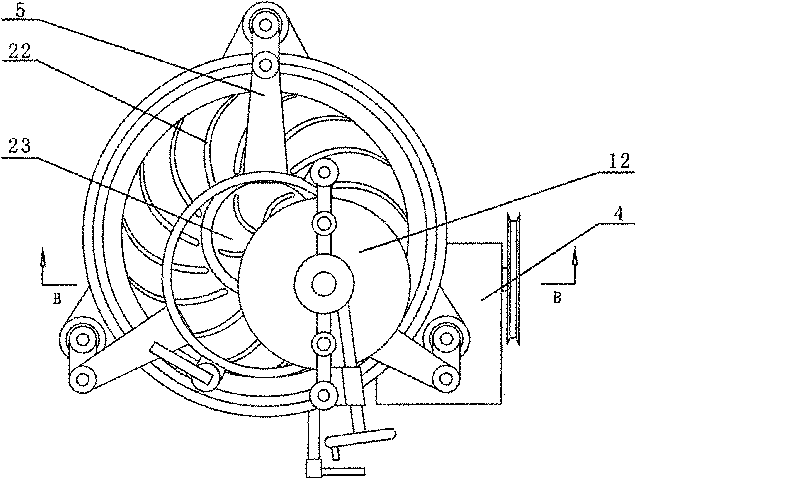

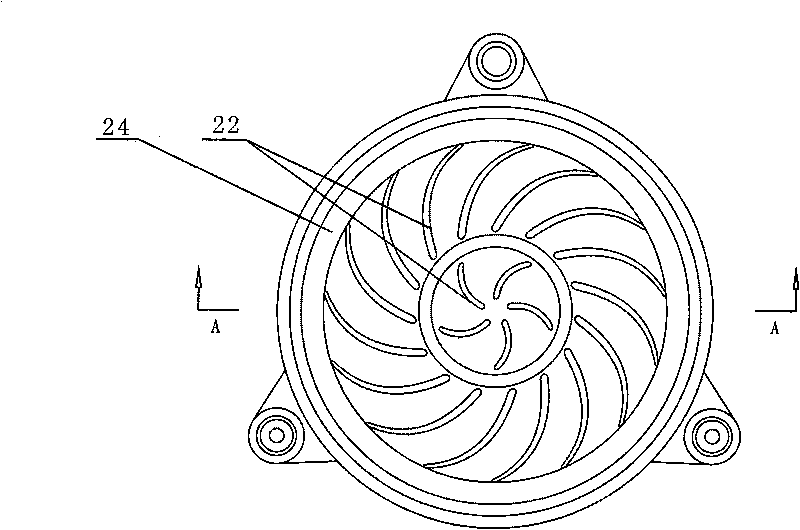

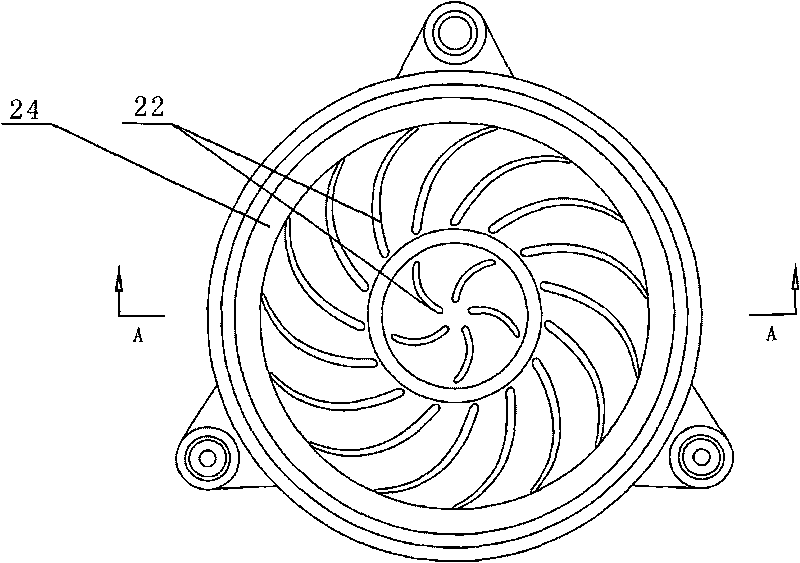

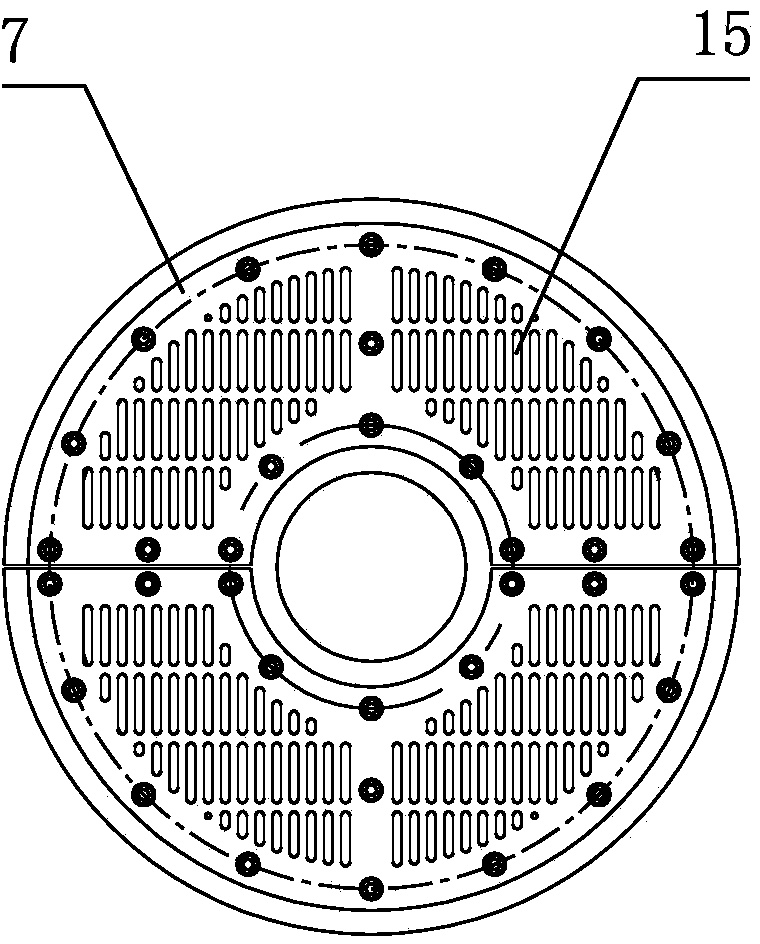

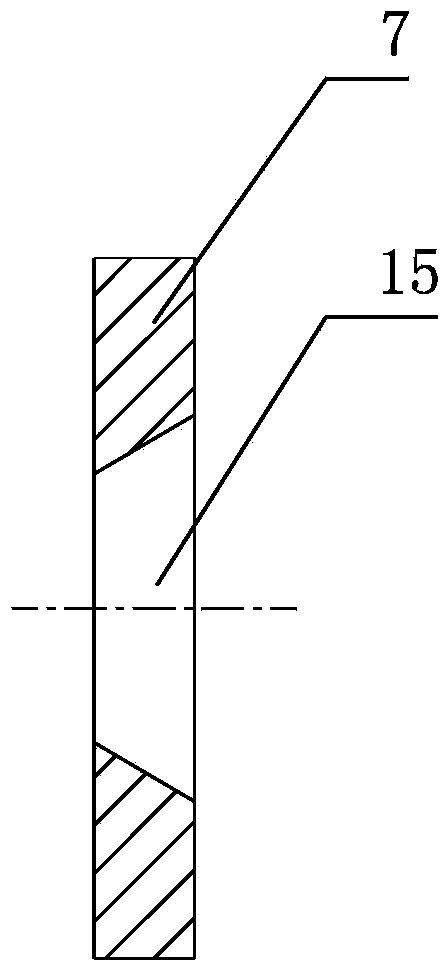

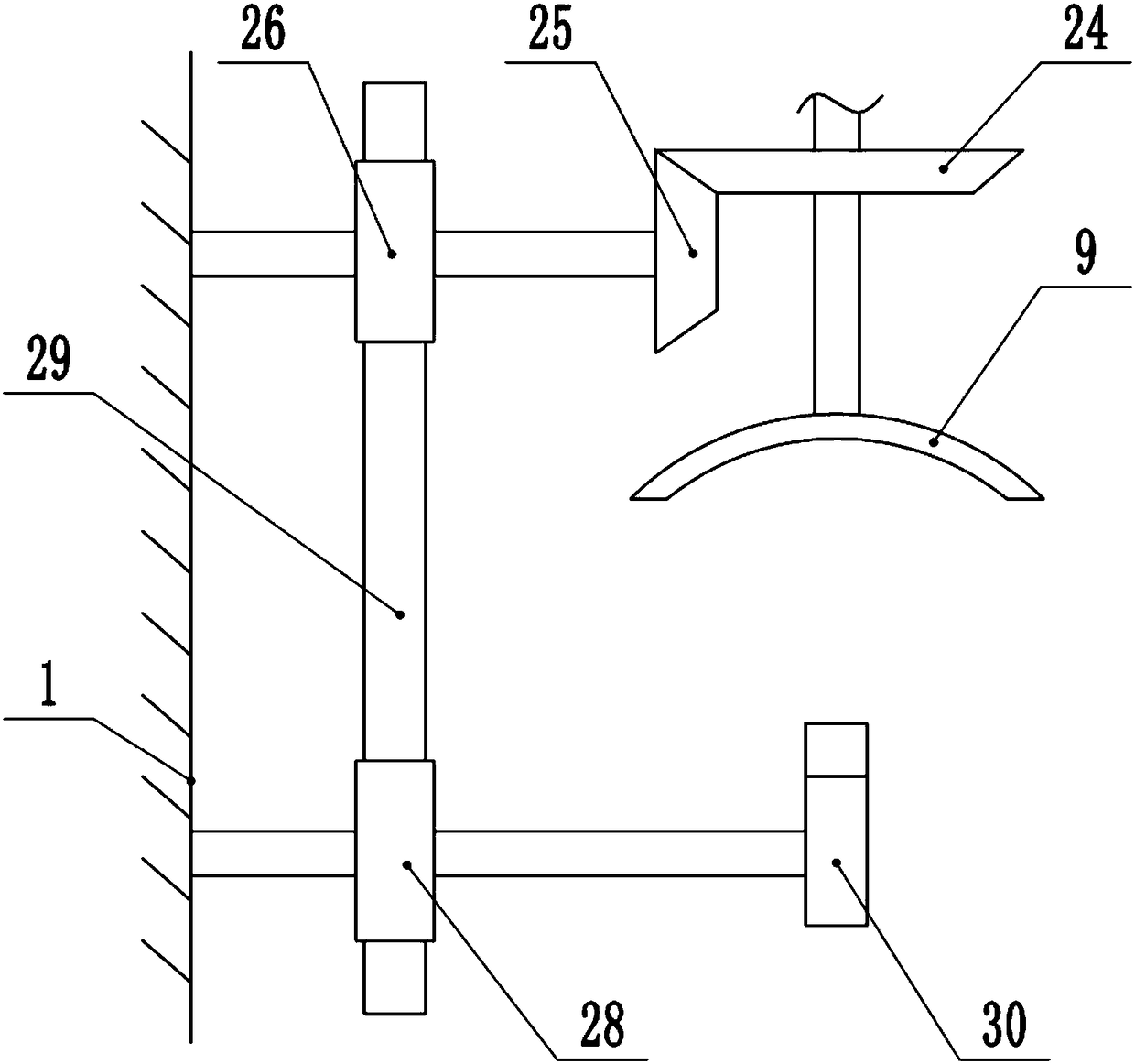

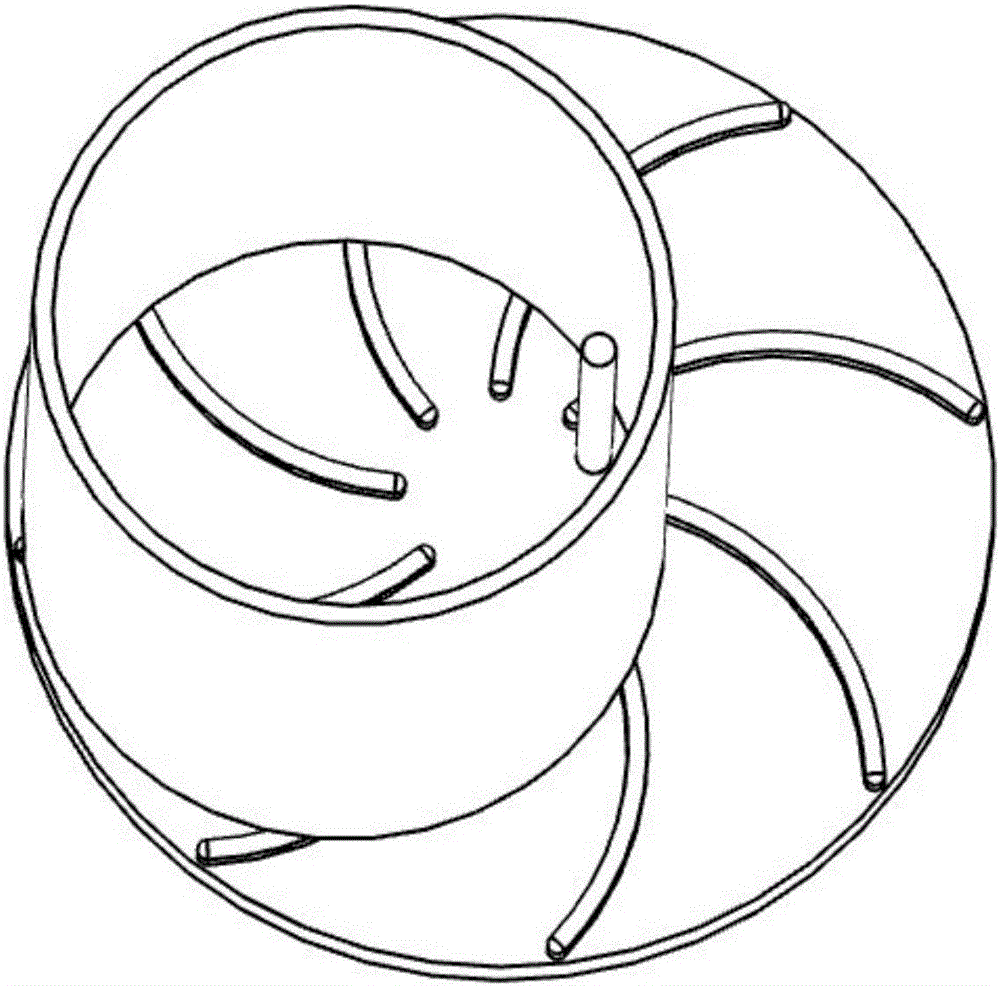

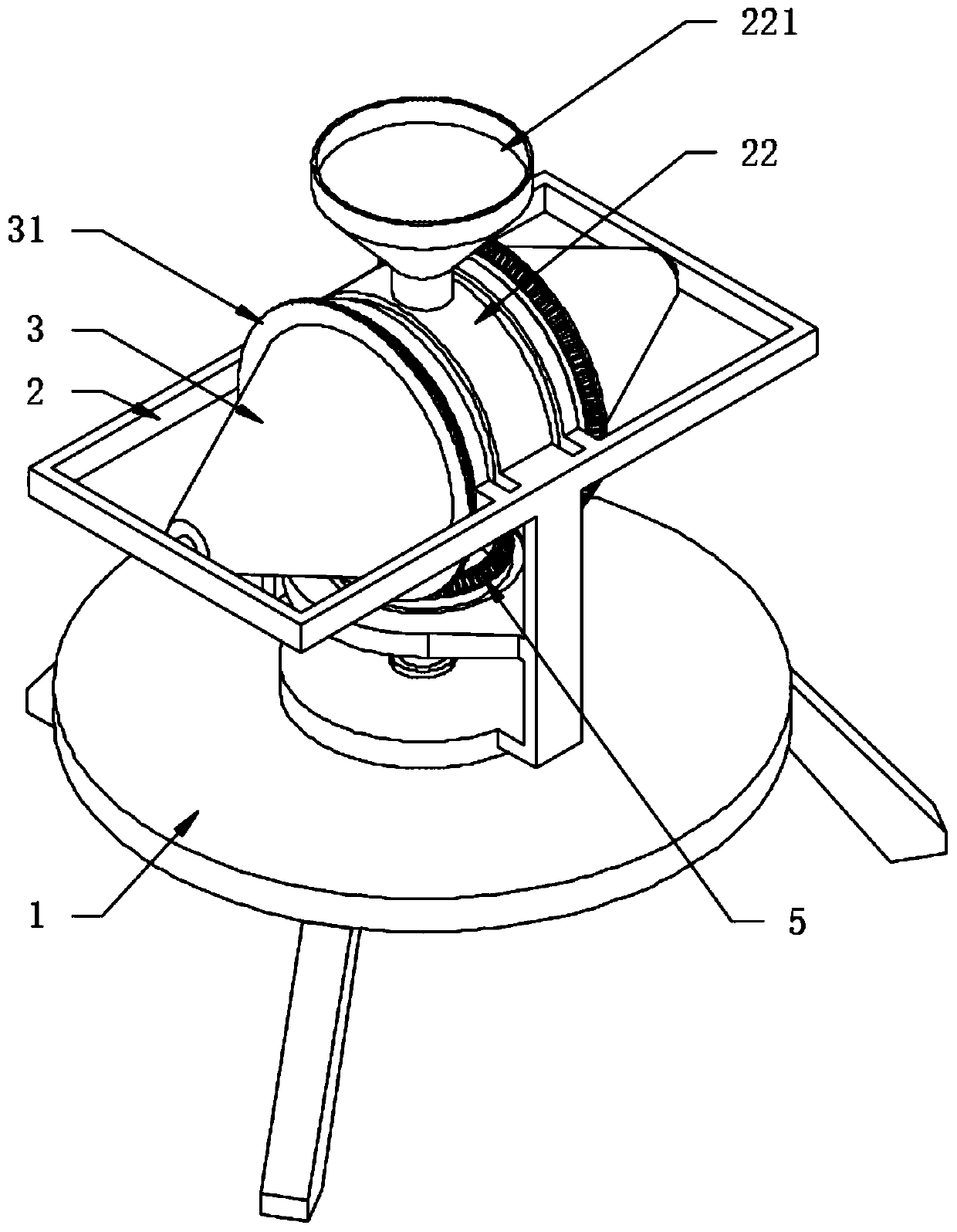

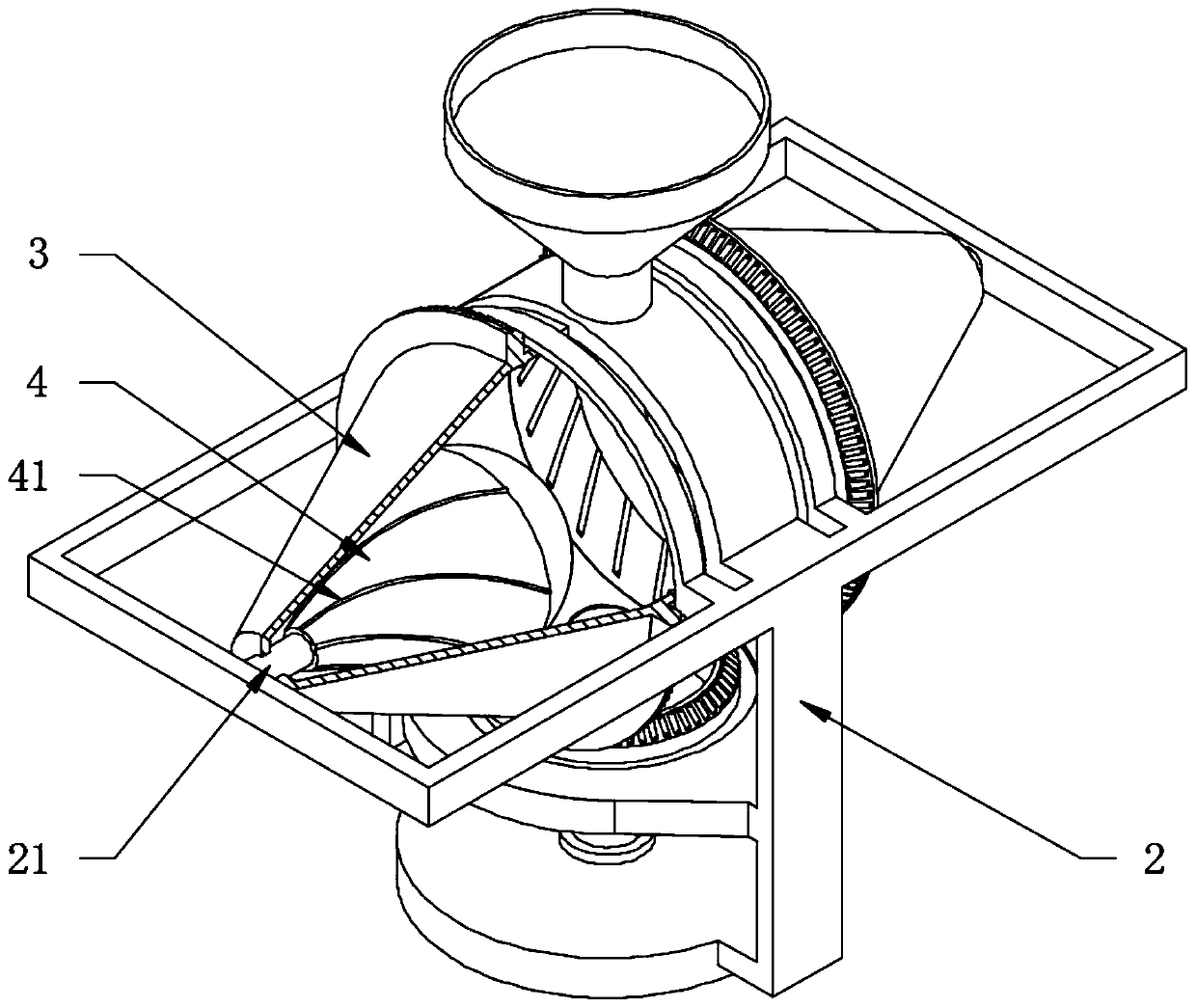

Novel tea knead entwist plate

InactiveCN101700085AReduce generationPrevent getting involvedPre-extraction tea treatmentSEMI-CIRCLESurface roughness

The invention discloses a novel tea knead entwist plate and relates to tea processing machinery parts. The knead entwist plate, an unloading plate and an edge bone are manufactured by adopting a casting method with the purposes of not only lowering the complexity of the technology, but also being convenient for molding, in particular to the molding of the broken tea terrace and the knead entwist area with an inclined angle. The knead entwist area with an inclined angle is in match with the edge bones which are arranged in a radiation shape, and the shape that the end of the edge bone close to the knead entwist plate is higher and the end close to the edge thereof is lower is beneficial for the separation of broken tea and mature tea, can improve stripping tea rate and can also reduce the generation of broken tea; the casting pieces have higher surface roughness and greater friction force, thus being beneficial for the improvement of knead entwist stripping tea rate. The section of the edge bone is approximately a semi circle, then in the processing of kneading and entwisting tea, the force transits smoothly, the kneading and entwisting and rolling speed of tea is even, and broken tea is not easy to generate, and the effect is particularly obvious in the central area in which the edge bone is higher and the tea rolls more frequently.

Owner:WUFENG TIANCHI TEA MACHINERY

Plateau brick machine

ActiveCN103707394APromote fragmentationQuality improvementCeramic extrusion diesFeeding arrangmentsBrickPulp and paper industry

The invention relates to a brick machine, in particular to a plateau brick machine applied to plateau sections. The plateau brick machine comprises an upper-level unit and a lower-level unit, wherein the upper-level unit comprises a stirring box, the front portion of the stirring box is connected with a feeding box, the feeding box is connected with a material collecting box in the lower-level unit, the front end of the material collecting box is connected with an extruder opening, a stirring thrust assembly is disposed in the stirring box, a discharging opening of the stirring box is provided with a sieve plate, a plurality of sieve holes are formed in the sieve plate, an extrusion shaft is arranged in the material collecting box, a paddle is arranged on the front portion of the extrusion shaft, and a spiral vane is disposed on the rear portion of the extrusion shaft. By means of the arrangement of the sieve plate and the paddle, pug is high in fragmentation degree in the upper-level stirring and crushing stage, is high in vacuum degree after being vacuumized and is stirred and crushed again in the lower-level extrusion process, so that gas in the pug overflows and is exhausted completely, the vacuum degree of the pug can meet production requirements of products in the plateau sections, and product quality and the yield are improved.

Owner:GONGLI MACHINE CO LTD

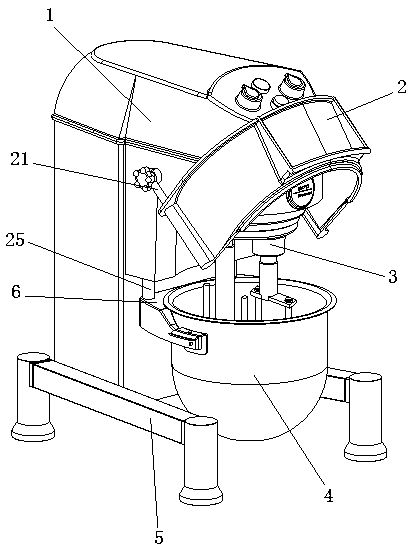

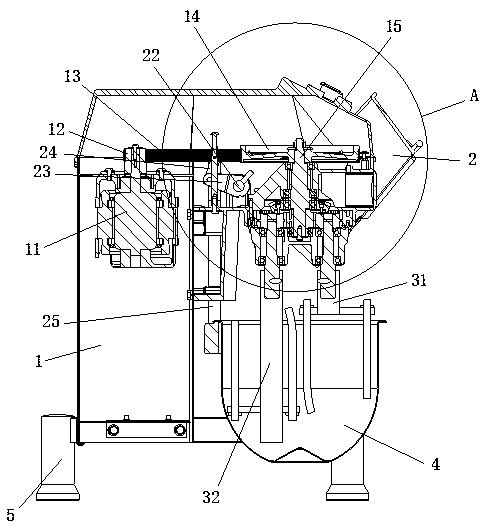

Bread dough mixer

ActiveCN110012916AKnead evenlyImprove uniformityMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsEngineering

Owner:豪士(福建)食品有限公司

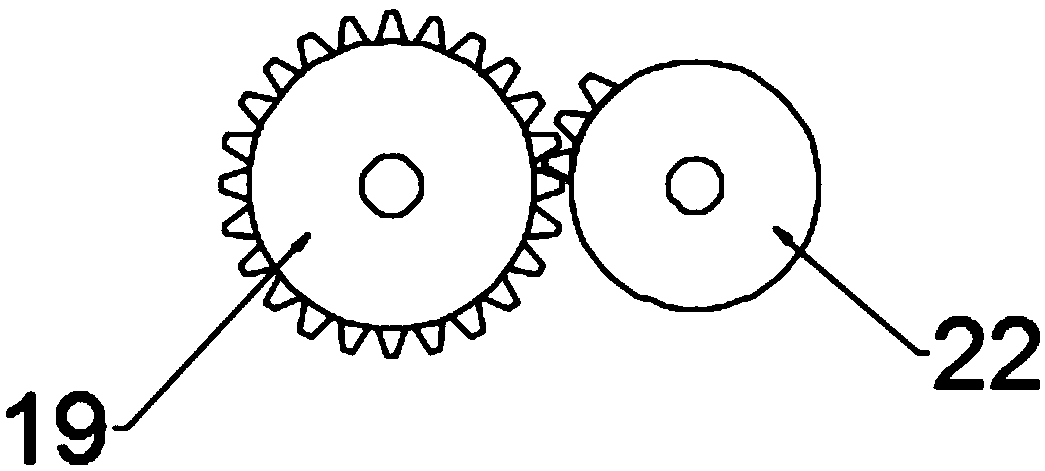

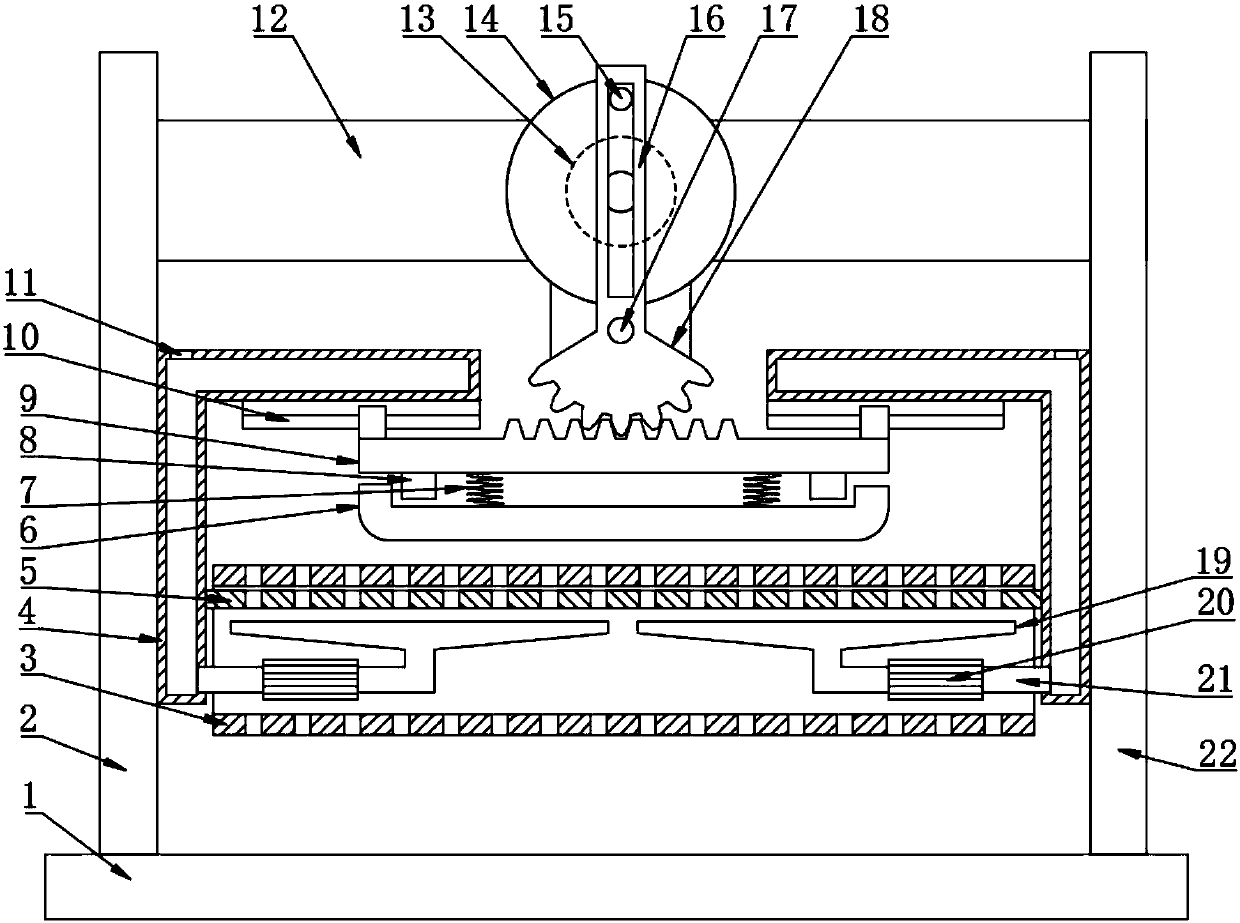

Crank type continuous dough kneading device for flour processing

InactiveCN108967459AImprove kneading efficiencyGood kneadingMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsGear wheelEngineering

The invention discloses a crank type continuous dough kneading device for flour processing. The crank type continuous dough kneading device comprises a bottom plate, a dough kneading frame, an installation frame, a rotary shaft, a gear, an incomplete gear, a first motor, an installation rod, fan-shaped collecting plates, springs, a second motor, a crank, a rod journal, a sleeve, a connection rod,a movable rod and two dough kneading balls. The crank type continuous dough kneading device is provided with the second motor, the crank, the rod journal, the sleeve, the movable rod, the dough kneading balls and the fan-shaped collecting plate, the two dough kneading balls knead dough continuously, the dough kneading efficiency is high, when the dough kneading balls move upwards, the corresponding fan-shaped collecting plates rotate upwards under the effects of springs, the dough is collected, so that dough kneading for the next time is facilitated, the dough can be further kneaded more sufficiently and uniformly, the dough kneading efficiency is improved, the first motor, the incomplete gear and the gear are arranged to intermittently drive the dough kneading frame to rotate a certain angle, so that the dough kneading balls can knead and press the different parts of the dough, thus dough kneading is more sufficient, and the dough kneading speed is increased.

Owner:CHANGSHA FENGYING MACHINERY TECH CO LTD

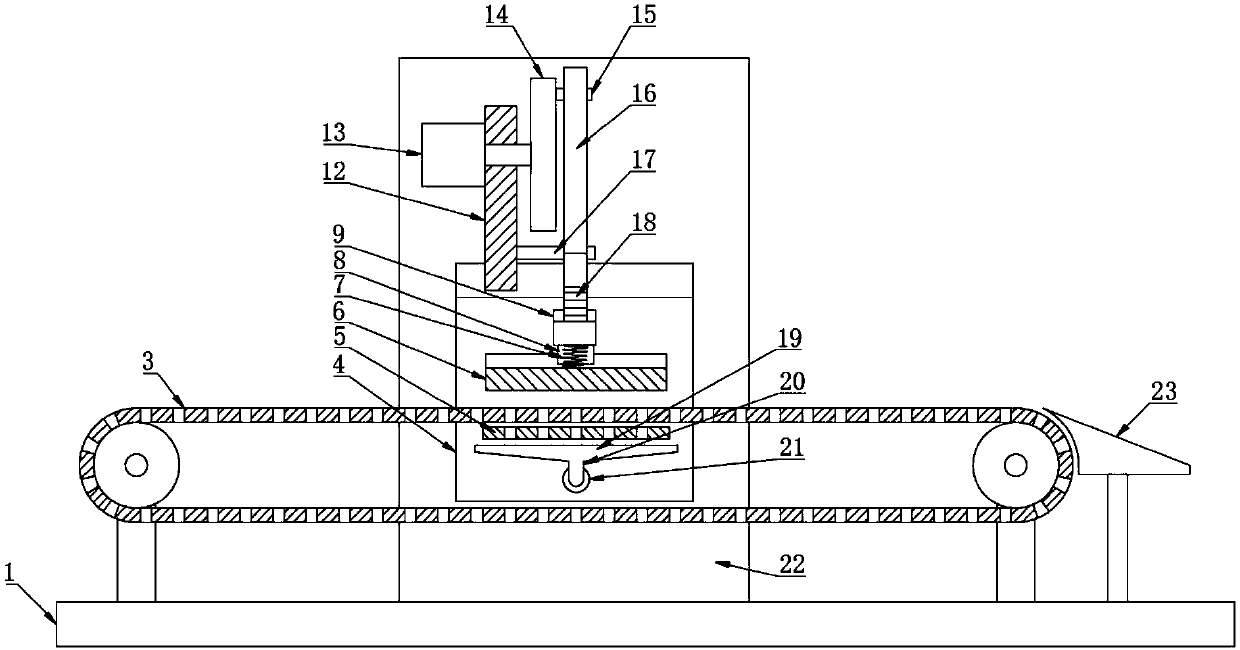

Rubbing and drying device for radix codonopsis

InactiveCN107669729AImprove processing efficiencyIncrease profitDrying gas arrangementsDrying chambers/containersCodonopsisEngineering

The invention discloses a rubbing and drying device for radix codonopsis. The rubbing and drying device comprises a base, wherein a left supporting plate and a right supporting plate are separately arranged on the left side and the right side of the top of the base; heat collecting plates are fixedly connected to the left supporting plate and the right heat collecting plate; sliding rails are respectively arranged on the bottom walls of the tops of the left and right heat collecting plates; a rack is in sliding connection with the lower parts of the sliding rails; a rubbing plate is connectedto the bottom of the rack through springs; a fixed plate is fixedly connected between the left supporting plate and the right supporting plate; a speed reducer is arranged on the fixed plate; a rotarytable is connected with a motor shaft of the speed reducer; a first pin shaft is arranged on the front end face of the rotary table; a sector gear meshed with the rack is rotationally connected to the bottom of the front end face of the fixed plate by a second pin shaft; a swing rod is fixedly connected to the top of the sector gear; a first pin shaft is positioned in a rectangular opening of theswing rod. According to the rubbing and drying device disclosed by the invention, the radix codonopsis is rubbed by left-right movement of the rubbing plate and is repeatedly performed, and the rubbing effect is good; by arranging compression springs, the rubbing plate can adapt to the radix codonopsis with different thicknesses, and the rubbing strength is more uniform.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

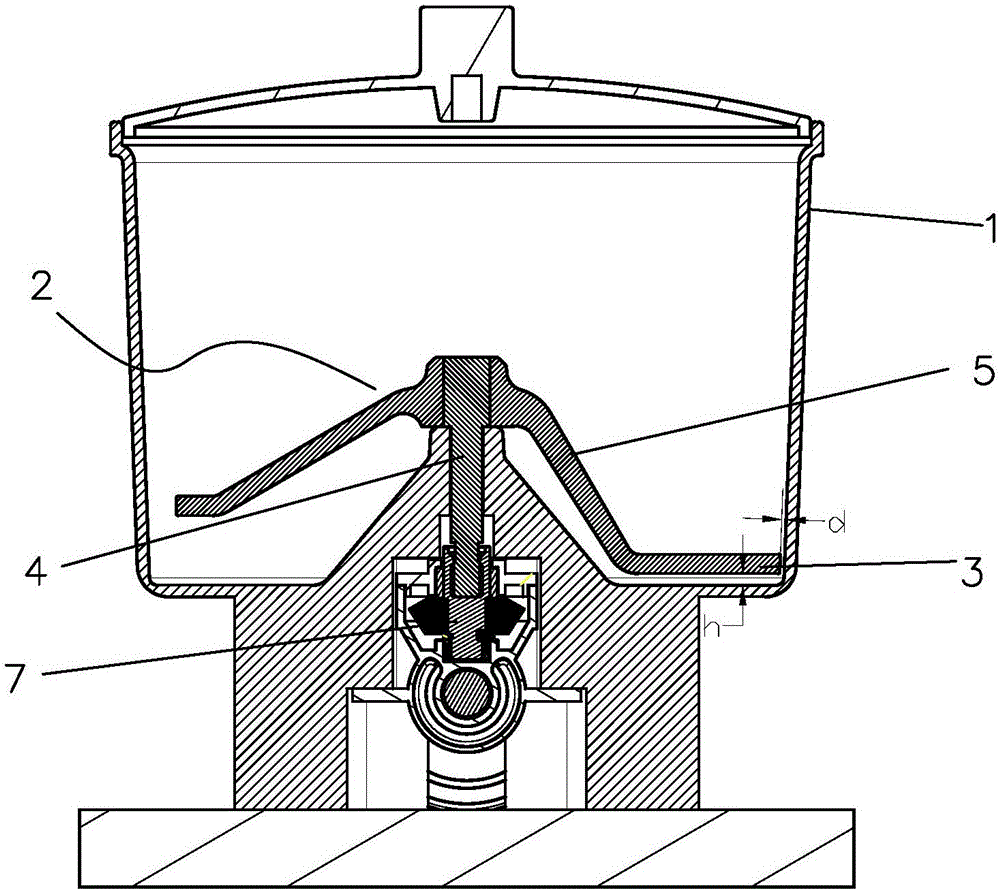

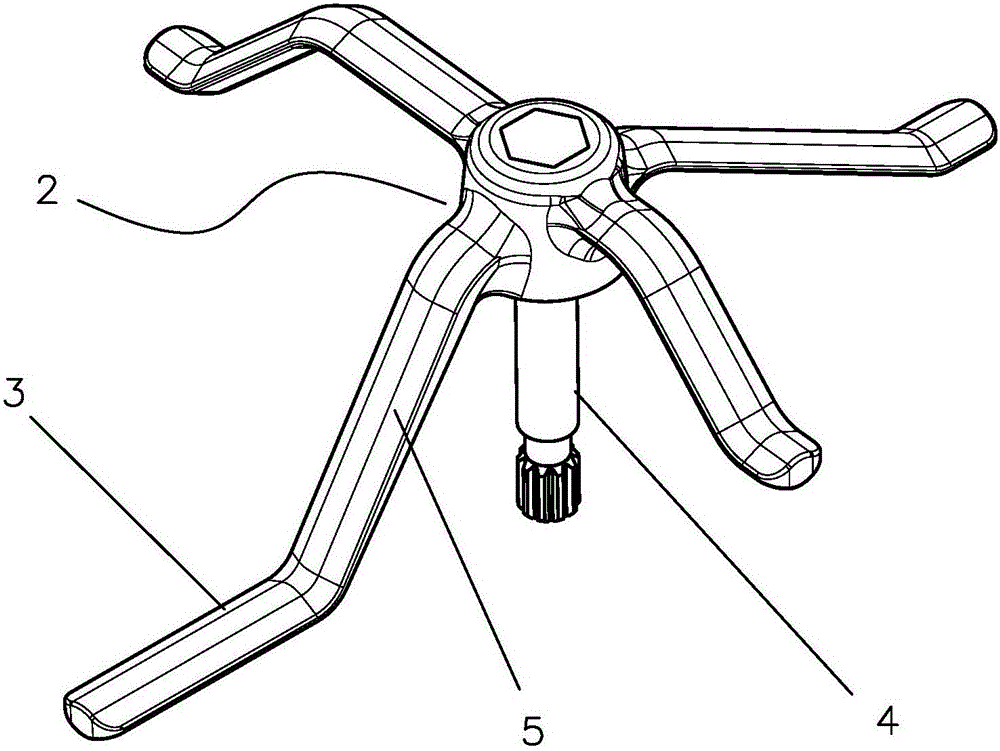

Noodle maker with good dough kneading effect

InactiveCN106665725AImprove kneading effectUniform sizeMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsEngineering

The invention discloses a noodle maker with a good dough kneading effect. The noodle marker comprises a dough kneading barrel, wherein a stirring device which can rotate in the dough kneading barrel to knead dough is arranged in the dough kneading barrel; the stirring device comprises a cutter bar which is connected with a driving device of the noodle marker; the cutter bar is connected with a plurality of cutter teeth; at least one of the cutter teeth comprises an extension segment extending towards the bottom of the dough kneading barrel and a dough pushing part which is connected with and is bent together with the extension segment; the lower end face of the dough pushing part is parallel with the bottom surface of the dough kneading barrel; the distance h between the lower end face of the dough pushing part and the bottom surface of the dough kneading part is larger than 0.1mm and less than 50mm. By adopting the noodle marker, the distance h between the lower end face of the dough pushing part and the bottom surface of the dough kneading part is larger than 0.1mm and less than 50mm, so that dough is kneaded uniformly, flour and water can be blended fully and uniformly, the dough is uniform in size, the dough inlet is not blocked, the flour is scraped completely, and the dough making efficiency is increased.

Owner:中山市小榄镇威的电器有限公司

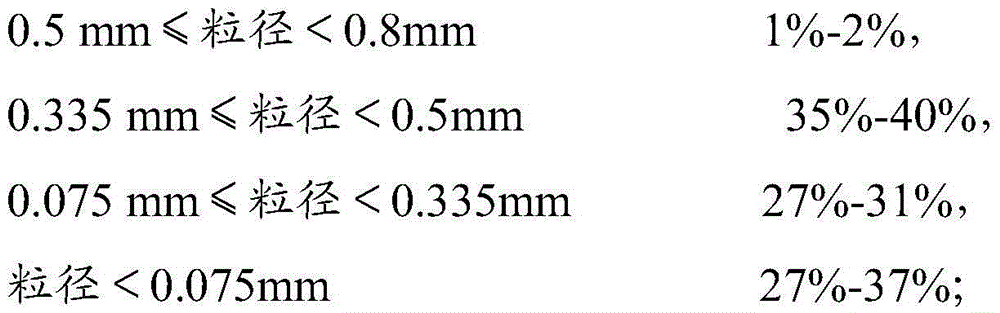

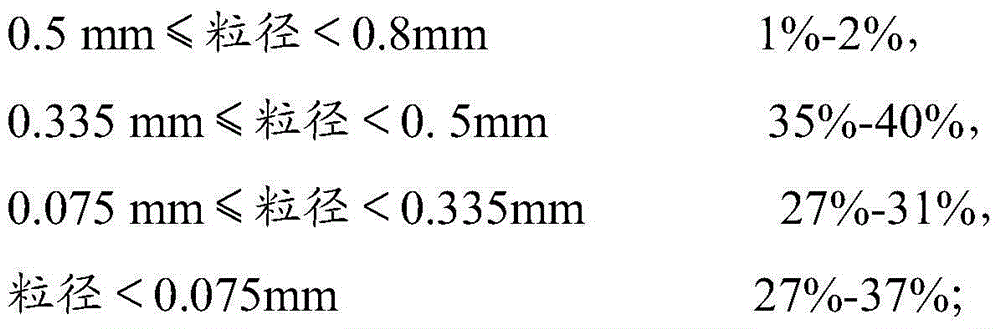

Graphite furnace lining used for high purity graphitization furnaces, and preparation method thereof

The invention discloses a graphite furnace lining used for high purity graphitization furnaces, and a preparation method thereof, and belongs to the technical field of graphite processing. The preparation method comprises steps of crushing, sieving, material preparing, dry blending, wet blending, moulding, primary roasting, primary dipping, secondary roasting, secondary dipping, tertiary roasting, and graphitization. In the raw materials of the graphite furnace lining, an aggregate is composed of calcined coke, pitch coke, and needle coke at a mass ratio of 80-82:10-15:5-8; wherein calcined coke is composed of particles with four following different particle size ranges: 0.5mm<=particle size<0.8mm, 0.335mm<=particle size <0.5mm, 0.075mm<=particle size<0.335mm, and particle size<0.075mm, and the weight amounts of the four particles account for 1 to 2%, 35 to 40%, 27 to 31%, and 27 to 37% respectively. Purity of the graphite furnace lining prepared via the preparation method is high; bulk density is large; porosity is low; ash content is low; oxidation resistance, compressive strength, and rupture strength are extremely excellent; and application requirements on high purity graphitization furnace linings are satisfied.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Tea leaf processing technology

InactiveCN107258956AIncrease contact areaUniform adhesionPre-extraction tea treatmentEngineeringRosin

The invention belongs to the field of tea leaf processing, and particularly relates to a tea leaf processing technology. The tea leaf processing technology comprises the following steps of fixation, twisting, fermentation and drying, a fermentation device is used for fermenting tea leaves, and the fermentation device is characterized in that rosin strips are used for splicing a charging box, and the charging device is heated by steam, so that the contact area of the tea leaves and spice is enlarged; and besides, the steam is used for driving a sector gear to rotate, a first gear rack, a second gear rack and a gear move to drive a rotating plate to rotate, and the rotating plate is used for turning over the tea leaves, so that the fragrance is uniformly adhered to the tea leaves, and the tea leaves are good in quality.

Owner:湄潭县一品缘茶业有限公司

Tea leaf fixation equipment

Owner:贵州省凤冈县翠巅香生态茶业有限公司

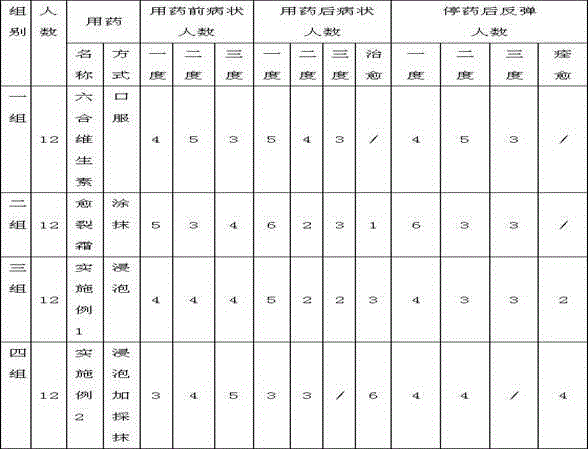

Traditional Chinese medicine for treating rhagadia

InactiveCN102940678AIncreased secretion of hormonesGood solvent propertiesDermatological disorderPlant ingredientsMedicinal herbsSafflowers

The invention relates to traditional Chinese medicines and particularly relates to a traditional Chinese medicine for treating rhagadia. The traditional Chinese medicine is characterized by being prepared from the following medicinal materials: 350 g of angelica, 350 g of safflower and 350 g of fresh licorice, or 350 g of angelica, 350 g of safflower, 350 g of fresh licorice, 100 g of white vinegar prepared by brewing with pure grains, and 20 g of hydrous glycerol; and glycerol vinegar is synthesized by the 100g of white vinegar, prepared by brewing with pure grains, and the 20g of hydrous glycerol and is used for external painting. According to the traditional Chinese medicine for treating the rhagadia, provided by the invention, the problem of rhagadia caused by reasons is solved, the preparation method is simple, and the traditional Chinese medicine is mainly used for treating the rhagadia of hands and feet caused by various reasons, can directly enter a nidus, and is easily operated.

Owner:XIAN FUAN INNOVATION CONSULTATION

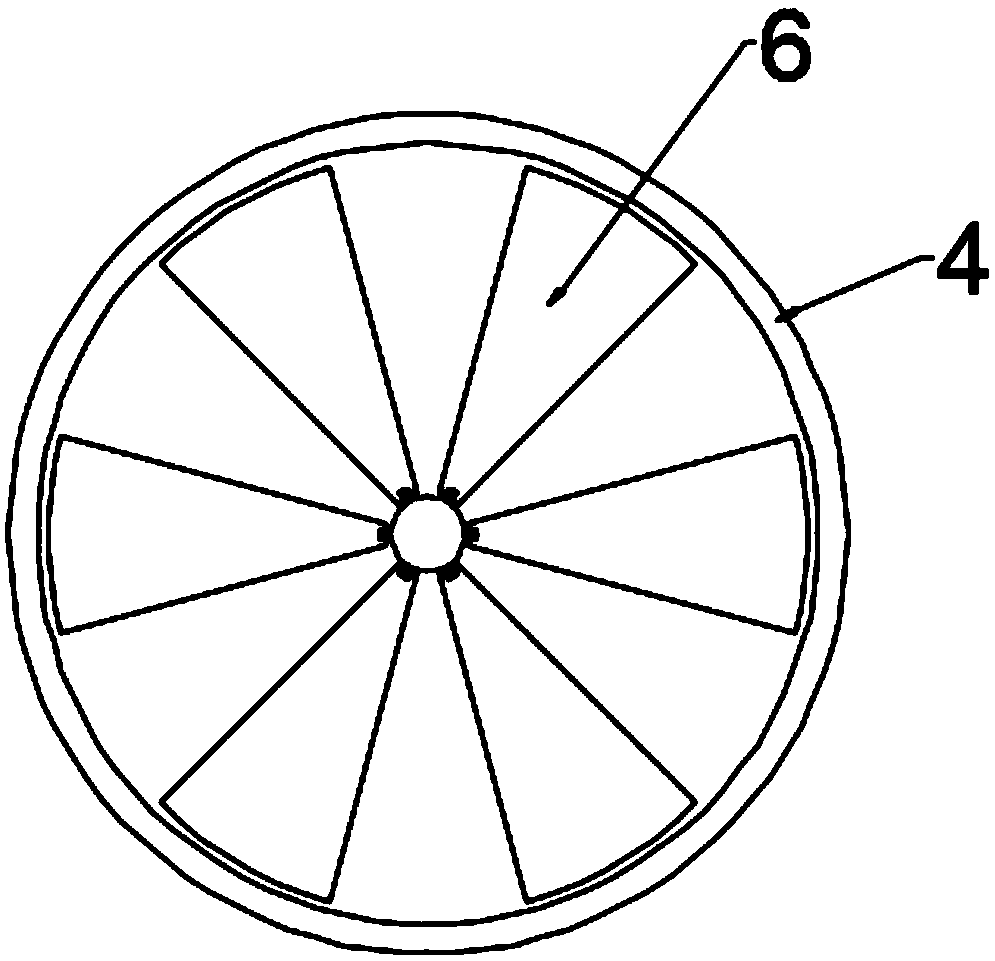

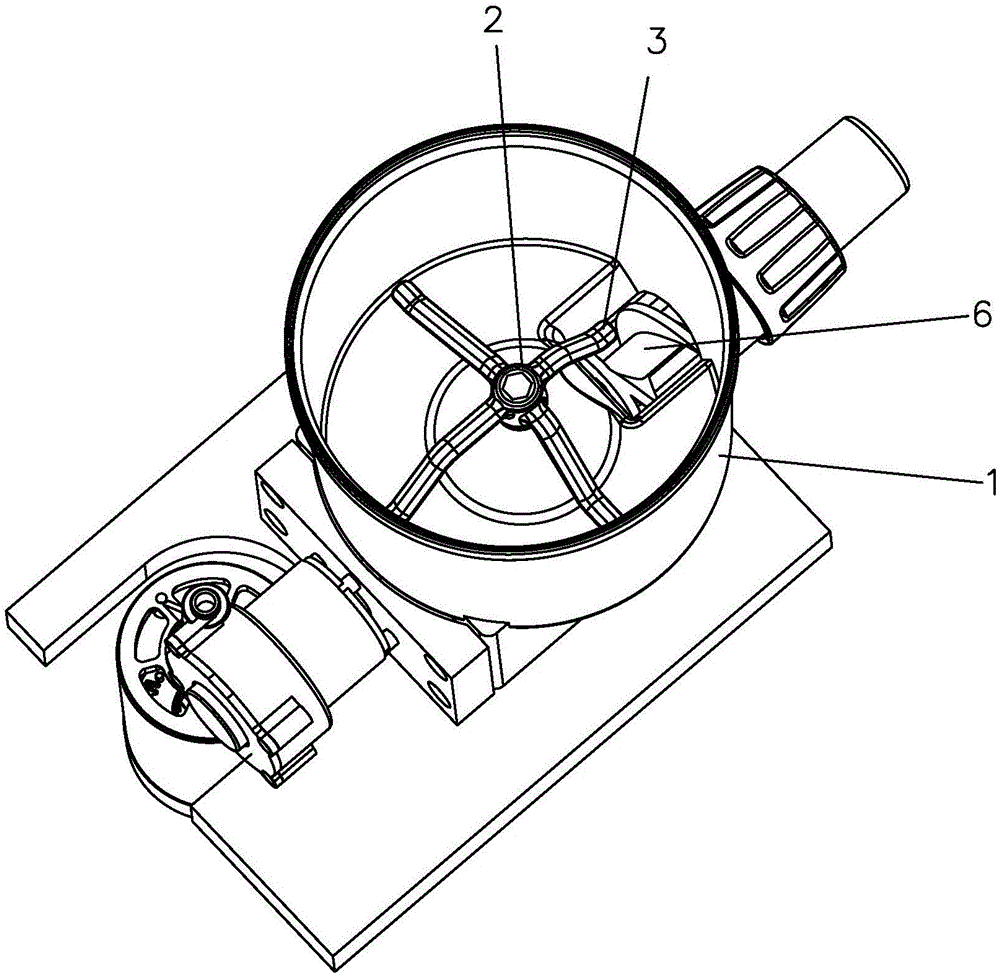

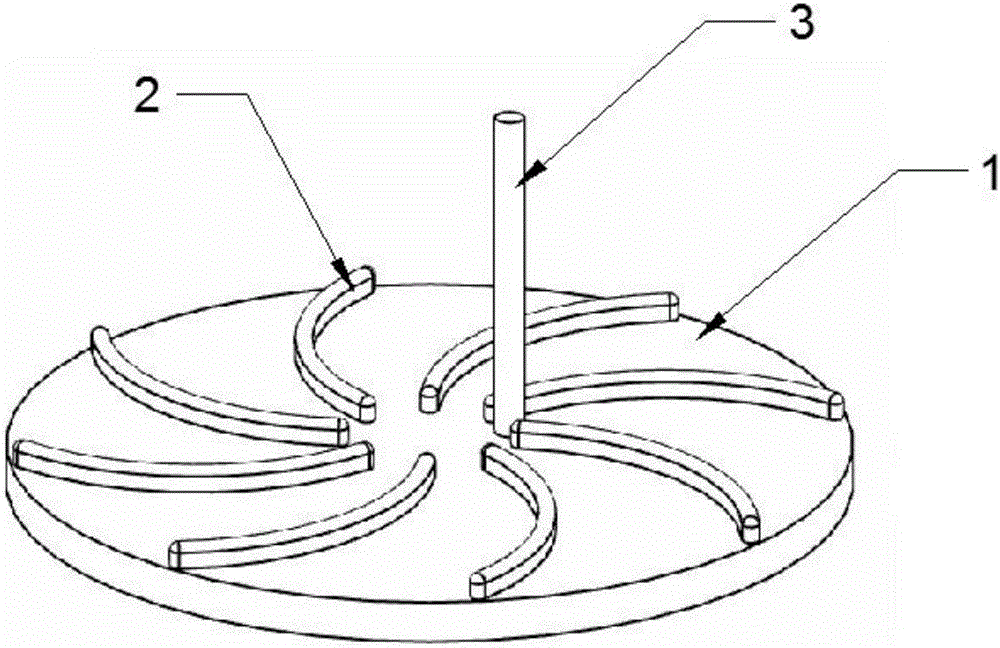

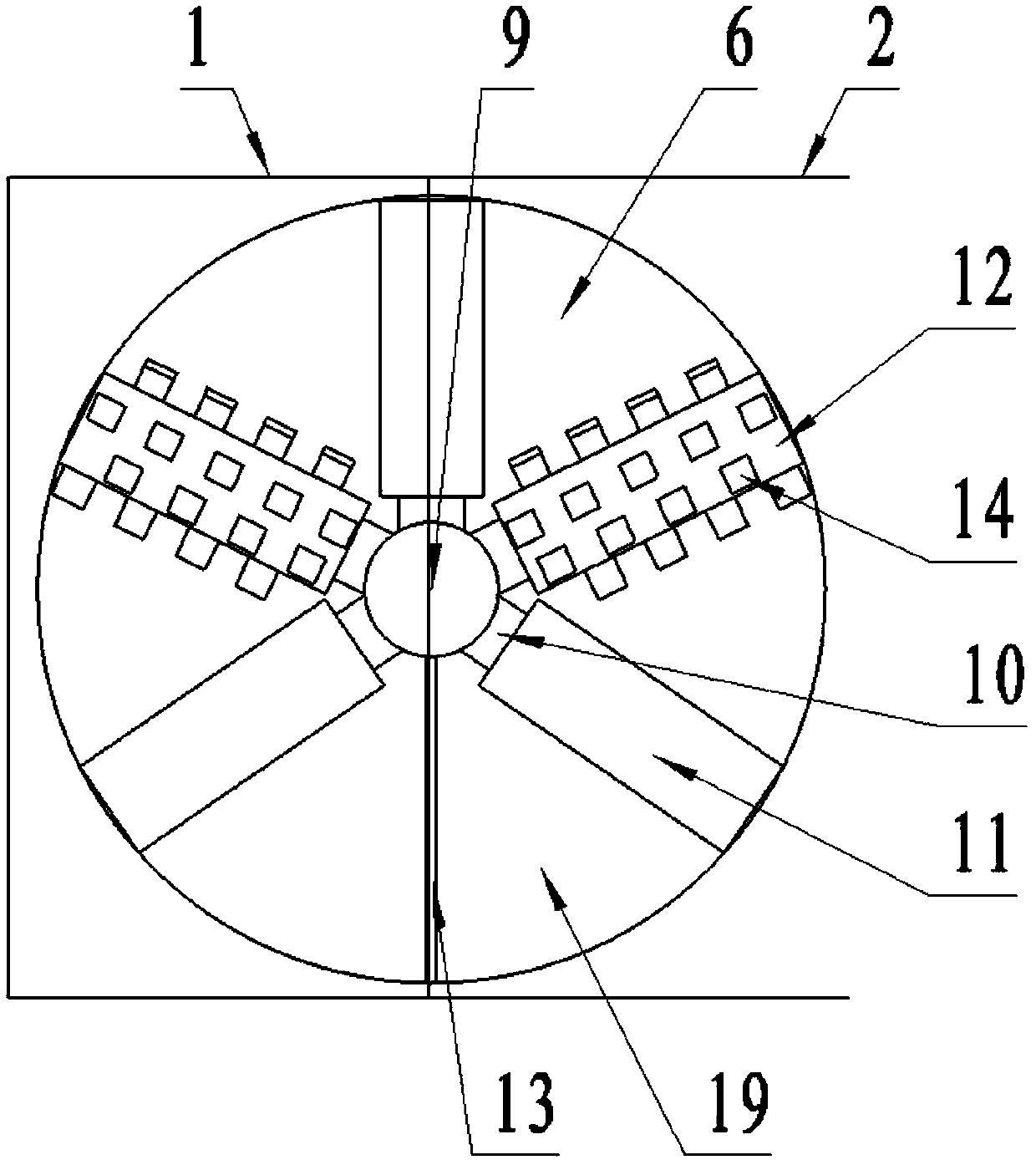

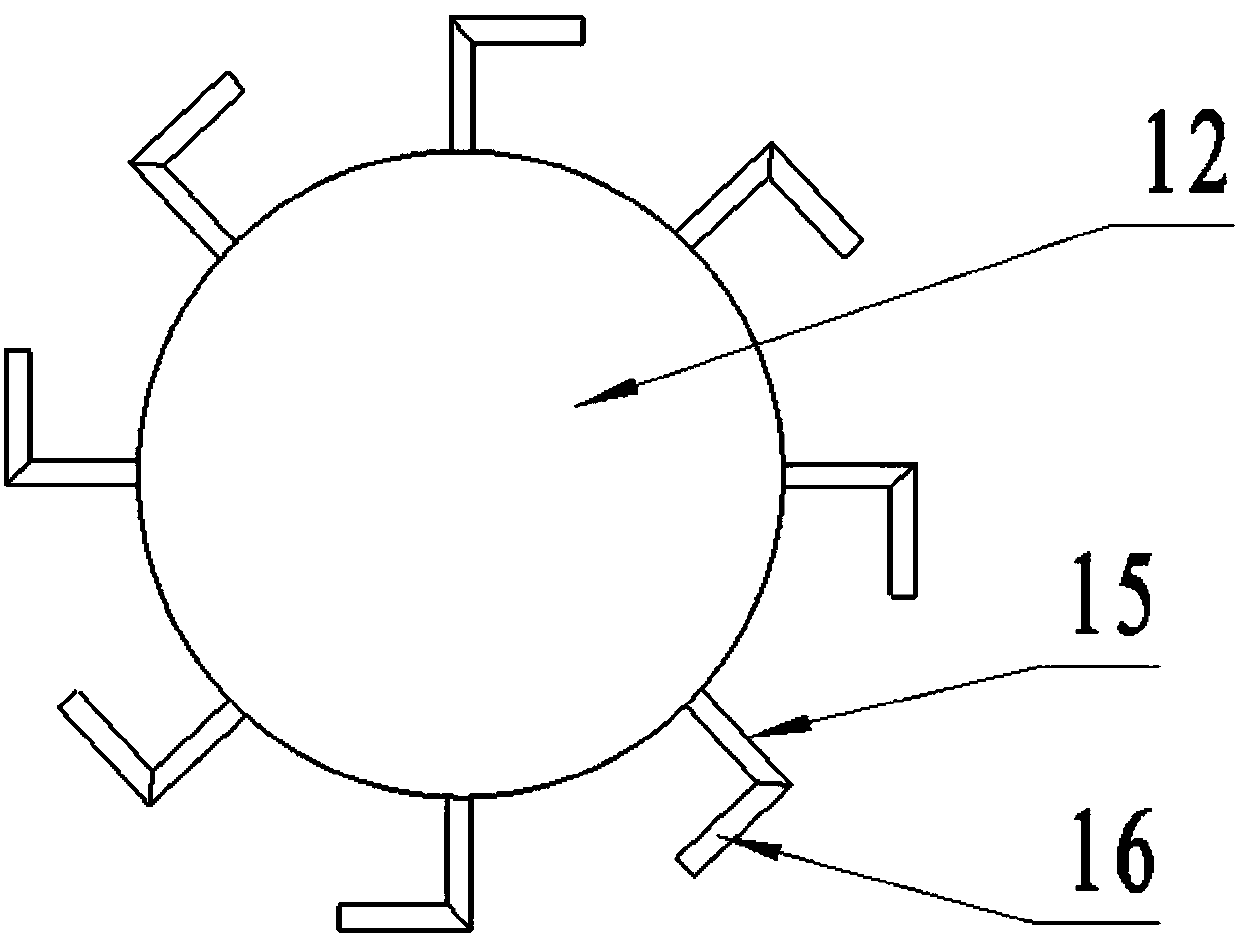

Rolling disk of tea leaf rolling machine

The invention belongs to the filed of rolling machines, and particularly relates to a rolling disk of a tea leaf rolling machine. In order to solve the problem that tea leaves cannot be sufficiently rolled when a conventional rolling machine is used for rolling tea leaves and especially under the condition that a large quantity of tea leaves are rolled, the invention provides the rolling disk of the rolling machine. The rolling disk comprises a rolling disk body (1), battens (2) and a stirring rod (3), wherein the rolling disk body (1) adopts a circular disk-shaped structure; the battens (2) are arc-shaped protrusions radiating all around from the center of the rolling disk body (1); the stirring rod (3) is arranged on the rolling disk body (1), the distance from the stirring rod to the center of a circle is not more than the difference value of the diameter of a rolling barrel and the radius of the rolling disk, and the height of the stirring rod can be adjusted along with the extrusion height of a pressing disk. The stirring rod (3) is arranged for stirring the tea leaves in the rolling process, so that the tea leaves are uniform to roll.

Owner:CHIZHOU JIULONGPU ECO AGRI COMPREHENSIVE DEV CO LTD

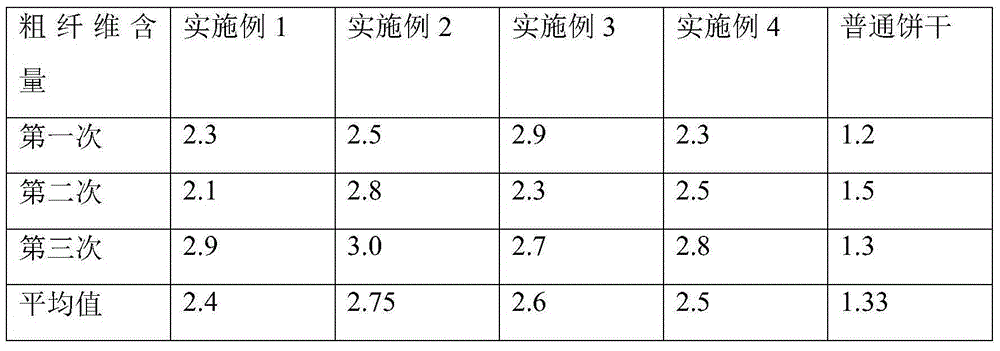

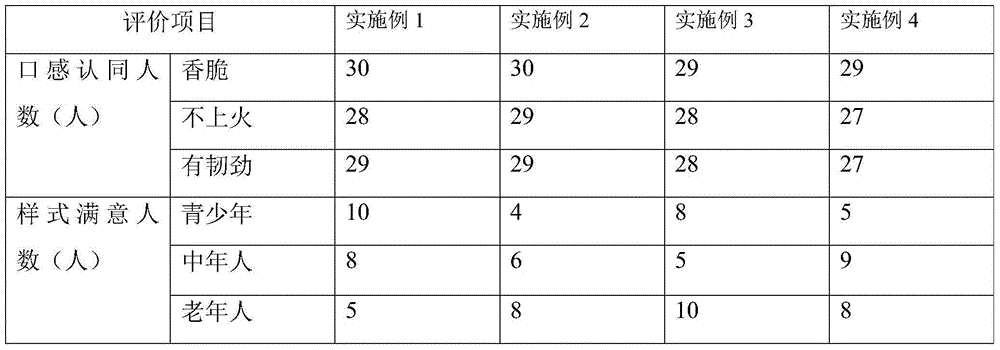

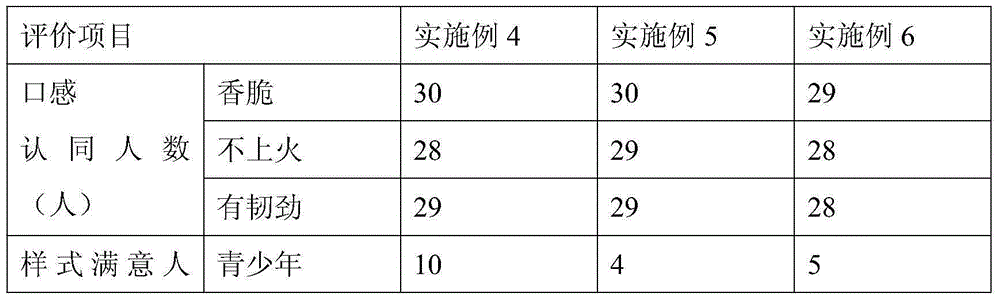

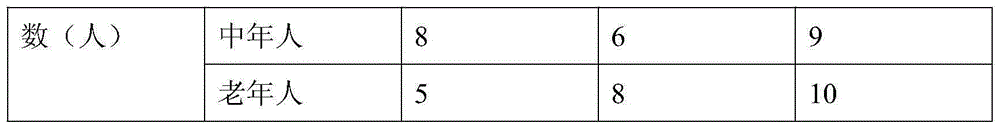

Dendrobium officinale cookie and preparation method thereof

The invention discloses a dendrobium officinale cookie and a preparation method thereof. The dendrobium officinale cookie comprises the following raw materials, by weight, 10 to 20 parts of dendrobium officinale filter residues, 10 to 20 parts of flour, 1 to 2 parts of butter, 2 to 3 parts of white sugar, 0.8 to 1.5 parts of baking soda, 0.2 to 0.4 part of ammonium bicarbonate, 0.2 to 0.4 part of salt, 1 to 2 parts of starch, 0.003 to 0.005 parts of sodium pyrosulfite and 2 to 5 parts of water. The preparation method comprises the following steps of 1. collecting dendrobium officinale filter residues; 2. modulating; 3. rolling and forming; and 4 baking and packaging. The dendrobium officinale cookie is abundant in nutrition, tasty, delicious and crisp, chewy, and low in heat content. The preparation method is simple in method and reasonable in design, the nutritive value of dendrobium officinale filter residues can be fully utilized.

Owner:GUANGXI JIANBAO SHIHU

Processing method of black tea

The invention relates to a processing method of tea leaves, in particular to a processing method of black tea. The processing method includes: picking fresh tea leaves; drying and discharging the tea leaves; dividing the tea leaves into a plurality circular piles, and spreading on a withering curtain; hot rolling the tea leaves in a heating pot of 65-68 DEG C, blowing hot air at the same time, delivering the hot air through a hot air duct which enters a position inside the tea leaves and is 1-2cm away from the bottom of the heating pot, cooling to room temperature, blowing cold air from the bottom of the tea leaves, and adding into a heating pot of 30-40 DEG C; spreading the rolled tea leaves in a fermentation chamber for fermenting; shaking out the tea leaves after the first fermentation, covering the lower tea leaves with a layer of plastic film every other 1cm, covering the uppermost tea leaves with a layer of plastic film, cooling to room temperature, and spreading in the fermentation chamber for second fermentation; drying; sieving the dried tea leaves, cutting off tea dust, winnowing to remove yellow tea leaves, removing impurities and bagging. The processing method of the black tea has the advantages that method is short in processing time, and the processed black tea is bright in color and mellow in taste.

Owner:黄世仁

Green tea processing method

InactiveCN106234677AImprove the efficiency of finishingReduce manufacturing costPre-extraction tea treatmentGinkgo GenusChemistry

The invention relates to the field of green tea, and concretely relates to a green tea processing method. The method comprises the following steps: 1, picking and processing of green tea leaves and Folium Ginkgo; 2, enzyme deactivation; 3, rolling; 4, fermenting; 5, drying; and 6, crushing. The Folium Ginkgo and the green tea leaves are mixed in the enzyme deactivating process, so a later stirring process is omitted, the processing link is reduced, and the working operation is simple; and an inducing agent is added in the fermentation link, so components of the Folium Ginkgo and the green tea leaves are uniformly mixed, and are easy for people to absorb.

Owner:GUIZHOU JUFUXUAN WANHUYUAN TEA

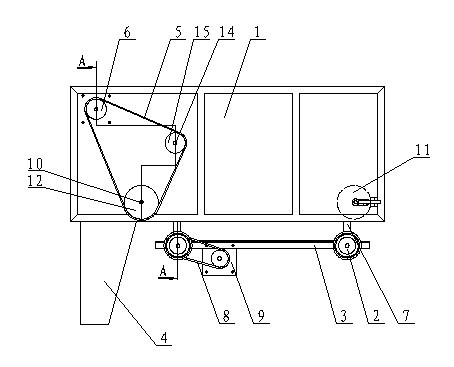

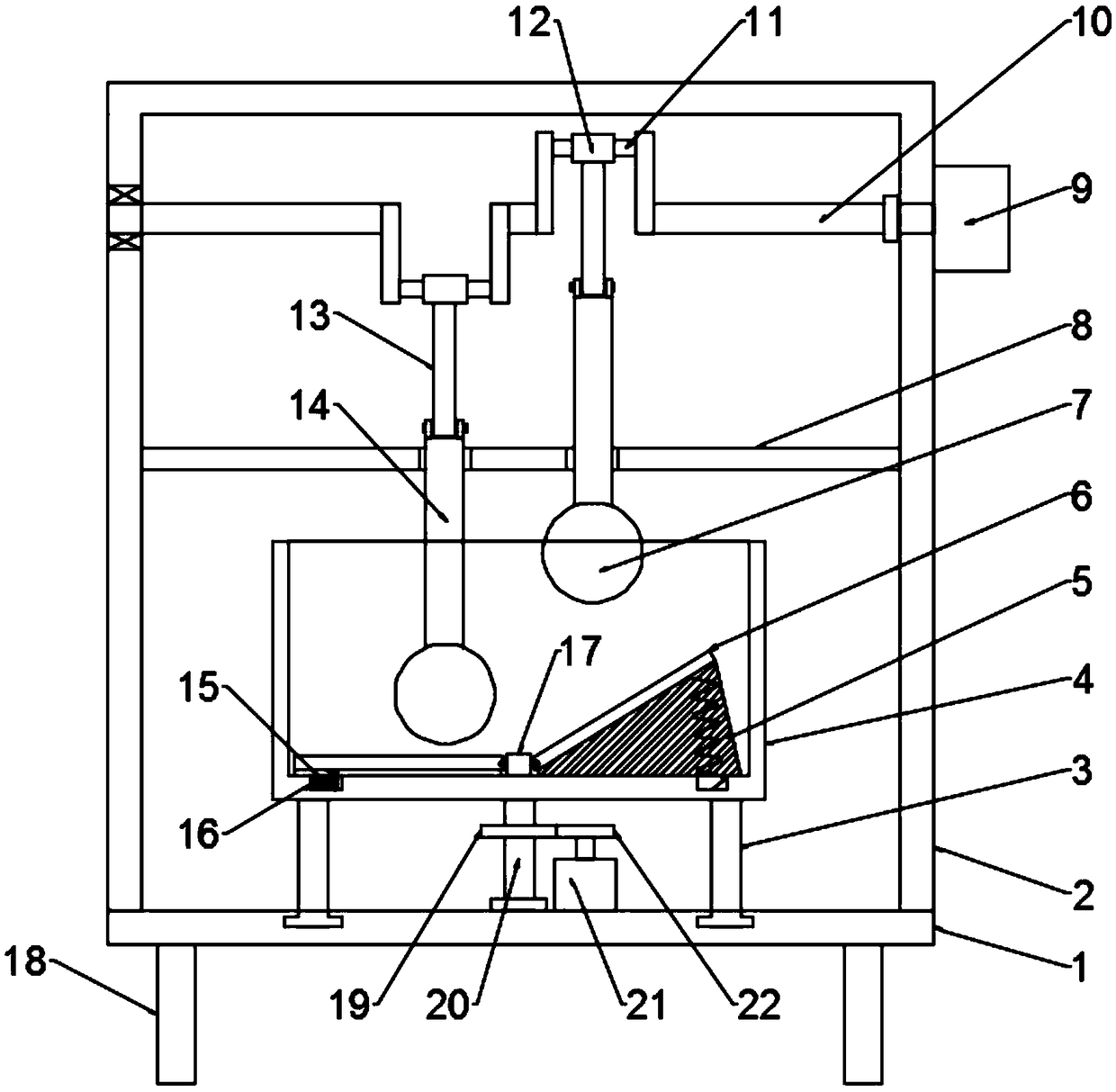

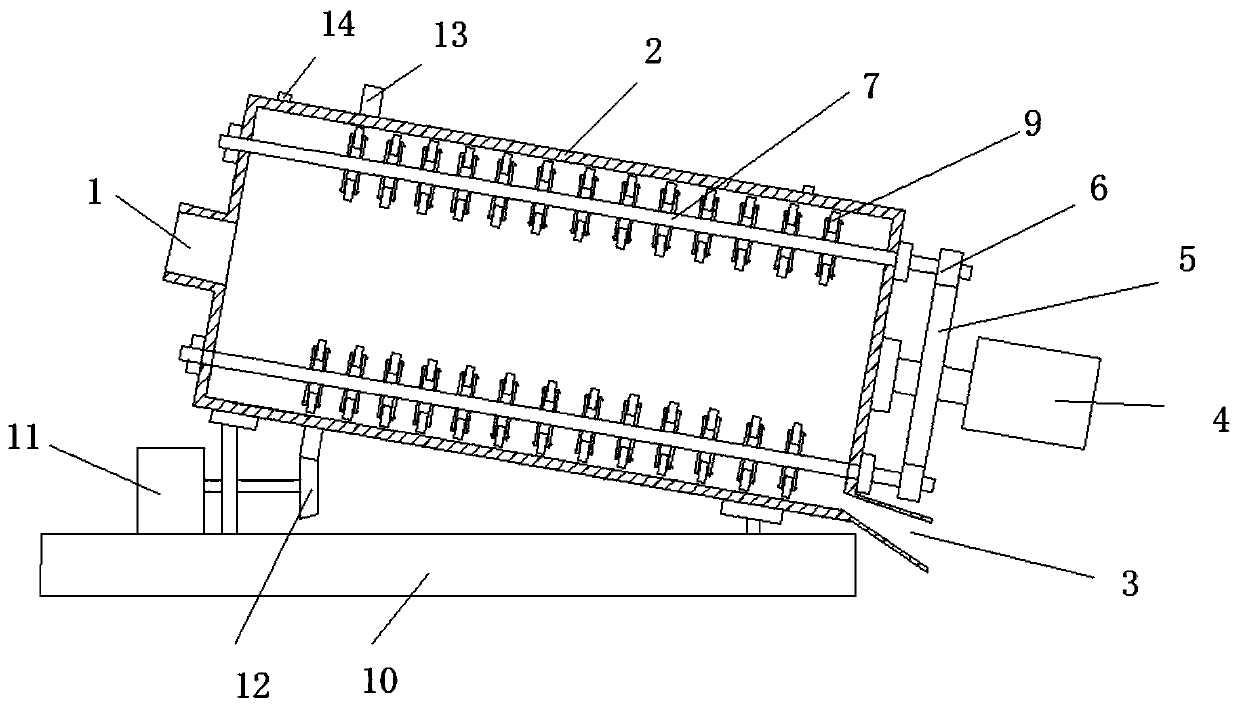

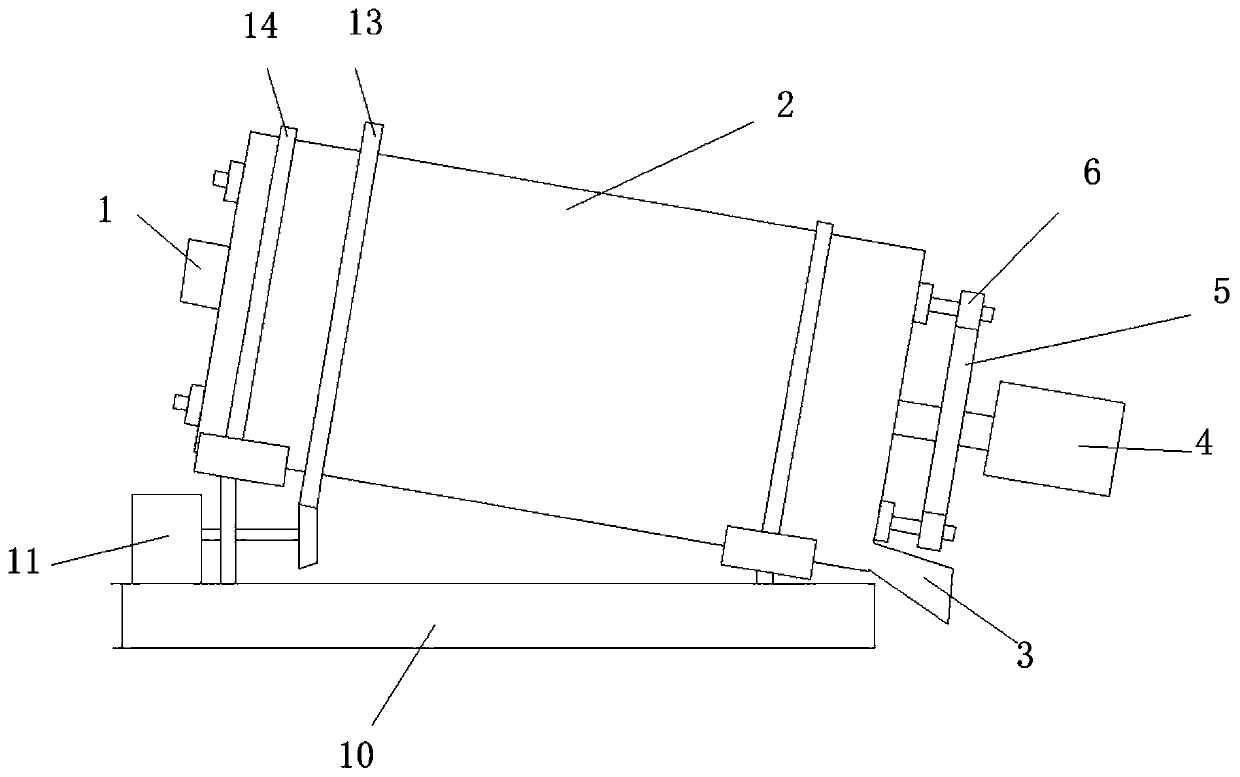

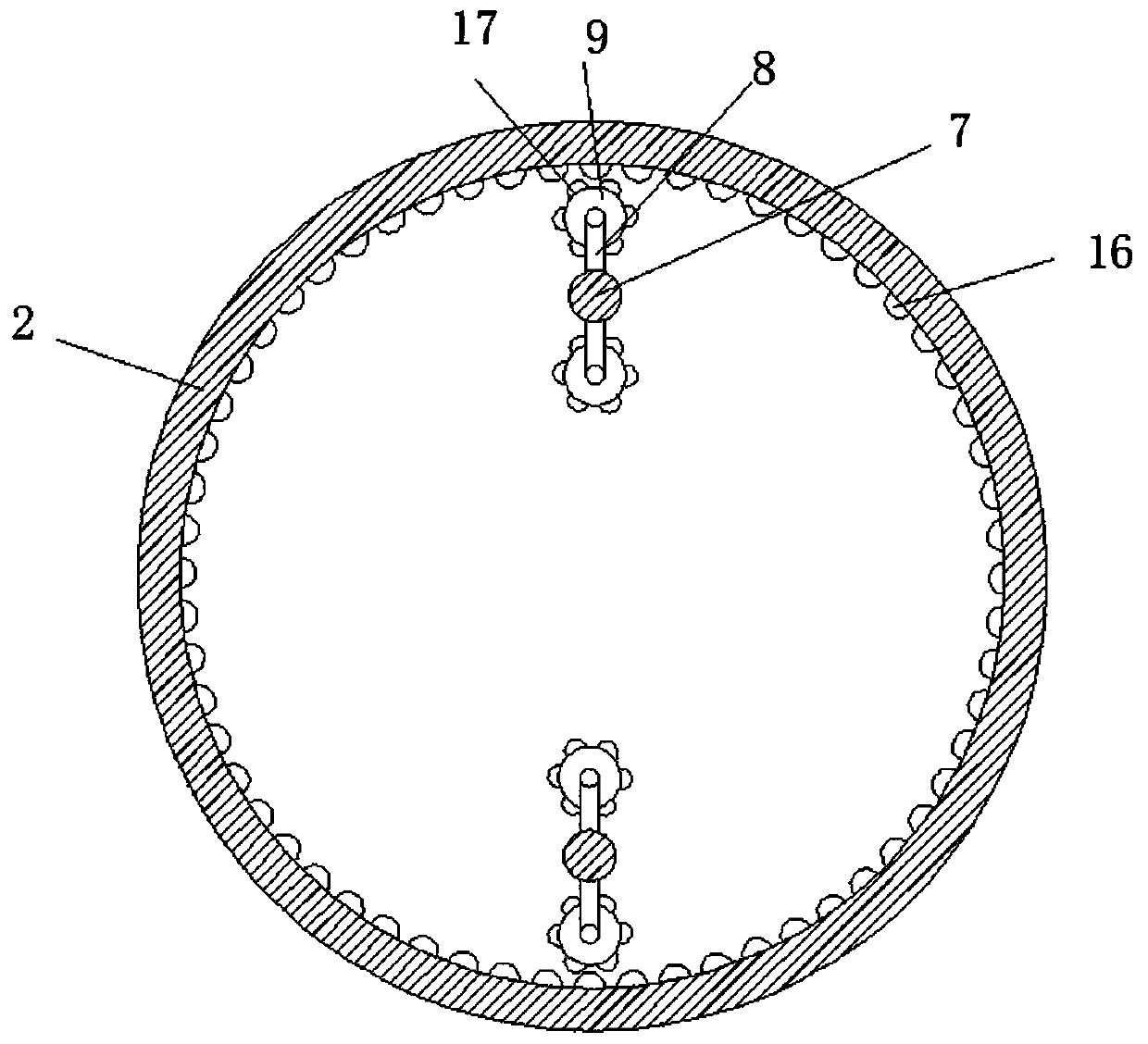

Tea continuous processing and rolling device

InactiveCN110338244AAchieving continuous production capacityTo achieve the effect of rotationPre-extraction tea treatmentGear wheelAgricultural engineering

The invention relates to the technical field of tea processing, and discloses a tea continuous processing and rolling device. The device comprises a rolling cylinder, a feeding port is formed in the left side of the rolling cylinder, and a discharging port is formed in the bottom of the right side of the rolling cylinder; a first motor is installed on the right side of the rolling cylinder, and afirst transmission gear is fixedly connected to the left side of the first motor; the outer side of the first transmission gear is connected with a second transmission gear, and the outer side of thetransmission rod is fixedly connected with a mounting rod; a rolling wheel is arranged on the outer side of the mounting rod, and a base is arranged at the bottom of the rolling cylinder; a second motor is fixedly connected to the left side of the top of the base, and a bevel gear is fixedly connected to the right side of the second motor. The rolling cylinder is placed at a certain inclination angle, so that tea leaves move downwards along with the rotation of the rolling cylinder under the action of gravity, then the continuous feeding and continuous discharging effects of the tea leaves areachieved, and the continuous production capacity of the tea leaves is realized.

Owner:湖南天爱农业科技有限公司

Graded twisting machine for tea leaves

InactiveCN111227065AKnead evenlyAdjustable kneading strengthPre-extraction tea treatmentAgricultural engineeringCentre of rotation

The invention discloses a graded twisting machine for tea leaves. The graded twisting machine comprises a loading plate, a load-bearing frame, two conical sleeves and cones, wherein the load-bearing frame is in horizontal running fit with the loading plate, the two conical sleeves are located in the load-bearing frame and are coaxial, axes of the two conical sleeves are of horizontal distribution,and the cones are located in the conical sleeves. According to the graded twisting machine for the tea leaves, the load-bearing frame which is in running fit in a horizontal direction is arranged onthe loading plate, the two conical sleeves which are symmetrically distributed relative to a center of rotation of the load-bearing frame are rotatably connected into the load-bearing frame and are coaxially distributed, the cones are arranged in the conical sleeves and are in axial elastic sliding fit with the load-bearing frame, gaps between the cones and the conical sleeves are twisting areas,a tea leaf placement chamber is formed by two bearing sleeves and the load-bearing frame, and the two bearing sleeves rotate in a vertical direction, are opposite in rotating direction and are combined with the horizontal-rotating load-bearing frame, so that adjustable twisting force, adjustable twisting speed, rolling type twisting and uniform twisting of the tea leaves under the action of centrifugation can be achieved; and the entire device is free of force of inertia and good in stability.

Owner:周倩倩

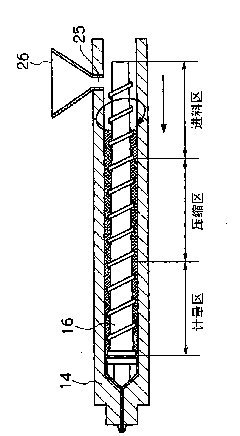

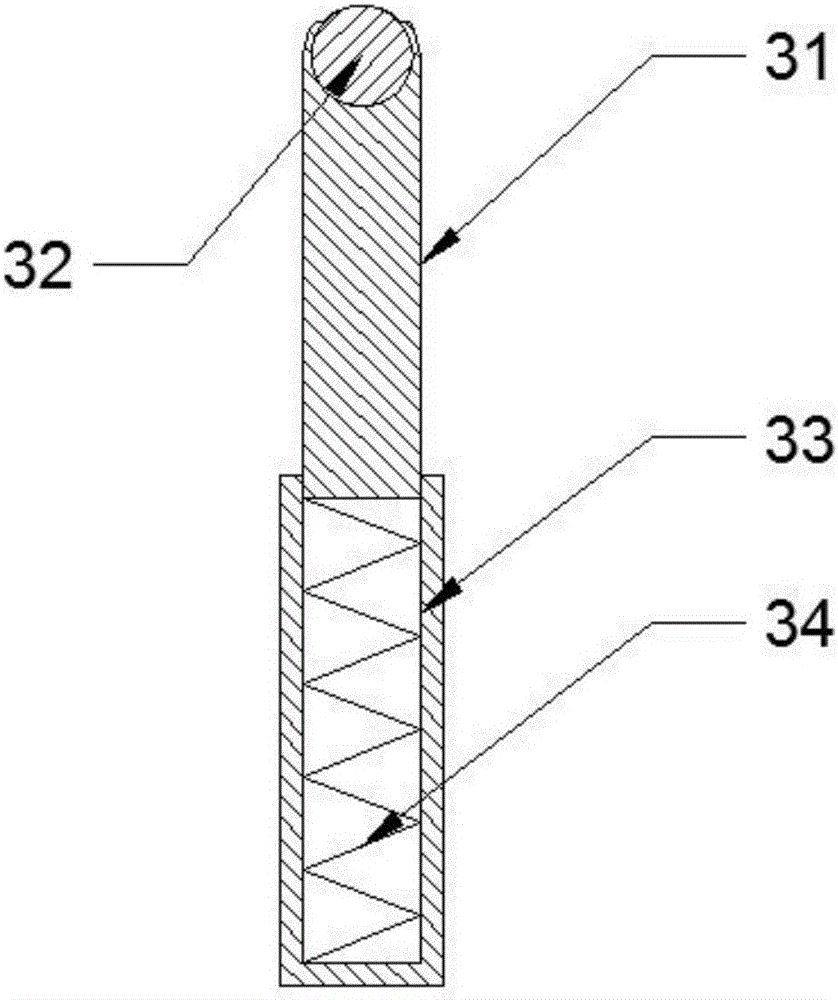

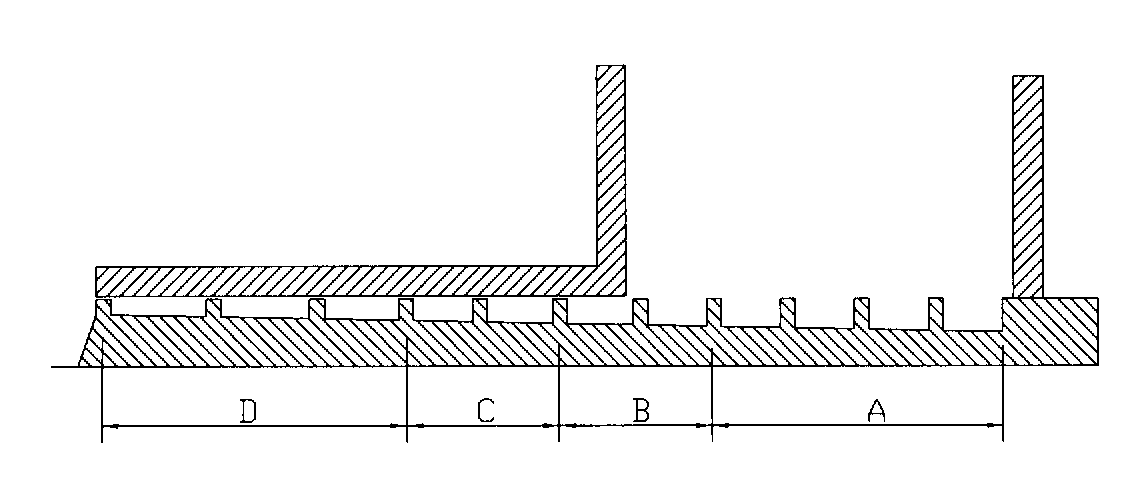

Sectional variable pitch screw

The invention discloses a sectional variable pitch screw, which is an outer screw thread straight rod member with a pitch of 100-140 mm and a tooth height of 14-23 mm, and is sequentially divided into a conveying section A, a feeding section B, a compression section C and an extrusion section D from the root to the end of the screw. The conveying section A is provided with 5-7 teeth, and the feeding section B is provided with 2-3 teeth, wherein an axial section area of each tooth of the feeding section B is 20-30% larger than an axial section area of each tooth of the conveying section A. The compression section C is provided with 2-3 teeth, wherein an axial section area of each tooth of the compression section C is 20-30% smaller than an axial section area of each tooth of the feeding section B. The extrusion section D is provided with 3-5 teeth, wherein parameters of various teeth are different, pitches are sequentially increased, tooth heights are sequentially decreased, axial section areas of various teeth of the extrusion section D are maintained to the same, and the section area is equal to an axial section area of each tooth of the extrusion section D. With the screw having a differentiation structure design, pasty BMC produces a kneading effect during extrusion, such that BMC homogenization is promoted, the material can not overflow in a reverse direction, and glass fibers in the pasty BMC can not be broken without reason.

Owner:MILIKUDO GLASS FIBER REINFORCED PLASTIC TAIZHOU

Controllable-temperature tea stir-frying machine capable of fully rolling tea leaves

The invention relates to a controllable-temperature tea stir-frying machine capable of fully rolling tea leaves, which comprises an outer furnace body, an inner furnace body, a tea rolling device anda heater, wherein the inner furnace body is embedded and fixed in the outer furnace body, an opening is opened on one side of the inner furnace body, the tea rolling device is located between the outer furnace body and the inner furnace body through the opening with a half position, and the other half position is located in the inner furnace body, the tea rolling device comprises a rolling platform and a plurality of rolling ends on the rolling platform, a sieve tray is arranged under the tea rolling device in the inner furnace body, the heater is connected with a temperature sensor, and a temperature display is provided on the temperature sensor. The rolling platform in the tea rolling device cooperates with a plurality of rolling ends to carry out the rolling of the tea leaves, so as toavoid the incomplete rolling of the tea leaves when the rolling end is used for rolling the tea leaves, the plurality of the rolling ends can improve the effect of the tea leaves, so that the tea leaves are fully rolled, and the working efficiency of the tea stir-frying machine and the final taste of the tea are improved.

Owner:谷约飞

Manufacture method for dendrobium officinale health-preserving cake

InactiveCN105029190ATake advantage of the valueEvenly distributedFood ingredient functionsFood preparationBiotechnologyNutritive values

The invention discloses a manufacture method for a dendrobium officinale health-preserving cake. The manufacture method comprises the following steps: step 1, juicing fresh branches of dendrobium officinale, filtering, and taking filter residues which are not filtered out for standby application; step 2, taking glutinous rice flour and corn flour, adding a proper amount of water in glutinous rice flour and corn flour, kneading into dough, adding the standby matter obtained in the step 1 and fermentation powder, putting the mixture into an automatic dough kneading machine for uniformly kneading and rolling for 10-15 min, and fermenting kneaded and rolled dough for 3-5 h for standby application; step 3, putting the fermented dough into a cake making machine so as to form a formed sample cake; step 4, putting the formed sample cake into a steaming and baking oven for steaming and baking for 10-20 min so as to obtain the dendrobium officinale health-preserving cake. The manufacture method provided by the invention is simple, the nutritional value of filter residues of the dendrobium officinale is used effectively, and the design is reasonable; the manufactured health-preserving cake is rich in fibrous matters required by human bodies, delicious in taste, crispy, and relatively low in heat content and has chewiness.

Owner:GUANGXI JIANBAO SHIHU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com