Rolling disk of tea leaf rolling machine

A kneading machine and tea technology, which is applied in tea processing before extraction, etc., can solve the problem of uneven tea kneading, achieve uniform distribution, reduce friction, and knead evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

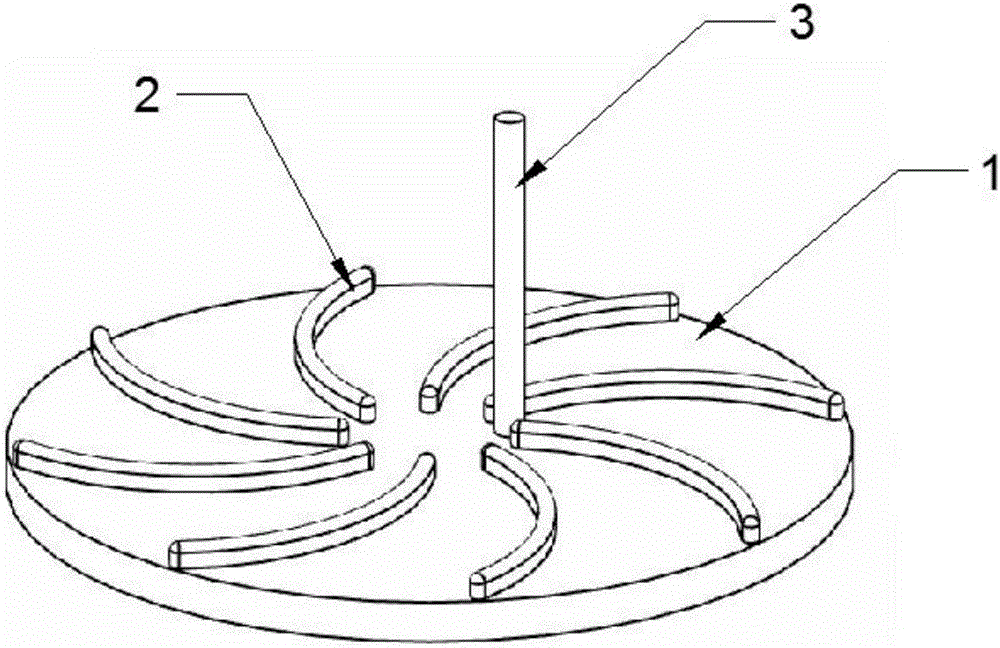

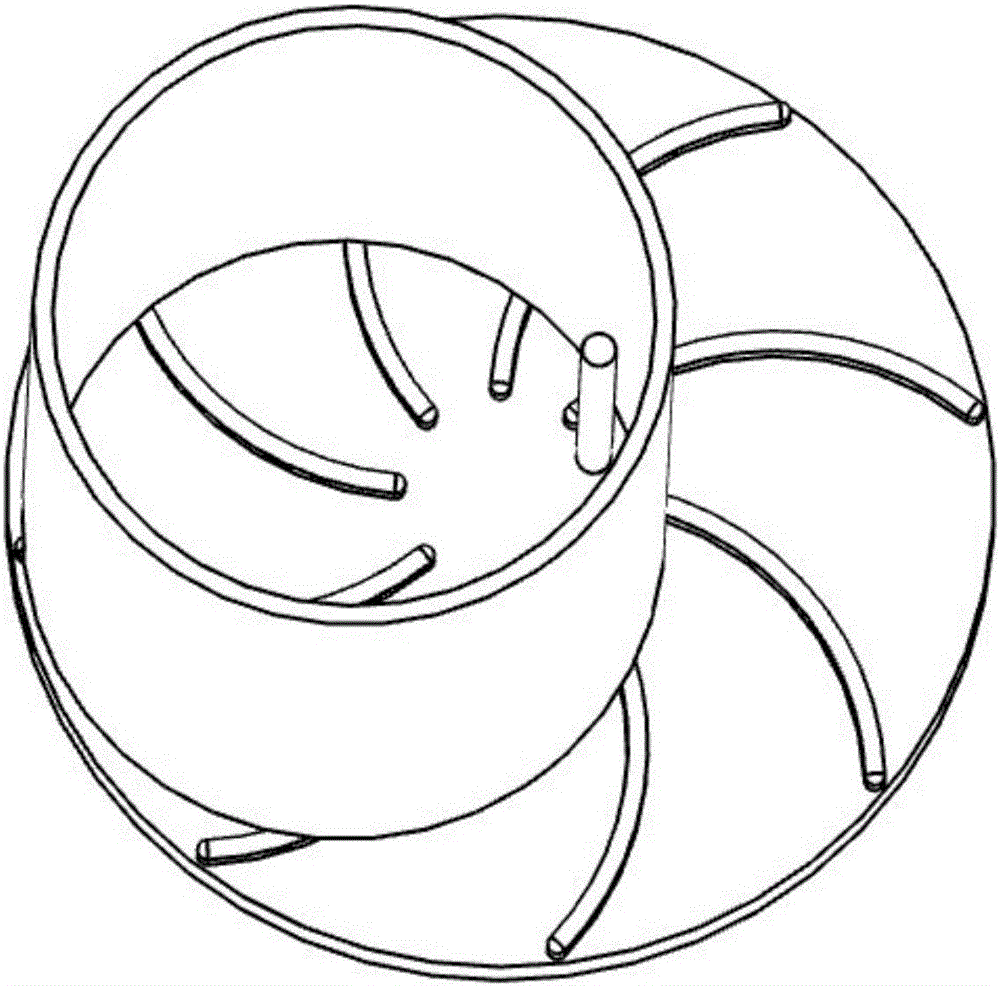

[0013] like figure 1 , figure 2 , image 3 The shown kneading plate of a tea kneading machine includes a kneading plate body 1, a rib 2, and a stirring rod 3; The stirring rod 3 is arranged on the kneading plate body 1, and the distance from the center of the circle does not exceed the difference between the diameter of the kneading barrel and the radius of the kneading plate, and its height can be adjusted with the extrusion height of the pressure plate.

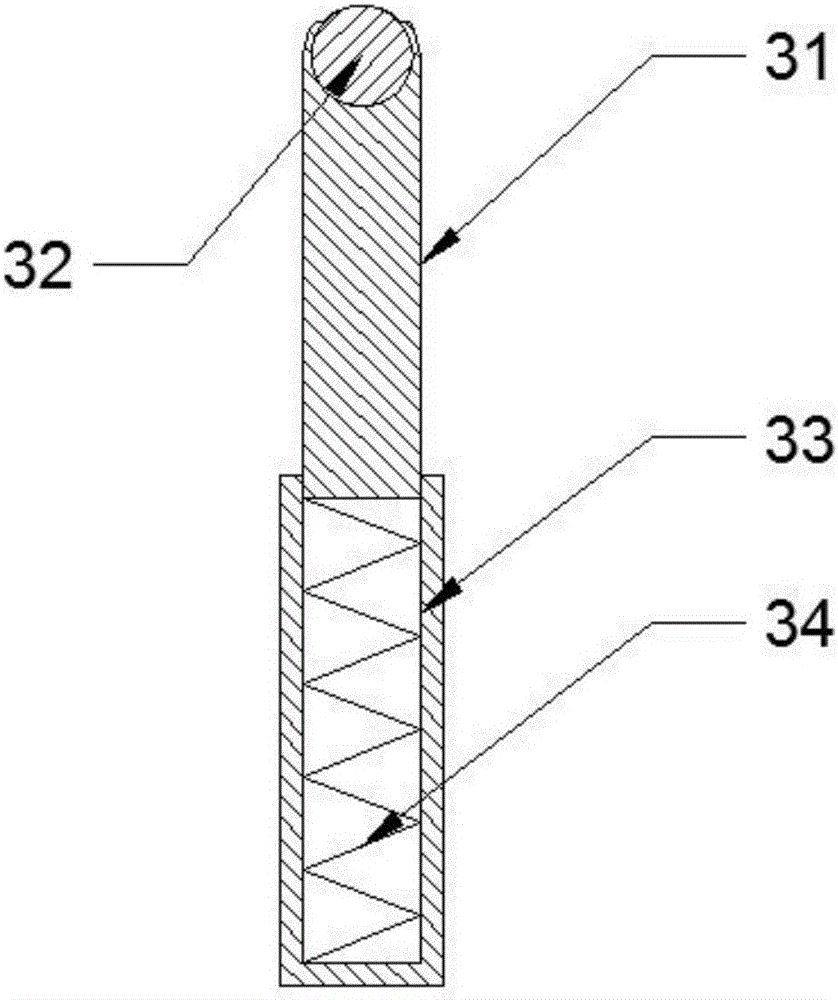

[0014] The stirring rod 3 includes a cylindrical inner sleeve rod 31, a ball 32 arranged at the top of the inner sleeve rod 31, an outer sleeve rod 33 sleeved outside the inner sleeve rod 31, and a spring 34 arranged inside the outer sleeve rod 33 and at the bottom of the inner sleeve rod 31. .

[0015] When working, the kneading bucket moves in a circular motion around the kneading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com