Injection molding method

A technology of injection molding and molding materials, applied in the field of injection molding, which can solve the problems of difficulty in stably preparing molded products with uniform quality and uniform kneading, and achieve the effect of reducing the amount of feed and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

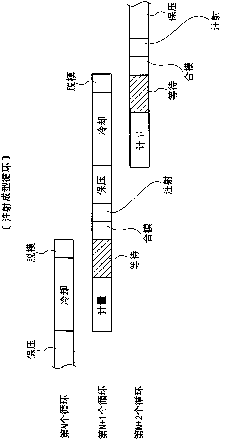

[0082] A first embodiment of the subject matter of the present disclosure is an invention relating to metering time control in an injection molding process.

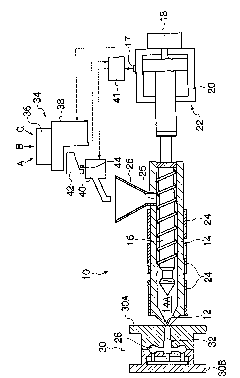

[0083] figure 1 is a schematic configuration diagram of one example of an injection molding apparatus that performs the injection molding method of the subject matter of the present disclosure.

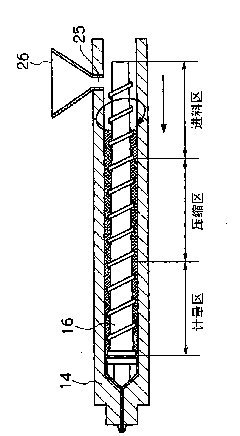

[0084] as in figure 1 As shown in , the injection molding apparatus 10 includes a barrel 14 having a nozzle 12 at the tip, and a screw 16 is rotatably disposed in the barrel 14 . At the end opposite the nozzle 12 and at the rear end of the screw 16, there is located an electric motor / piston arrangement 22 comprising an electric motor 18 rotating the screw 16 and a piston arrangement 20 at a set point based on pressure and speed. The constant stroke (stroke) in the axial direction ( figure 1 In the transverse direction) the screw rod 16 is advanced and reversed. The piston device 20 causes the screw to figure 1 Push to the l...

no. 2 approach

[0133] A second embodiment of the disclosed subject matter relates to simultaneous feeding in an injection molding process.

[0134] The simultaneous feeding in the subject matter of the present disclosure can be performed so that the molding material containing at least the powder material and the granular material among the powder material, the granular material and the liquid material is directly fed into the barrel via the hopper 26 of the injection molding apparatus 10 In the case of injection molding in 14, it also prevents clogging and kneads the molding material in the barrel 14 uniformly.

[0135] It goes without saying, however, that synchronous feeding is combined with the "dosing time control" described above to further provide the advantages of synchronous feeding.

[0136] Figure 8 is a schematic configuration diagram showing an example of injection molding equipment that can perform simultaneous feeding. The basic structure of injection molding equipment 10 a...

Embodiment 1

[0237] In Example 1, a small metering feeder was installed to the injection molding equipment, the molding material having the above composition was placed in a plastic bag, shaken well and uniformly mixed, and then placed in the metering feeder. Set back pressure to 30kg / cm 2 , the rotation speed of the screw was set to 200 rpm, and the molding material was fed into the barrel at a feed speed at which the metering time was 20 seconds. Specifically, in Example 1, the feed rate of the molding material fed into the barrel was adjusted regardless of the rotation speed of the screw and the set value of the back pressure, thus controlling the metering time in the metering step to 20 seconds. As a result, the uniform kneading of the granular material and the powder material was fully performed, and the result of the Charpy impact test was 7.1 (KJ / cm 2 ), the flame retardancy was V-0, the dispersibility was A, and it was judged to be acceptable. Figure 11A is a photograph showing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com