Patents

Literature

63results about How to "Improve kneading efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

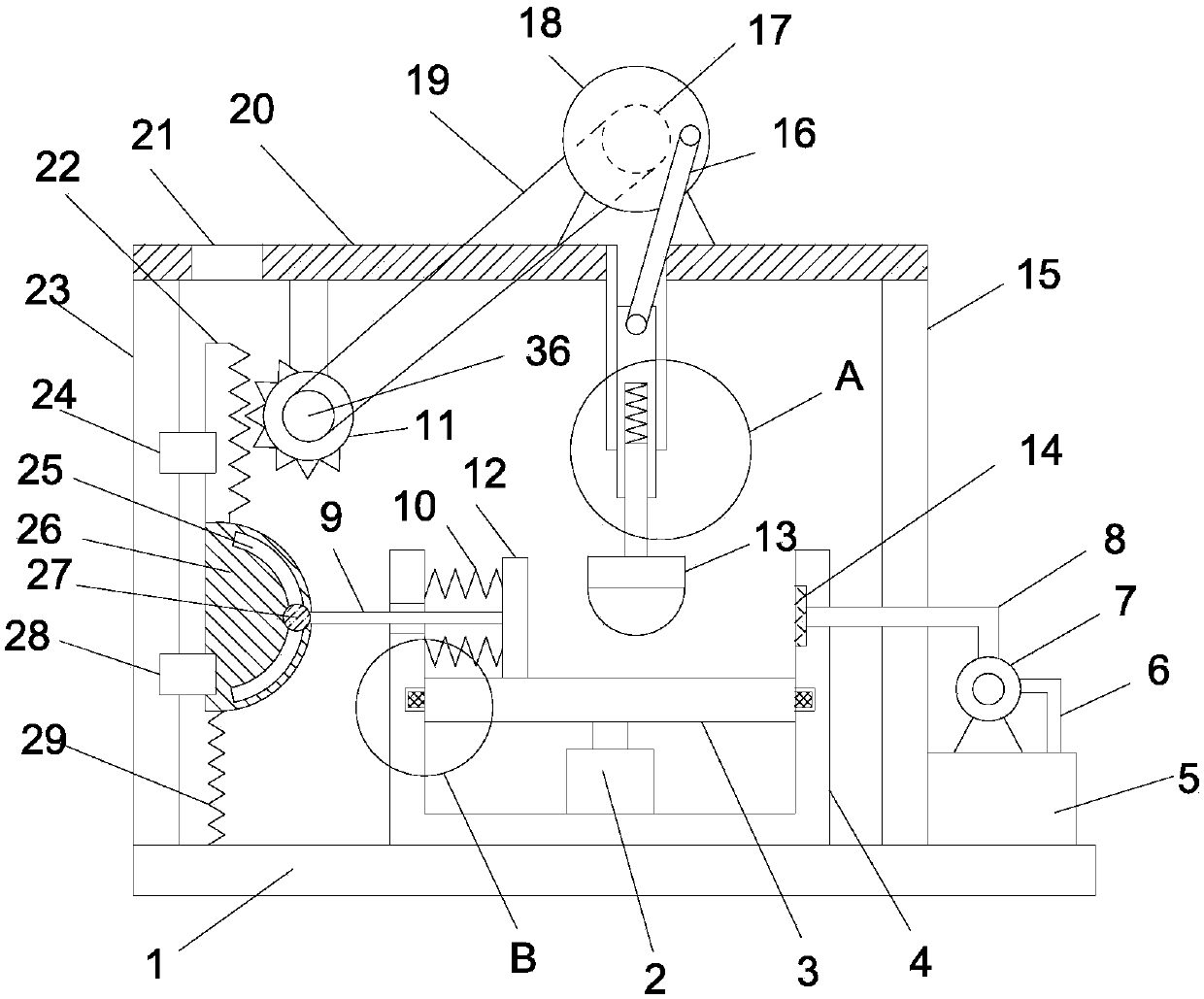

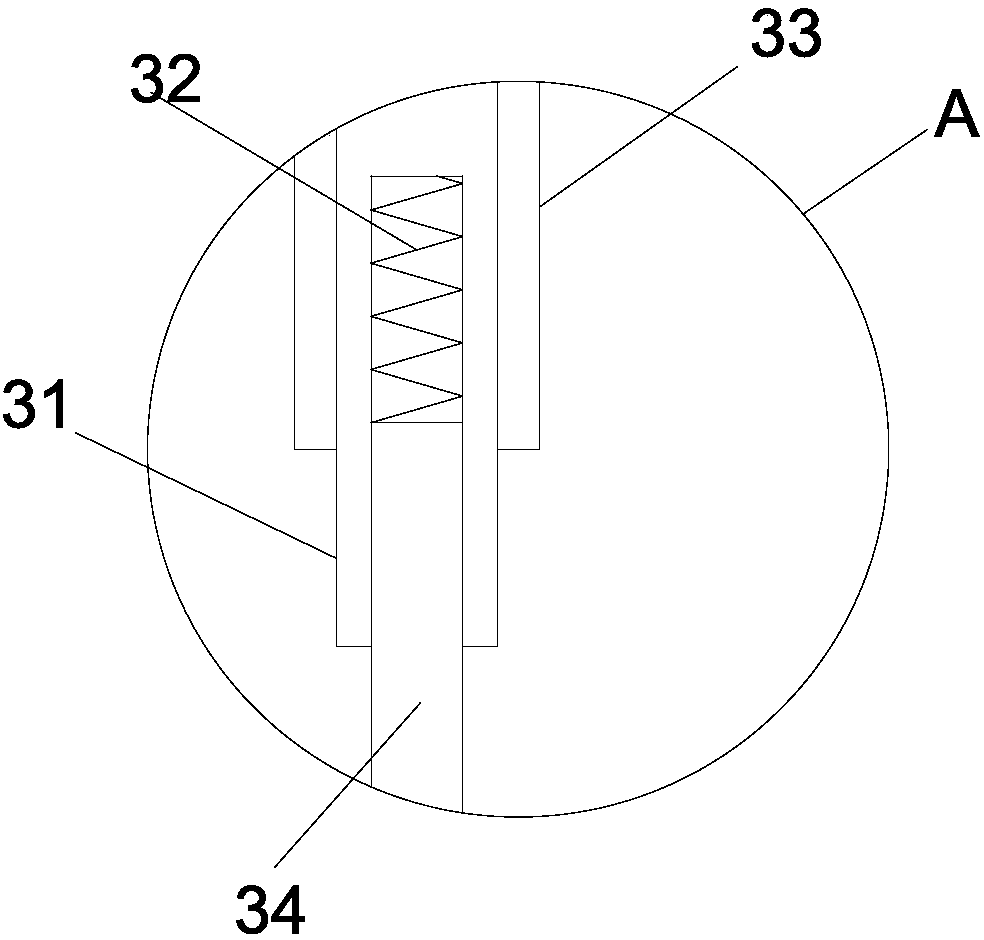

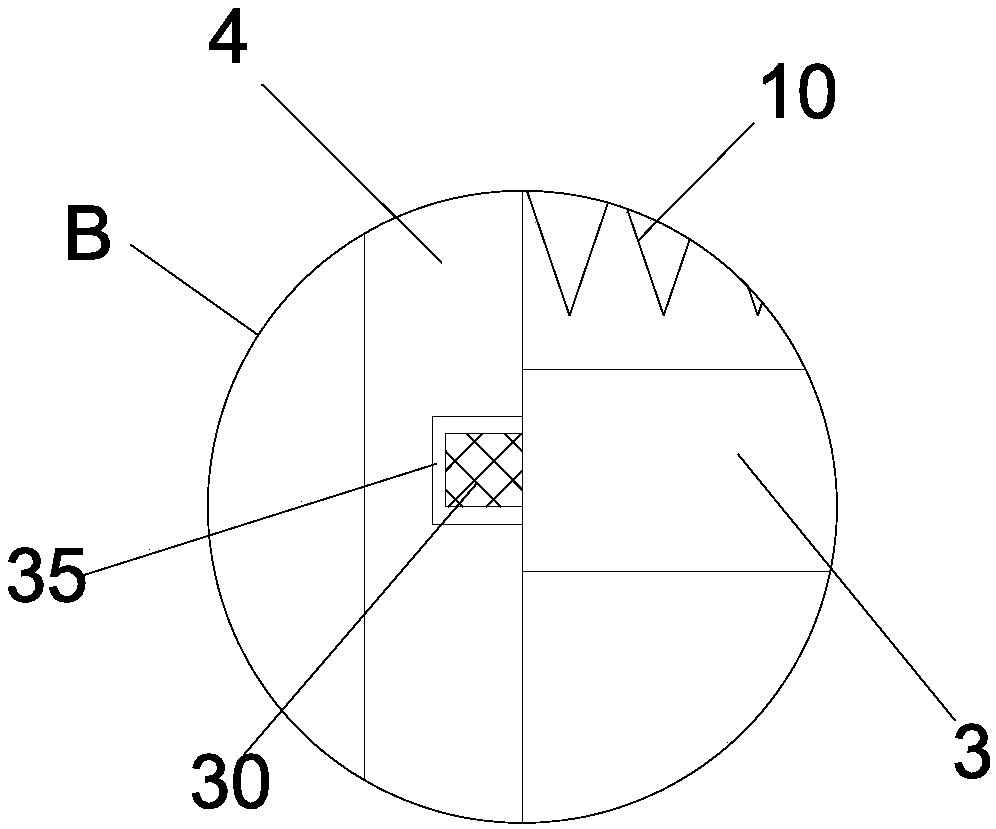

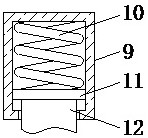

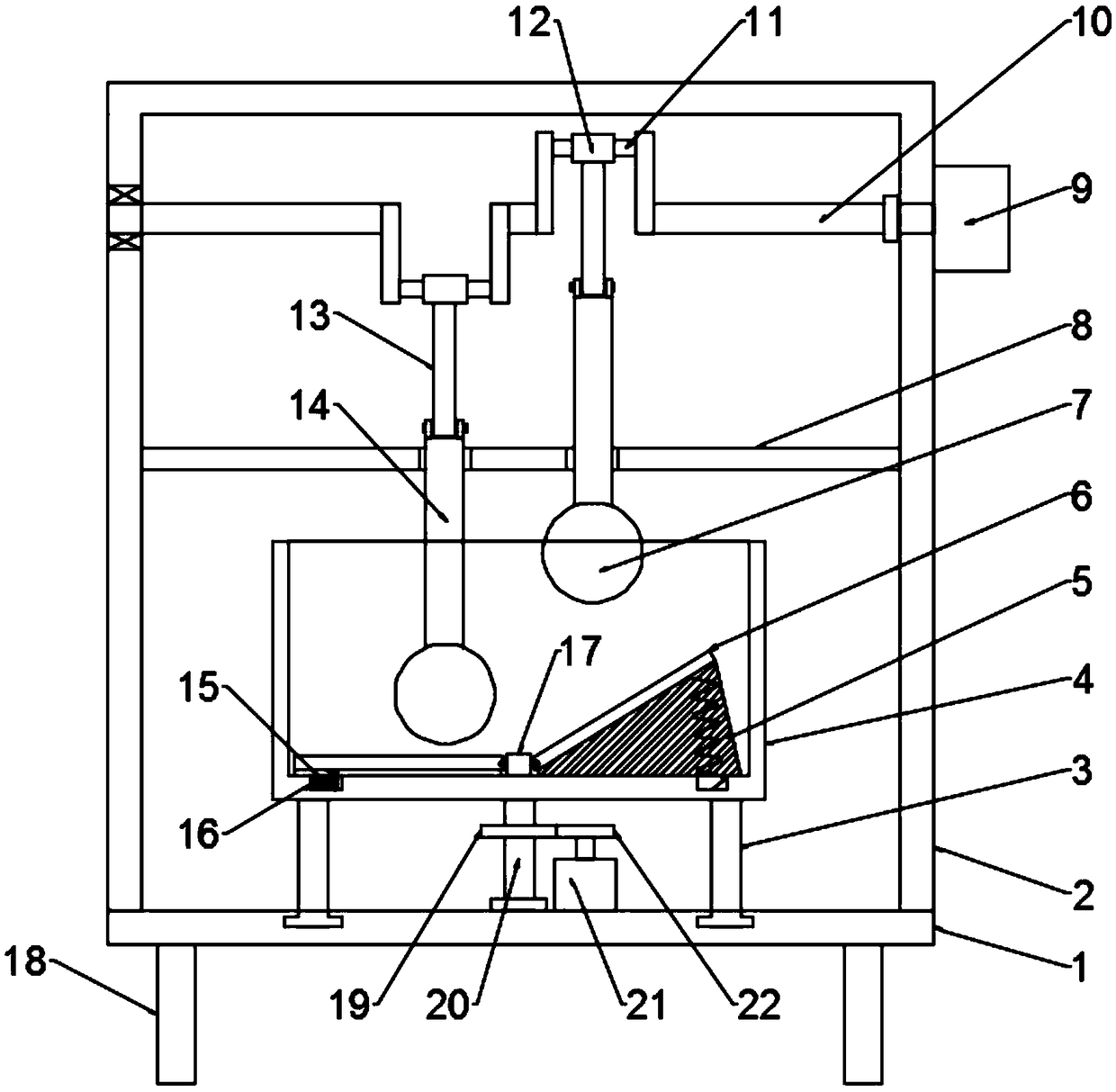

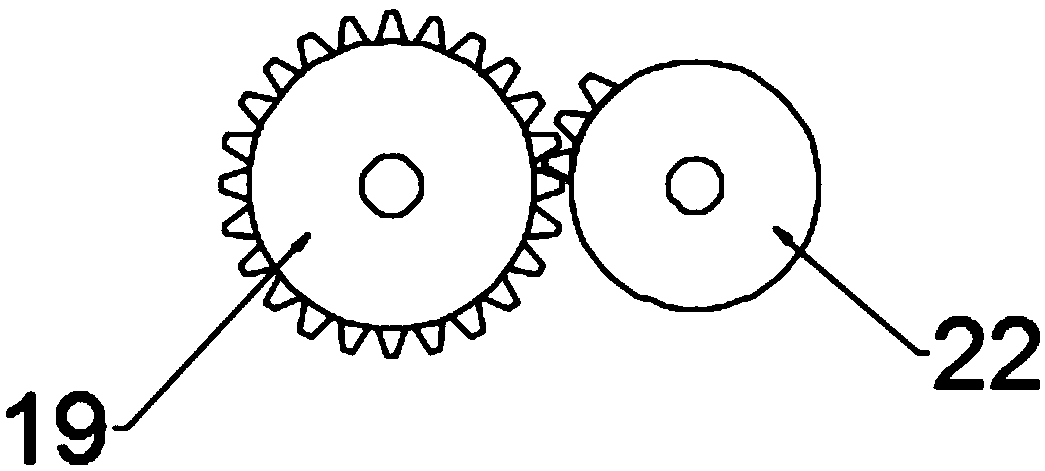

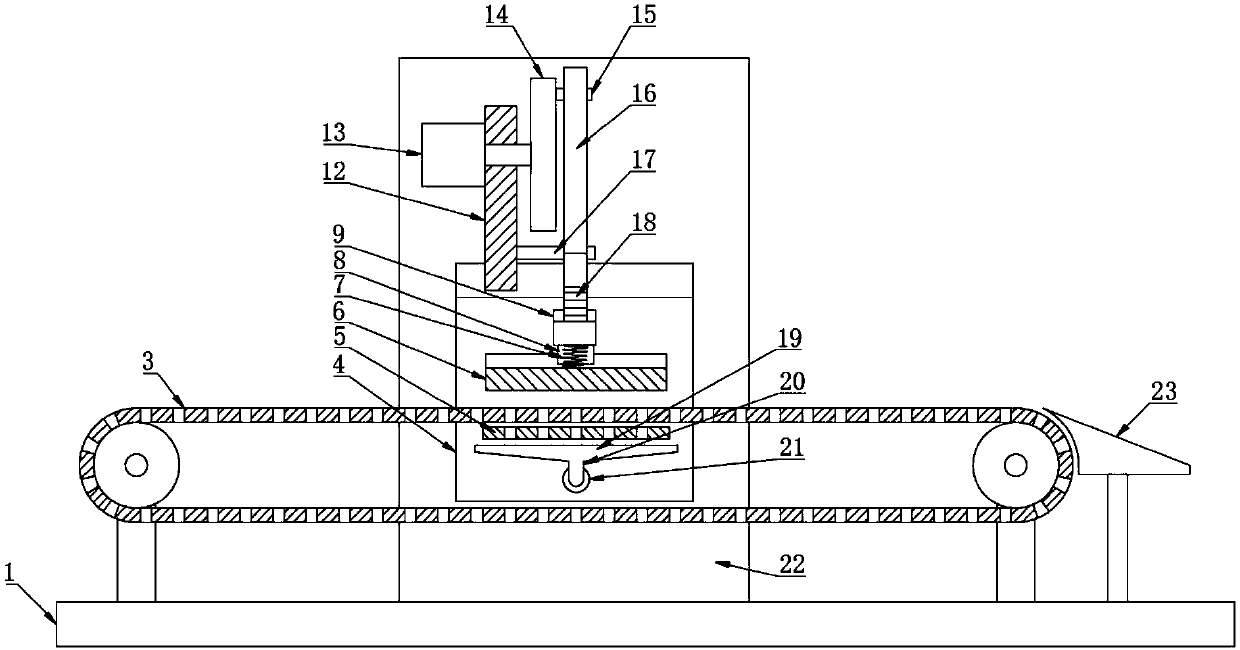

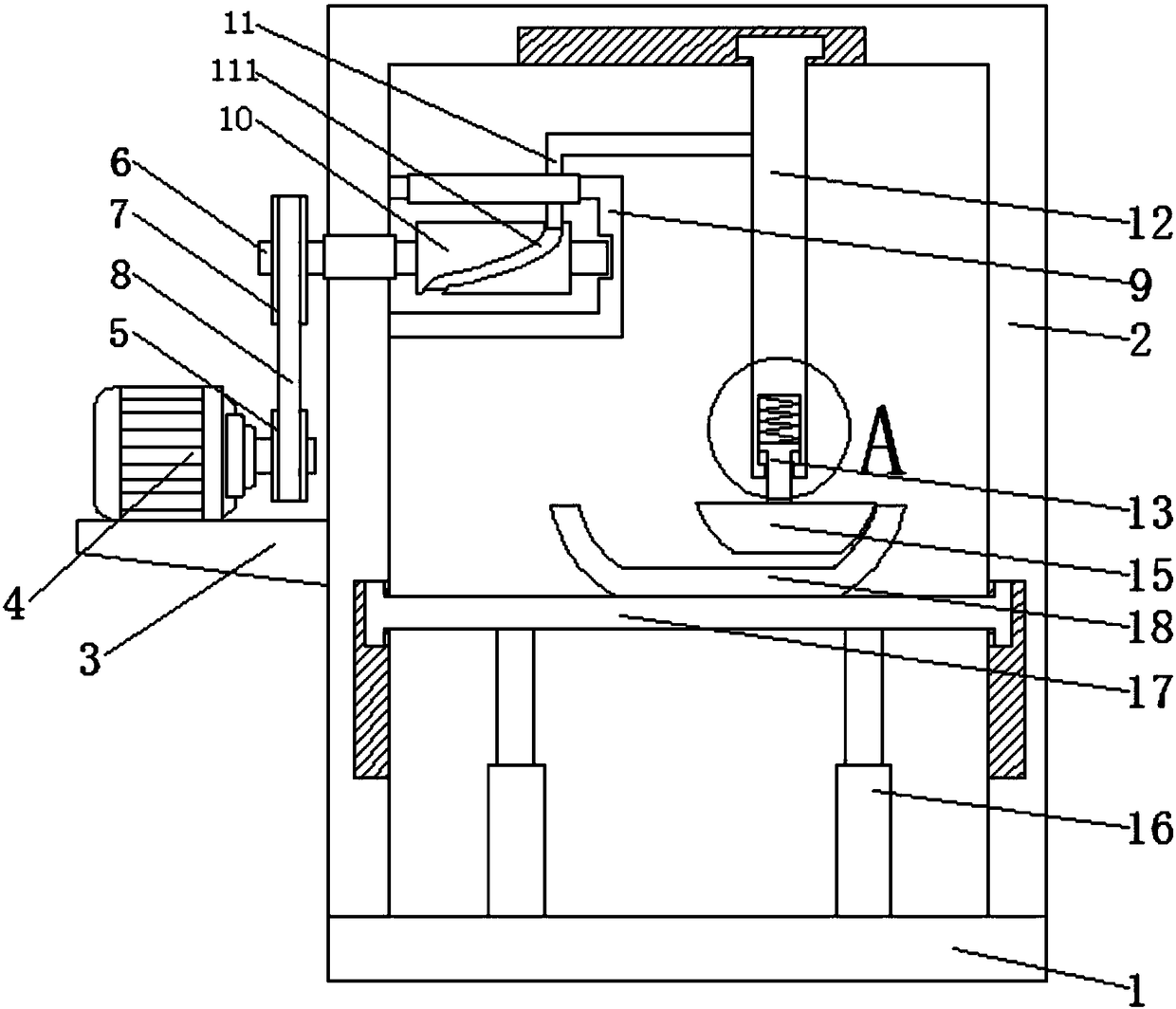

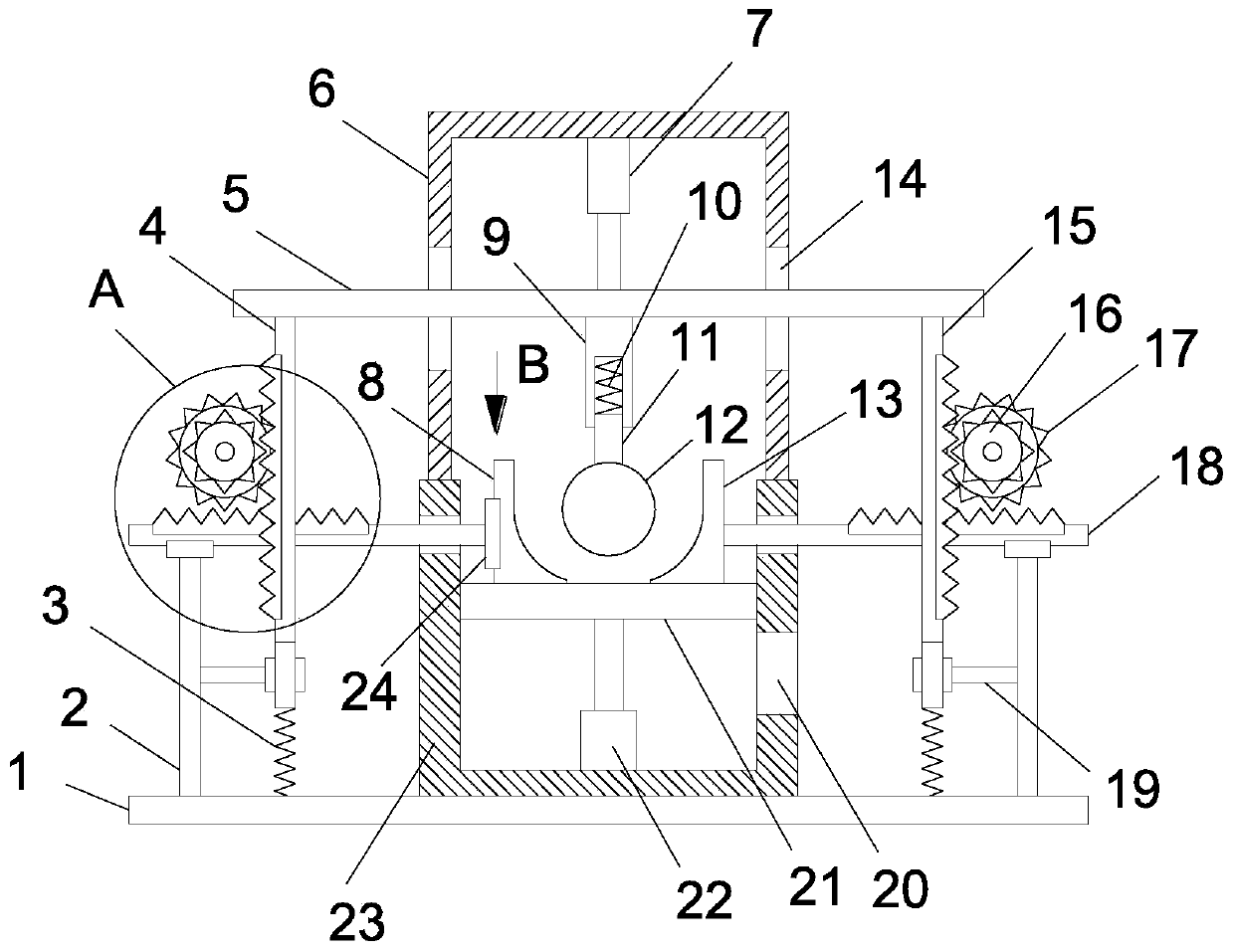

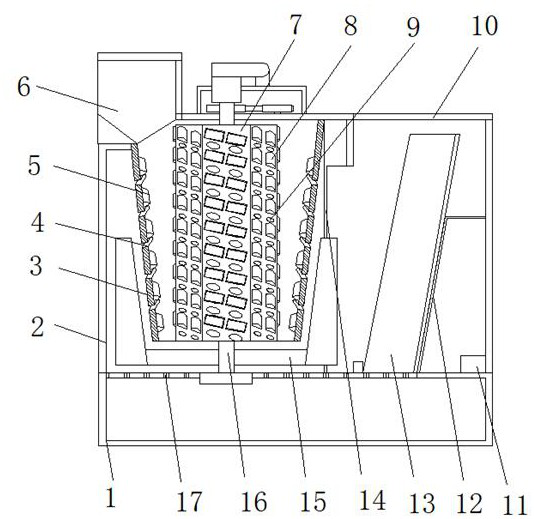

Dough kneading device for noodle production processing

InactiveCN107549224AExtend squeeze timeReduce rigid impactMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsGear wheelReciprocating motion

The invention discloses a dough kneading device for noodle production processing. The device comprises a bottom plate, wherein a slide bar is vertically arranged in a spacing sleeve in a sliding manner; a connecting rod is connected between the slide bar and a rotating wheel; a segment gear is arranged on the lower bottom of a top plate in a rotating manner; a driven belt pulley is coaxially fixedly arranged on the segment gear, a driving belt pulley is coaxially fixedly arranged on the rotating wheel, transmission belts are wound on the driving belt pulley and the driven belt pulley, and a first spacing spring is arranged between a semi-circular block and the bottom plate; a push-pull rod is horizontally fixedly arranged on a spacing pin bolt; a dough kneading groove is fixedly formed inthe bottom plate, and a gear motor is arranged at the bottom of the dough kneading groove. According to the dough kneading device, a dough in the dough kneading groove is repeatedly extruded and kneaded by up-down reciprocating motion of a dough kneading briquette, and the dough is extruded by the dough kneading briquette and is rotated, so that the dough can be extruded in different positions; and the dough is extruded rightward intermittently by a push plate, so that the dough can be concentrated and sufficiently contacted with the dough kneading briquette, and the dough kneading efficiencycan be greatly increased.

Owner:融滋合味(上海)科技有限公司

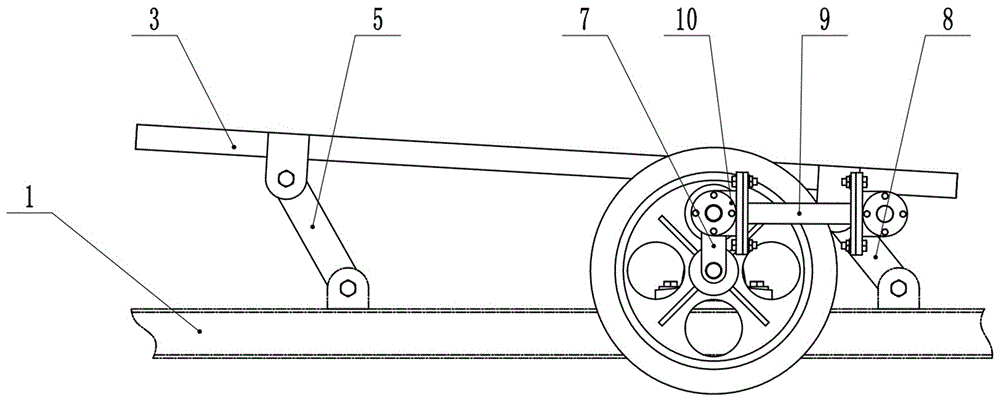

Kneading device of straw kneading machine

InactiveCN105195294AGood kneadingThe kneading device of the kneading machine has a simple structure and is easy to useCuttersGrain treatmentsFixed frameEngineering

The invention provides a kneading device of a straw kneading machine. The kneading device comprises a bottom plate, a first bracket device, a first air cylinder device, a second air cylinder device, a material collection box, a feeding device, a second bracket device, a third air cylinder device and a crushing device, wherein the bottom plate is provide with a first fixed block; the first bracket device is provided with a first bracket, a second bracket, a first inclined rod and a second inclined rod; the first air cylinder device is provided with a first air cylinder, a first pushing rod, a first pushing plate and a first slide plate; the second air cylinder device is provided with a second air cylinder, a second pushing rod, a third bracket and the like; the feeding device is provided with a feeding hopper, a material collection hopper, a material distribution block, a fixed plate and the like; the second bracket device is provided with a first fixed plate, a second fixed frame, a third inclined rod and the like; the third air cylinder device is provided with a fourth air cylinder, a fourth pushing rod, a sixth bracket and the like; the crushing device is provided with a crushing frame, a rotary wheel, crushing teeth and the like. The kneading device can be used for efficiently kneading straws and crushing the kneaded straws, so that the straws are more fine and smooth.

Owner:蔡旭东

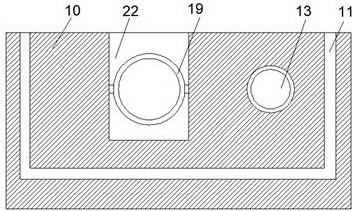

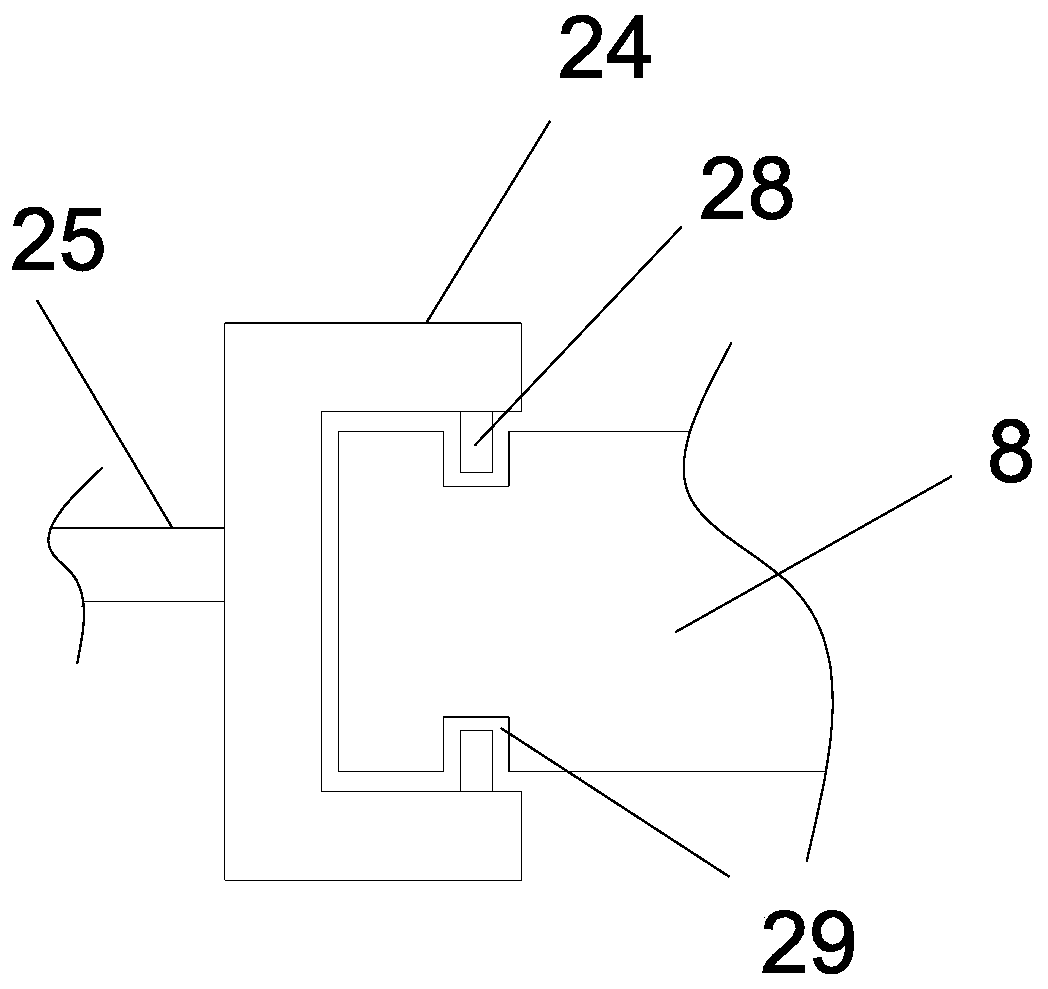

Battery cell flattening device

PendingCN110165304APrevent eversionGuaranteed kneading effectPrimary cell manufactureAssembling battery machinesEngineeringSurface structure

The invention relates to the technical field of battery preparation, and discloses a battery cell flattening device. The device comprises an ultrasonic flattening mechanism arranged on a battery cellconveying path. Ultrasonic flattening mechanisms are respectively arranged at the two ends of the battery cell to synchronously conduct ultrasonic flattening on the two ends of a battery cell, and each ultrasonic flattening mechanism comprises an ultrasonic flattening head, wherein grooves are formed in the ultrasonic flattening heads, and the two ends of the battery cell are correspondingly inserted into the grooves in the ultrasonic flattening heads at the two sides, and the bottoms of the grooves are of a grid-shaped convex surface structure. According to the battery cell flattening deviceprovided by the invention, the grooves are formed in the ultrasonic flattening heads, so that the end parts of the battery cell can be limited, and battery cell materials is prevented from turning outwards, thereby guaranteeing the flattening effect. The grid-shaped convex surface structures at the bottoms of the grooves enable the battery cell materials on the end surface of the battery cell to be uniformly distributed in the grooves, so that the battery cell materials can be better flattened, thereby improving the flattening effect. In addition, the battery cell materials on the end face ofthe battery cell can be fixed and limited, so that the battery cell materials can be in better contact with the ultrasonic kneading heads to prevent outward turning and improve the kneading efficiency.

Owner:WUHAN YIFI LASER EQUIP CO LTD

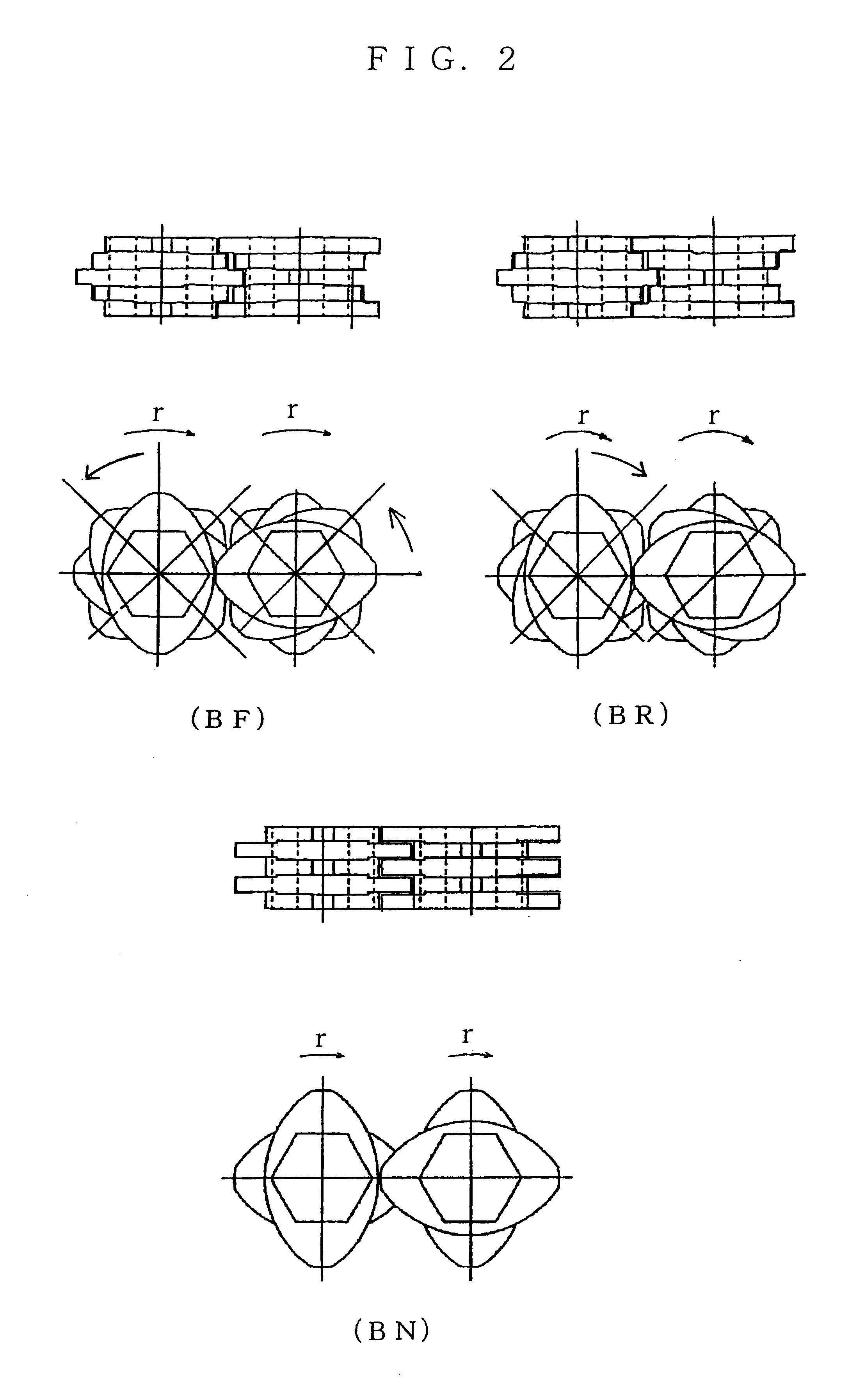

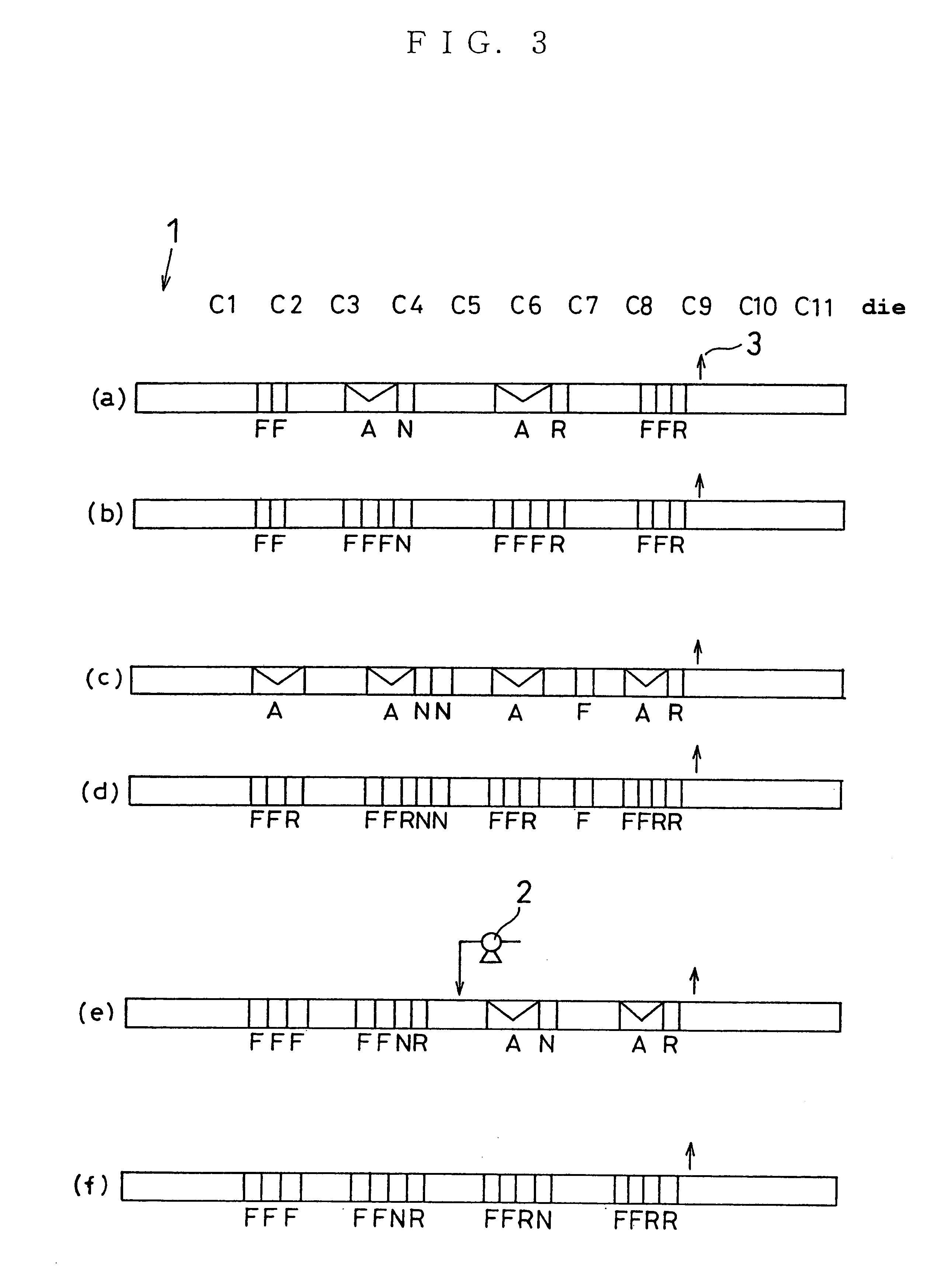

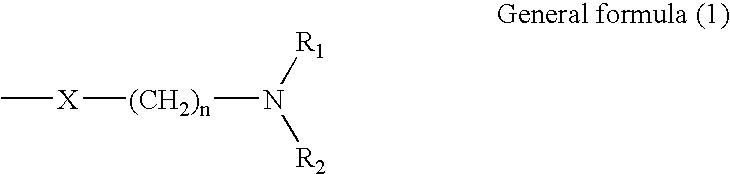

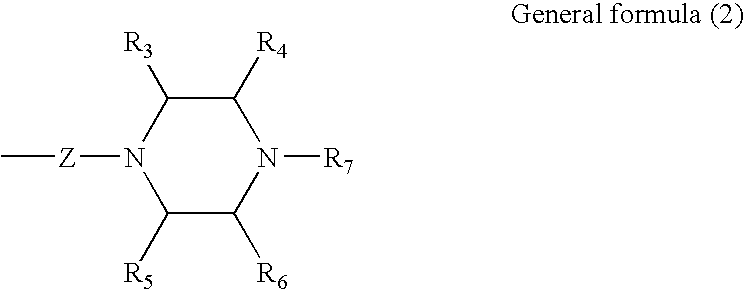

Method for manufacturing olefinic thermoplastic elastomer composition

InactiveUS6599981B2Increase production capacityNice appearanceChemical/physical/physico-chemical stationary reactorsPolyolefinThermoplastic elastomer

This invention relates to a method for manufacturing an olefinic thermoplastic elastomer composition, characterized by disposing specific kneading segment at least at one place of the screw on the occasion of manufacturing an olefinic thermoplastic elastomer composition comprising a polyolefin resin and a crosslinked rubber by dynamic crosslinking with a twin screw extruder.

Owner:MITSUI INC

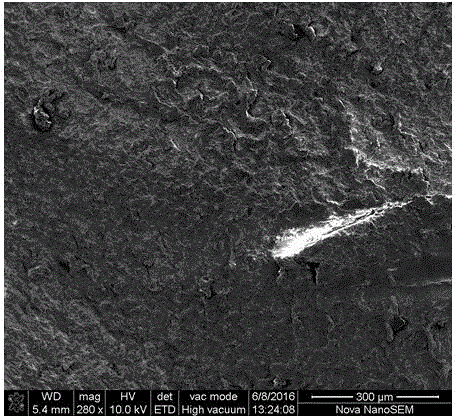

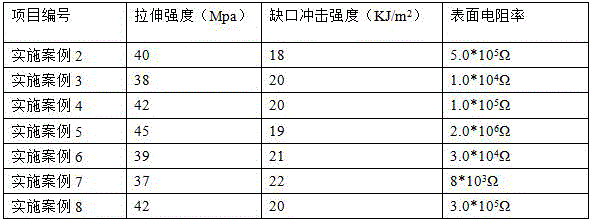

Preparation method of static-conductive PVC (polyvinyl chloride) mining pipe

The invention discloses a preparation method of a static-conductive PVC (polyvinyl chloride) mining pipe. The method comprises the following steps: (1) adding a PVC resin and a two-dimensional-plane-structure nano carbon material into a kneader, and kneading to obtain a PVC / nano carbon master batch; and (2) proportionally adding the PVC resin, conductive carbon black, a compatibilizer, a heat stabilizer, lubricant and processing aids into the PVC / nano carbon master batch, stirring and mixing, and carrying out melting and extrusion forming to obtain the mining pipe finished product. The method can enhance the static conductivity of the PVC mining pipe, and can also enhance the impact resistance, corrosion resistance, heat stability and other properties of the PVC mining pipe.

Owner:DEYANG CARBONENE TECH

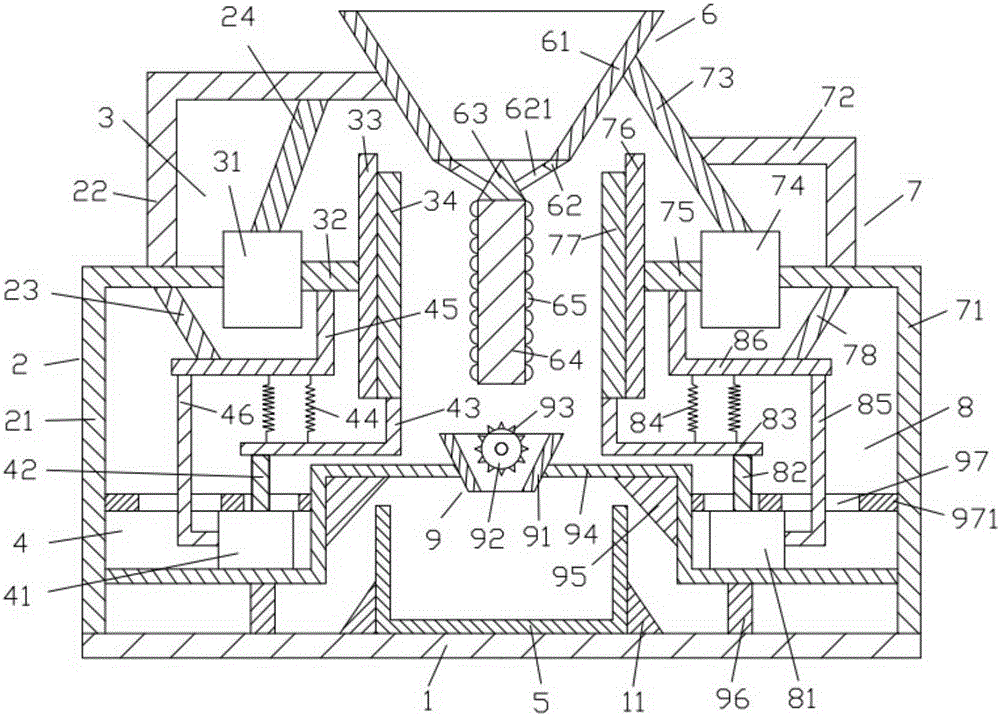

Medicinal material rubbing equipment for traditional Chinese medicine processing

The invention discloses medicinal material rubbing equipment for traditional Chinese medicine processing. The medicinal material rubbing equipment for traditional Chinese medicine processing comprisesa grinding tank, a conveying tank is fixedly connected to the top of the grinding tank, a feeding tank is fixedly connected to the right side of the top of the conveying tank, grinding boxes are fixedly connected to the tops of the two sides of an inner cavity of the grinding tank, and arc-shaped plates are fixedly connected to the bottoms of inner cavities of the grinding boxes. Through cooperation of the grinding tank, the conveying tank, the feeding tank, the grinding boxes, the arc-shaped plates, first motors, lead screws, sliding sleeves, sleeves, reset springs, limiting plates, first vertical plates, first grinding rollers, partition plates, fixed plates, rotating discs, connecting rods, moving blocks, second vertical plates, second grinding rollers, first filter screens, second filter screens, a discharging pipe, a second motor, a rotating rod, spiral blades and a discharge pipe, the advantage of efficient rubbing is achieved, and the problems that at present, most devices adopt manual rubbing, consequently, time and labor are wasted, efficiency is low, and the effect is poor are solved.

Owner:魏喜荣

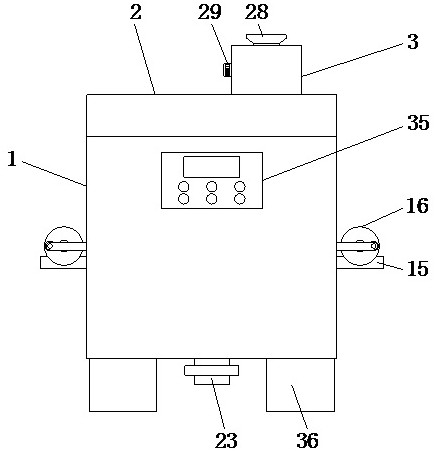

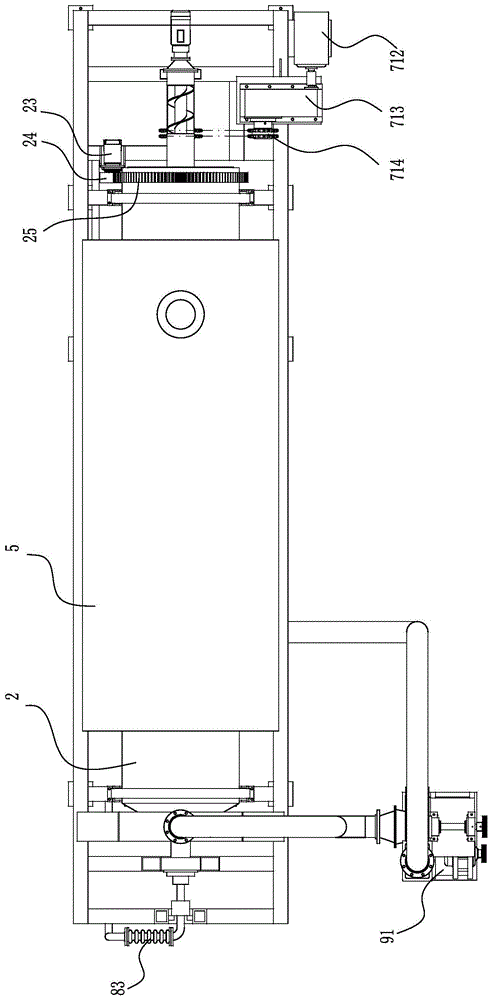

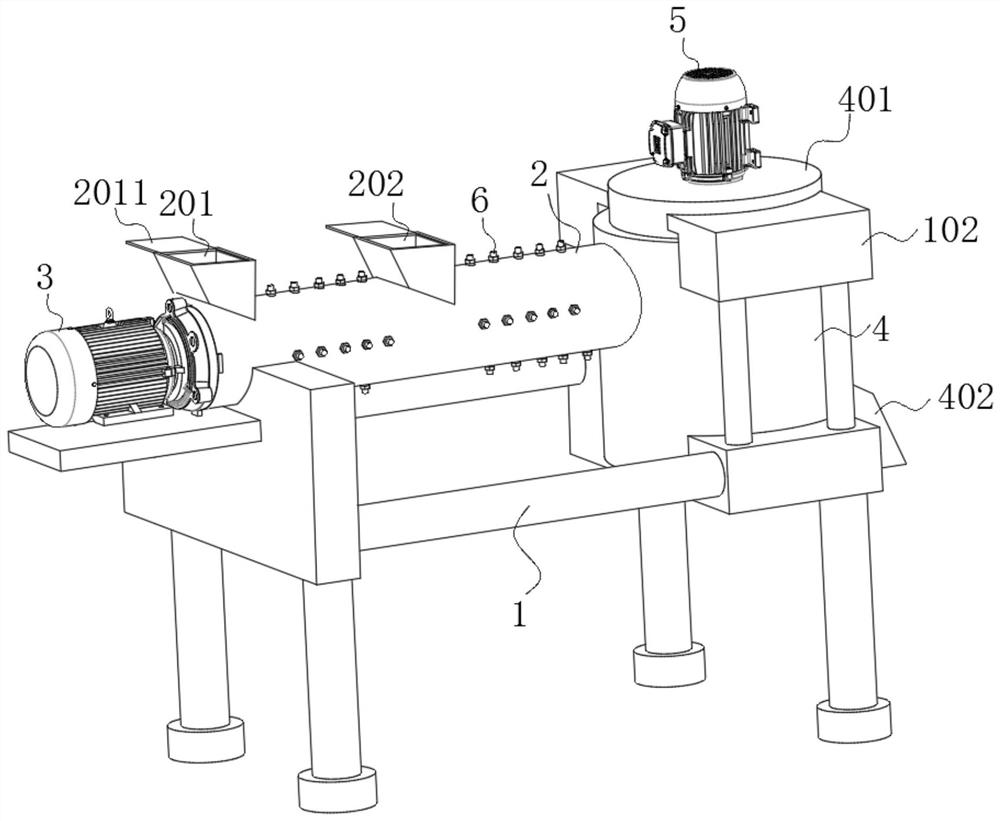

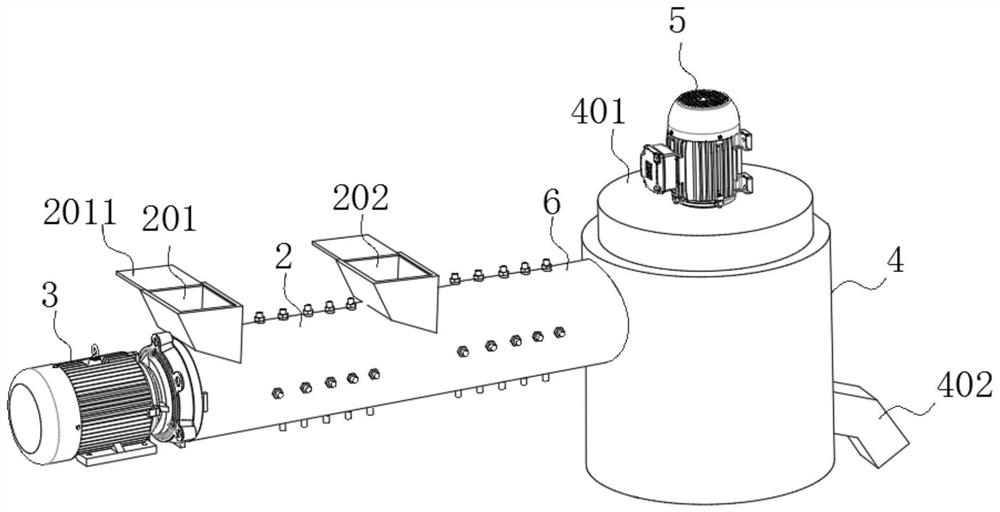

Environment-friendly kneading machine

PendingCN109395654AKnead fastImprove kneading efficiencyRotary stirring mixersTransportation and packagingMotor driveEngineering

The invention discloses an environment-friendly kneading machine. The problem that an existing kneading machine is provided with no heating device and is low in kneading efficiency is solved. The environment-friendly kneading machine comprises a stirring barrel, a kneading barrel and a packing auger barrel which are connected and communicated in sequence. A stirring shaft and a stirring blade arevertically arranged in the stirring barrel, a stirring motor drives the stirring shaft to rotate, two kneading rolls are arranged in the kneading barrel, and a kneading motor drives the two kneading rolls to rotate in opposite directions at ununiform speeds through a transmission assembly. A packing auger is arranged in the packing auger barrel in the axial direction, and a packing auger motor drives the packing auger to rotate. Hot air pipes are arranged at the tops in the stirring barrel and the kneading barrel respectively, the hot air pipes are communicated with nozzles respectively, and the hot air pipes are communicated with an air heater through connecting pipes. A heat exchange pipe is wound around one side of the packaging auger barrel. Heat generated by the air heater of the environment-friendly kneading machine is fed into the stirring barrel and the kneading barrel, and the kneading efficiency on materials is improved. The temperature of the kneaded materials can be reducedthrough the heat exchange pipe on the packing auger barrel.

Owner:威海天宇新材料科技有限公司

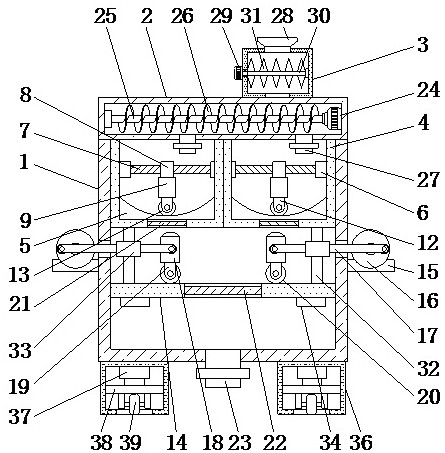

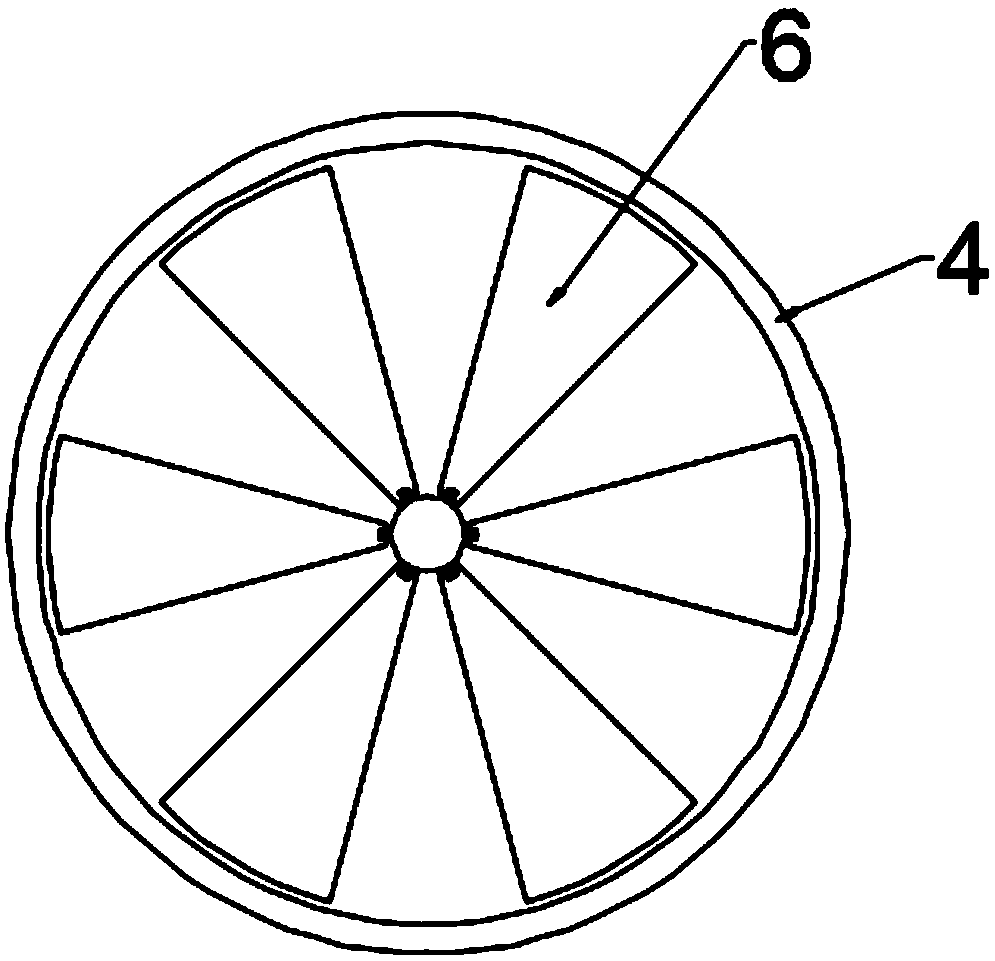

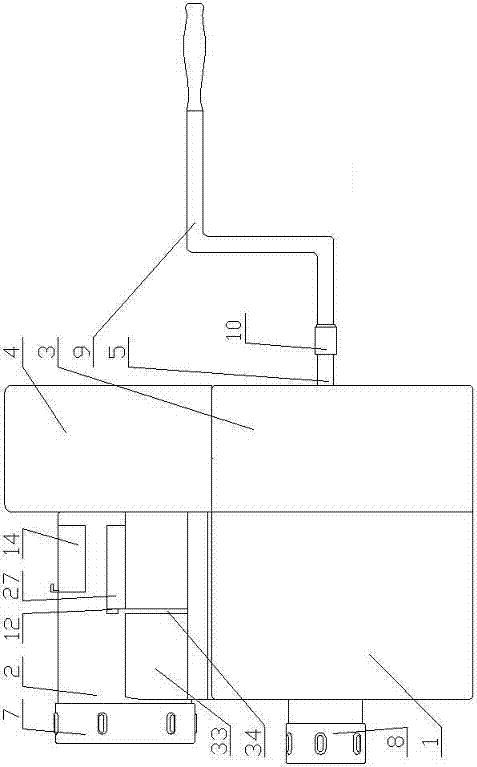

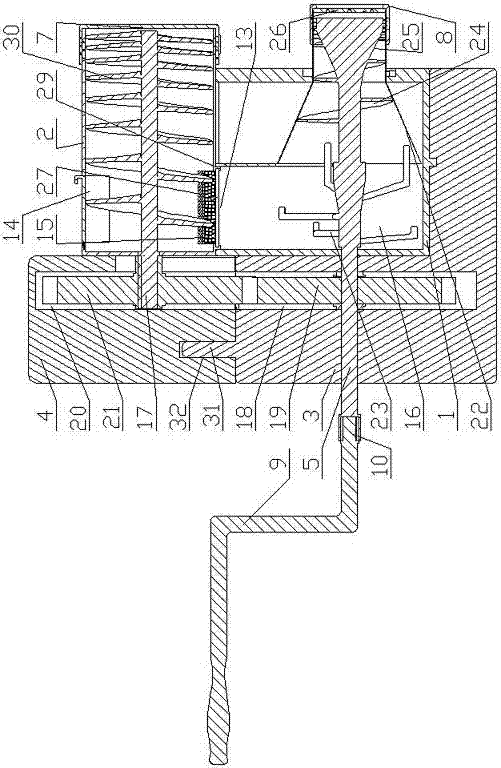

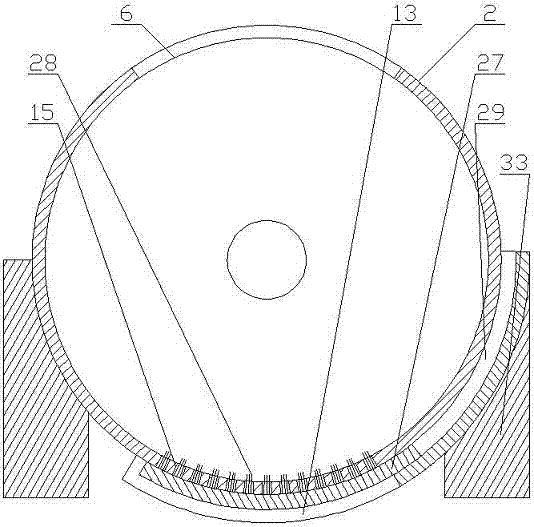

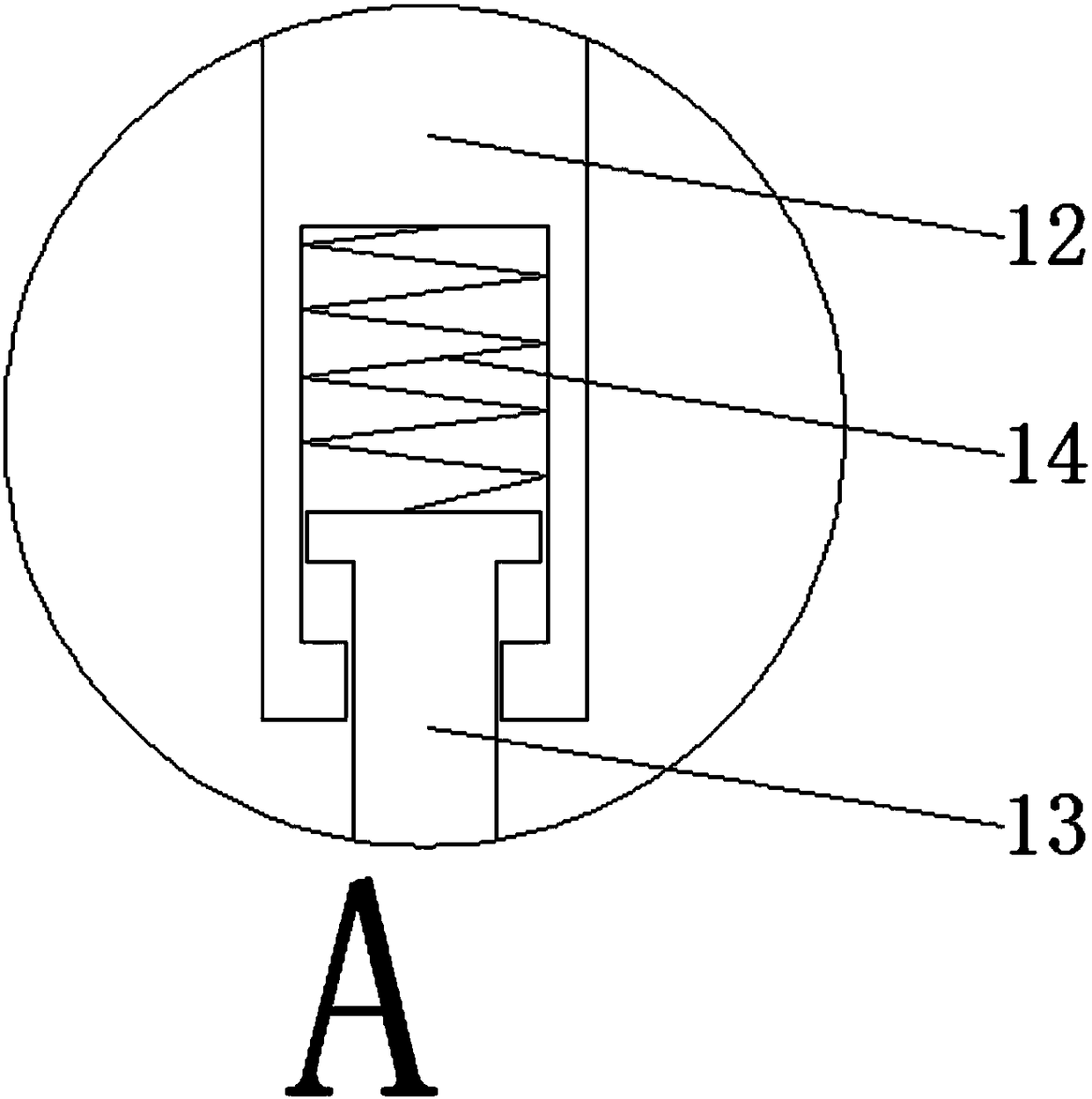

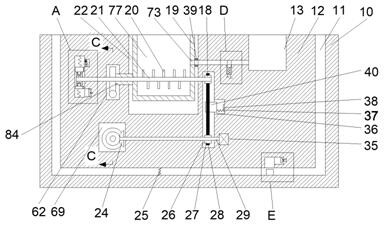

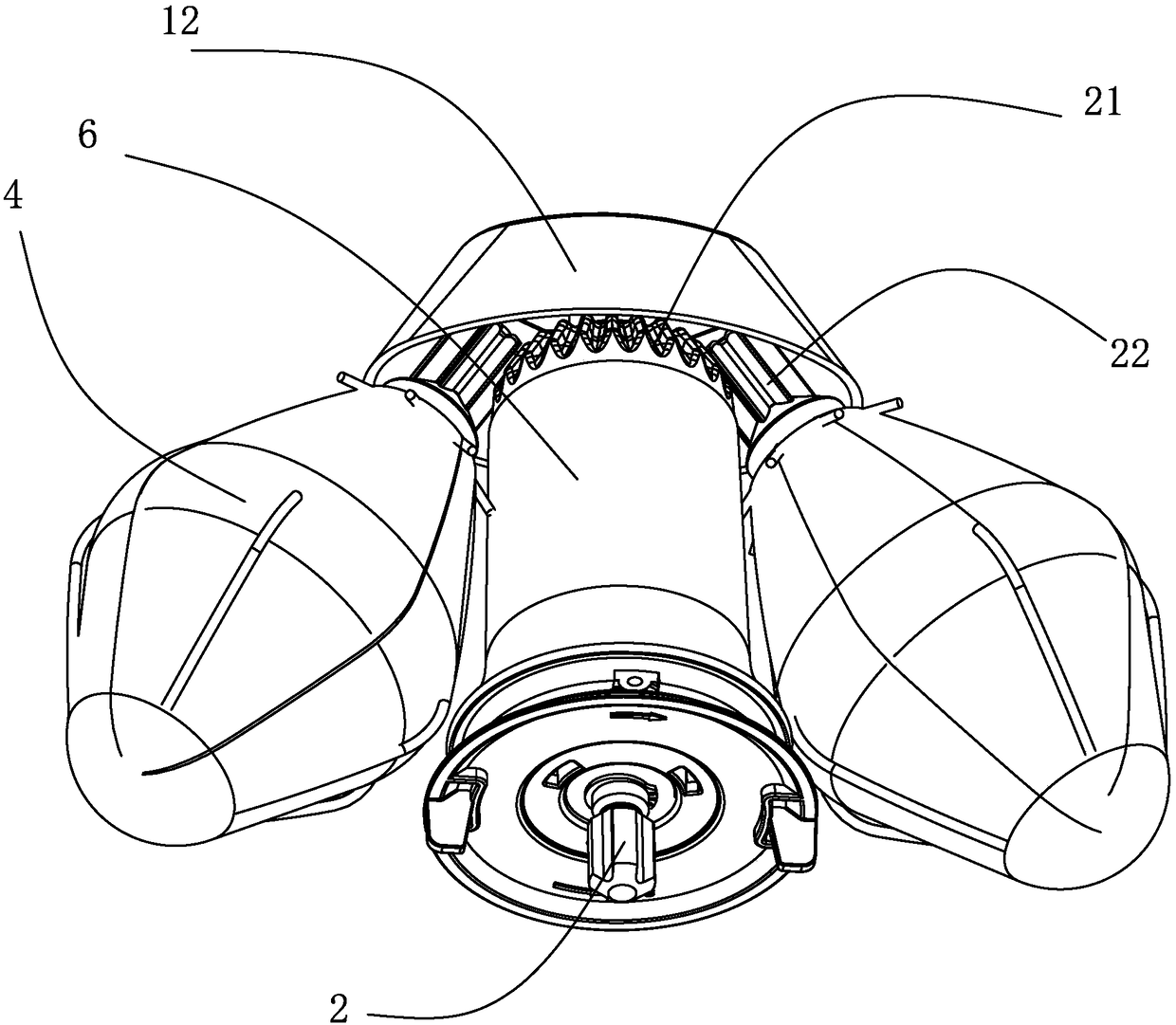

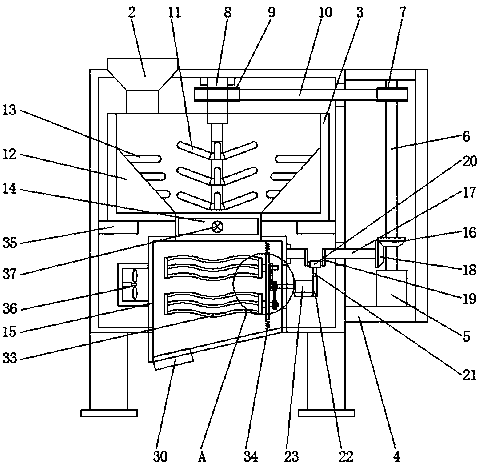

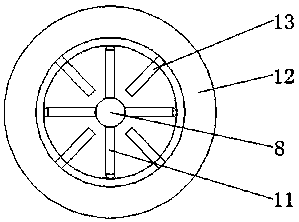

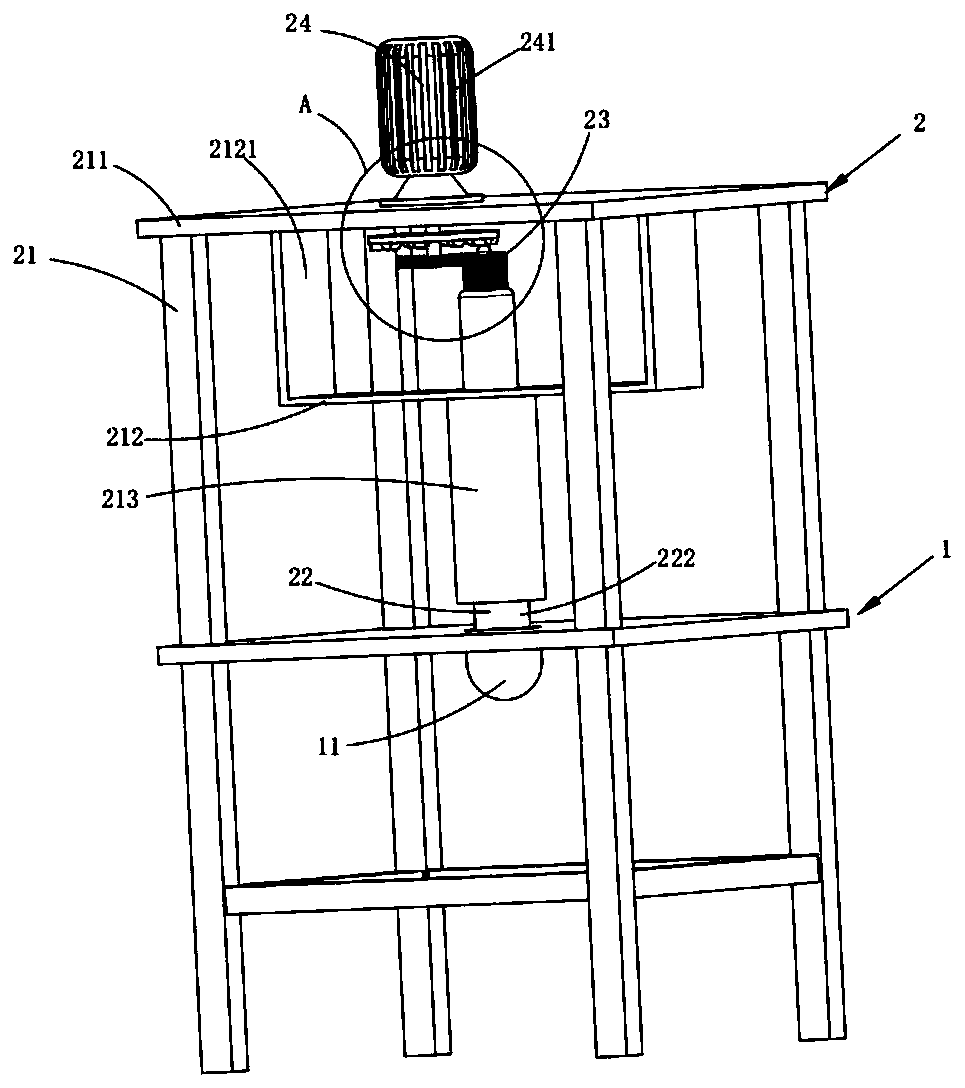

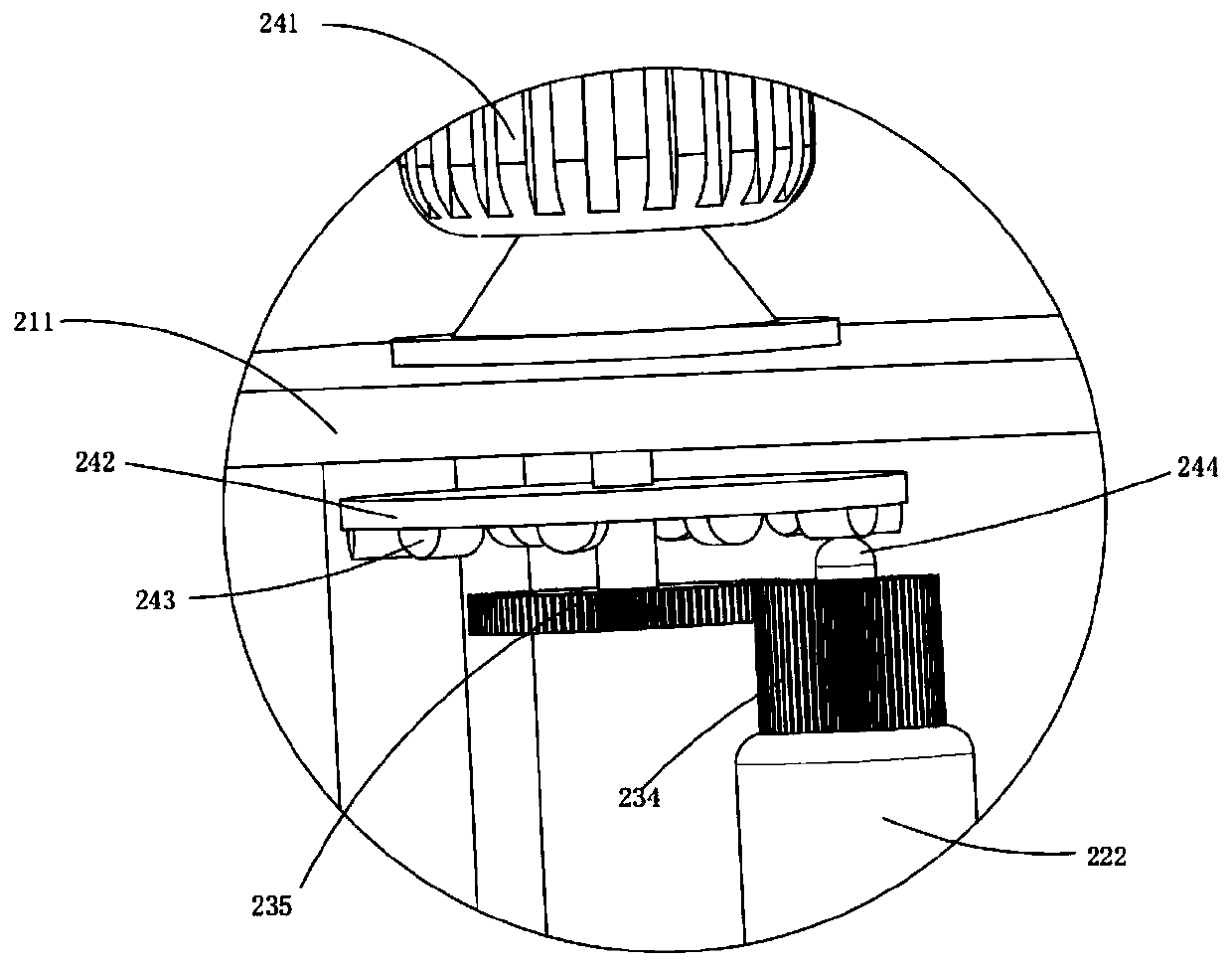

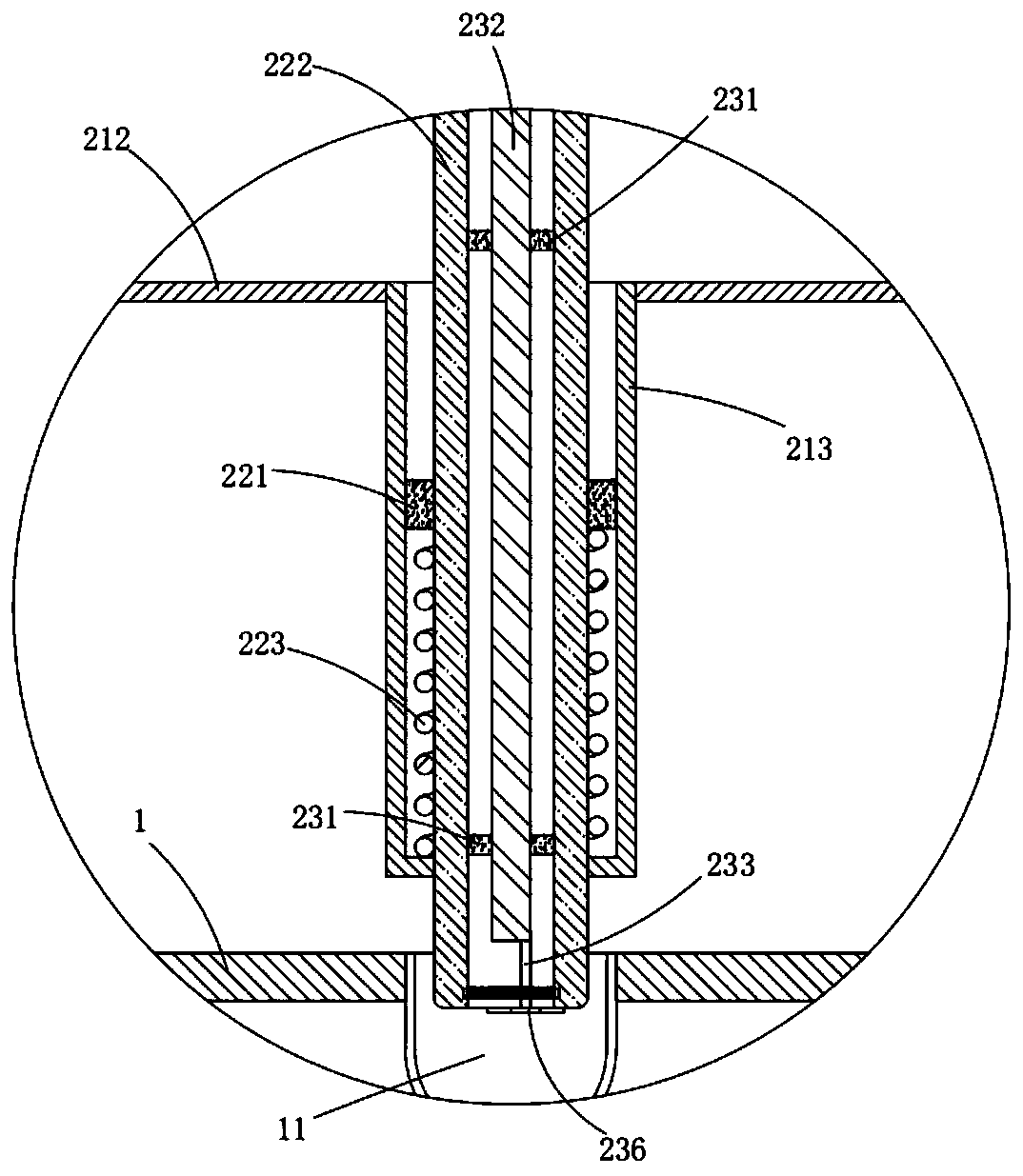

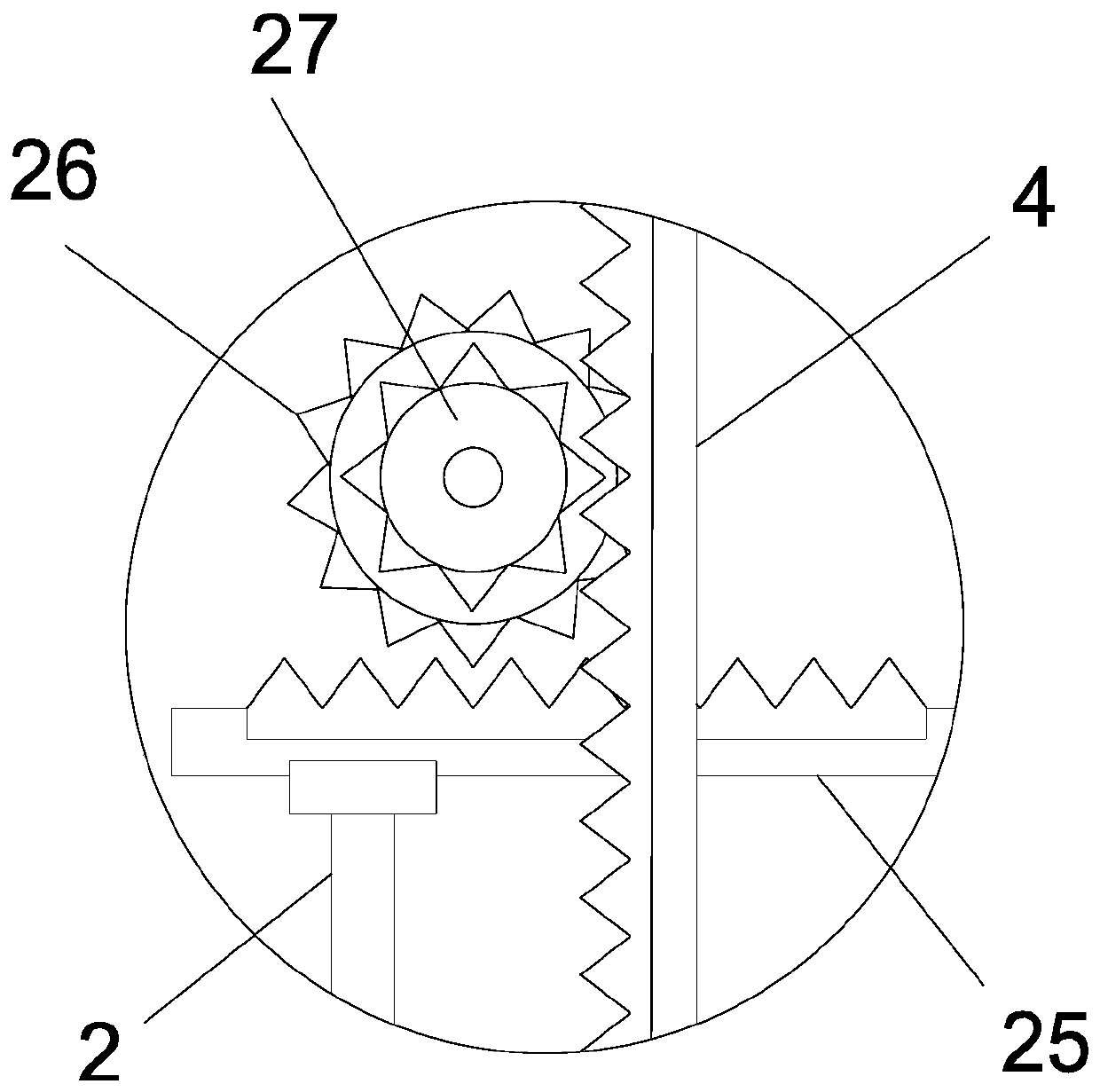

Crank type continuous dough kneading device for flour processing

InactiveCN108967459AImprove kneading efficiencyGood kneadingMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsGear wheelEngineering

The invention discloses a crank type continuous dough kneading device for flour processing. The crank type continuous dough kneading device comprises a bottom plate, a dough kneading frame, an installation frame, a rotary shaft, a gear, an incomplete gear, a first motor, an installation rod, fan-shaped collecting plates, springs, a second motor, a crank, a rod journal, a sleeve, a connection rod,a movable rod and two dough kneading balls. The crank type continuous dough kneading device is provided with the second motor, the crank, the rod journal, the sleeve, the movable rod, the dough kneading balls and the fan-shaped collecting plate, the two dough kneading balls knead dough continuously, the dough kneading efficiency is high, when the dough kneading balls move upwards, the corresponding fan-shaped collecting plates rotate upwards under the effects of springs, the dough is collected, so that dough kneading for the next time is facilitated, the dough can be further kneaded more sufficiently and uniformly, the dough kneading efficiency is improved, the first motor, the incomplete gear and the gear are arranged to intermittently drive the dough kneading frame to rotate a certain angle, so that the dough kneading balls can knead and press the different parts of the dough, thus dough kneading is more sufficient, and the dough kneading speed is increased.

Owner:CHANGSHA FENGYING MACHINERY TECH CO LTD

Rubbing and drying device for radix codonopsis

InactiveCN107669729AImprove processing efficiencyIncrease profitDrying gas arrangementsDrying chambers/containersCodonopsisEngineering

The invention discloses a rubbing and drying device for radix codonopsis. The rubbing and drying device comprises a base, wherein a left supporting plate and a right supporting plate are separately arranged on the left side and the right side of the top of the base; heat collecting plates are fixedly connected to the left supporting plate and the right heat collecting plate; sliding rails are respectively arranged on the bottom walls of the tops of the left and right heat collecting plates; a rack is in sliding connection with the lower parts of the sliding rails; a rubbing plate is connectedto the bottom of the rack through springs; a fixed plate is fixedly connected between the left supporting plate and the right supporting plate; a speed reducer is arranged on the fixed plate; a rotarytable is connected with a motor shaft of the speed reducer; a first pin shaft is arranged on the front end face of the rotary table; a sector gear meshed with the rack is rotationally connected to the bottom of the front end face of the fixed plate by a second pin shaft; a swing rod is fixedly connected to the top of the sector gear; a first pin shaft is positioned in a rectangular opening of theswing rod. According to the rubbing and drying device disclosed by the invention, the radix codonopsis is rubbed by left-right movement of the rubbing plate and is repeatedly performed, and the rubbing effect is good; by arranging compression springs, the rubbing plate can adapt to the radix codonopsis with different thicknesses, and the rubbing strength is more uniform.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

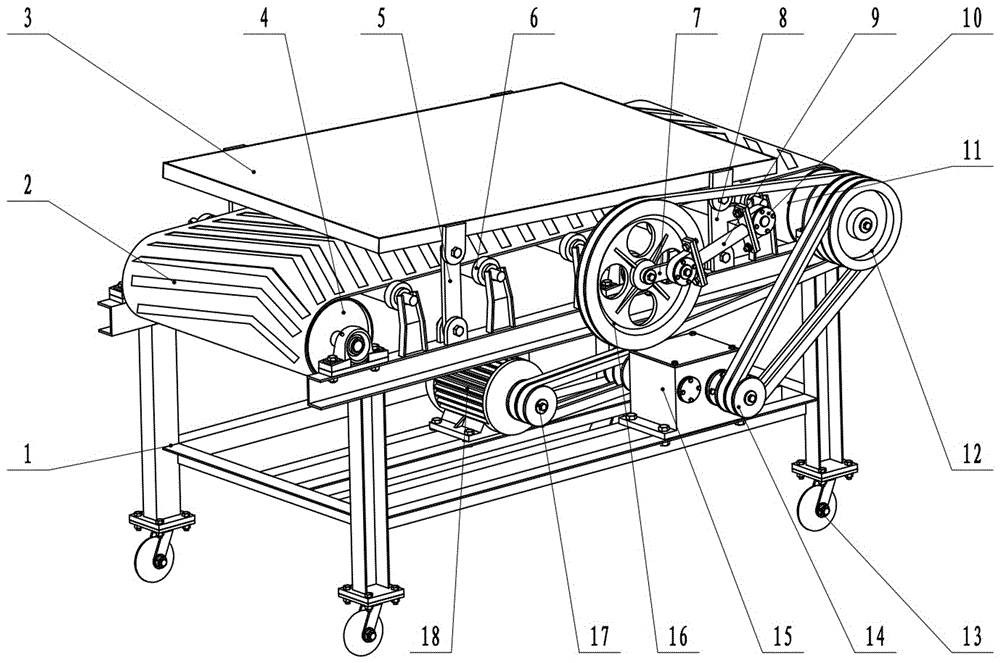

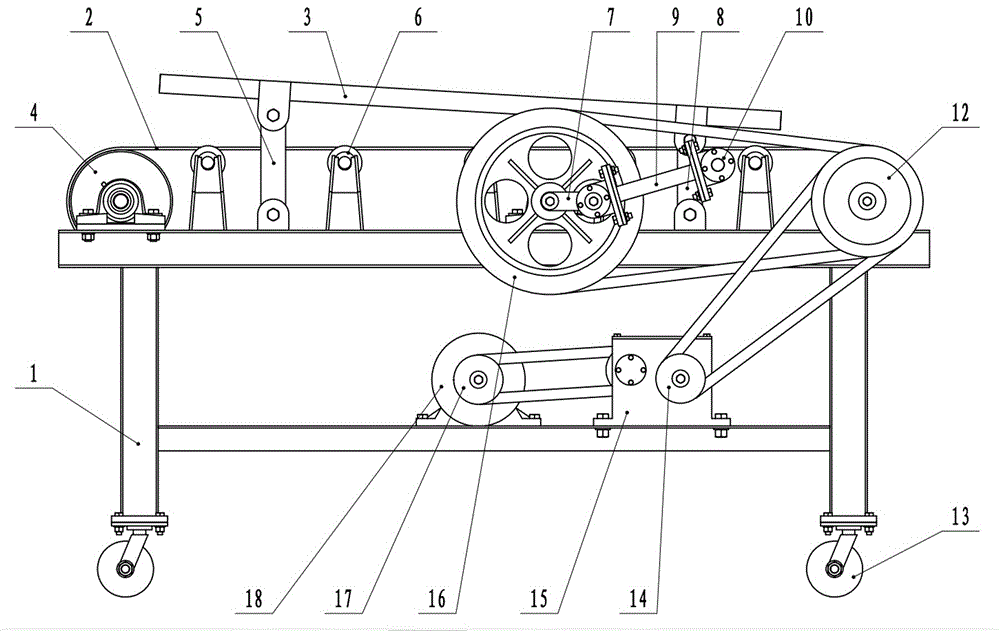

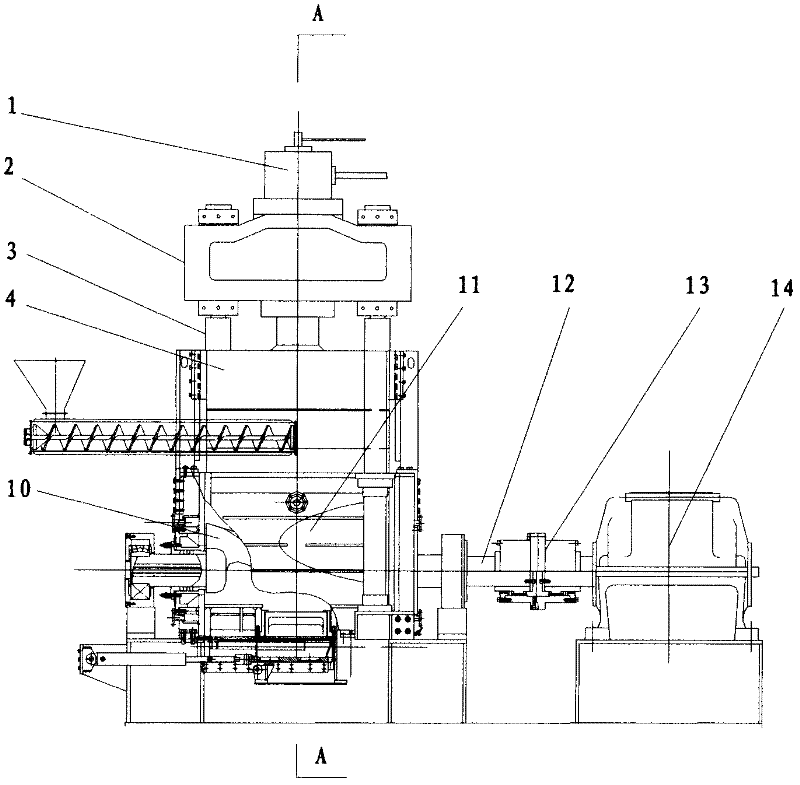

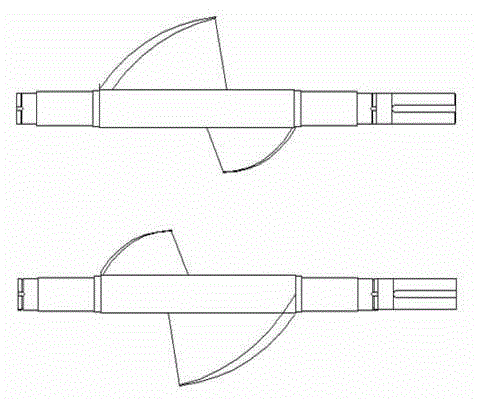

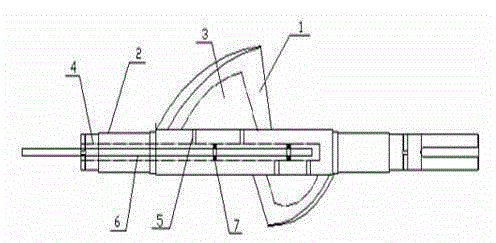

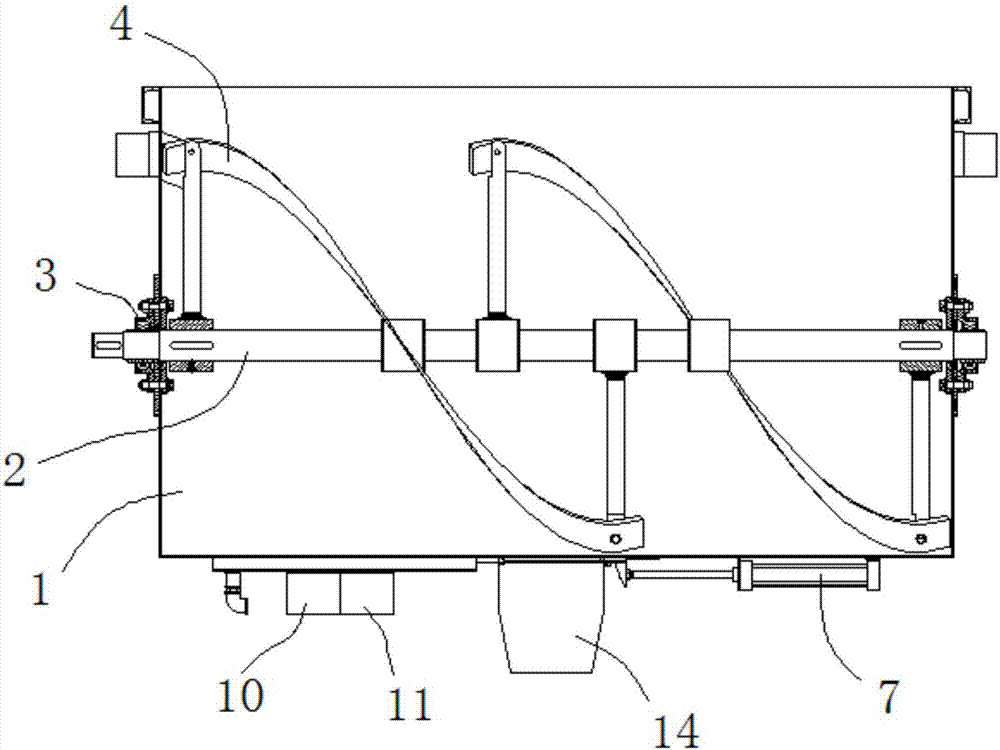

Crank rocker type root traditional Chinese medicinal material kneading machine

InactiveCN107521929AImprove kneading efficiencySimple structure and principleConveyorsCleaning using toolsMedicinal herbsFiber

The invention discloses a crank rocker type root traditional Chinese medicinal material kneading machine which mainly comprises a rack, a drive roller, a conveying belt, a driven roller, a supporting roller, a motor, a gear box, supporting wheels, a multi-stage belt drive and a kneading mechanism, wherein the supporting wheels are arranged below the rack; the motor and the gear box are arranged at middle-lower positions of the rack; the conveying belt is wound on the drive roller and the driven roller; the supporting roller is mounted at a position, which is located below the upper part of the conveying belt, of the upper portion of the rack; the kneading mechanism is mounted at the upper part of the rack and is located above the conveying belt; and the multi-stage belt drive enables the motor, the gear box, the drive roller and the kneading mechanism to be connected. The kneading mechanism enables a kneading plate to form reciprocating motion to rub off fibers of root traditional Chinese medicinal materials between the conveying belt and the kneading plate and straighten main roots of the root traditional Chinese medicinal material via rubbing; the diameter of the drive roller is smaller than that of the driven roller, and due to a herringbone pattern design on the conveying belt, the root traditional Chinese medicinal materials on the conveying belt can be conveyed to the back conveniently, and the kneading quality is guaranteed; and by the design of the supporting wheels, the machine can conveniently move in a working region, and the transportation performance is improved.

Owner:甘肃省农业机械化技术推广总站

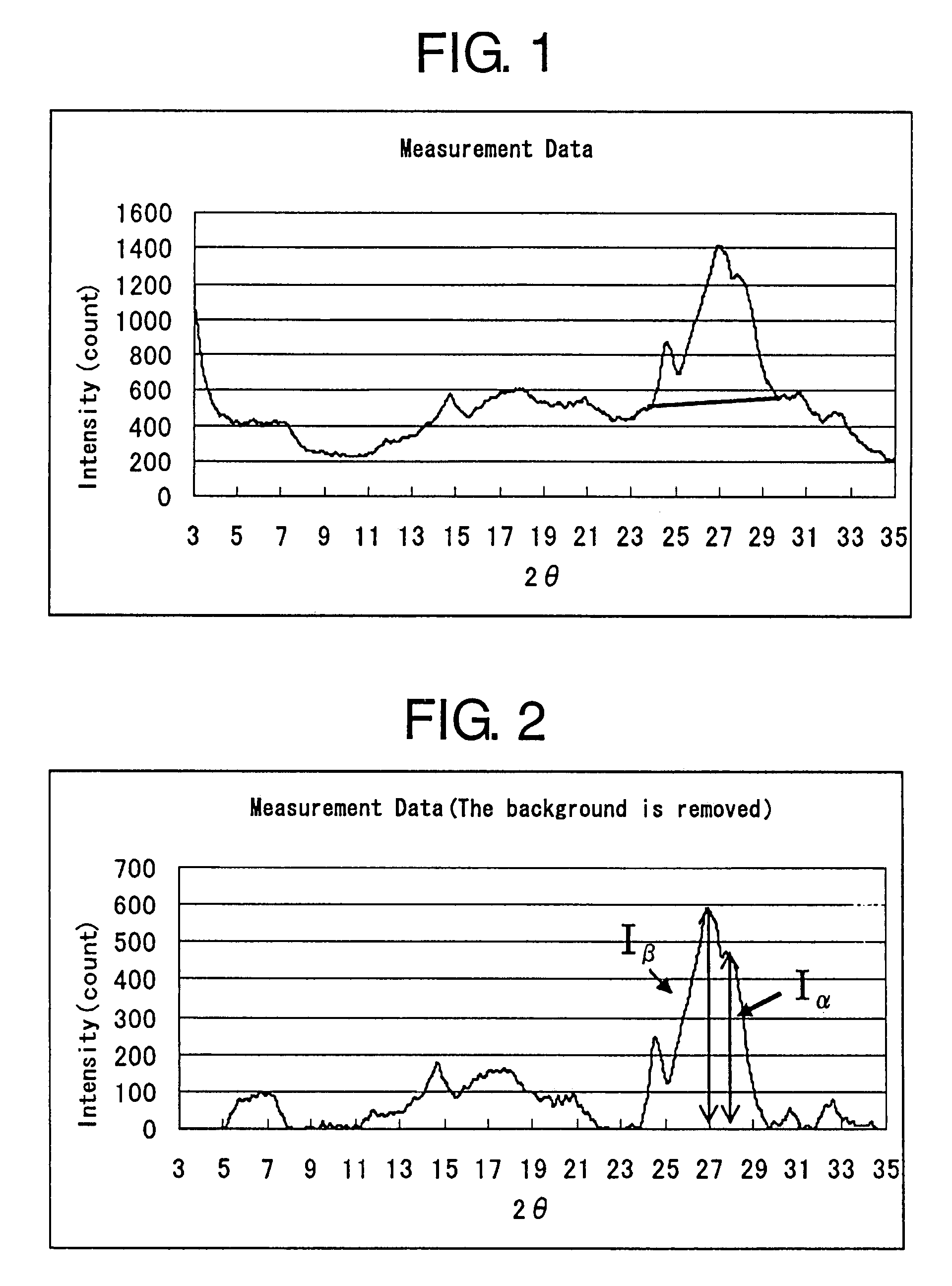

Process for producing dichlorodiketopyrrolopyrrole pigment of the alpha modification, dichlorodiketopyrrolopyrrole pigment of the alpha modification produced by the process, and coloring composition using the same

A process for producing dichlorodiketopyrrolopyrrole pigment of the α modification, which comprises wet milling crude dichlorodiketopyrrolopyrrole pigment wherein an α modification and a β modification coexist in the presence of a milling agent and a wetting agent, dichlorodiketopyrrolopyrrole pigment of the α modification obtained the process and a color composition which contains the pigment and a pigment carrier.

Owner:TOYO INK SC HOLD CO LTD

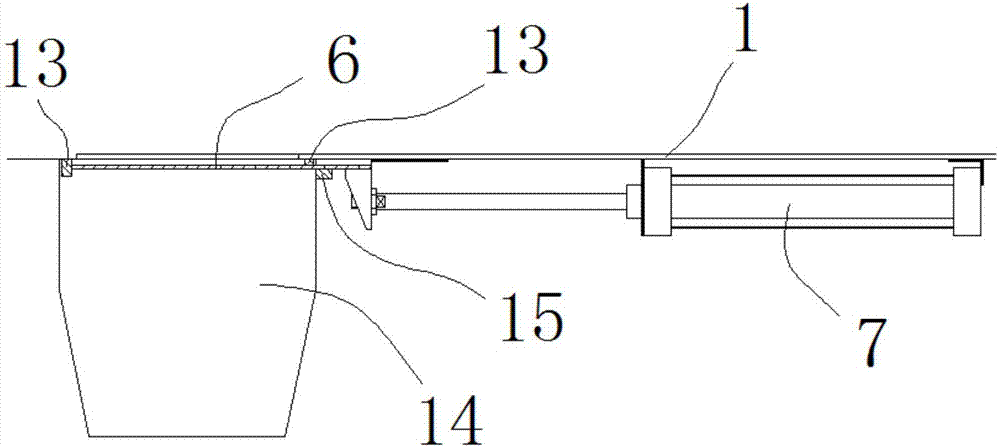

Juice pressing device of colorful noodle maker

InactiveCN107183099AWell mixedImprove efficiencyMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsEngineeringVegetable Juices

The invention discloses a juice pressing device of a colorful noodle maker. The top of the juice pressing device is provided with a feeding inlet, and one end of the juice pressing device is provided with a residue discharge outlet fixedly provided with an end cover through threads; a main shaft B inside the juice pressing device is driven through a driving device. According to the above structure, the juice pressing device of a colorful noodle maker presses vegetable juice out, and compared with juice squeezed by a juice extractor, the juice pressing device of a colorful noodle maker can effectively reduce the residue content in the juice, thereby guaranteeing the taste of colorful noodles.

Owner:CAOXIAN LUGONG MACHINERY CO LTD

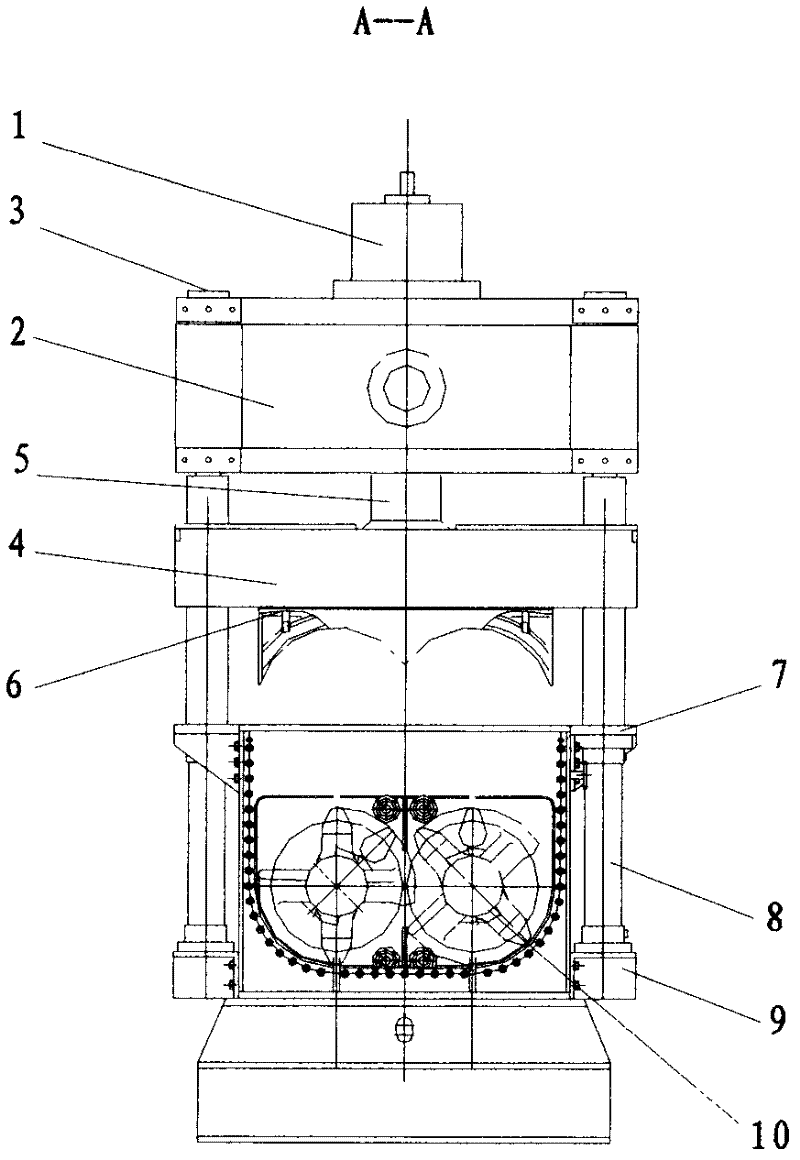

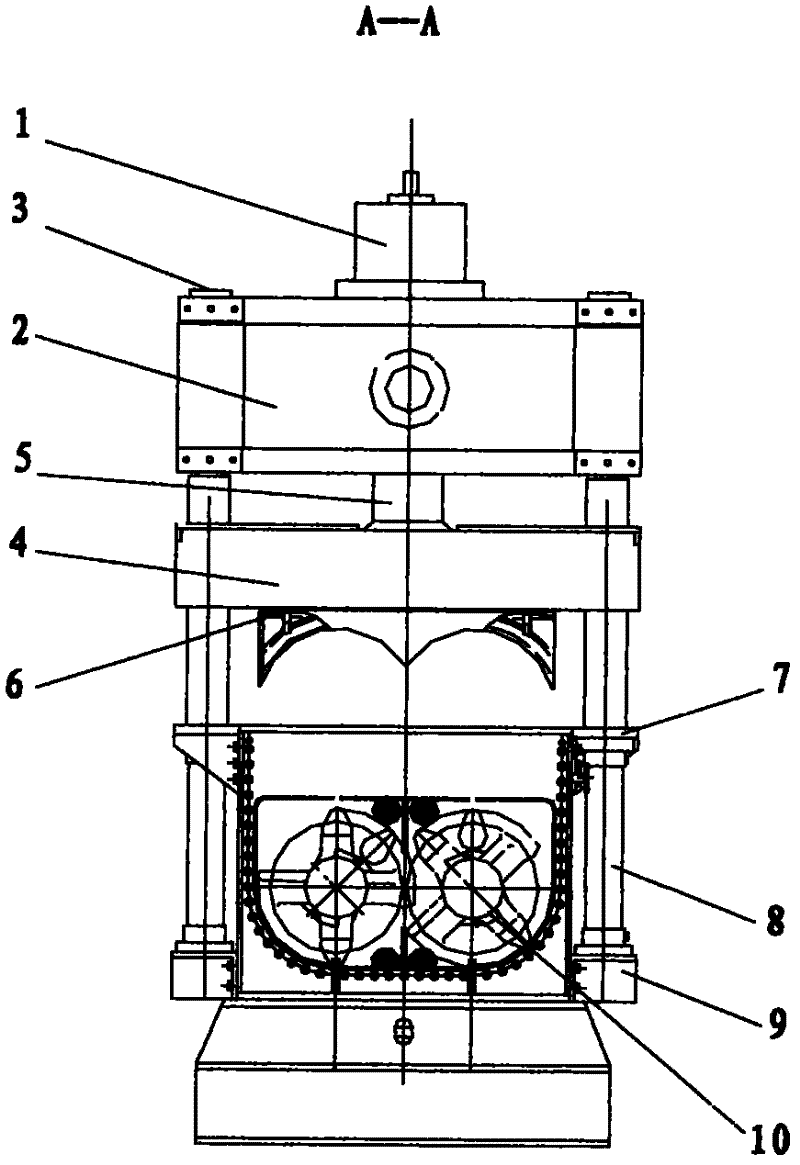

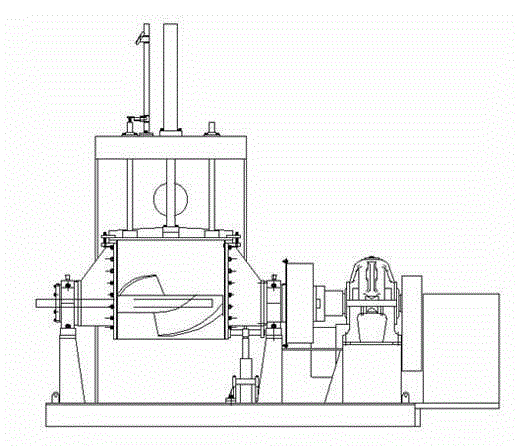

Pressure kneading machine

InactiveCN102389731AReduced freedom of movementIncrease temperatureRotary stirring mixersMixer accessoriesHydraulic cylinderEngineering

The invention provides a pressure kneading machine, which comprises a pressure pot cover, a hydraulic driving device, a pot body assembly, a stirring shaft, a stirring knife and other necessary parts of the kneading machine. The hydraulic driving device has a piston rod, an upright post, a hydraulic cylinder upper supporting ear, a hydraulic cylinder, and a hydraulic cylinder lower supporting ear; the hydraulic driving device is connected with the pressure pot cover and controls the pressure pot cover to move up and down; the up and down movement stroke of the pressure pot cover is 10 to 100 centimeters; and a sealing ring is arranged between the pressure pot cover and the pot body assembly. The stirring shaft and the stirring knife are arranged in the pot body assembly, and a steam or hot oil heating device is arranged in the outer wall of the pot body assembly. According to design requirements, when the kneading machine operates, the stirring shaft drives a material to overturn in the pot body assembly, the hydraulic driving device drives the pressure pot cover to move up and down to reduce the free movement space of materials and to apply extra pressure onto the material to compact the material; meanwhile, the heating device heats the material to rise the temperature of the kneaded material and increase the flowability of the material, thereby reducing resistance during kneading and improving kneading efficiency.

Owner:范慧君

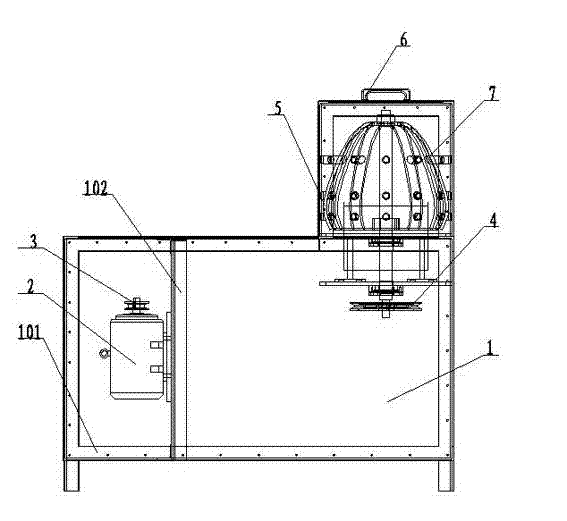

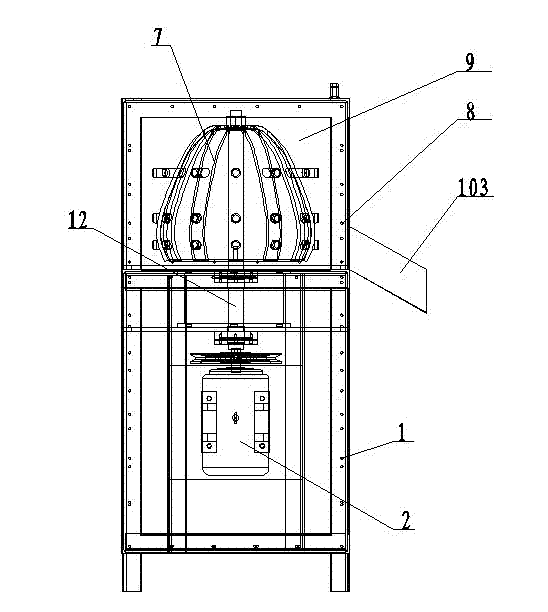

Kneading type garlic peeling machine

InactiveCN103494313AStrong kneading abilityNo pollutionFood treatmentEngineeringUltimate tensile strength

A kneading type garlic peeling machine comprises a supporting device, a power device and a peeling device. The power device and the peeling device are arranged at the two ends of the supporting device respectively. The peeling device comprises a peeling cavity and a kneading mechanism, wherein the peeling cavity is provided with a garlic inlet, a garlic outlet and a sundry outlet, and the kneading mechanism is arranged inside the peeling cavity. The kneading mechanism comprises a rotating wooden wheel, a rotating shaft and a plurality of annular parts, wherein the rotating shaft drives the rotating wooden wheel to rotate, and the annular parts are evenly distributed on the outer surface of the rotating wooden wheel. Each annular part is composed of an arc-shaped strip and protrusions installed on the arc-shaped strip, the length direction of the arc-shaped strips is consistent with the axial direction of the rotating shaft, and the distances between the outmost ends of the protrusions and the center line of the rotating shaft are equal. The kneading wooden wheel and kneading curved parts are novel in materials, simple and reasonable in appearance, strong in capability of kneading garlic peels and capable of not damaging the garlic peels. The kneading type garlic peeling machine has the advantages of being low in cost, high in kneading efficiency, low in labor intensity and the like, and does not pollute the environment.

Owner:HENAN UNIV OF SCI & TECH

Special color master batch kneader stirring paddle

InactiveCN103331123AImprove the mixing effectSimple structureMixer accessoriesTemperature controlPulp and paper industry

The invention discloses a special color master batch kneader stirring paddle, which is characterized in that the special color master batch kneader stirring paddle comprises two Z-shaped stirring paddles arranged in a parallel manner, wherein the Z-shaped blade of the Z-shaped stirring paddle is an asymmetric structure having a long portion and a short portion, the two asymmetric Z-shaped stirring paddles are reversely arranged and engaged, and the Z-shaped stirring paddle is further provided with a liquid circulation channel for introducing of cold / hot water to carry out temperature control on a color master batch. With the technical scheme, the special color master batch kneader stirring paddle adopts the two asymmetric and reversely-arranged Z-shaped stirring paddles to stir a color master batch, such that the color master batch can be pushed back and forth between the stirring paddles so as to enhance a stirring effect; and the liquid circulation channel is added to introduce cold / hot water to carry out temperature control so as to increase kneader kneading efficiency.

Owner:NANTONG KNEADING MIXING MACHINE

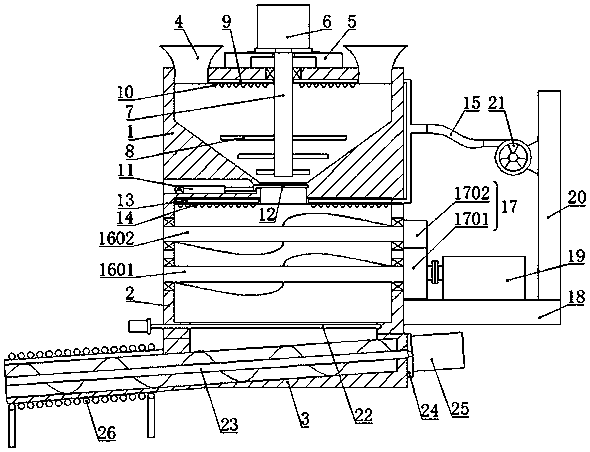

High-efficiency tea processing and rubbing machine apparatus

InactiveCN108522704AImprove kneading efficiencySolve the problem of automatic kneadingPre-extraction tea treatmentEngineeringRubbing

The invention discloses a high-efficiency tea processing and rubbing machine apparatus. The high-efficiency tea processing and rubbing machine apparatus comprises a base; a roller is fixedly connected, inside a U-shaped inner frame, with a surface of a rotating shaft; a right-angle bar is in sliding connection with a surface of the roller; a first sliding rod is fixedly connected, far away from the roller, with one end of the right-angle bar; a top of the first sliding rod is in sliding connection with a top of an inner wall of an outer frame; a spring is fixedly connected with a top of a second sliding rod; a rubbing block is fixedly connected, far away from the spring, with one end of the second sliding rod; a rubbing table is fixedly connected with a top of a sliding board; a concave curved surface, which is adaptive to a surface of the rubbing block, is formed in a top of the rubbing table; and a bottom of the concave curved surface formed in the top of the rubbing table and a bottom of the rubbing block are both arranged as flat surfaces. The high-efficiency tea processing and rubbing machine apparatus relates to the technical field of tea processing. The high-efficiency tea processing and rubbing machine apparatus achieves the effect of automatic rubbing, and is simple in structure and convenient to use; moreover, manual labor is reduced with high rubbing efficiency realized due to achievement of automatic rubbing, and thus, work efficiency is greatly improved.

Owner:安吉恒盛白茶有限公司

Efficient practical kneader

InactiveCN108719372AEasy kneadingEasy to kneadDough homogenizationHydraulic cylinderArchitectural engineering

The invention discloses an efficient practical kneader, comprising a frame, and a support plate at the lower portion of the frame. An electric hydraulic cylinder is arranged at the top of the frame; the output end of the electric hydraulic cylinder is connected with a hammerhead via a connection rod; a hammer trough is arranged right below the hammer trough; the hammer trough includes a bottom plate arranged on the support plate, two fixed plates arranged on the two parallel sides of the bottom plate, and two moving plate arranged on the other two parallel sides; the outer sides of the movingplates are connected with electric push bars mounted at the lower portion of the frame; the geometric center of the bottom plate is provided with a mounting hole; a rotating plate is disposed in the mounting hole; a rotating motor is disposed at the bottom of the support plate. The efficient practical kneader is simple in structure and reasonable in design, replaces manual kneading via mechanicaloperation, enables automatic kneading to be facilitated and labor intensity to be reduced, has improved kneading efficiency, and can prevent pollution of dough caused by manual kneading.

Owner:SICHUAN XIONGJIAN IND

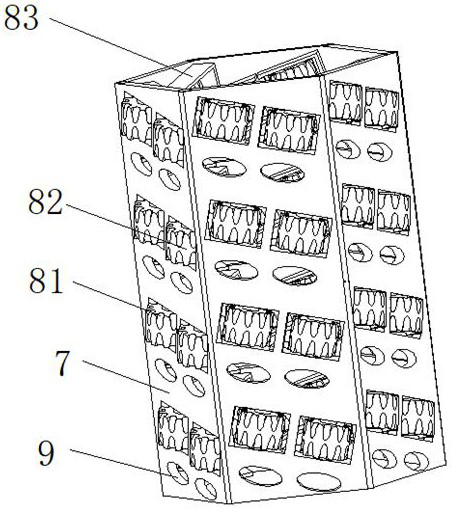

Horizontal type rotary blade paddle system of kneader

InactiveCN107497316APrevent leakagePrevent excessive kneadingRotary stirring mixersTransportation and packagingPulp and paper industryElectromagnetic valve

The invention relates to a horizontal type rotary blade paddle system of a kneader. The system comprises a kneading barrel and a kneading main shaft, wherein the kneading main shaft is horizontally and rotationally arranged inside the kneading barrel, and the two ends of the kneading main shaft are rotationally connected with the side walls of the two ends of the kneading barrel through a sealing device; two kneading blades are arranged inside the kneading barrel which are arranged at interval, and the two ends of each kneading blade are connected with the kneading main shaft through cutter bars; a discharging hole is formed in the bottom of the kneading barrel, and brackets are arranged at two sides of the kneading barrel and are provided with movable insertion plates; an air cylinder is fixedly arranged at the lower end of the kneading barrel, an output shaft of the air cylinder is connected with the insertion plate, and the insertion plate is driven to horizontally move to the discharging hole through flexibility of the air cylinder; the air cylinder is connected with an air source device through an electromagnetic valve; and the lower end of the kneading barrel is provided with a time relay and a pressure relay. Compared with the prior art, the system has the advantages that material feeding can be automatically controlled, the excessive kneading in the kneading barrel can be prevented, and the kneading quality can be guaranteed.

Owner:SHISHI XINHUA PLASTIC MACHINERY

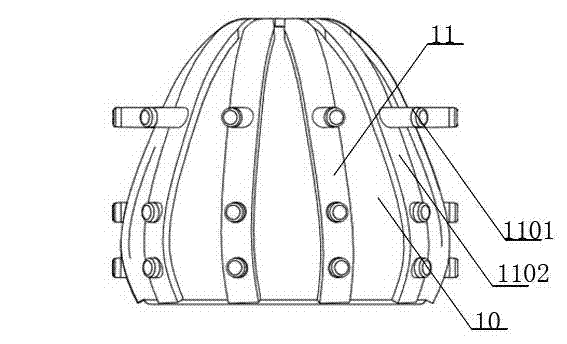

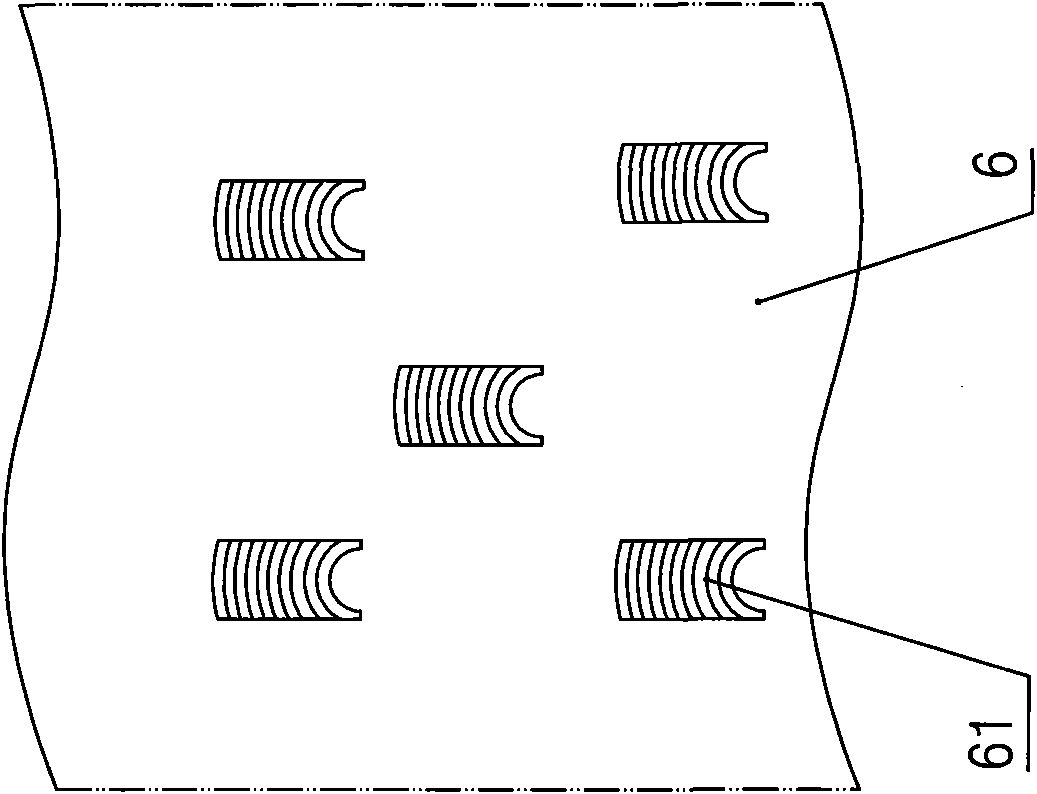

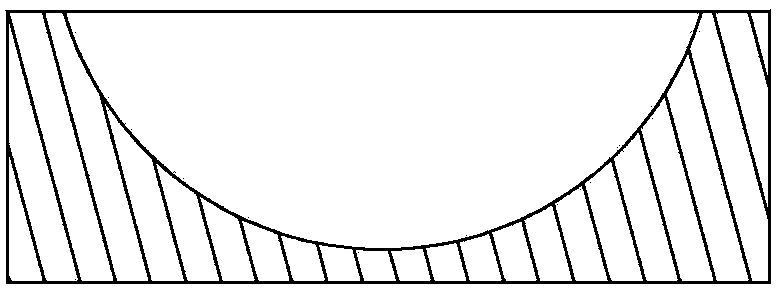

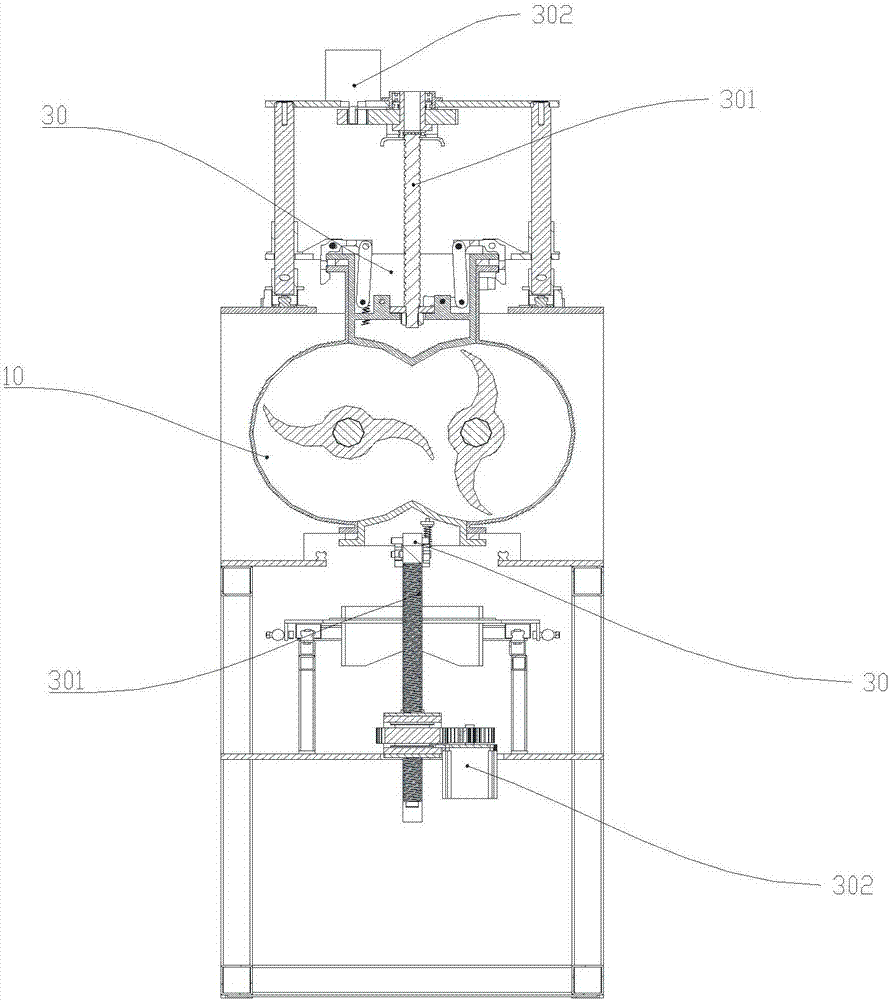

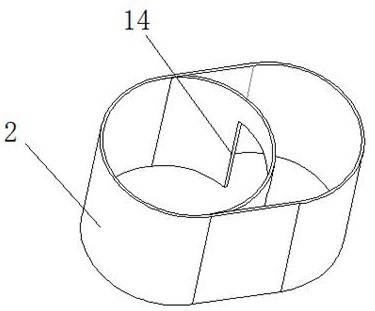

Kneading groove in kneading machine

The invention discloses a kneading groove in a kneading machine for improving shearing force to materials, which comprises a groove wall and a groove bottom, wherein the inner surface of the groove bottom is provided with a plurality of bosses, and a plurality of veins are arranged on the surface of each boss. The inner surface of the groove bottom of the kneading groove is provided with the plurality of bosses to increase the shearing force to the materials so as to achieve the aims of shortening the kneading time of silicone rubber and improving the kneading efficiency of the silicone rubber. In addition, the veins arranged on the surface of each boss can further increase the shearing force to the materials in the process of stirring so as to further shorten the kneading time of the silicone rubber, improve the kneading effect on the silicone rubber, and reduce about 5 percent of the energy consumption.

Owner:ZHANGJIAGANG LANHANG MACHINERY

Reversible automatic dough kneading device capable of automatically adding water by hardness of dough

InactiveCN112335704AModerate hardnessRealize automatic water additionMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsEngineeringMechanical engineering

The invention relates to the field of food processing, and discloses a reversible automatic dough kneading device capable of automatically adding water by the hardness of dough. The reversible automatic dough kneading device comprises a box body; an outer cylinder cavity with an opening facing upwards and backwards is arranged in the box body; the interior of the outer cylinder cavity is connectedwith an outer cylinder in a sliding fit manner; the left side of a turbine cavity is provided with a water adding control cavity; and a stirring shaft extending rightwards to penetrate through the turbine cavity and an inner cylinder rotating cavity and an inner cylinder cavity to the interior of a stirring belt wheel cavity and extending leftwards into the water adding control cavity is connected with the interior of the right end wall of the water adding control cavity in a running fit manner; flour is stirred by a belt wheel and a stirring rod to form the dough, and in the stirring process, the hardness of the dough is judged by the rotating speed of the stirring shaft; opening and closing of a flowing water cavity are controlled by a rack and a reel to control water adding, and thus,automatic water adding of the dough is realized, and the dough with the proper hardness is obtained; the dough kneading efficiency is improved, the quality of the dough is improved, the labor is reduced, and overturning of a stirring cylinder is achieved through a turbine worm, so that the dough is convenient to take out.

Owner:新昌县洪希食品科技有限公司

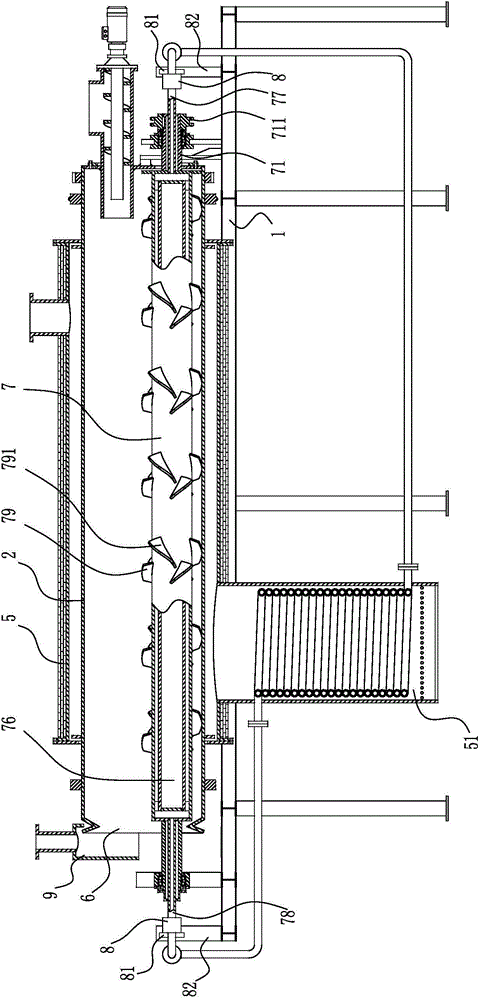

Full-thermal type rolling and kneading machine

ActiveCN104437194AWell mixedPlay a cleaning roleRotating receptacle mixersTransportation and packagingEngineeringKiln

The invention discloses a full-thermal type rolling and kneading machine. The full-thermal type rolling and kneading machine comprises a base, a kneading roller, a heating kiln shell, a heat transfer oil boiler and a rolling and kneading roller, wherein the rolling and kneading roller is a hollow roller and is positioned in the kneading roller; a hearth of the heat transfer oil boiler communicates with the heating kiln shell; the heat transfer oil boiler is connected with the rolling and kneading roller through a pipeline. The full-thermal type rolling and kneading machine has the advantages that materials are kneaded according to the gravity principle, namely, the gravity of the rolling and kneading roller is completely applied to the bottom part of the kneading roller, and a rolling and kneading blade and the kneading roller oppositely rotate to highly shear, tear and roll the materials, so as to enable the dry materials to be prepared into thick materials with a certain temperature and uniformly mixed and agitated; the heat transfer oil boiler and the heating kiln shell are integrally combined, so that the shortage of loss of a lot of heat in the traditional heat transfer oil boiler can be overcome, the lost heat of the traditional heat transfer oil boiler can be fully absorbed, and as a result, the heat efficiency can be greatly raised. With the adoption of the full-thermal type rolling and kneading machine, the rolling and kneading roller can float to adapt to the materials doped with inclusions such as metal, so as to damage to the rolling and kneading blade; the outstanding advantages that cannot be achieved by the common kneading machine are brought.

Owner:WEIFANG JINSIDA NEW ENERGY SCI & TECH

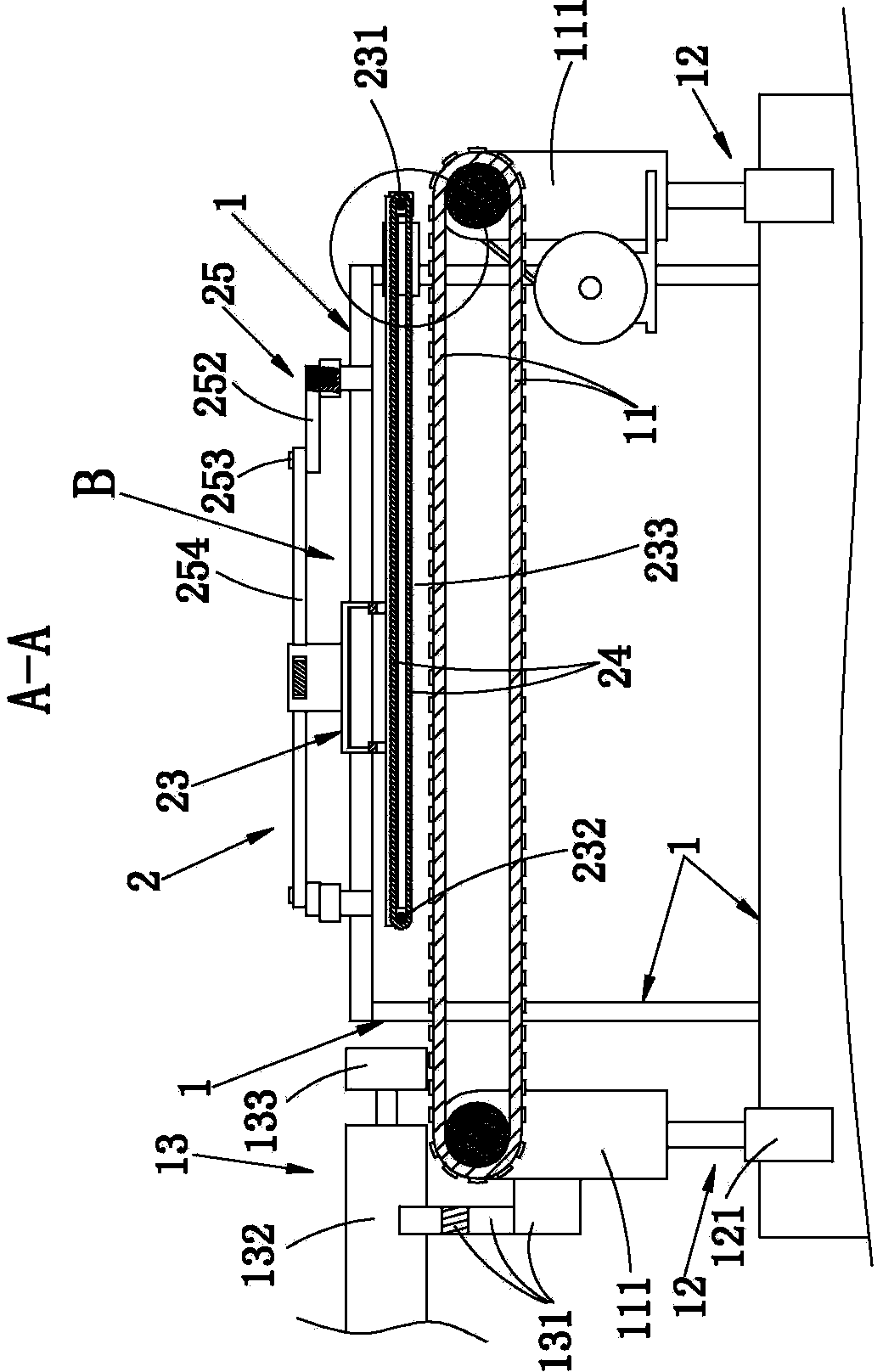

Tea kneading device and kneading method thereof

ActiveCN103891929ASimple structureEasy to usePre-extraction tea treatmentAgricultural engineeringConveyor belt

The invention relates to a tea kneading device and a kneading method thereof. The tea kneading device comprises a main frame body, wherein a tea conveyor belt / conveyor chain and a kneading mechanism are arranged on the main frame body, a plurality of first bulges are arranged on the conveying surface of the tea conveyor belt / conveyor chain, the kneading mechanism comprises a rotary frame, a first motor, an assembling frame and a kneading belt, the rotary frame is assembled on the main frame body, the first motor is used for driving the rotary frame to swing and rotate along a horizontal direction in a reciprocating manner, the assembling frame is fixedly assembled on the rotary frame, the kneading belt is assembled on the assembling frame, the bottom surface of the kneading belt and the top surface of the tea conveyor belt / conveyor chain are parallel and are arranged at an interval, and a plurality of second bulges are arranged on the bottom surface of the kneading belt. According to the tea kneading device disclosed by the invention, tea can be continuously and automatically kneaded, the kneading efficiency of tea is effectively improved, and the streamline production of the tea is facilitated. In addition, the integrity of the tea is effectively improved in the tea kneading process, and the quality of the tea is ensured.

Owner:林清矫

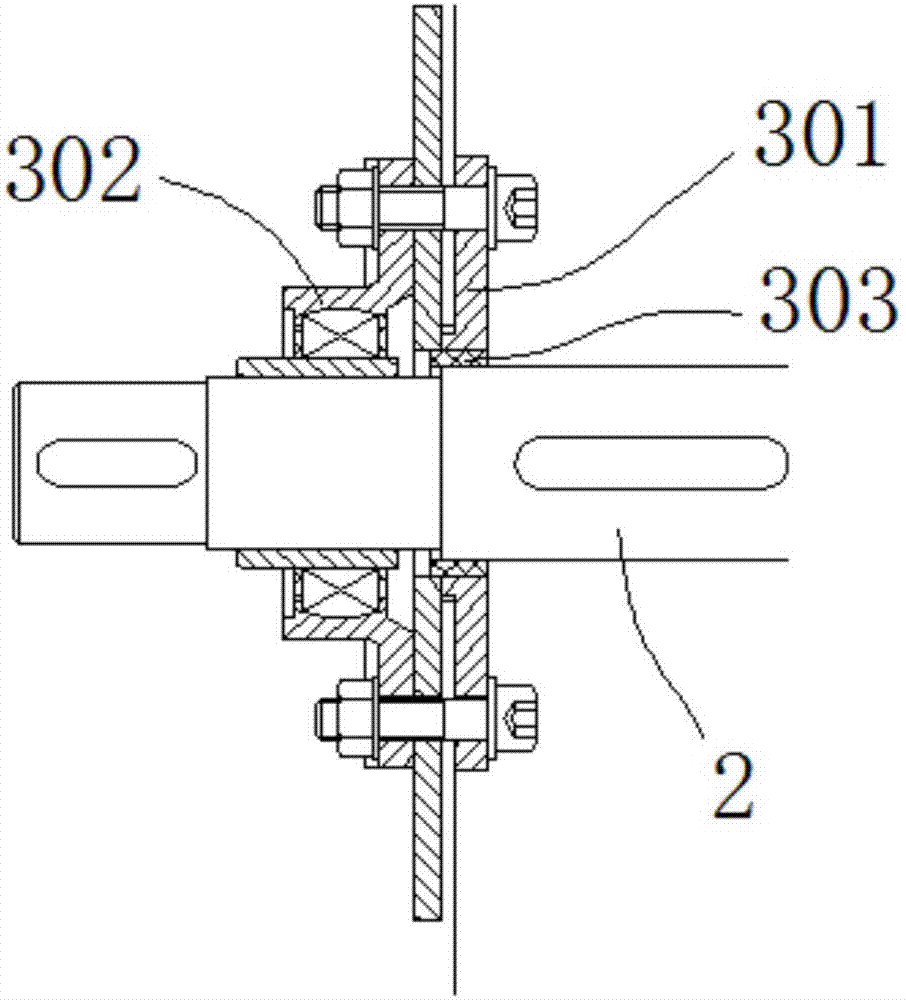

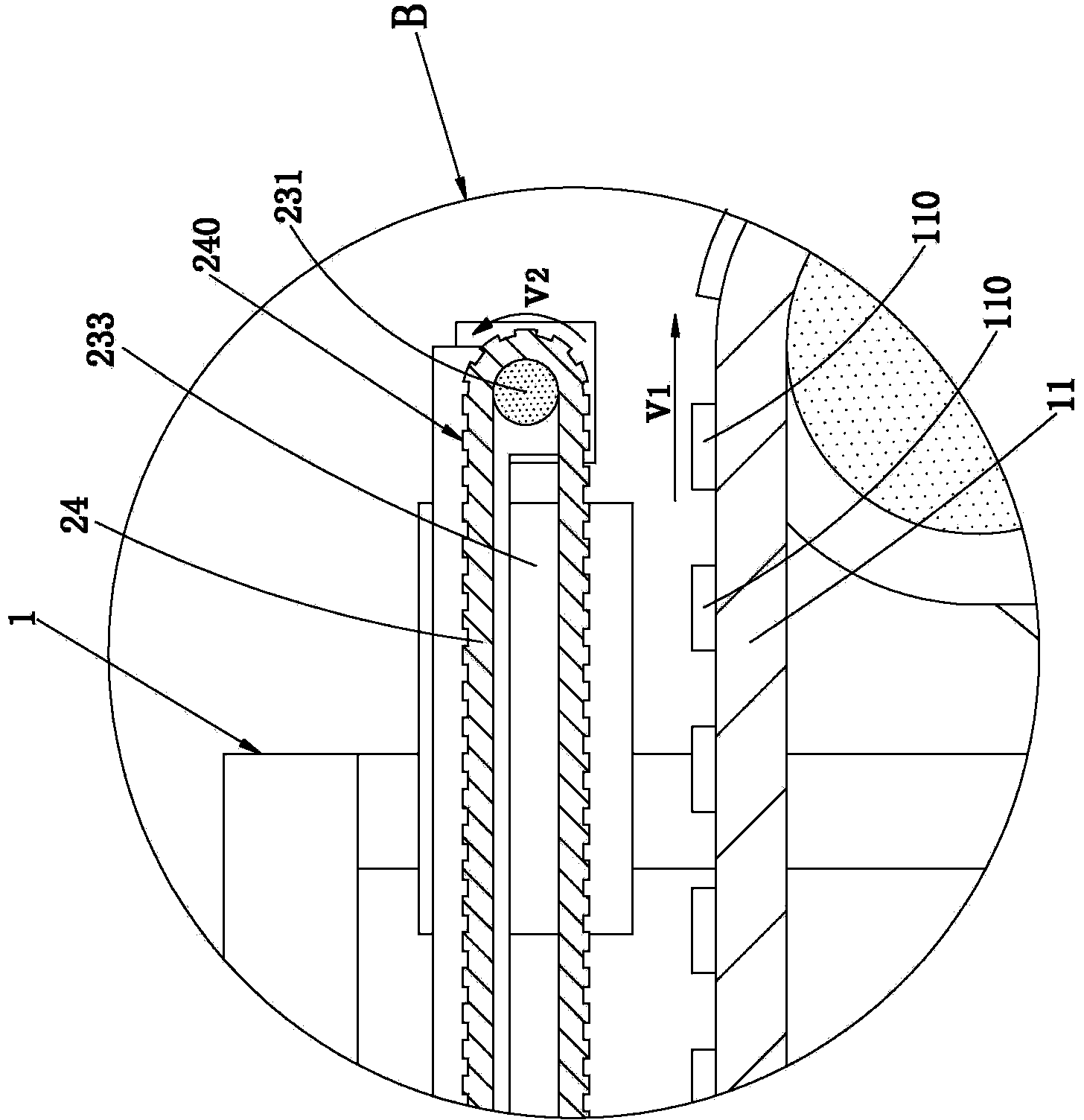

Dough kneading machine

PendingCN108260613AAvoid vibrationExtended service lifeMixing/kneading structural elementsKitchen equipmentDrive shaftDrive motor

The invention discloses a dough kneading machine. The machine comprises a dough kneading bowl and a dough kneading assembly; a bowl cover is arranged on the dough kneading bowl; a drive shaft is arranged in the dough kneading bowl; the drive shaft vertically passes through a fixing hole at the bottom of the dough kneading bowl, and the lower end of the drive shaft is connected to a driving motor;the drive shaft is connected to the dough kneading assembly; the dough kneading assembly comprises a mounting frame and a first connecting rod and a second connecting rod which are arranged at two ends of the mounting frame; the length of the first connecting rod is shorter than the length of the second connecting rod, and the end of the first connecting rod is connected to a first L-shaped connecting rod; the end of the second connecting rod is connected to a second L-shaped connecting rod; the first L-shaped connecting rod and the second L-shaped connecting rod are both inclined towards to the bottom of the dough kneading bowl; the vertical rod of the first L-shaped connecting rod is shorter than the vertical rod of the second L-shaped connecting rod; and the cross bar of the first L-shaped connecting rod and the cross bar of the second L-shaped connecting rod are both arranged towards the central part of the first L-shaped connecting rod and the second L-shaped connecting rod. The dough kneading machine provided by the invention can reduce the vibration of a dough kneading process, and improve the working efficiency of dough kneading.

Owner:JIANGMEN HOUSOEN ELECTRIC MFG

Kneading equipment for food processing

InactiveCN110169554AKnead fullyImprove kneading effectPharmaceutical product form changeFood shapingFistBiochemical engineering

The invention discloses kneading equipment for food processing, comprising a tank body, the top of the tank body is provided with a material inlet, the bottom of the material inlet is provided with afirst kneading frame, the bottom of one side of the tank body is provided with a supporting plate, a first motor is arranged on the supporting plate, the output shaft of the first motor is fixedly connected with a fist rotating shaft, the upper end of the first rotating shaft is fixedly connected with a fist belt pulley in a sleeving manner, a first rotating rod is arranged above the first kneading frame, the upper end of the first rotating rod is fixedly connected with a second belt pulley in a sleeving manner, the lower end of the rotating rod extends into the first kneading frame, and the outer wall of the lower end of the first rotating rod is uniformly fixed with a plurality of stirring rods, the inner walls of two sides of the first kneading frame are provided with inclined materialguiding plates, the inclined slope surfaces of the material guiding plates are uniformly fixed with a plurality of fixed rods, the bottom of the first kneading frame is provided with a first materialoutlet, and the bottom of the first material outlet is connected with a second kneading frame. The kneading equipment is convenient to use, can improve the kneading effect to make food materials be kneaded more sufficiently, and improve the kneading efficiency.

Owner:卢雪薇

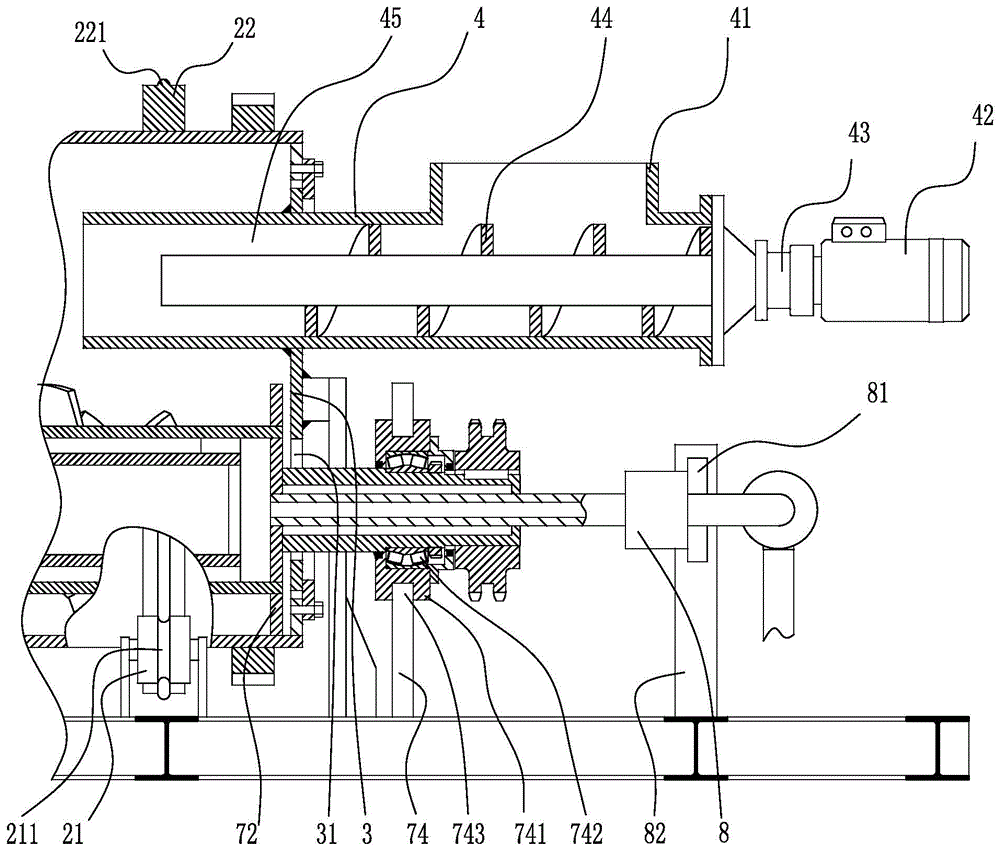

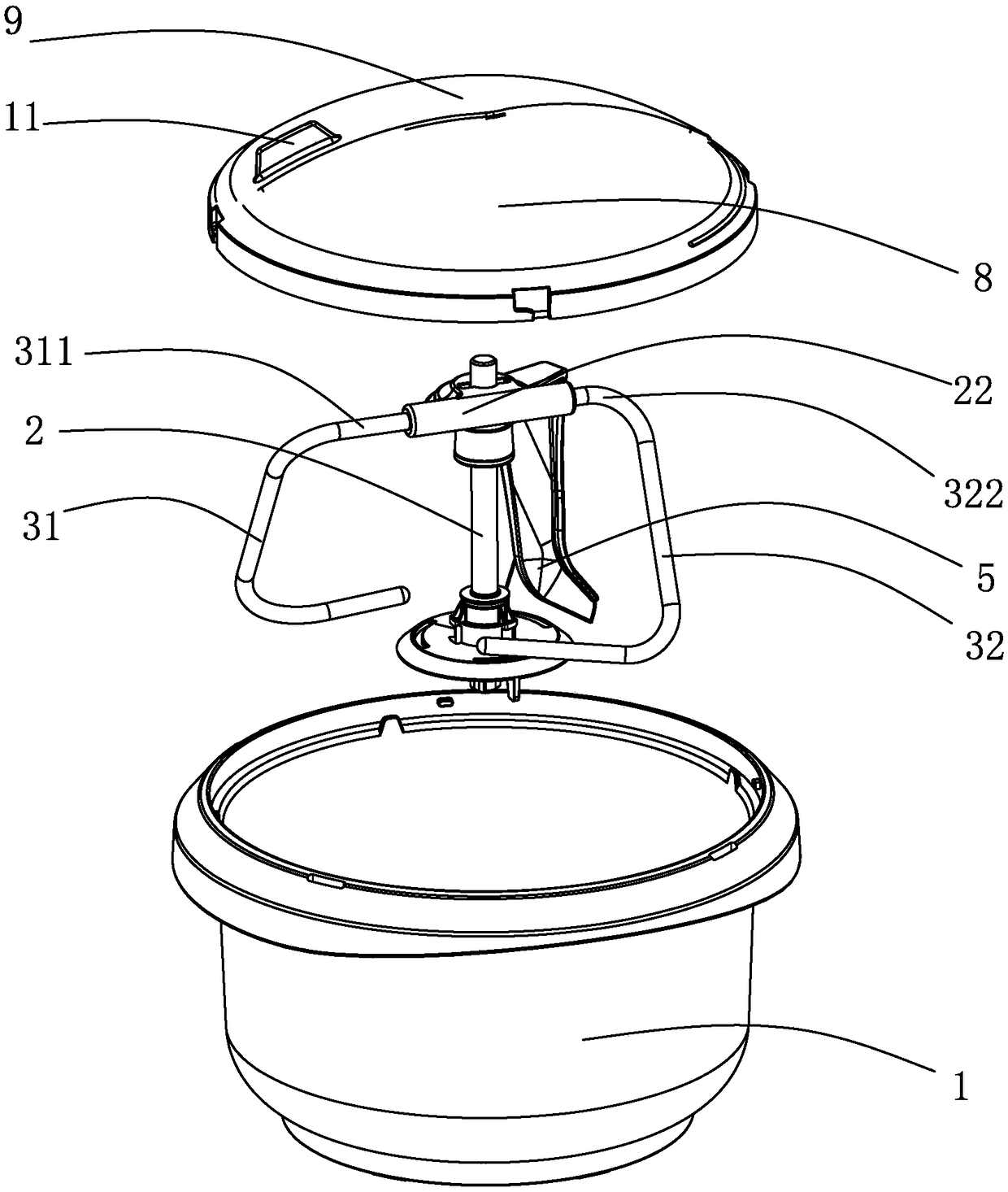

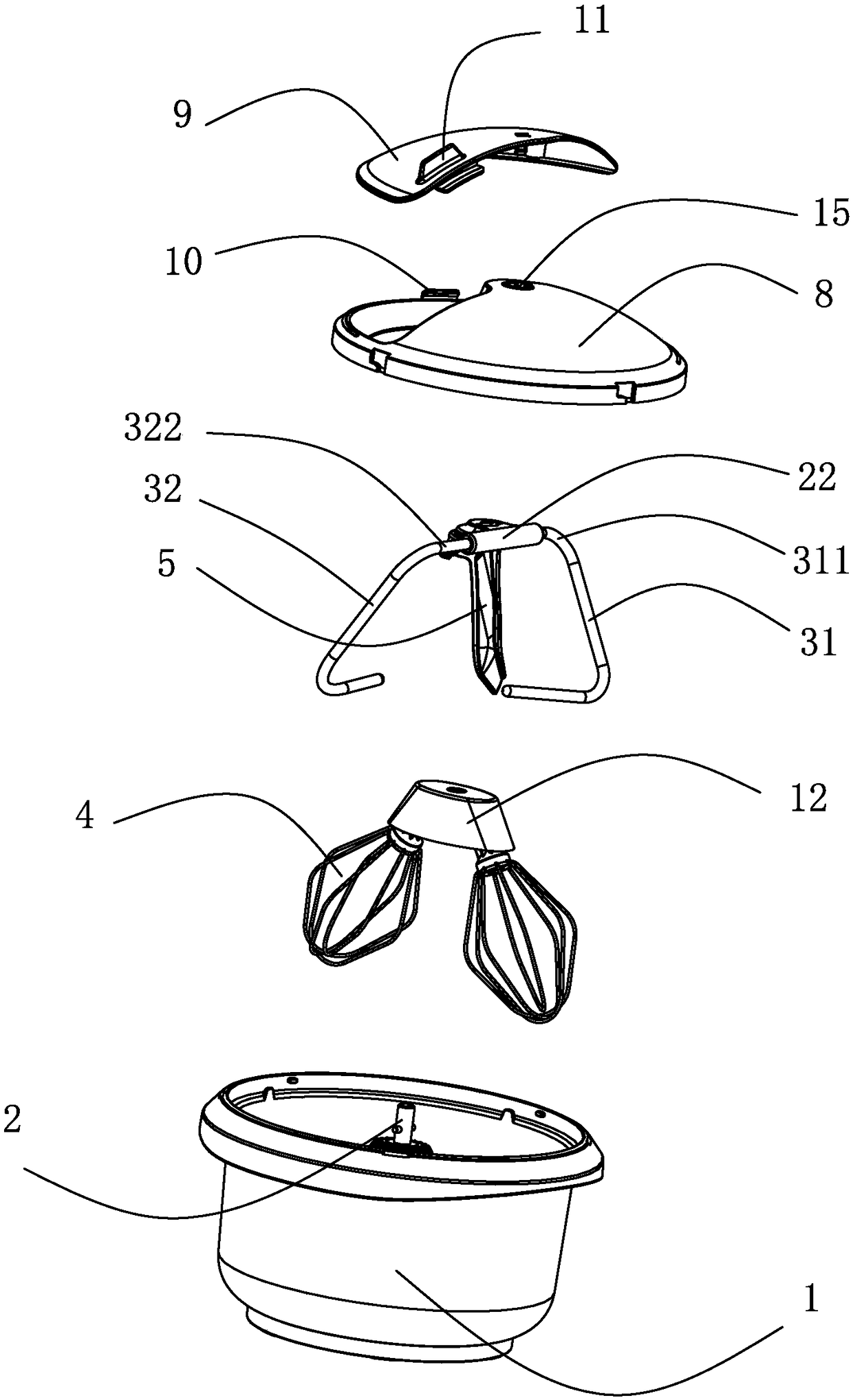

Dough kneading equipment

ActiveCN111034747AEasily brokenHigh strengthMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsGear wheelEngineering

The invention provides dough kneading equipment which comprises a workbench and a dough kneading device. A dough kneading bin is arranged in the middle of the workbench. The dough kneading device comprises a mounting assembly, a control assembly, a dough kneading assembly and a power assembly. A limiting disc rotates to control a moving rod to extend and retract back and forth into the dough kneading bin to press dough, meanwhile, a rotating shaft rotates to drive a rotating disc to rotate, a gear ring is matched with a gear c, the rotating disc rotates to rub the dough while rotating along with the rotating shaft, artificial dough kneading is simulated, and the technical problem that in the prior art, the dough is easily scattered during dough kneading and consequently the dough chewinessis reduced is solved.

Owner:安徽省金皖颖食品有限公司

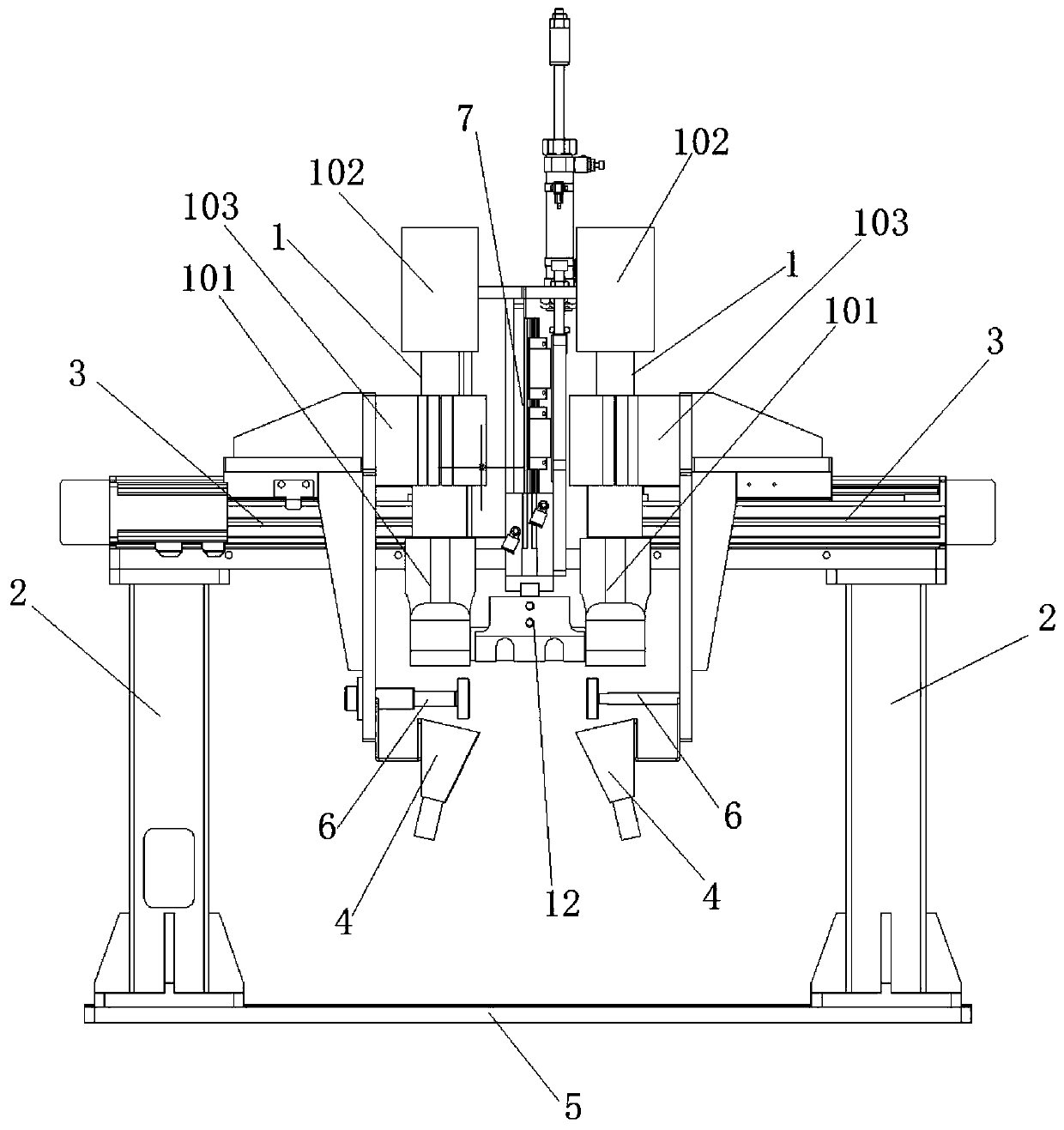

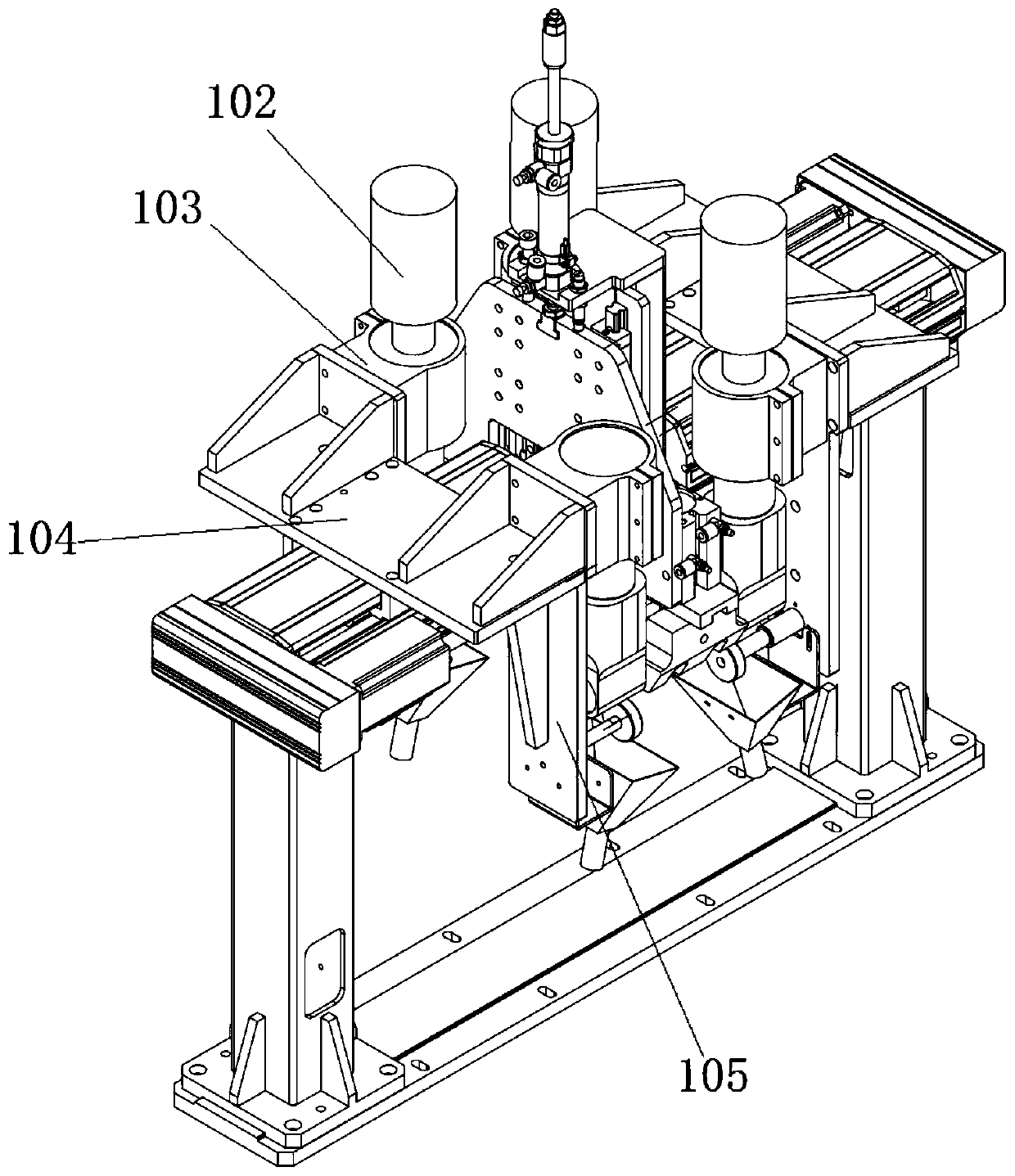

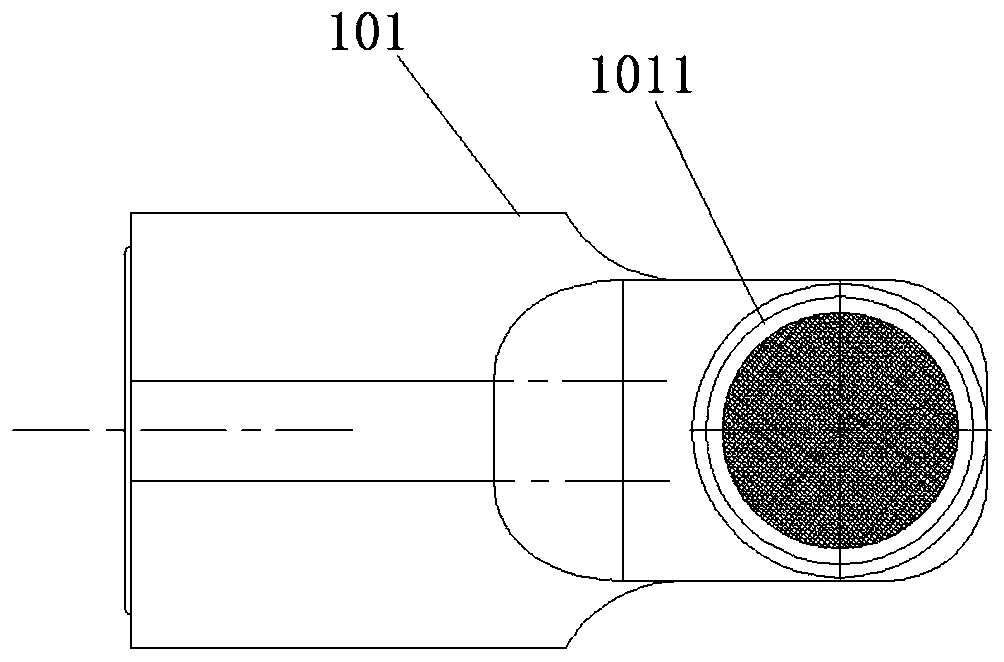

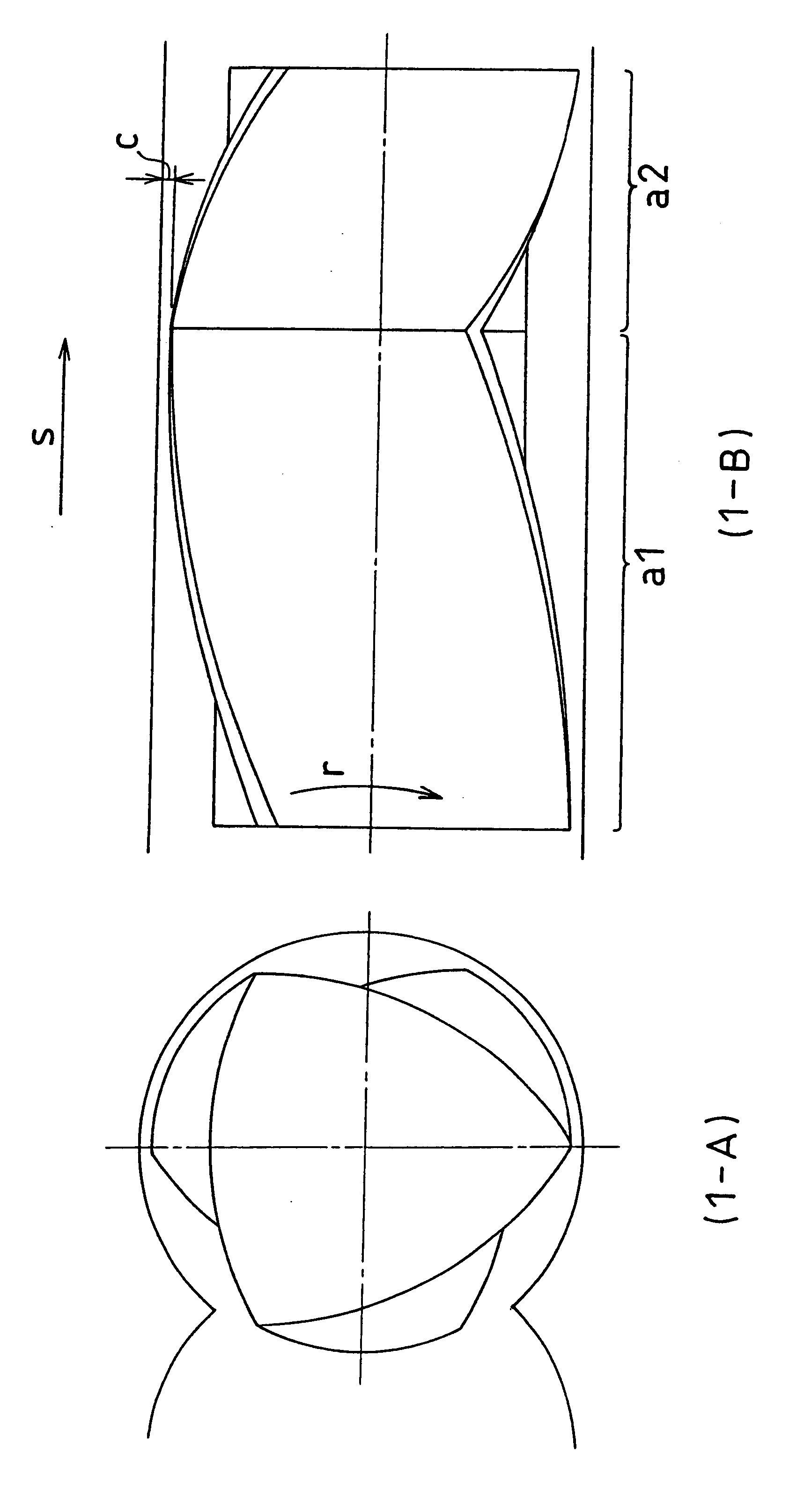

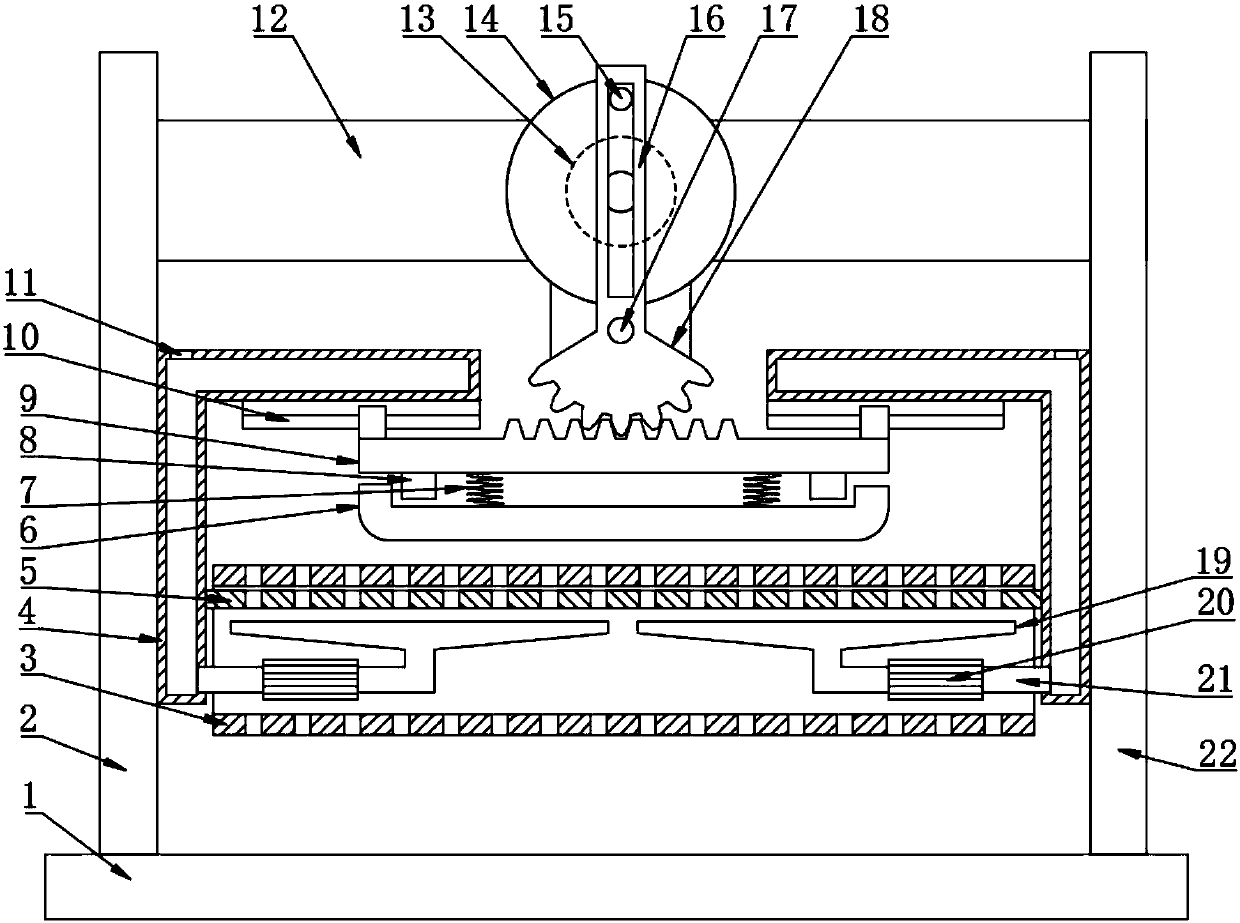

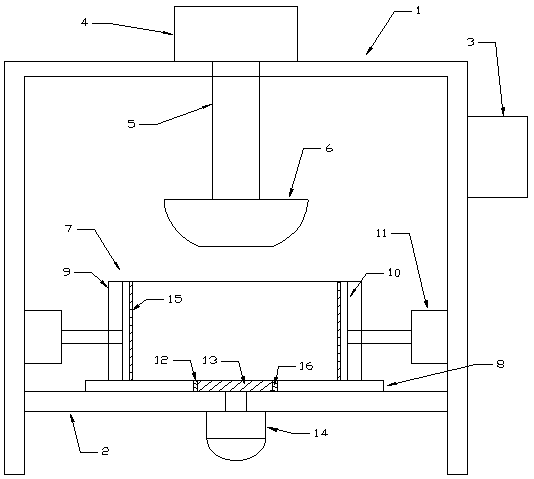

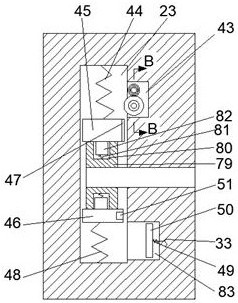

An automatic noodle kneading device for noodle production and processing

ActiveCN107889864BComprehensive and full kneading effectImprove kneading efficiencyDough extruding machinesEngineeringMechanical engineering

The invention discloses an automatic dough kneading device for cooked wheaten food production processing. The device comprises a base plate, a dough kneading box is fixedly installed on the base plate, the bottom of the interior of the dough kneading box is provided with an electric retractable rod, and a bearing plate in contact connection with the inner side wall of the dough kneading box is fixedly installed on the electric retractable rod; the upper portion of a second transverse rack is rotatably provided with a third gear meshed with the second transverse rack, a fourth gear is coaxiallyand fixedly installed on the third gear, an electric retractable air cylinder is arranged between the top of the inner side of a gantry frame and a transverse plate, and a limit sleeve is internallyand slidingly provided with a sliding rod; according to the automatic dough kneading device, the second transverse rack and a first transverse rack drive a left push block and a right push block to move towards each other respectively, and therefore transverse dough squeezing and kneading on the bearing plate is achieved; when the left push rod and the right push rod move away from each other, a squeezing ball conducts longitudinal dough squeezing and kneading on the dough downwards, transverse dough squeezing and kneading and longitudinal dough squeezing and kneading are combined and alternately and repeatedly conducted so that the dough can be comprehensively and fully kneaded and pressed, and the dough kneading efficiency is higher.

Owner:上海天信绿色食品有限公司 +2

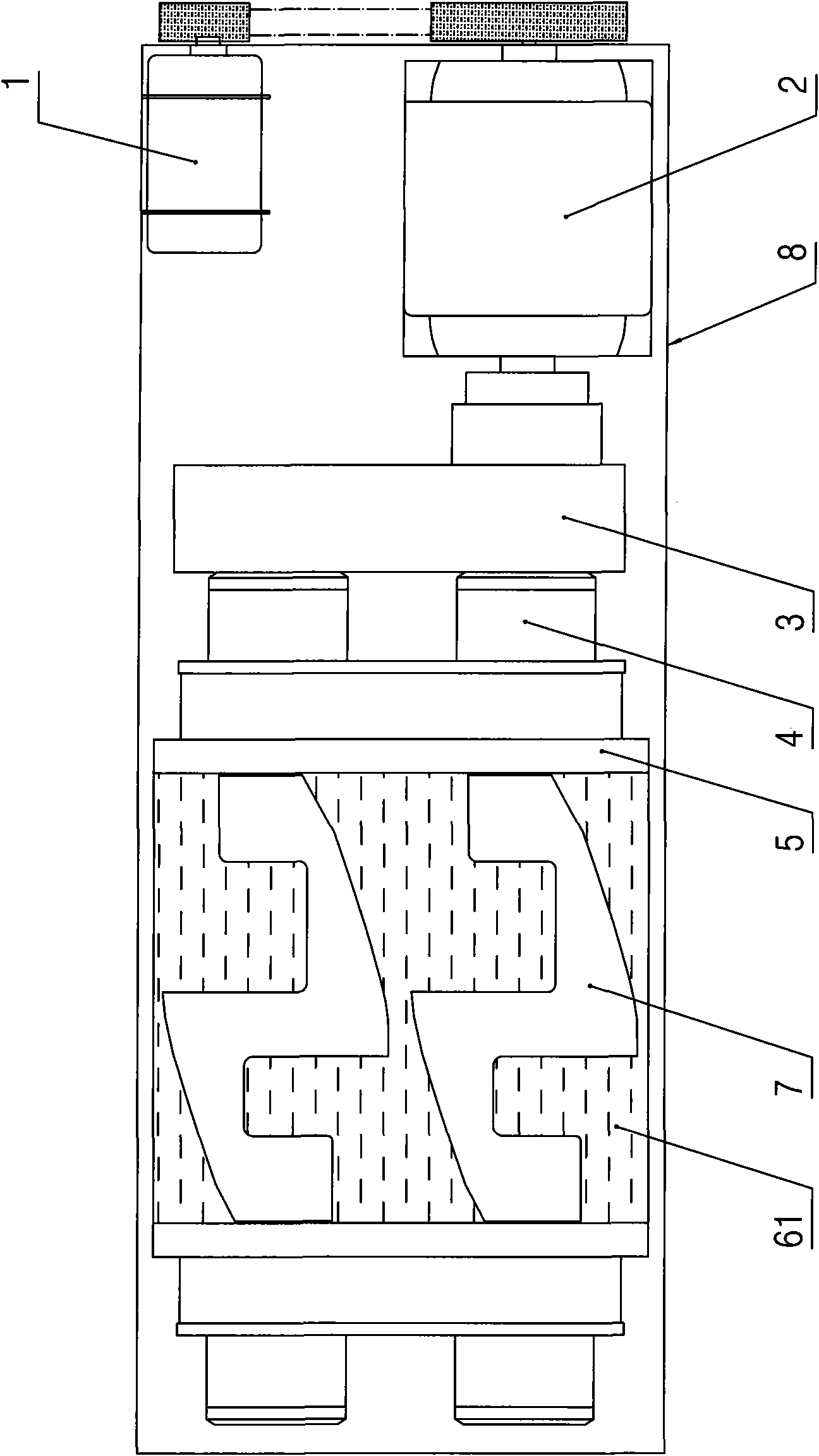

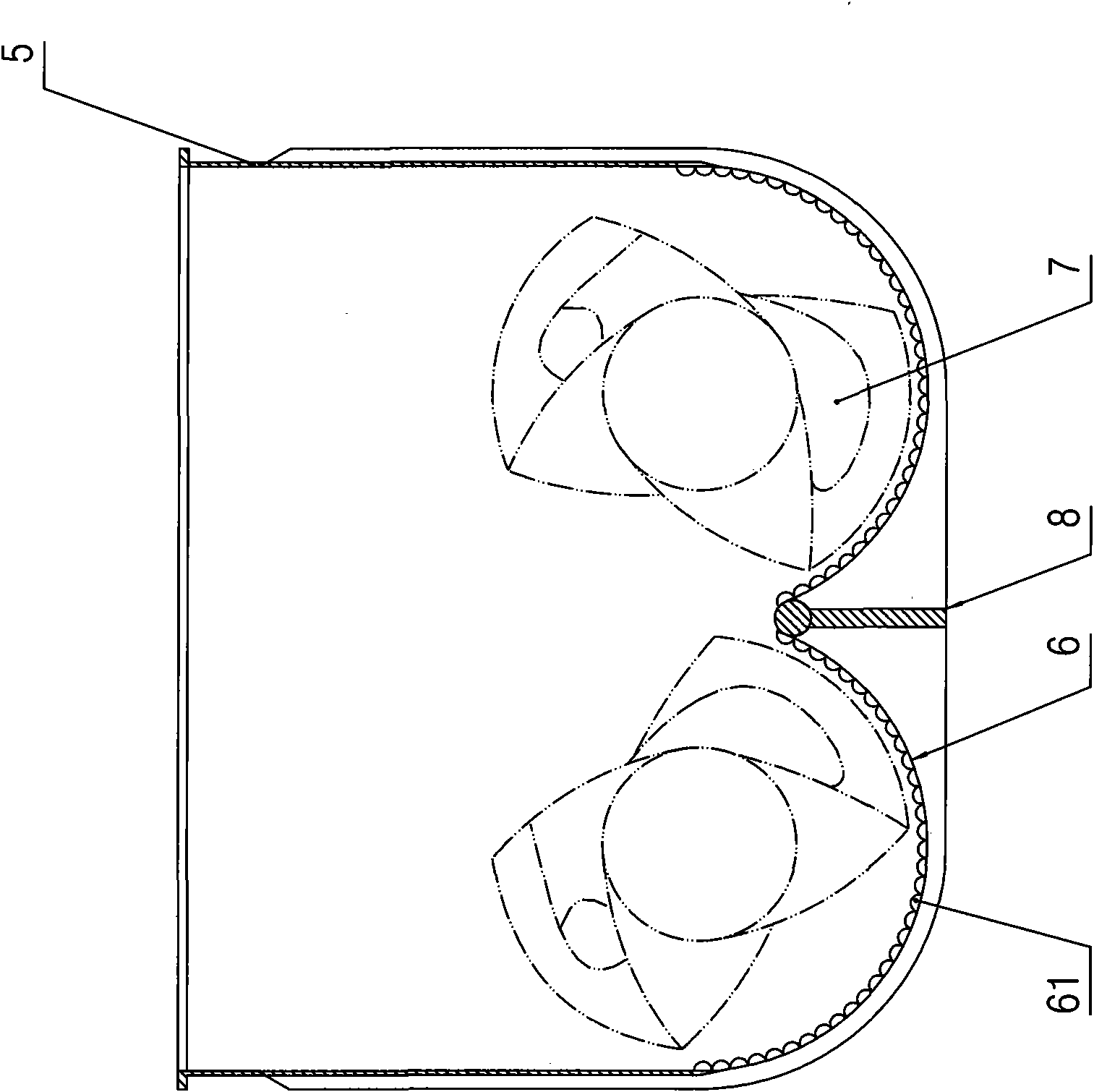

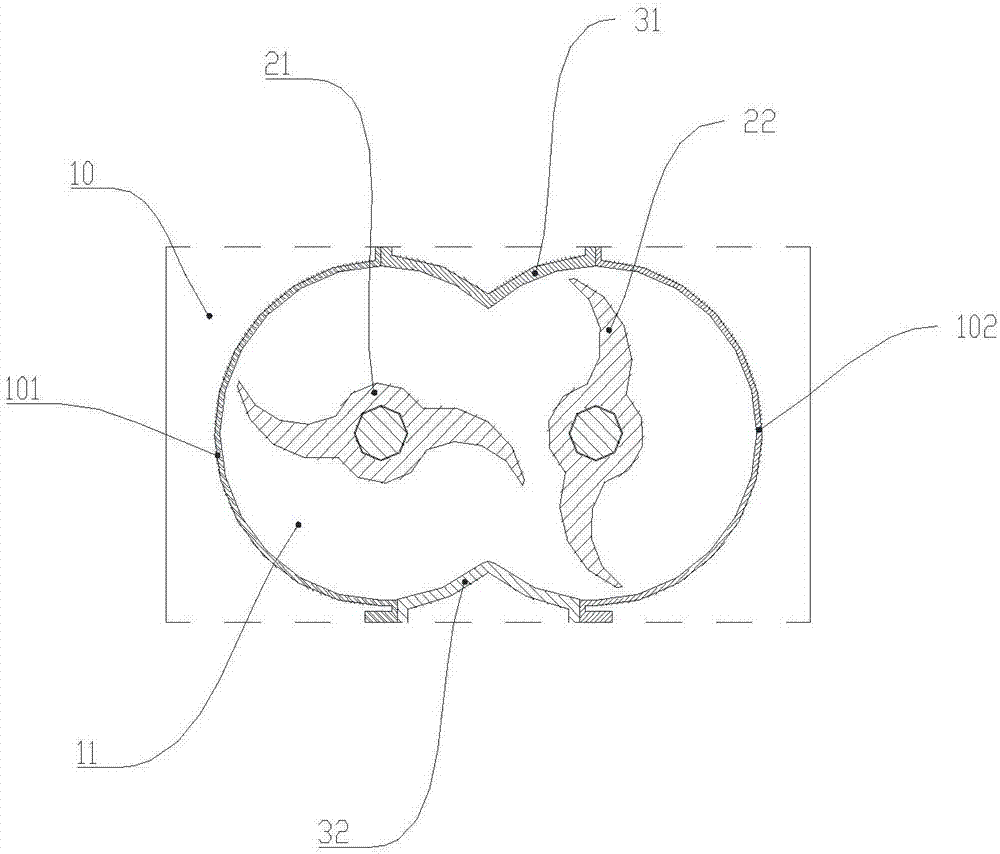

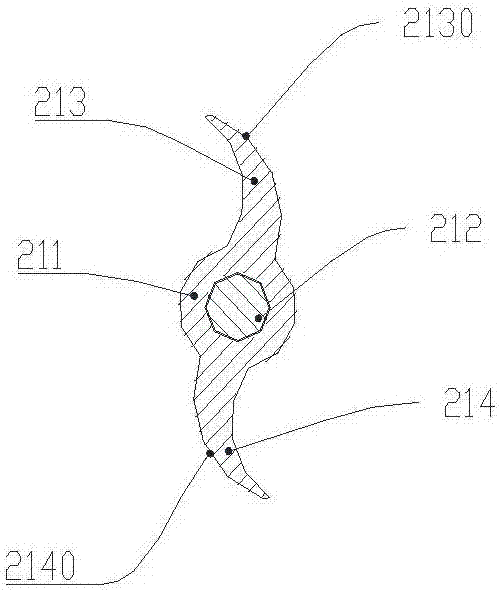

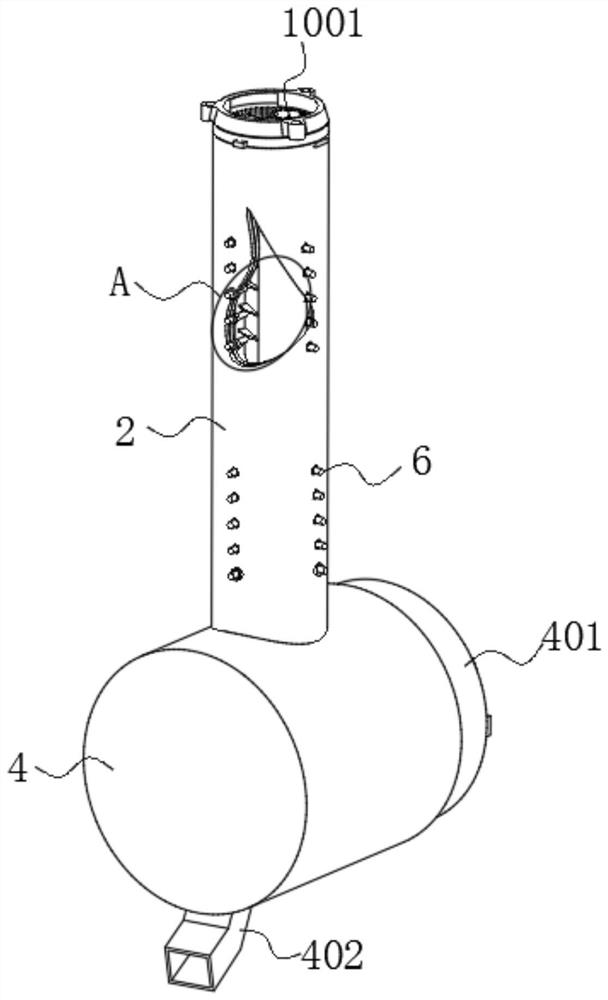

Manipulator dough mixer mechanism

PendingCN107047672AGreat tasteImprove kneading efficiencyMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsEngineeringManipulator

The invention discloses a manipulator dough mixer mechanism, comprising a container for dough mixing and kneading, wherein the cavity of the container is internally provided with a first blade and a second blade which can rotate around the axis, wherein the first blade and the second blade can rotate reversely synchronously, and the first blade and the second blade each comprise a rotary shaft connecting portion, and arc-shaped sheets extending out in opposite directions from the side of the rotary shaft connecting portion. The manipulator dough mixer mechanism simulates the manual dough mixing and kneading through the coordination of the container with the pair of blades. The mechanism, on one hand, realizes mixing and kneading dough simultaneously in the same cavity; on the other hand, improves the efficiency of dough kneading and the dough taste.

Owner:深圳厨奇自胜智能装备技术有限公司

Kneading device for preparing magnesium stearate

InactiveCN112892349AImprove kneading efficiencyGood crushing effectTransportation and packagingMixersMagnesium stearateStearic acid

The invention discloses a kneading device for preparing magnesium stearate. The kneading device comprises a supporting frame, a conveying cylinder is arranged in the middle of the supporting frame, a crushing column is movably arranged in the conveying cylinder, at least three crushing grooves are formed in the crushing column, a rotating shaft is arranged in each crushing groove, two sets of smashing teeth and spiral feeding teeth used for conveying materials are sequentially arranged on the peripheral side walls of the rotating shafts, a transmission mechanism comprises a driving gear and three driven gears meshed with the driving gear, the driving gear is fixedly installed at the middle axis position of the top of the crushing column, and the driven gears are fixedly connected with the tops of the rotating shafts in a one-to-one correspondence mode. According to the kneading device for preparing magnesium stearate, provided by the invention, through kneading between the kneading column and the crushing teeth, the kneading column and the crushing teeth are subjected to primary crushing, through combination of the spiral feeding teeth and the crushing teeth, stearic acid and magnesium hydroxide can be mixed, the crushing and mixing effects are relatively good, and subsequent processing is facilitated.

Owner:安徽沙丰新材料有限公司

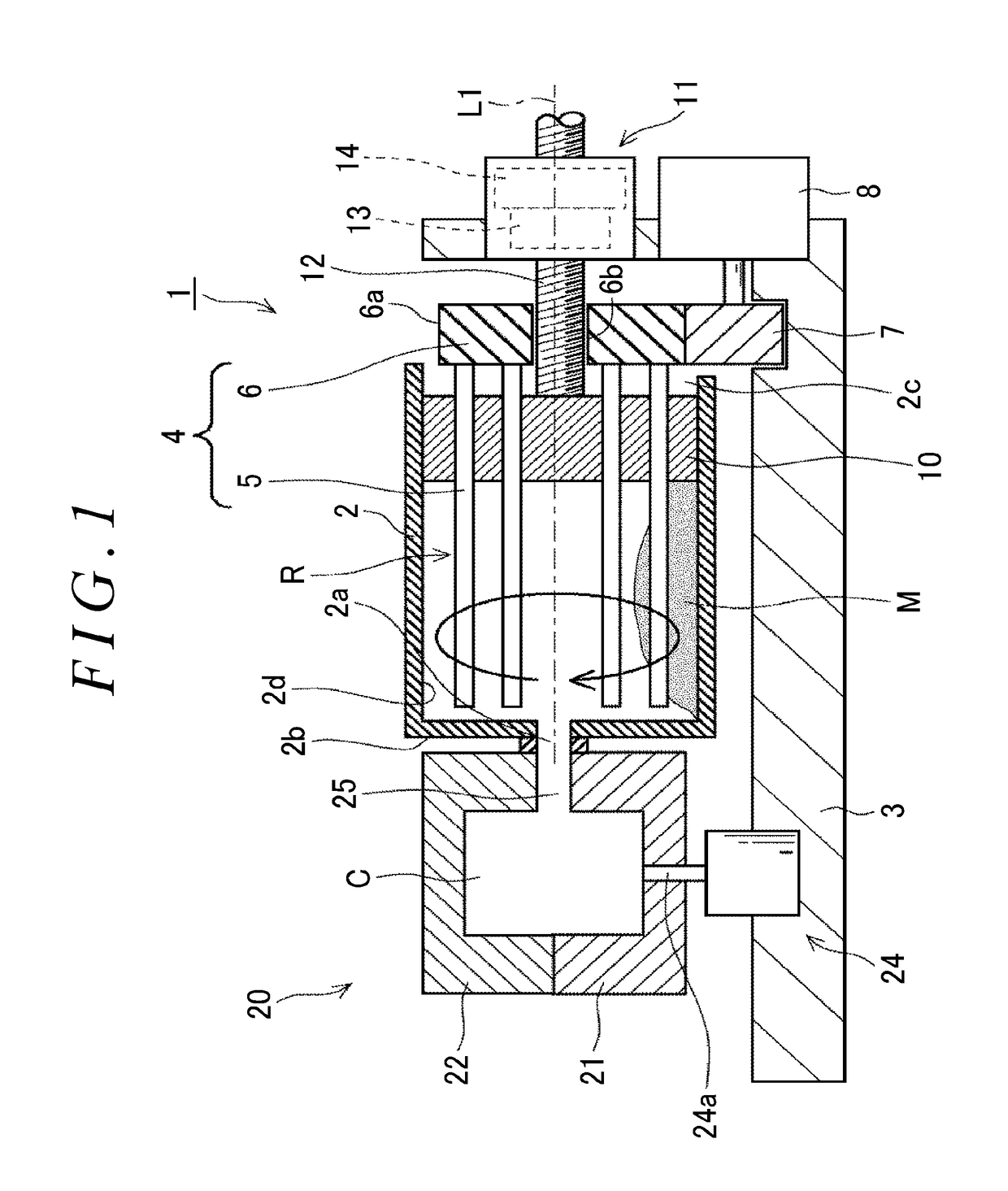

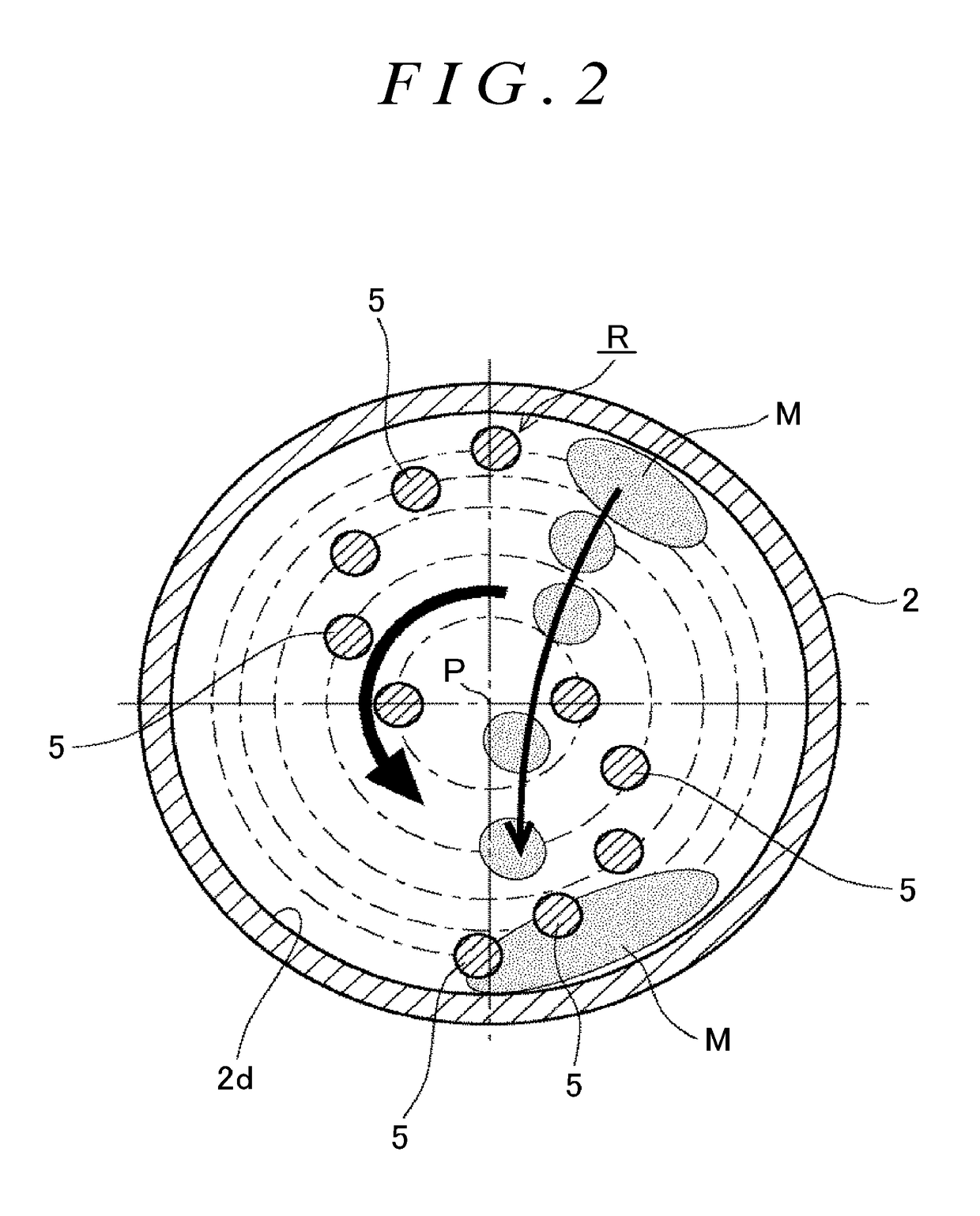

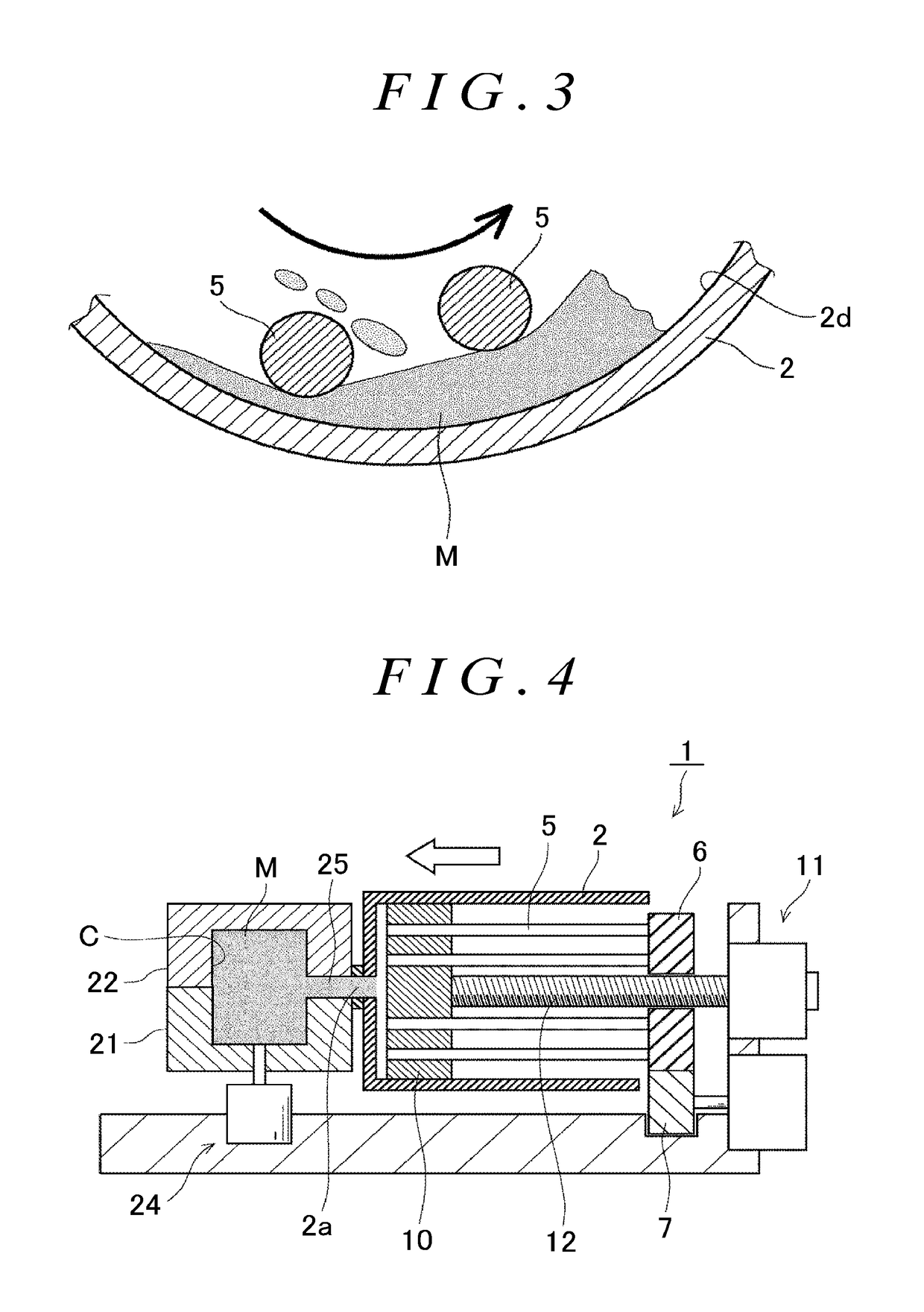

Kneading apparatus

Agitating pins employed in a kneading apparatus extend in the horizontal direction and rotate around a rotation axis of an agitator extending in the horizontal direction, so that the kneading apparatus can repeat a process in which a material is kneaded and beaten against an inner wall surface of a kneading vessel and the material adhering to the inner wall surface of the kneading vessel, especially on the upper side from the rotation axis of the agitator, falls under its own weight through the clearance between the agitating pins. As a result, the material hardly adheres to the inner wall surface of the kneading vessel, so that the kneading efficiency can be enhanced.

Owner:TOYOTA JIDOSHA KK

Ramie raw material rubbing device for production of linen for calligraphy and paintings

ActiveCN111763992AIncrease kneading densityImprove cleaning qualityMechanical treatmentWater flowMechanical engineering

The invention discloses a ramie raw material rubbing device for production of linen for calligraphy and paintings, and relates to the technical field of production of linen for calligraphy and paintings. In order to solve the problem that fiber is likely to be snapped in the rubbing process of a ramie bark fiber rubbing processing device, the device specifically comprises a box. A shell is fixedlyinstalled at the top end of the box, and an isolation plate of the arc structure is fixedly installed inside the shell, a feeding hopper is fixedly installed at one side of the top of the shell, a movable cover is hinged to the other side of the top of the shell, a drainage hole is formed in the top end of the box, and a supporting rod is installed at the top end of the box through a bearing. Inthe water flowing process, due to the cooperation of spiral distribution of an arc protrusion and a rubbing mechanism, fiber produced by rubbing is conveniently conveyed, snapping is avoided, the quality of raw materials is ensured, the discharging operation can be completed just by pulling out a gathering discharging mechanism periodically, the whole device adopts a circulation for performing a large quantity of circulation flowing, and the cleaning quality of the ramie raw materials is improved.

Owner:XUZHOU PUSU INTERIOR DECORATION MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com