Special color master batch kneader stirring paddle

A technology of stirring paddle and kneader, which is applied in the field of stirring paddle, and can solve the problems such as the unsatisfactory stirring effect of the double paddle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

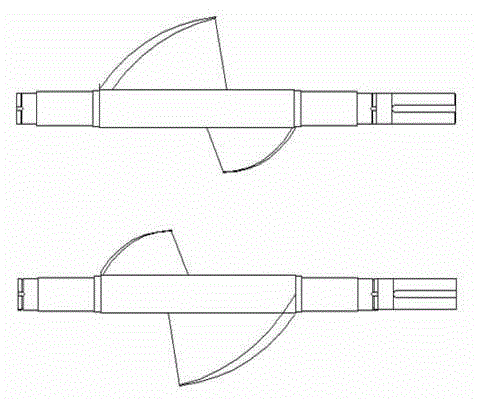

[0013] Such as figure 1 As shown, the kneader stirring paddle dedicated to color masterbatch of the present invention is composed of two Z-shaped paddles arranged in parallel, and the Z-shaped blades of the Z-shaped paddles are an asymmetrical structure with one long and one short, and the two Two asymmetrical Z-shaped impellers are set in opposite directions to mesh with each other. Through the design of such an asymmetric structure, when the color masterbatch is being stirred and kneaded, the color masterbatch is pushed back and forth between the two Z-shaped stirring paddles, which makes the stirring effect more uniform and improves the stirring efficiency , thus improving the efficiency of color masterbatch kneading.

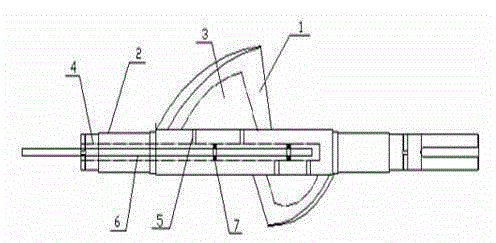

[0014] Such as figure 2 or image 3 As shown, there is a liquid circulation channel inside the Z-shaped stirring paddle for feeding cold and hot water for temperature control. The structure of the Z-shaped paddle with a liquid circulation channel is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com