Manipulator dough mixer mechanism

The technology of manipulator and noodle warehouse is applied in the field of automatic noodle processing equipment, which can solve the problems of low kneading efficiency, hard taste and complex structure, and achieve the effect of improving taste and kneading efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

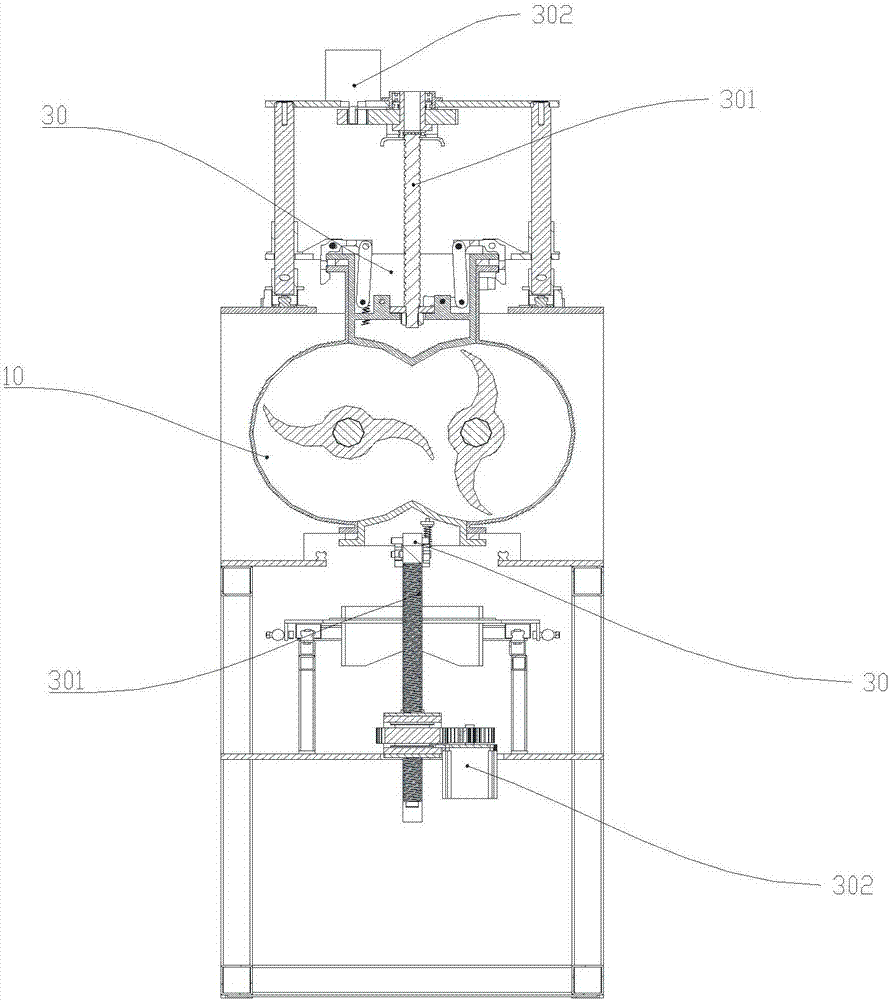

[0019] The present invention will be further elaborated below with reference to the accompanying drawings.

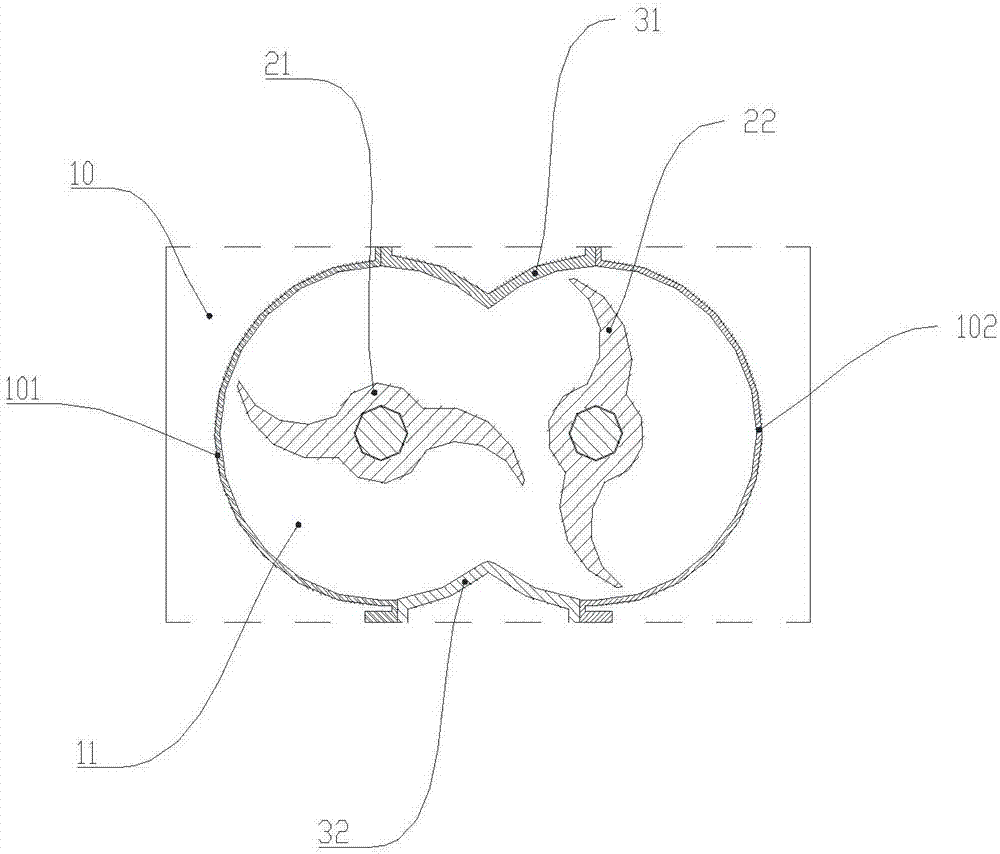

[0020] Please refer to the attached figure 1 to attach image 3 , in this embodiment, mainly introduce the noodle chamber and other internal structures of the robot kneading mechanism. The robot kneading mechanism includes: a noodle bin 10 for kneading dough, the cavity 11 of the noodle bin 10 is provided with a first blade 21 and a second blade 22 that can rotate around an axis, and the first blade 21 The first blade 21 and the second blade 22 rotate in opposite directions synchronously, and the rotation speeds of the first blade 21 and the second blade 22 are different according to different processes of dough kneading and dough kneading.

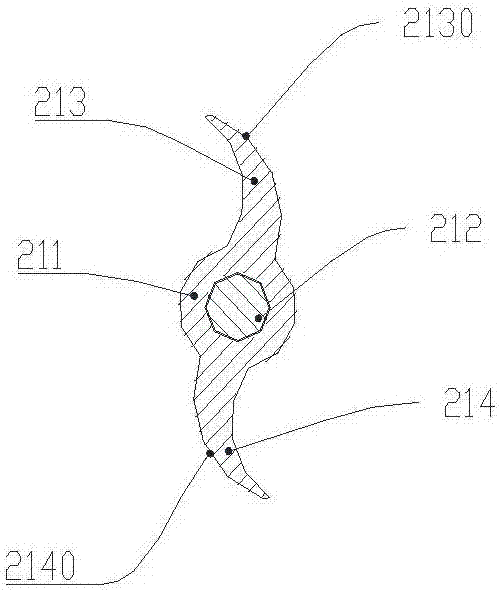

[0021] Please refer again to the attached figure 2 , the structure of the first blade 21 and the second blade 22 is the same, taking the first blade 21 as an example, it includes: a rotating shaft connection part 211, an arc-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com