An automatic noodle kneading device for noodle production and processing

An automatic and pasta technology, applied in the direction of dough extruder, etc., can solve the problems of difficult dough kneading, poor dough kneading effect, insufficient dough toughness, etc., to achieve full extrusion kneading effect, high kneading efficiency and ingenious structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

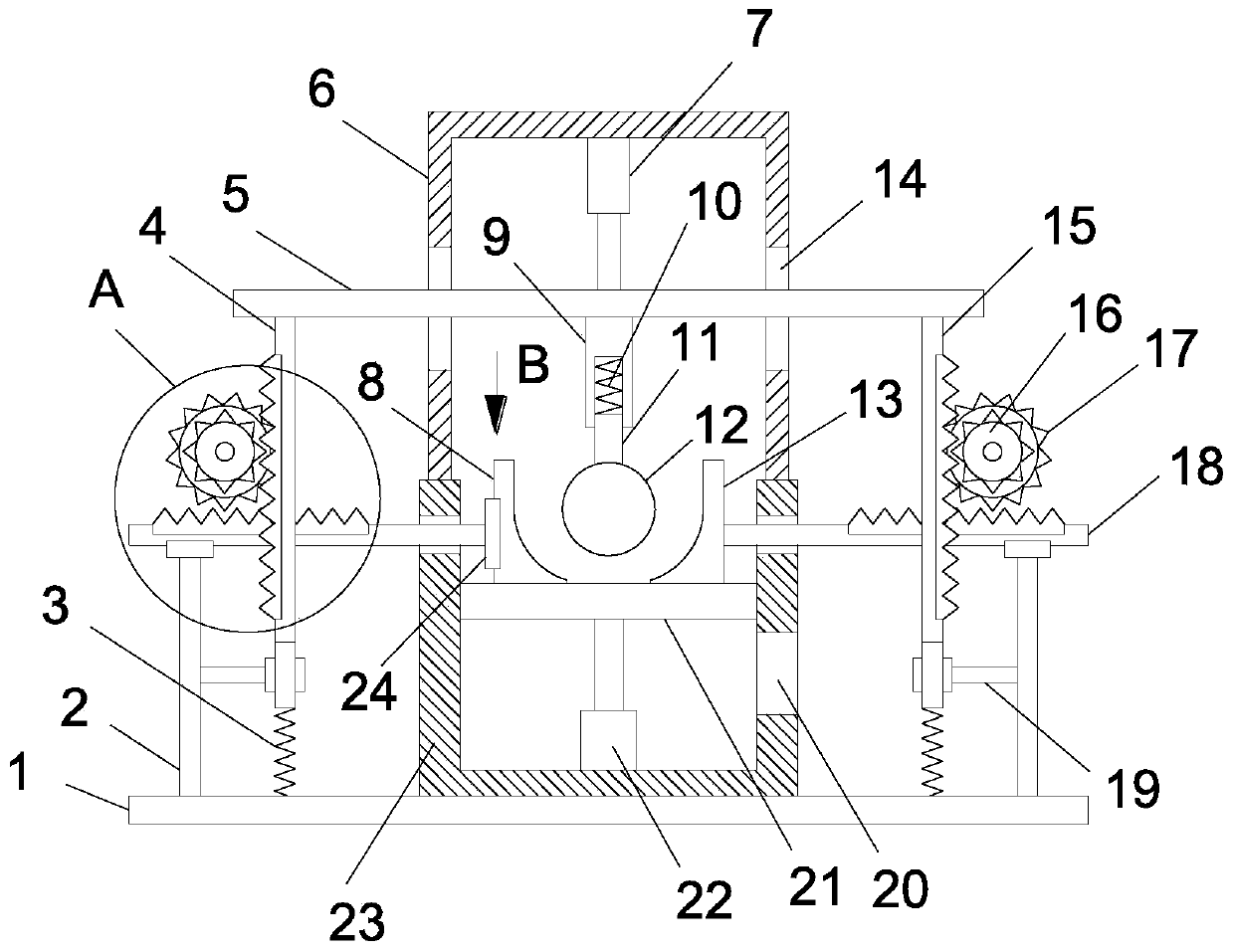

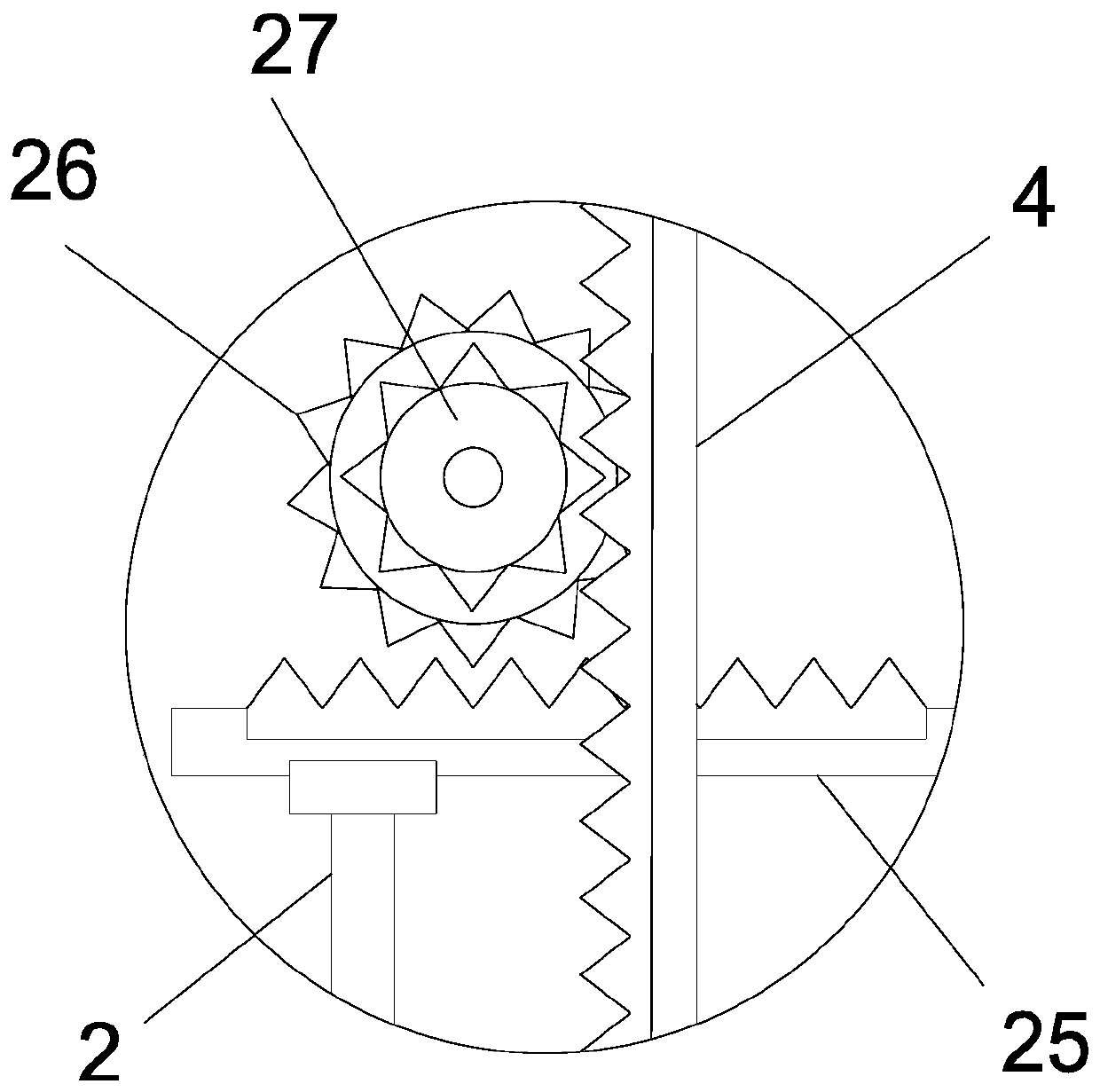

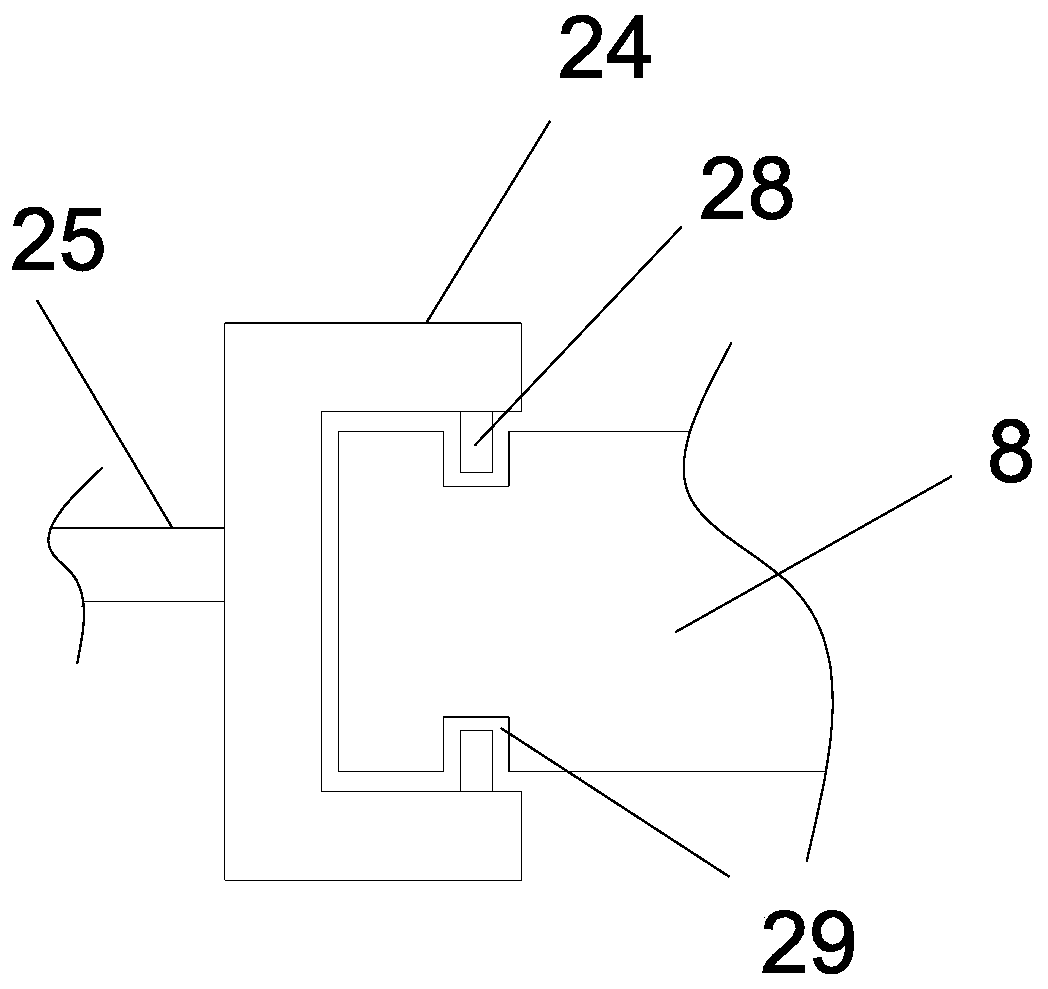

[0019] see Figure 1-3 , an automatic dough kneading device for pasta production and processing, comprising a base plate 1, a kneading dough box 23 is fixedly installed on the base plate 1, an electric telescopic rod 22 is arranged at the inner bottom of the kneading dough box 23, and an electric telescopic rod 22 is fixedly installed with The bearing plate 21 that contacts and connects with the inner side wall of the kneading box 23; the left and right ends of the upper surface of the bottom plate 1 are vertically fixed with two horizontal limit frames 2, and the horizontal limit frame 2 is respectively horizontally slid to be provided with the first Two transverse racks 25 and the first transverse rack 18, the second transverse rack 25 is located on the left side of the first transverse rack 18; the second transverse rack 25 rotates above the third gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com