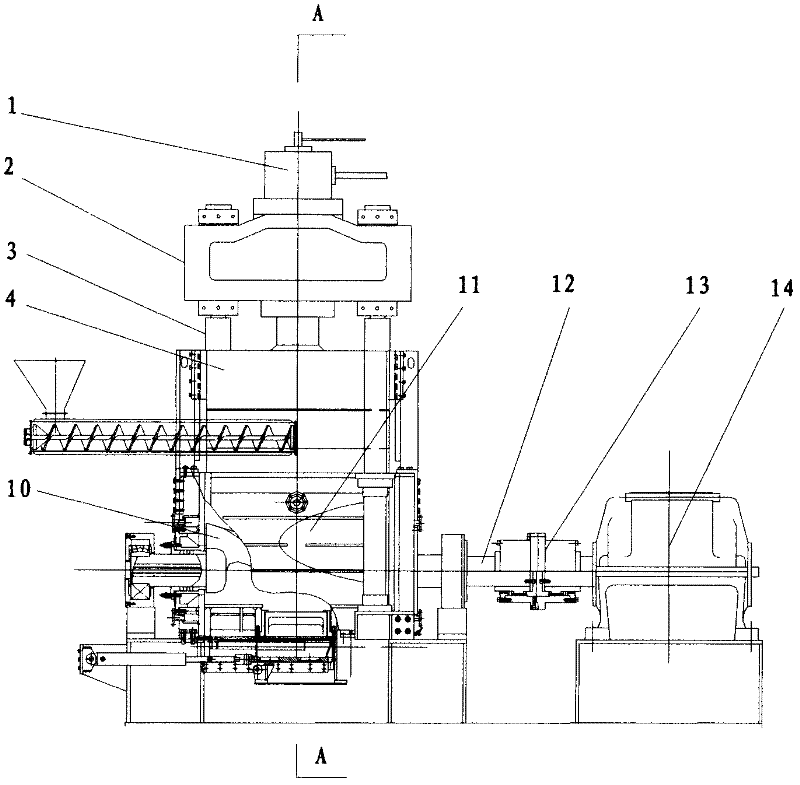

Pressure kneading machine

A kneader and hydraulic technology, applied in mixers, mixers with rotary stirring devices, mixer accessories, etc., can solve the problems of materials that cannot be compacted, and achieve the effects of increasing fluidity, reducing resistance, and improving kneading efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

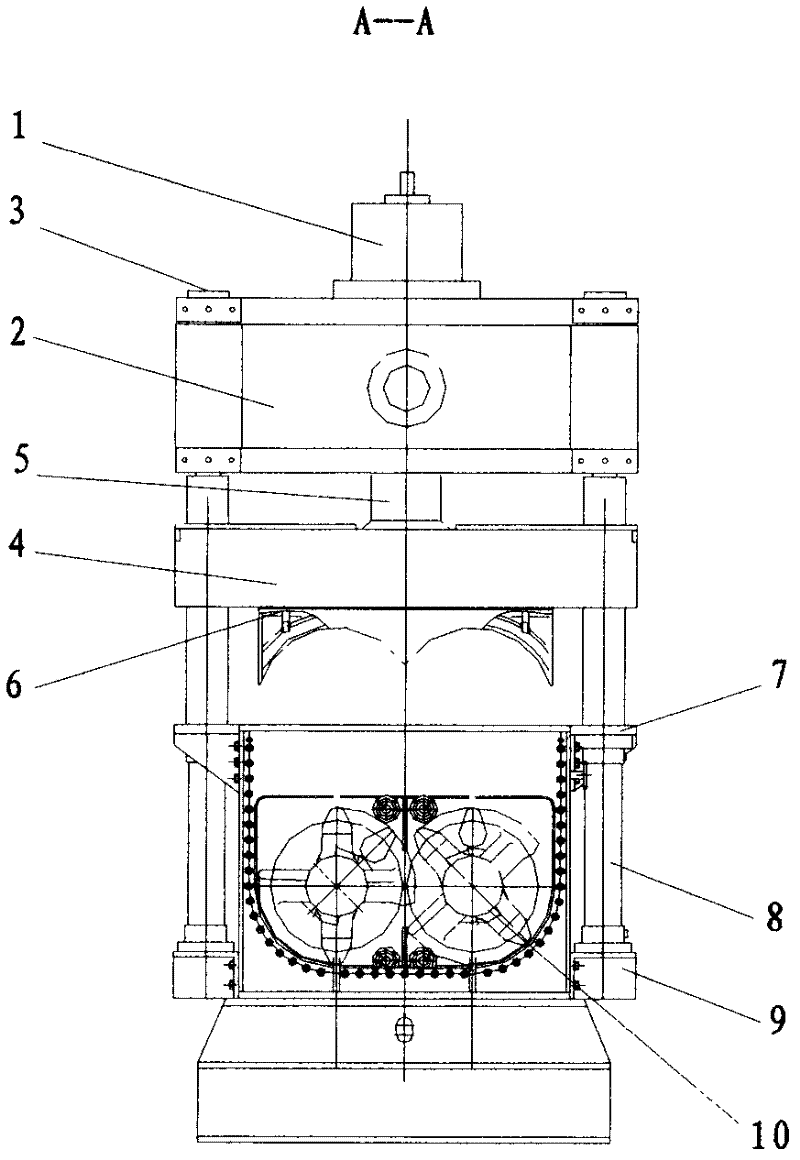

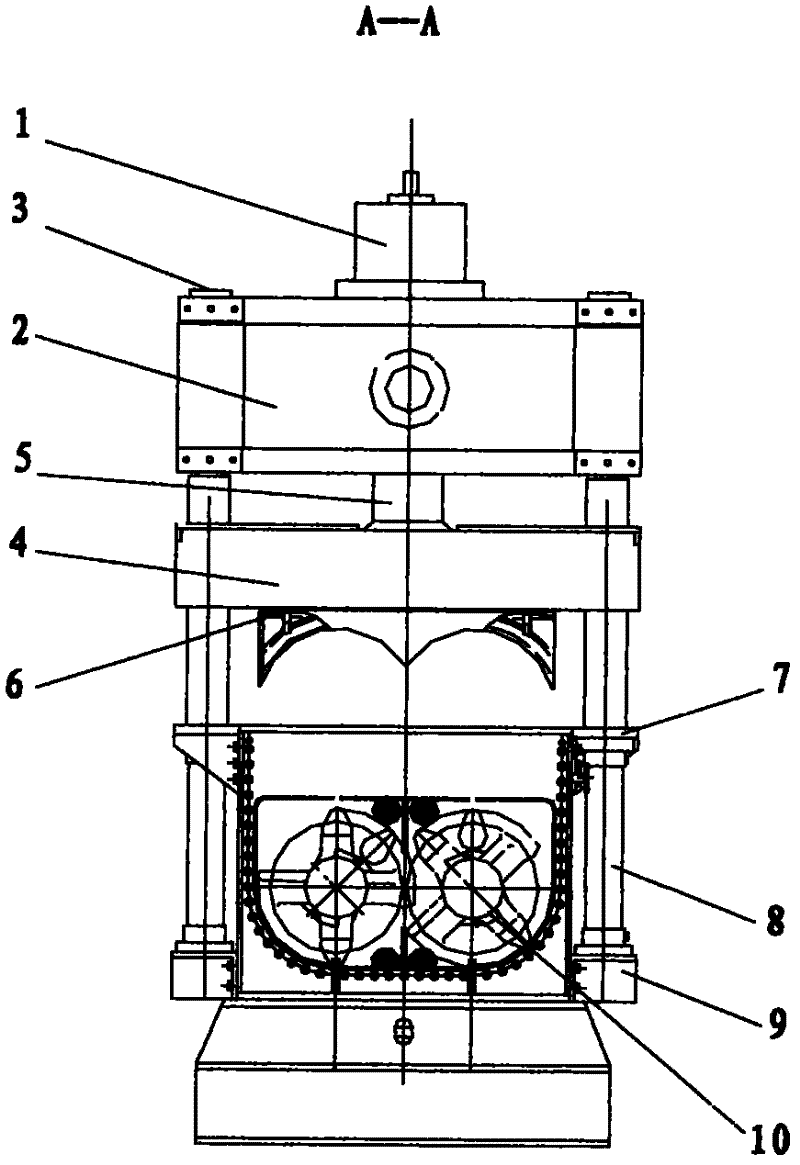

[0018] The stroke of the pressure pot 4 moving up and down is 30cm, and there is a sealing ring 6 between the pressure pot cover 4 and the pot body assembly 11 . The hydraulic drive device has a column 3 and a matching hydraulic cylinder 8, which are arranged on the periphery of the pot body assembly 11. There is a steam heating device in the outer wall of the pot body assembly 11 .

Embodiment 2

[0020] The stroke of the pressurized pot cover 4 moving up and down is 60cm, and a sealing ring 6 is arranged between the pressurized pot cover 4 and the pot body assembly 11 . The hydraulic drive device has four columns 3 and four matching hydraulic cylinders 8, which are arranged in a rectangular shape on the periphery of the pot body assembly 11. There is a thermal oil heating device in the outer wall of the pot body assembly 11 .

[0021] In the above-mentioned embodiments 1 and 2, when the kneader is working, the stirring shaft 12 and the stirring knife 10 drive the material to turn over in the pot body assembly 11, and the piston rod 5 of the hydraulic drive device drives the pressurized pot cover 4 to move up and down to adjust the material room for movement, exerting additional pressure on the material. At the same time, the heating device heats the material, which increases the temperature of the kneaded material, increases the fluidity of the material, reduces the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com