Electric stepless flow regulating valve

A flow regulating valve, stepless technology, applied in the field of liquid flow control valves, electric stepless flow regulating valves, can solve the problems of poor regulation linearity, complex structure of flow regulating valves, etc., to ensure the linearity of flow regulation and ensure linearity degree, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

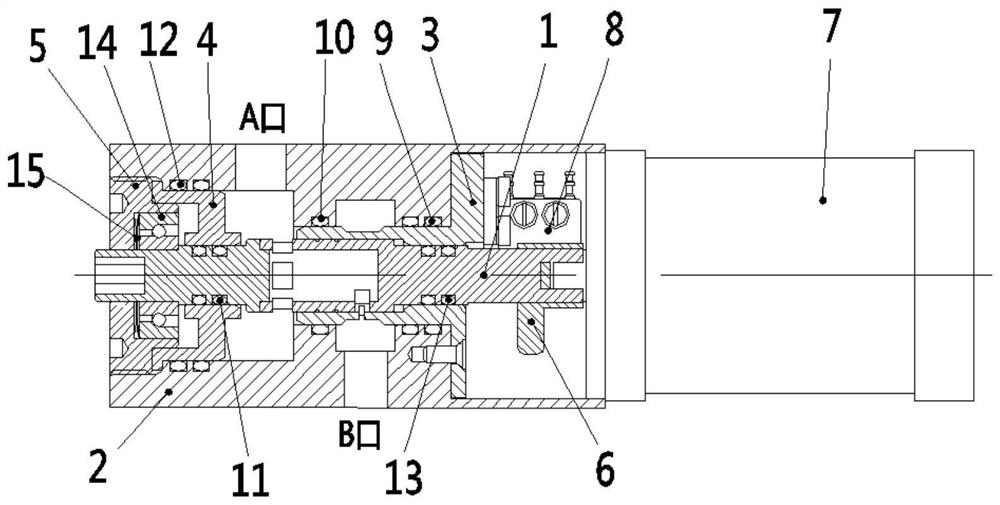

[0039] The invention provides an electric stepless flow regulating valve, which is directly driven by a stepping motor, rotates the valve stem, and shields the throttle window to realize the flow regulating function. The special window structure design ensures the better linearity of the electric stepless flow control valve. The invention has the characteristics of good linearity, compact structure, reliable action, good sealing performance and the like.

[0040] Specifically, the electric stepless flow regulating valve includes a valve stem 1, a valve body 2, a bushing 3, an unloading ring 4, a bearing seat 5, a micro switch 8, a trigger sleeve 6 and a stepping motor 7;

[0041] The valve stem 1 runs through the entire flow regulating valve, the left side penetrates the unloading ring 4, the bearing 14 and the bearing seat 5, the right side penetrates the bushing 3 and the trigger sleeve 6; the leftmost end is provided with an inner hexagon for manual operation The valve ste...

Embodiment 2

[0053] like figure 1 As shown, an electric stepless flow control valve is mainly composed of a valve stem 1, a valve body 2, a bushing 3, an unloading ring 4, a bearing 14, a bearing seat 5, a micro switch 8, a trigger sleeve 6 and a stepper Motor 7 is composed.

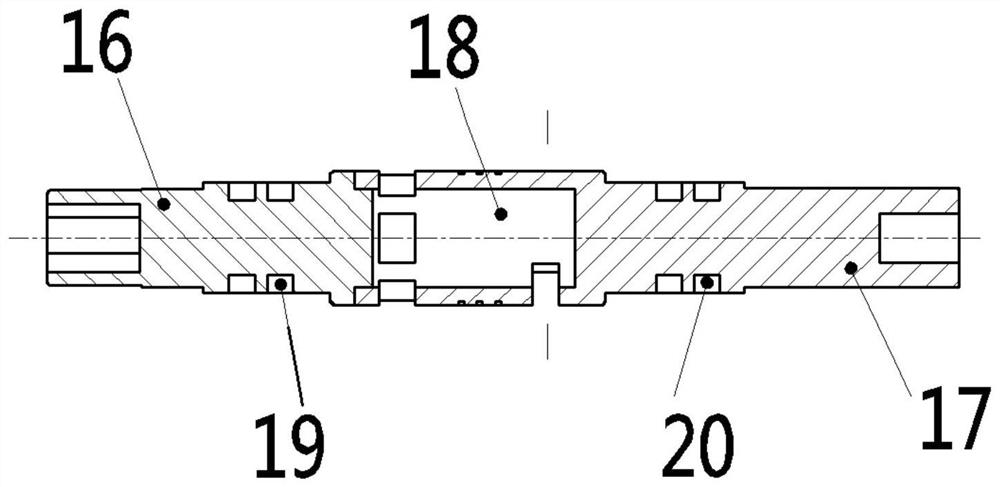

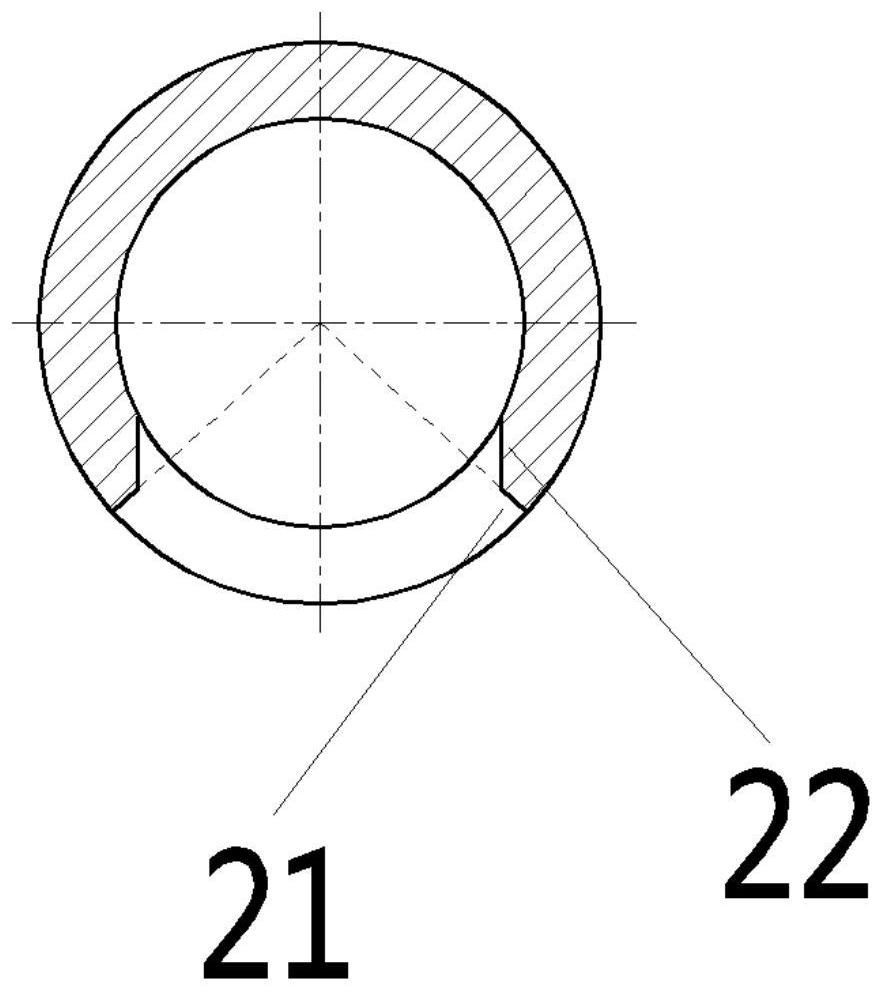

[0054] The structure of the electric stepless flow control valve is as follows: the valve stem 1 penetrates the entire flow control valve, the left side penetrates the unloading ring 4, the bearing 14 and the bearing seat 5, and the right side penetrates the bushing 3 and the trigger sleeve 6; The inner hexagon is used to manually operate the rotation of the valve stem 1; the rightmost end is provided with a flat groove, which is connected with the output shaft of the stepping motor 7; the left side 16 of the valve stem and the right side 17 of the valve stem are connected by welding, and are formed inside the right side after being connected. In the flow channel space with windows, there are four windows on the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com