Patents

Literature

64results about How to "Shorten kneading time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat accumulation and energy storage graphite material for solar thermal power generation and preparation method thereof

ActiveCN101948675AImprove thermal conductivityImprove heat storage capacityHeat-exchange elementsCooking & bakingThermal expansion

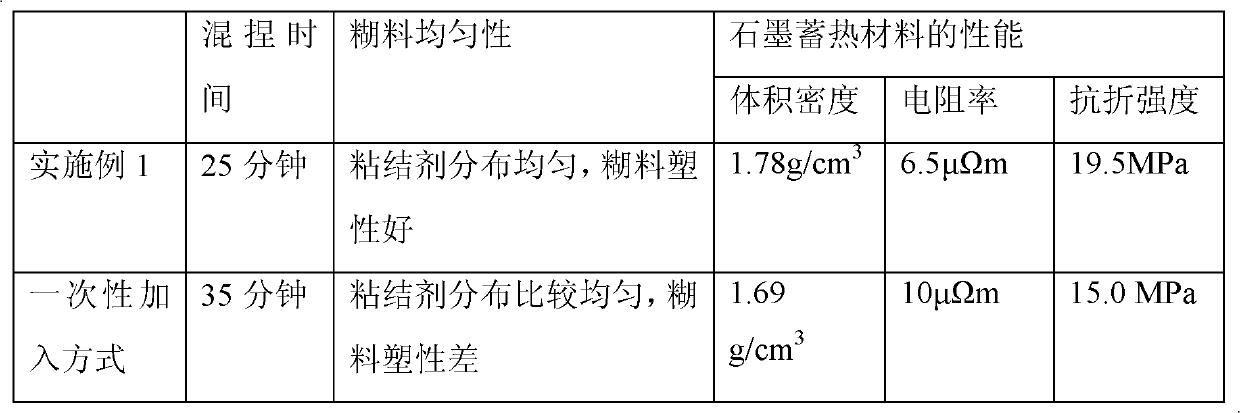

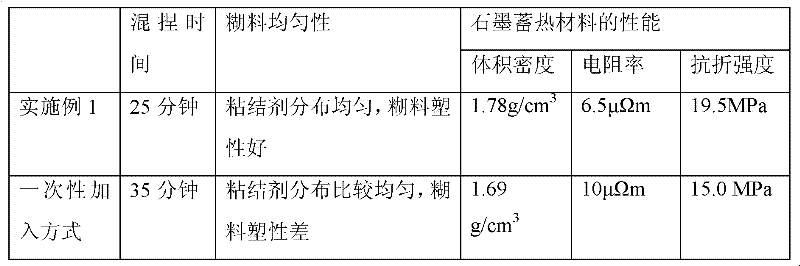

The invention relates to a heat accumulation and energy storage graphite material for solar thermal power generation and a preparation method thereof. The performance parameters of the graphite material meet the following requirements that: volume density is more than or equal to 1.75 g / cm<3>; electrical resistivity is less than or equal to 7.5 mu ohm m; ash content is less than or equal to 0.2 percent; rupture strength is more than or equal to 18.5 Mpa; elastic modulus is less than or equal to 8.8 Gpa; and thermal expansion coefficient is less than or equal to 2.0*10<-6> / DEG C<-1>. The graphite material of the invention has the advantages of high thermal capacity, high heat conductivity, long service life, low cost and the like. In the preparation method, the focusing solar thermal power generation and heat accumulating material is prepared from raw materials by the steps of sieving, burdening, kneading, airing, vibration molding, baking, soaking, secondary baking, graphitizing and machining.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

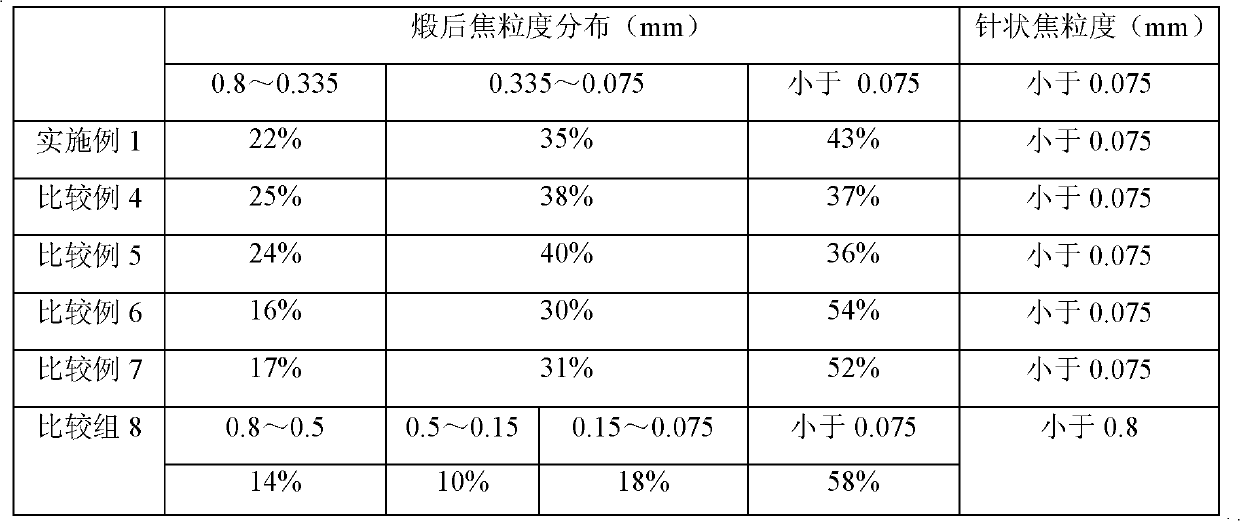

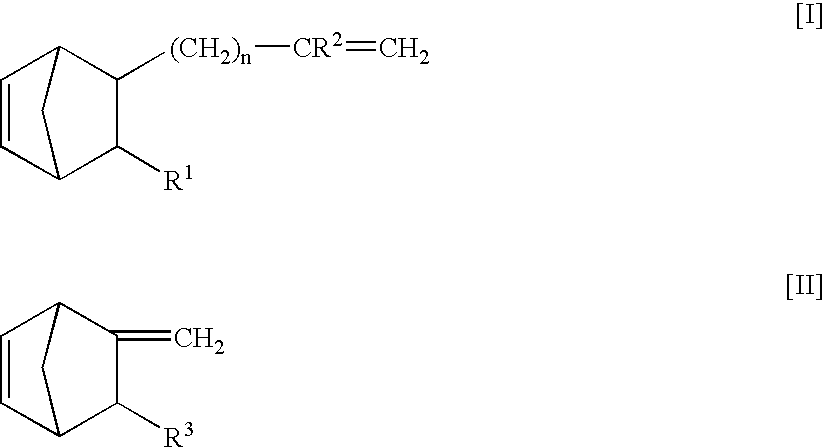

Pellet comprising ethylene-alpha-olefin-non-conjugated polyene copolymer, method for producing thermoplastic elastomer, and method for producing pellet comprising ethylene-alpha-olefin-non-conjugated polyene copolymer

InactiveUS20060142437A1Excellent cross-linking reactivityShorten kneading timeOrganic dyesPlasticizerThermoplastic elastomer

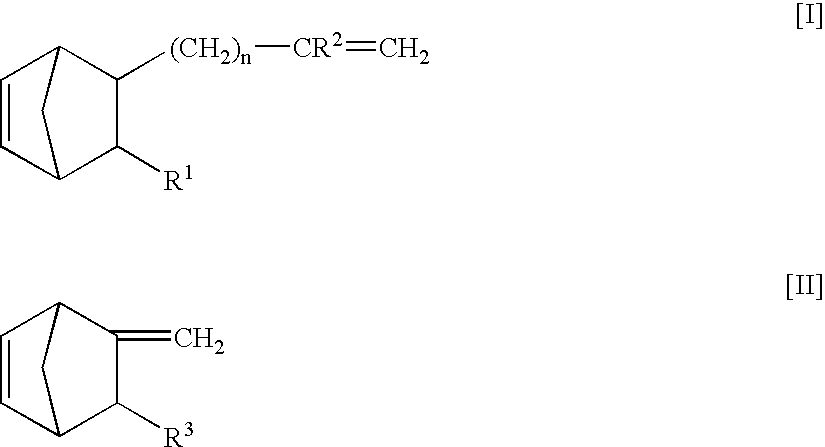

A pellet comprising 100 parts by weight of an ethylene / α-olefin / non-conjugated polyene copolymer (A) containing a constitutional unit derived from non-conjugated polyene represented by a specific Formula, 1 to 150 parts by weight of a plasticizer (B) relative to 100 parts by weight of the above (A), and 0 to 30 parts by weight of a thermoplastic resin (C) relative to 100 parts by weight of the above (A), is obtained, and a vulcanized rubber or a thermoplastic elastomer which does not cause blocking and has excellent crosslinking reactivity and thus excellent properties can be prepared therefrom. According to a process for preparation of a thermoplastic elastomer using the above-mentioned pellet, a thermoplastic elastomer having excellent compression set or dispersibility can be economically and efficiently prepared. In particular, since it can be prepared continuously using a twin screw extruder, the process is excellent from an industrial viewpoint. According to a process for preparation of a pellet of an ethylene copolymer rubber composition according to the invention, it is possible to obtain a copolymer pellet which has a low degree of crystallinity, does not cause blocking, has excellent crosslinking reactivity and has carbon-carbon double bonds of excellent crosslinking reactivity.

Owner:MITSUI CHEM INC

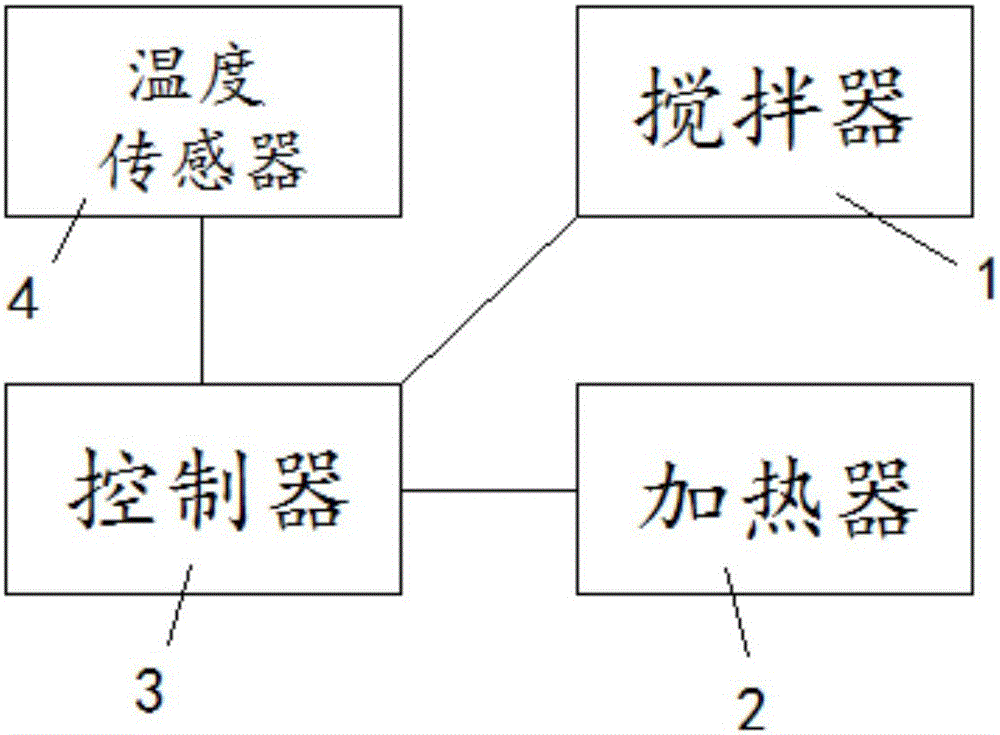

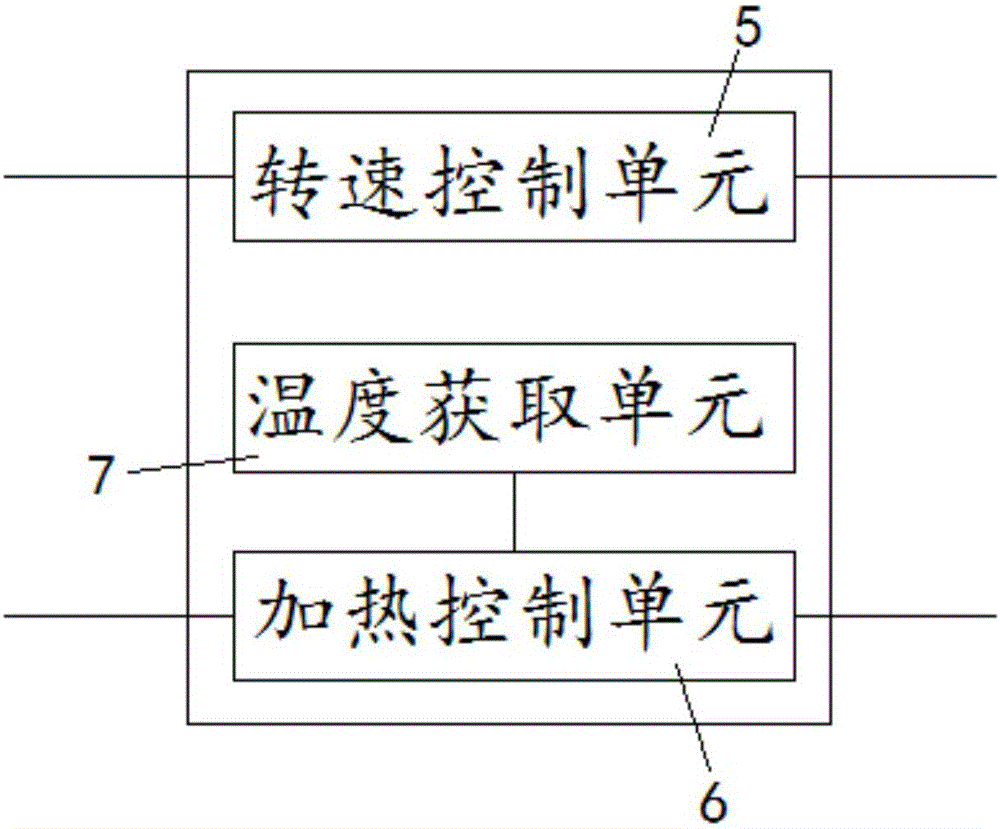

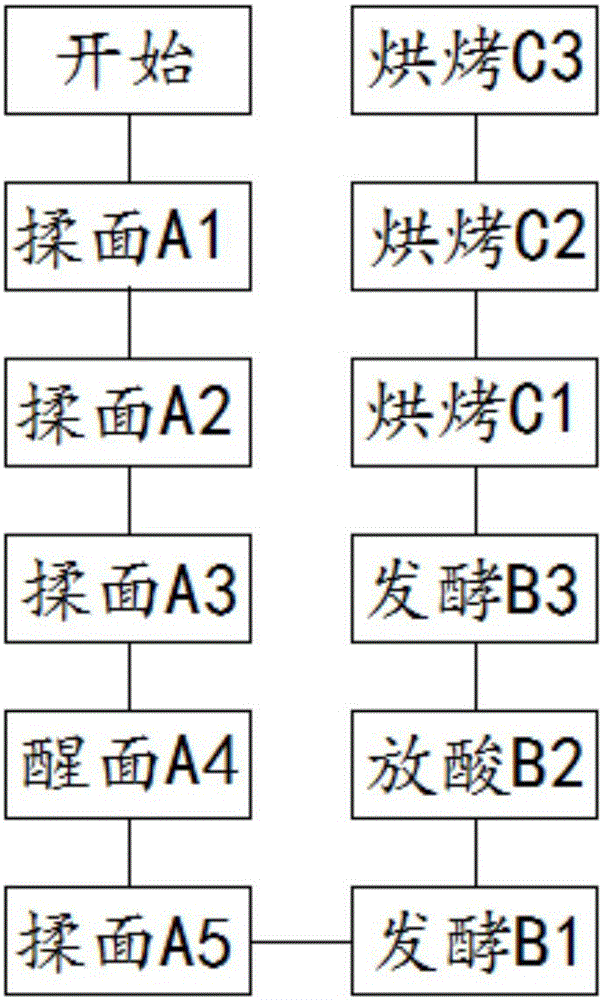

Bread maker control system, device and method

InactiveCN106308566AImprove production efficiencyImprove qualityBread-toastersCooking & bakingControl system

The invention relates to a bread maker controller system, device and method. By means of variable-speed control over stirring rotation speed and duration and precise control over heating temperature and duration in different stage of bread making, combined dough kneading is conducted at different rotation speeds and durations, the manual dough kneading process is simulated, quick film output can be achieved, dough quality is high, time for fermentation and baking in later stages is greatly shortened, and bread making time is greatly shortened. After bread is cut, the bread is uniform in bread pore density, and the bread sends out strong wheat aroma, can be tore into slices and is better in taste.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

Polypropylene cable sheath material for submersible pump and producing technology thereof

ActiveCN1923883AMeet needsImprove product qualityInsulated cablesInsulated conductorsManufacturing technologyEngineering

The invention discloses a polypropylene cable protective material and manufacturing technology of submersible pump, which comprises the following parts: 100wt% polypropylene resin, 30-50wt% modifier, 0.2-1wt% lubricant, 0.5-1wt% anti-oxidant and 0.2-0.8wt% copper-proof agent.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

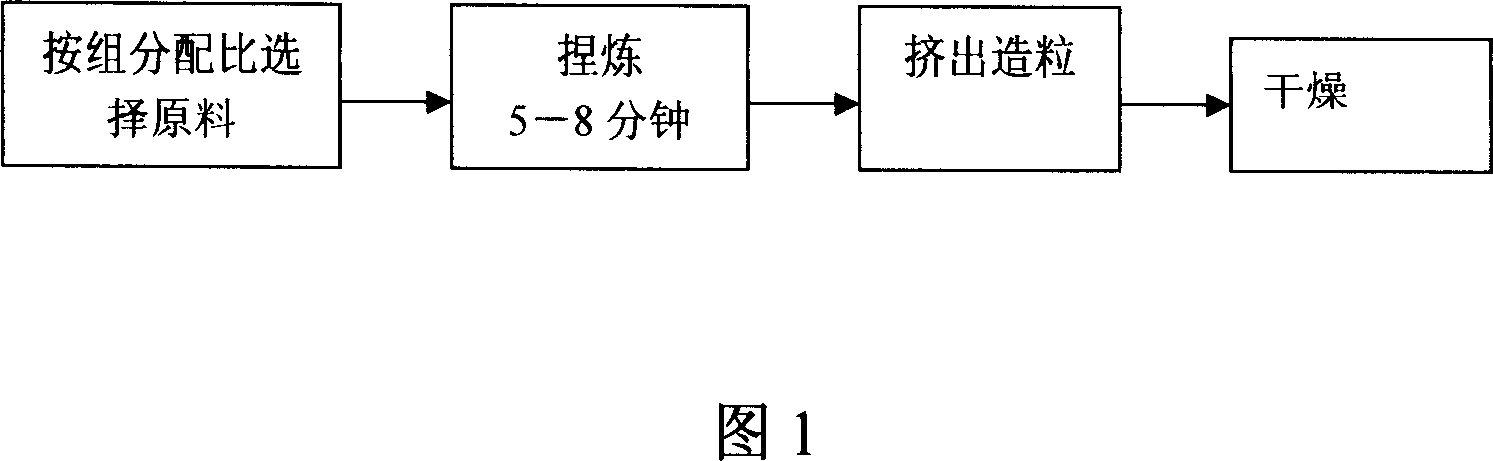

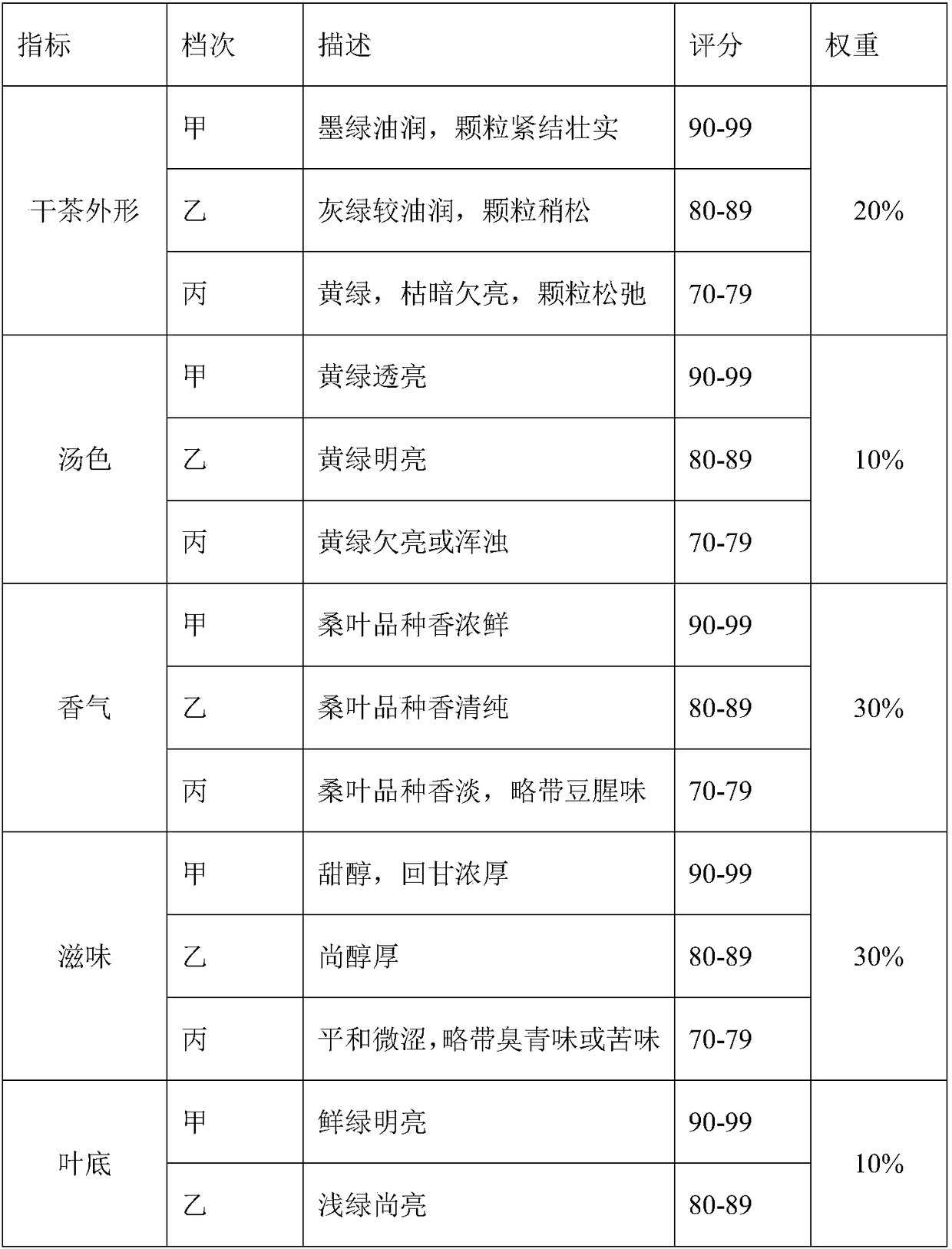

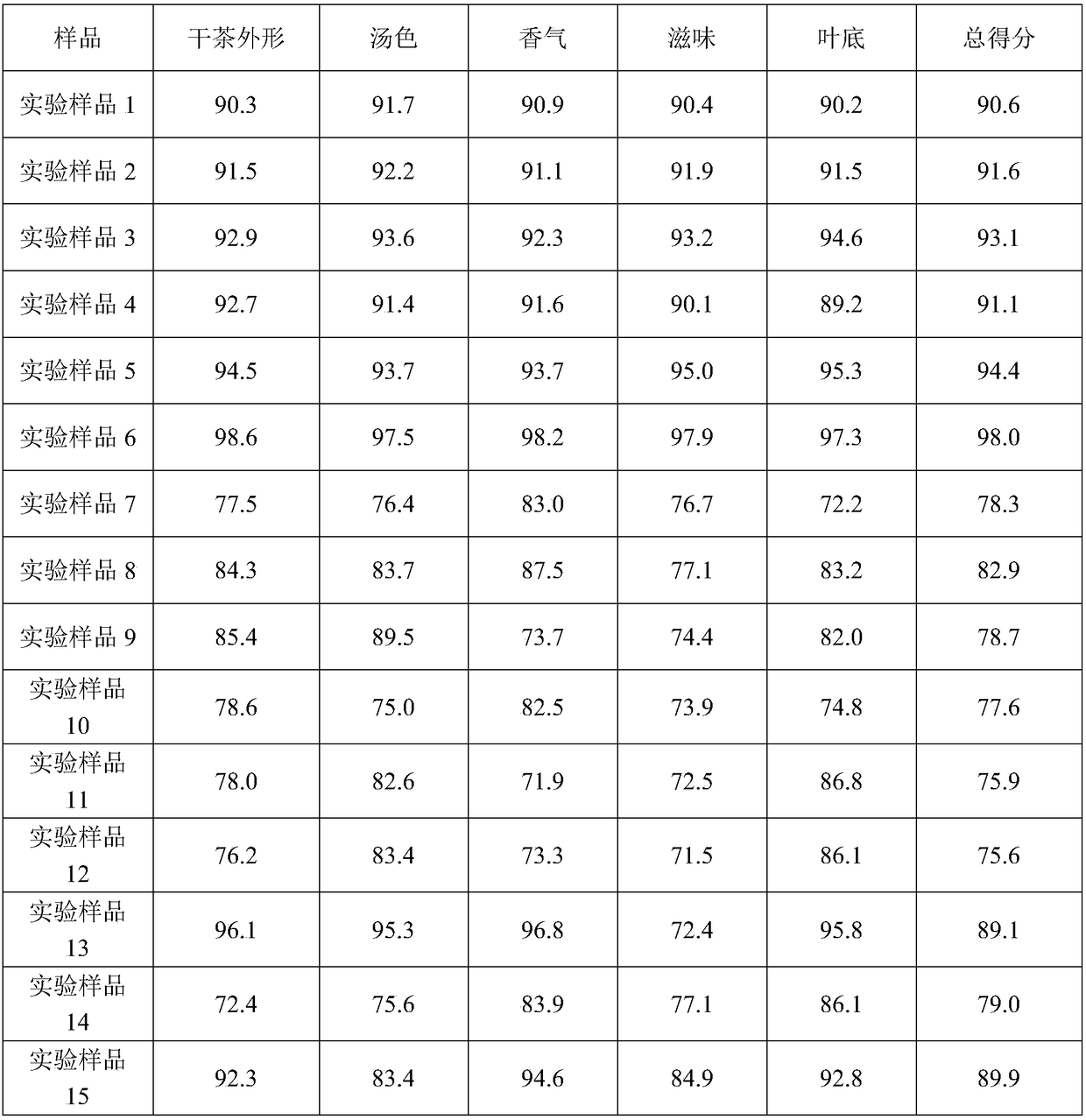

Mulberry leaf green-tea and preparation technology thereof

ActiveCN108432923AThe particles are tight and strongDark green oily colorTea substituesEpigallo-catechin gallateBiology

The invention provides mulberry leaf green-tea and a preparation technology thereof, and specifically relates to the technical field of tea preparation. The preparation technology of the mulberry leafgreen-tea comprises the following steps: a. Picking fresh mulberry leaves; b. withering the picked mulberry leaves; c. cutting the withered mulberry leaves into strips; d. carrying out drum fixation;e. carrying out spreading-cooling; f. carrying out secondary microwave fixation; g. carrying out cooling and water-regaining; h. carrying out rolling; and i. carrying out stir-frying and shaping. Thestep of withering moisture in the mulberry leaves, the fixation temperature and the rolling methods in the preparation technology are optimized so that the prepared mulberry leaf green-tea has uniquecharacteristic varietal aroma of mulberry leaves, and is tight and compact in granules, dark green and oily in color and lubricant in color and luster, yellowish green, translucent and bright in soupcolor, sweet and pure in taste, and mellow in after taste; moreover, the preparation technology of the mulberry leaf green-tea is stable and controllable in preparation processes, high in productionefficiency, and suitable for large-scale production.

Owner:柳城县国营伏虎华侨农场茶厂

Processing method of floral aroma type black tea

InactiveCN104472739AHelps decompose conversionPromote conversionPre-extraction tea treatmentBlack teaGreen tea

The invention discloses a processing method of floral aroma type black tea. The processing method comprises the following process steps: selecting fresh leaves, performing indoor natural withering, withering with sunlight, heating and rocking, airing, rolling, fermenting, heating and tidying tea strips, shaping and drying. The processing method disclosed by the invention performs adjustment and improvement on a traditional black tea production process, and the prepared tea has flat, smooth, upright and beautiful shape and also has the advantages of bright yellow-red color, clear soup color, clear yellow-red color, sweet and pure aroma, slight flower fragrance, sweet, mellow and smooth taste, sweet after-taste, effect of promoting fluid production, red and green tea residue color and appearance of green leaves rimmed with red edges.

Owner:YIBIN CHUANHONG TEA IND GRP

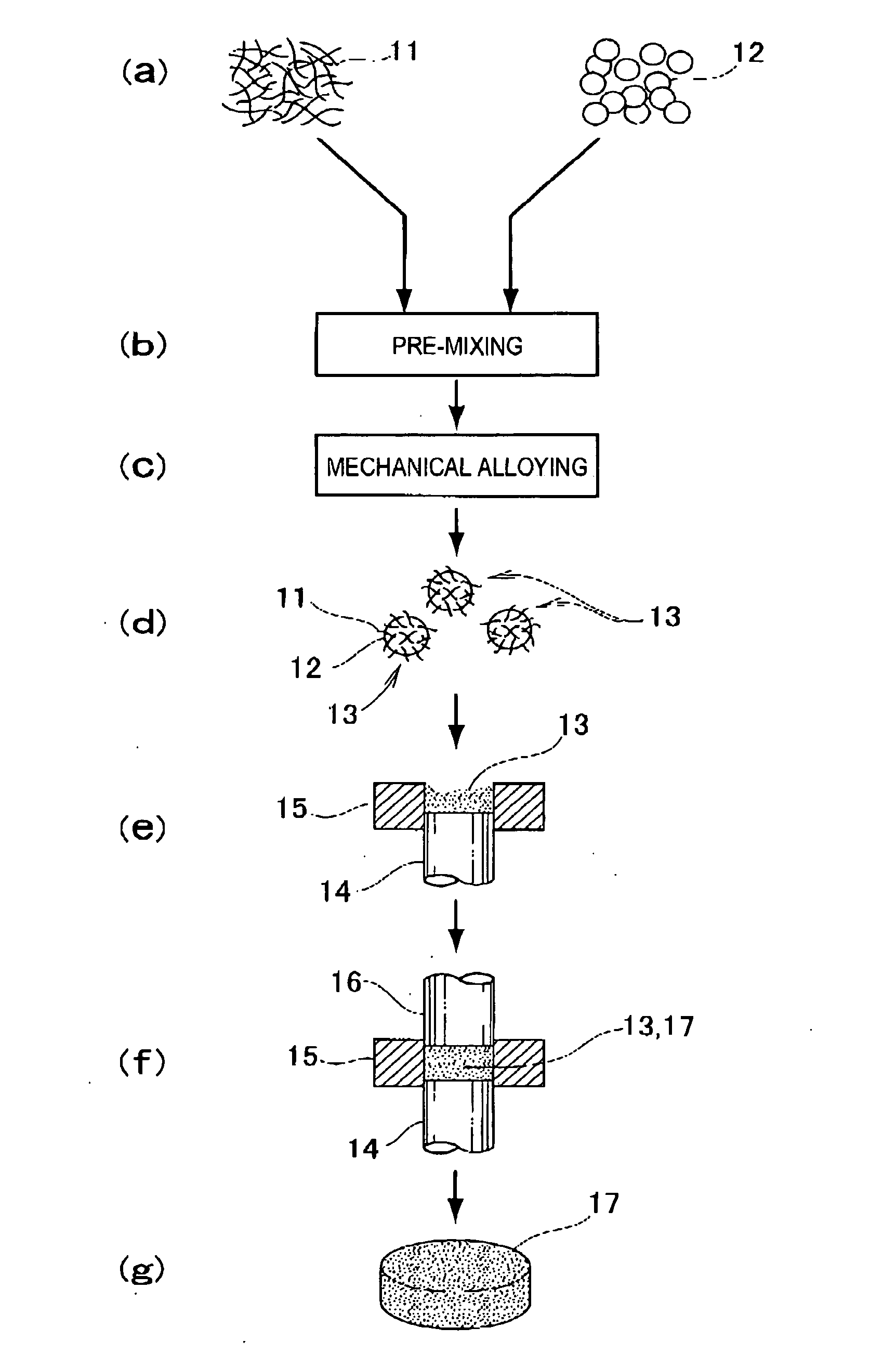

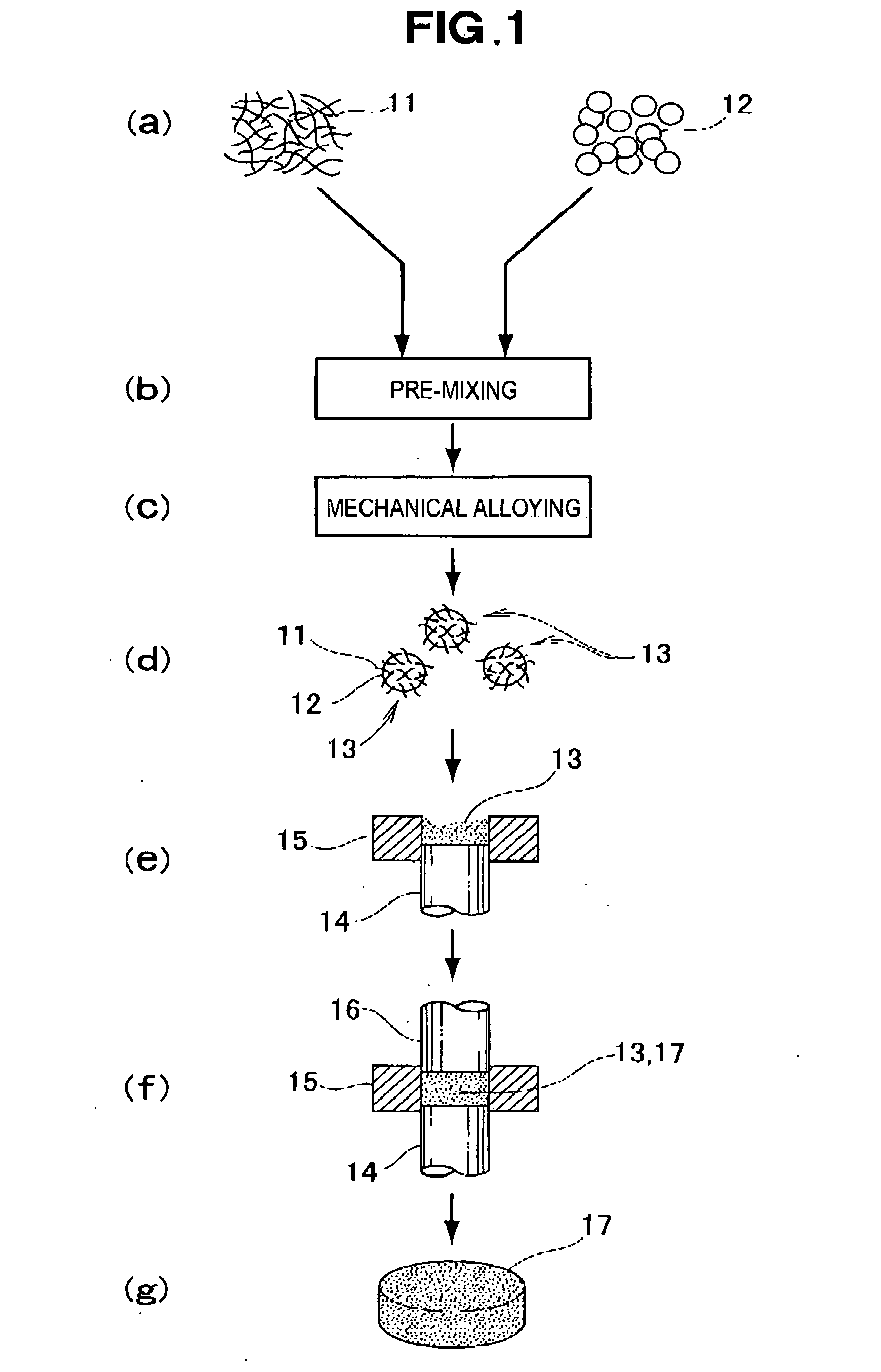

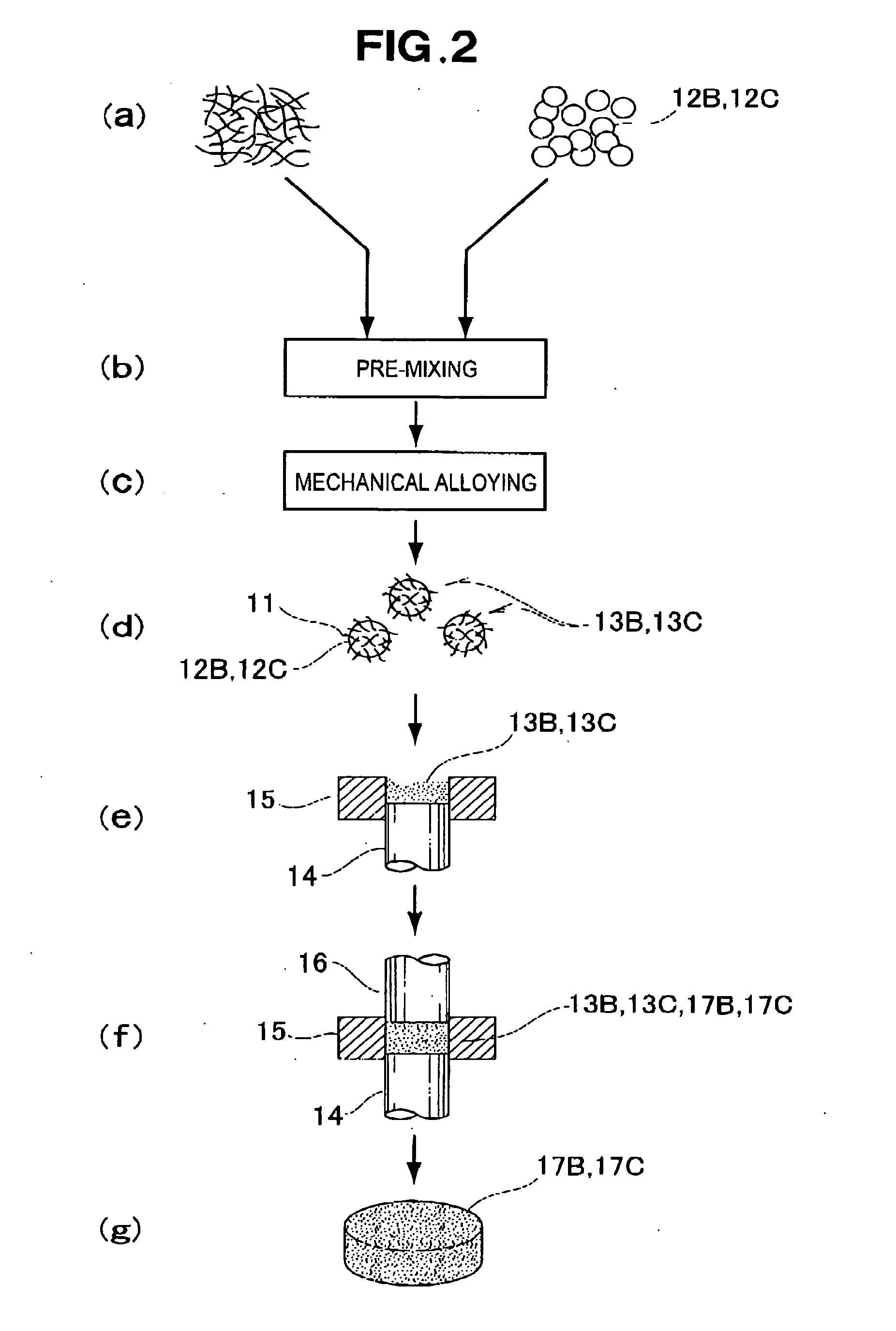

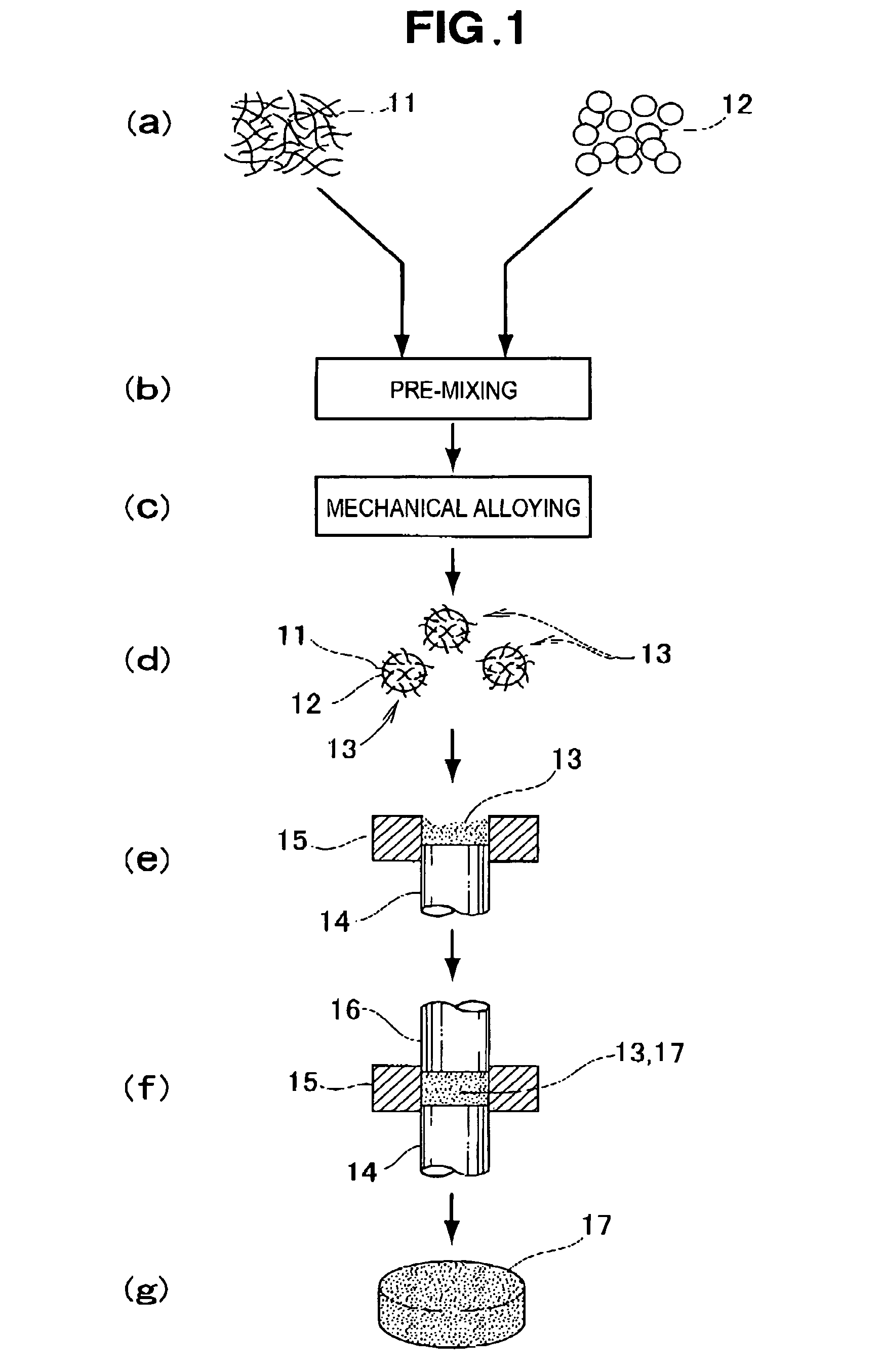

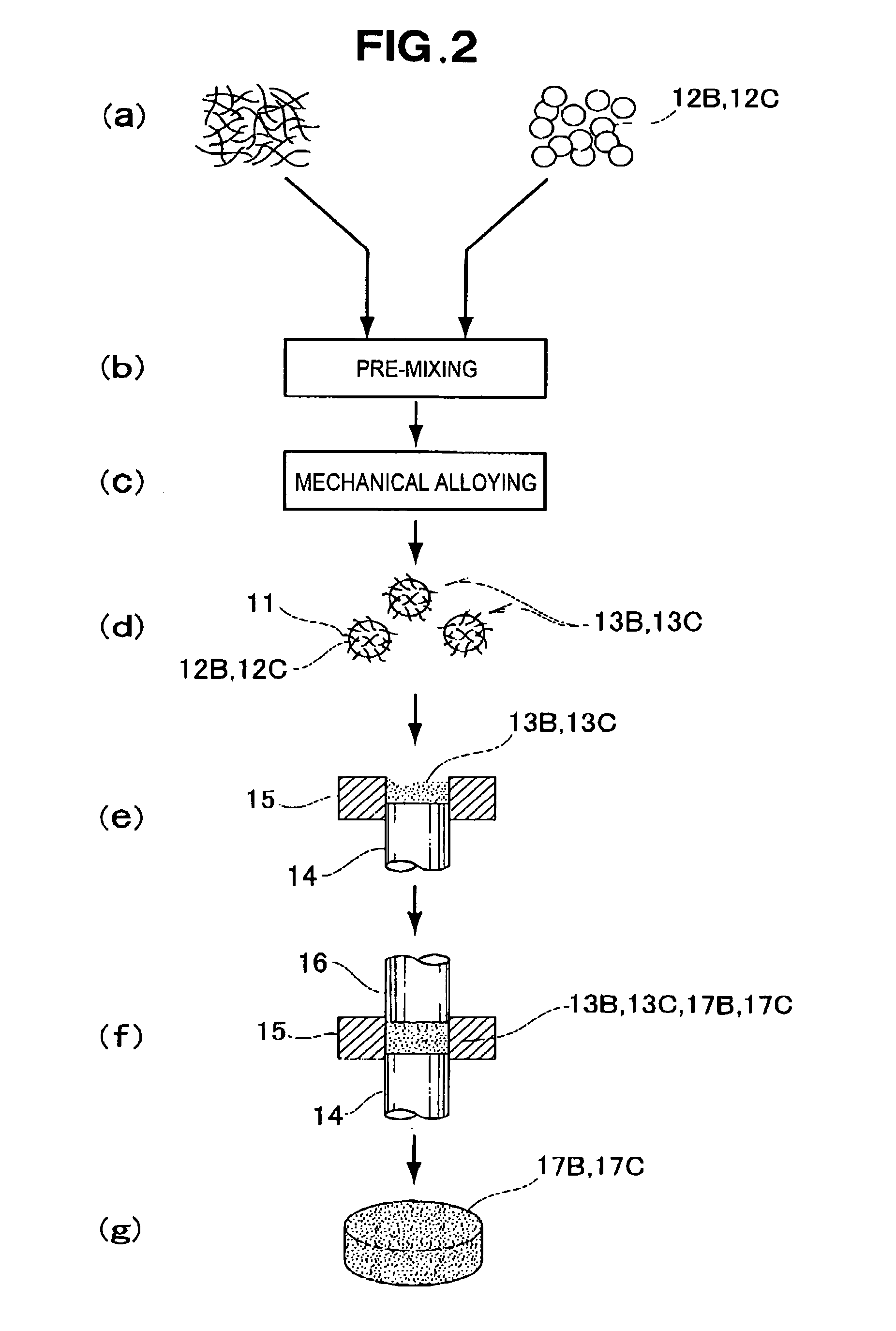

Method for manufacturing composite metal alloy and method for manufacturing article from composite metal

InactiveUS20100068089A1Improve wettabilityImprove featuresFoundry mouldsFoundry coresMetal alloyCarbon nanomaterials

A method for manufacturing a composite metal alloy from a carbon nanomaterial and a metal material is disclosed. The carbon nanomaterial and the metal material are mixed, and a mixture is obtained. Afterwards, the mixture is dissolved. In the dissolving step, the carbon nanomaterial moves through the melt while adhering to the metal material.

Owner:NISSEI PLASTIC IND CO LTD

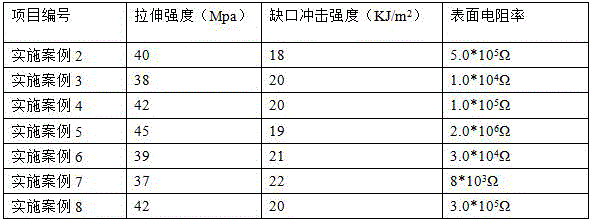

Preparation method of static-conductive PVC (polyvinyl chloride) mining pipe

The invention discloses a preparation method of a static-conductive PVC (polyvinyl chloride) mining pipe. The method comprises the following steps: (1) adding a PVC resin and a two-dimensional-plane-structure nano carbon material into a kneader, and kneading to obtain a PVC / nano carbon master batch; and (2) proportionally adding the PVC resin, conductive carbon black, a compatibilizer, a heat stabilizer, lubricant and processing aids into the PVC / nano carbon master batch, stirring and mixing, and carrying out melting and extrusion forming to obtain the mining pipe finished product. The method can enhance the static conductivity of the PVC mining pipe, and can also enhance the impact resistance, corrosion resistance, heat stability and other properties of the PVC mining pipe.

Owner:DEYANG CARBONENE TECH

Rosemary flower tea and preparation method thereof

The invention belongs to the technical field of tea processing, and particularly relates to a rosemary flower tea and a preparation method thereof. The rosemary flower tea is prepared by scenting leaves and fresh flower of rosemary and compounding lemon, mint leaves, hawthorn and licorice, and has the characteristics of coolness, sweetness, strong fragrance, soft taste and the like. In the preparation process of the rosemary flower tea, before an enzyme-deactivating process in production of a rosemary tea blank, processes of soaking sodium glutamate and performing microfermentation are added, so that the amino acid content of the rosemary flower tea is increased and the nutritional quality of the rosemary flower tea is improved; by a low-temperature, high-dampness and constant-temperature enzyme-deactivating process, enzymes in rosemary can be effectively destroyed; in combination of room-pressure rolling and pressurized rolling, the rolling time is shortened, so that cells can be sufficiently crushed; a drying process is performed before and after scenting respectively so as to ensure the final quality of the rosemary flower tea; after scenting and compounding, an intermittent microwave drying process is performed so as to improve the leaching rate of water-soluble substances in the final rosemary flower tea; the preparation method is reasonable in process; the rosemary flower tea is nutritional and good in color; nutritional components in the rosemary flower tea can be effectively retained; the leaching rate of nutrients in the brewing process can be improved.

Owner:湖南省雅迭香科技有限公司

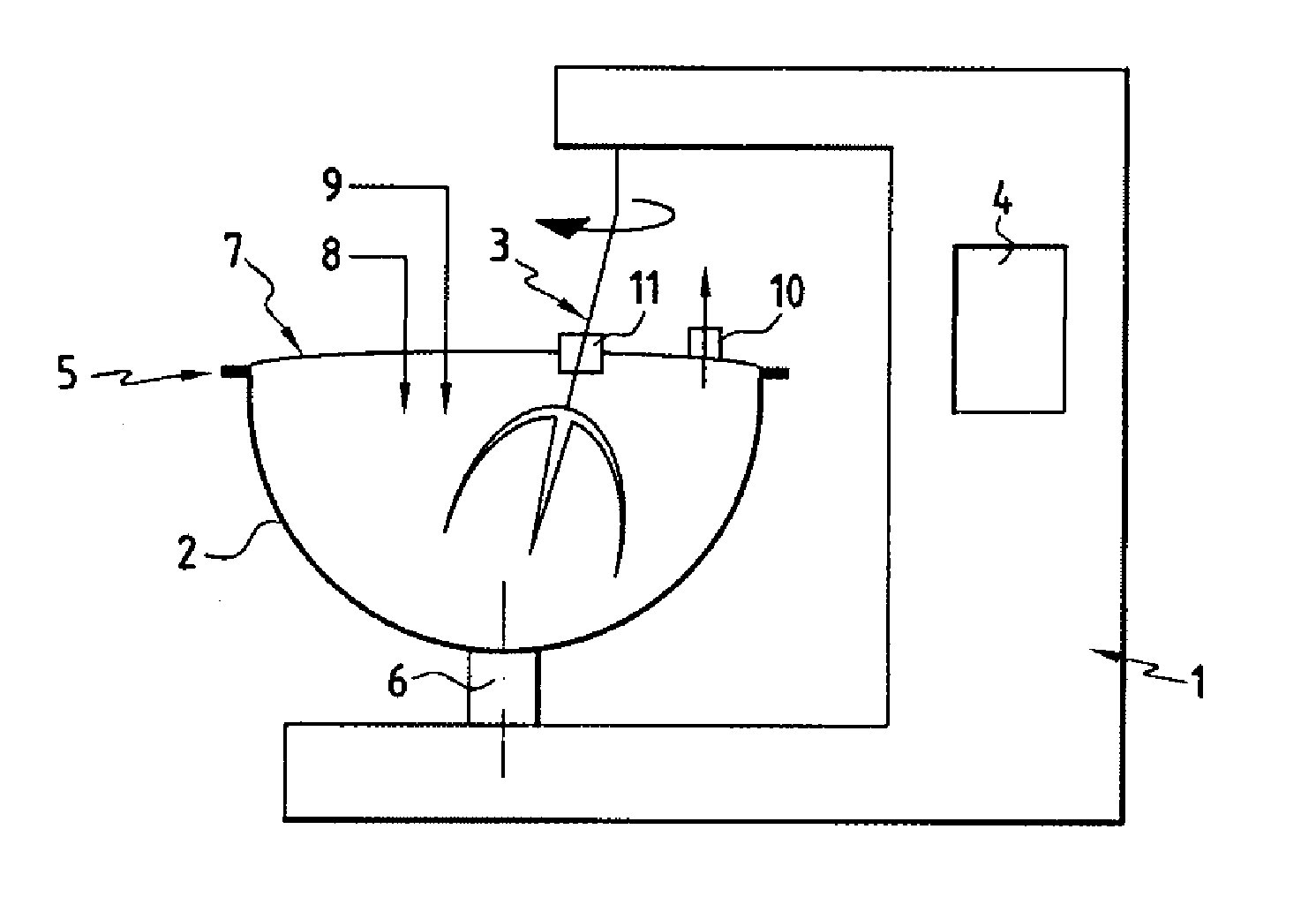

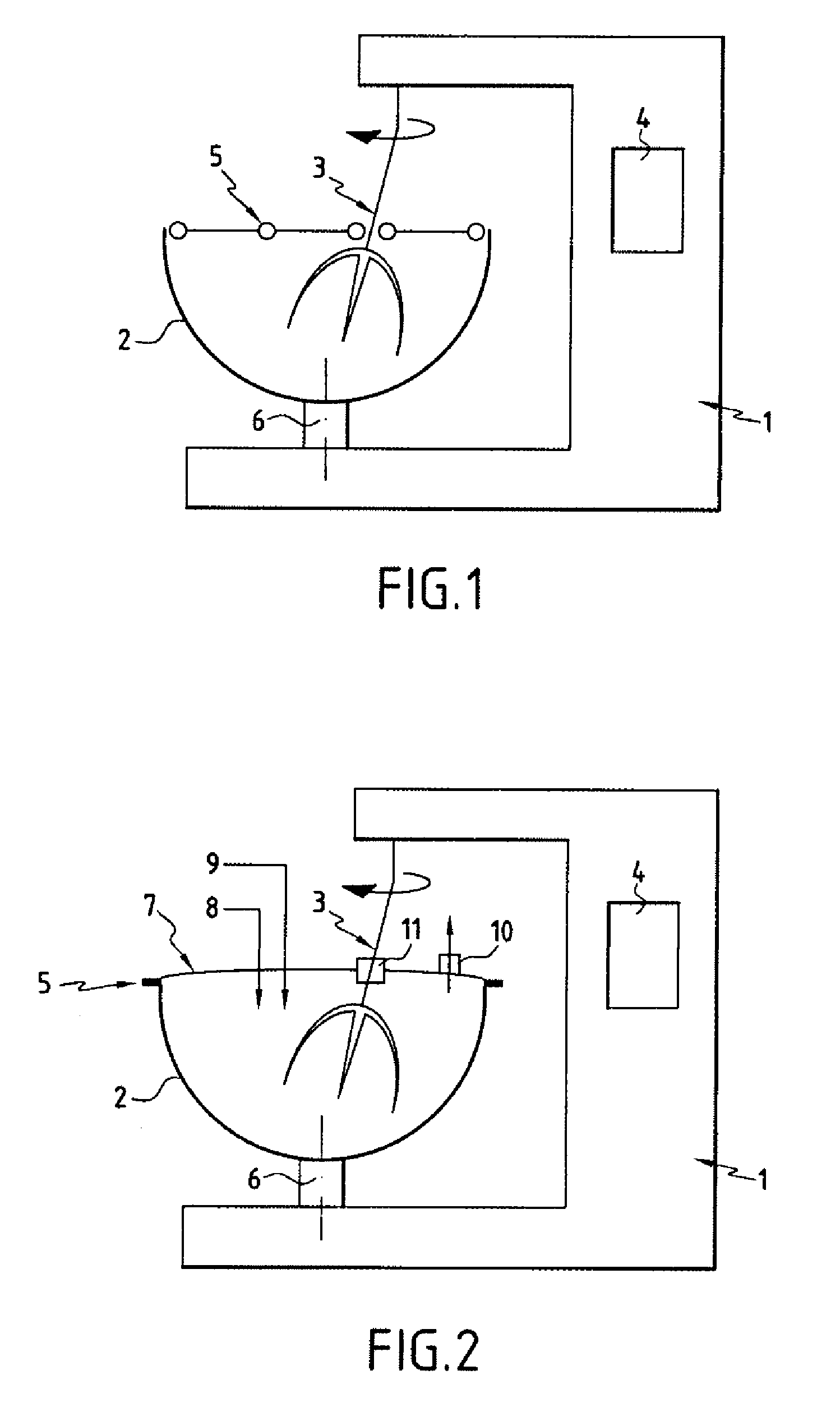

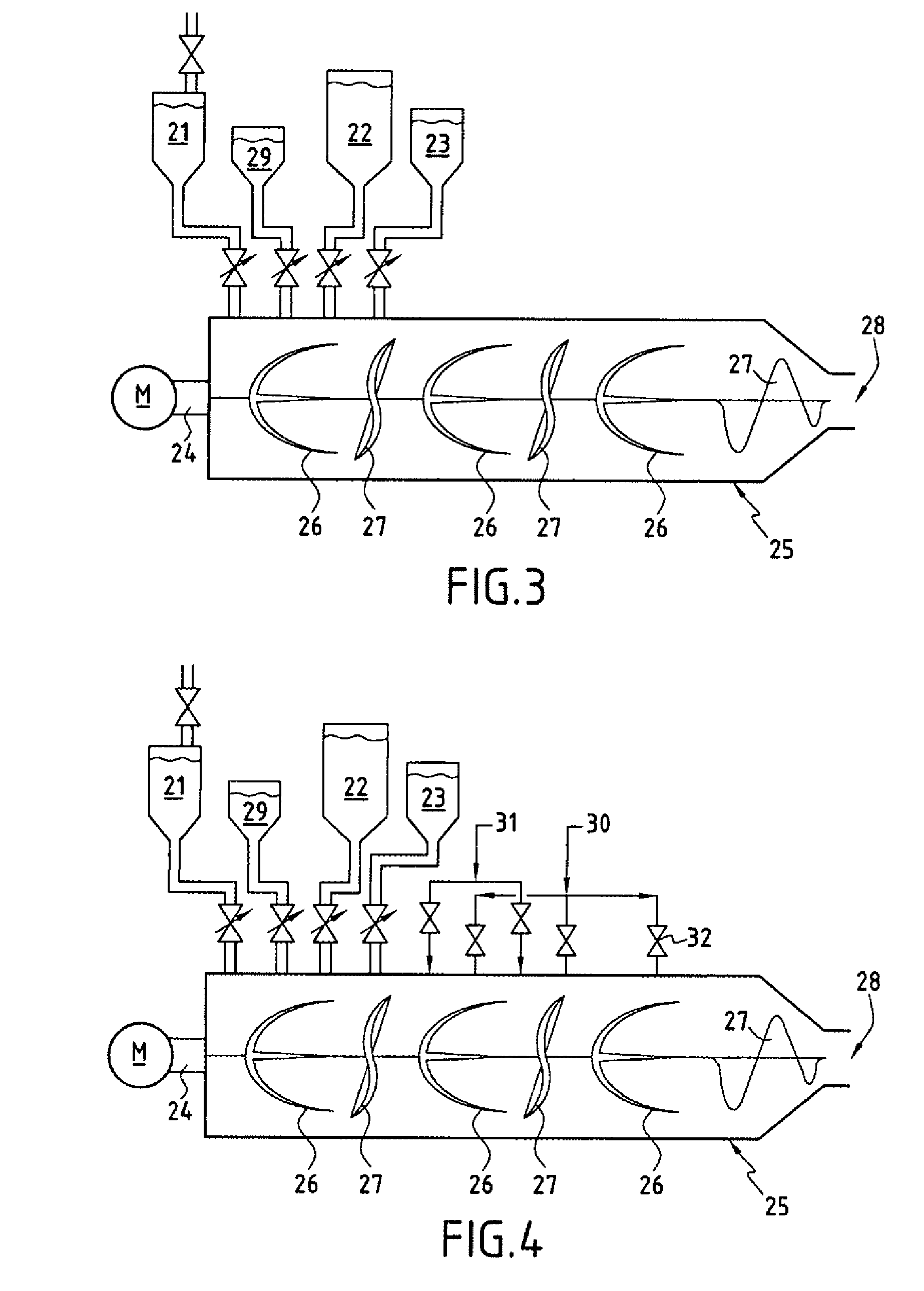

Use of Ozone for Improving Kneading

InactiveUS20080044519A1Facilitate actionIncrease rotation speedDough treatmentMixing/kneading structural elementsChemistryOzone

The object of the present invention is a new method for kneading dough containing soft wheat flour, conducted in the presence of ozone and using at least one mechanical agitator (“fraser”). The dough so produced may be used to manufacture finished cereal bakery products such as loaves or related products (raised pizza dough for example).A further object of the invention is new kneading devices adapted for kneading in the presence of ozone.

Owner:GREEN TECHNOLOGIES SARL

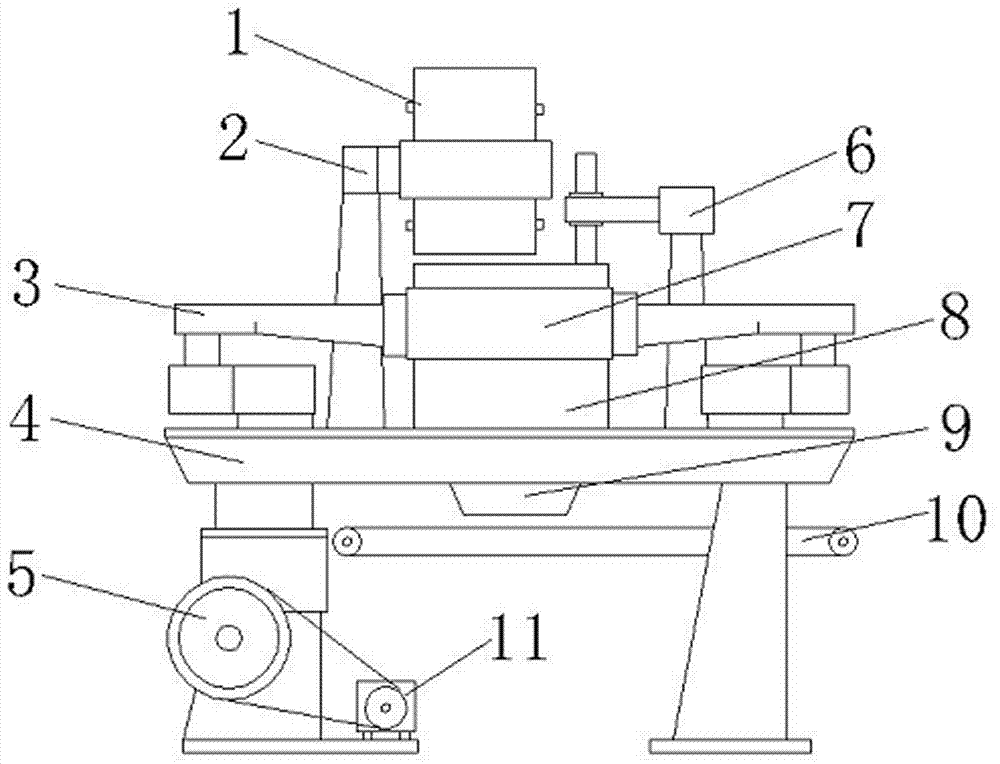

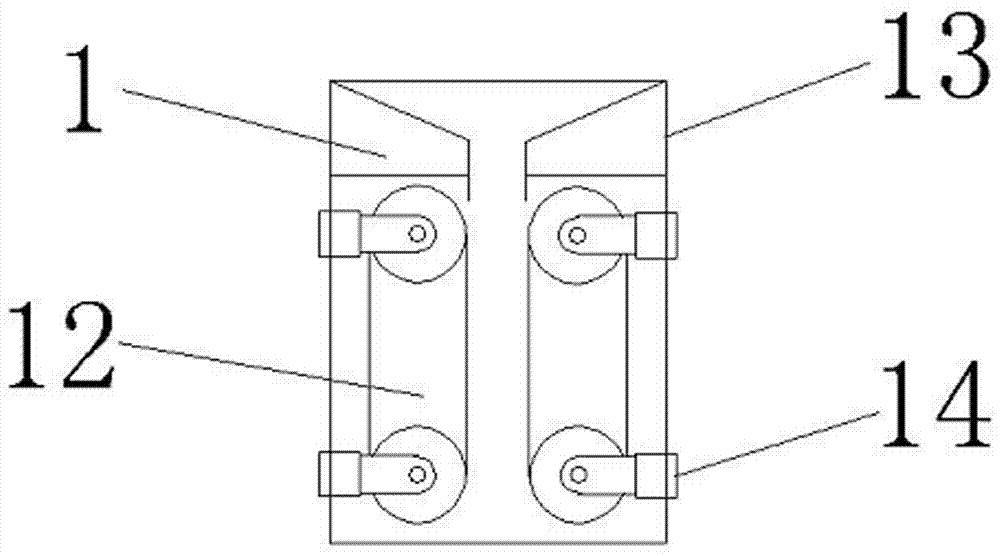

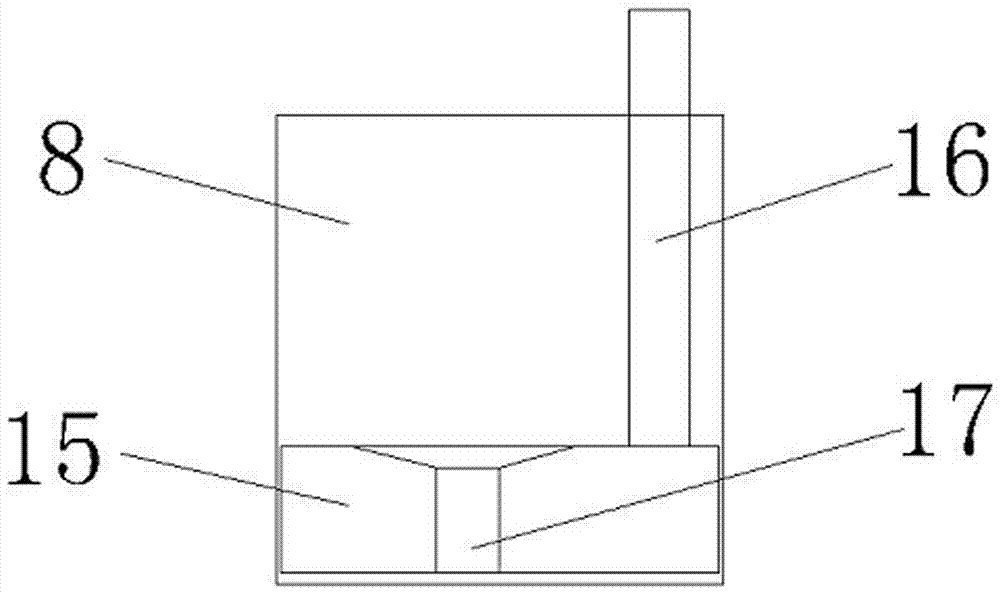

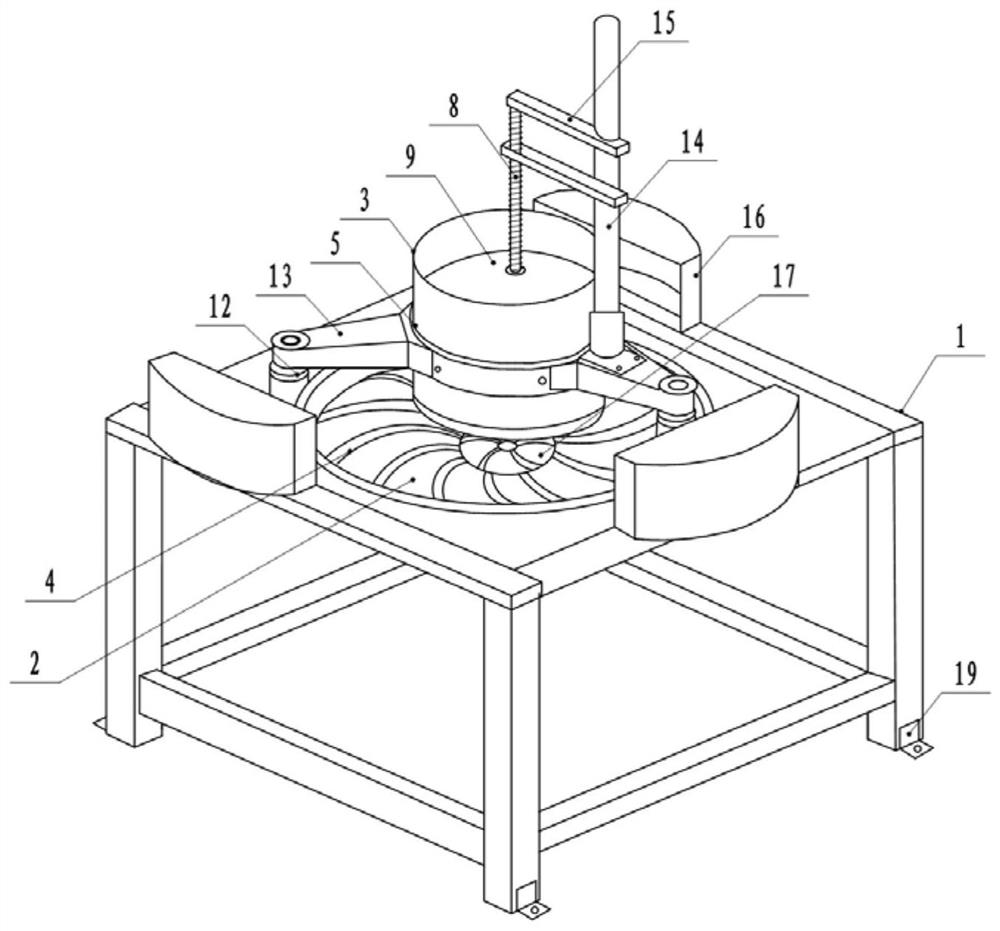

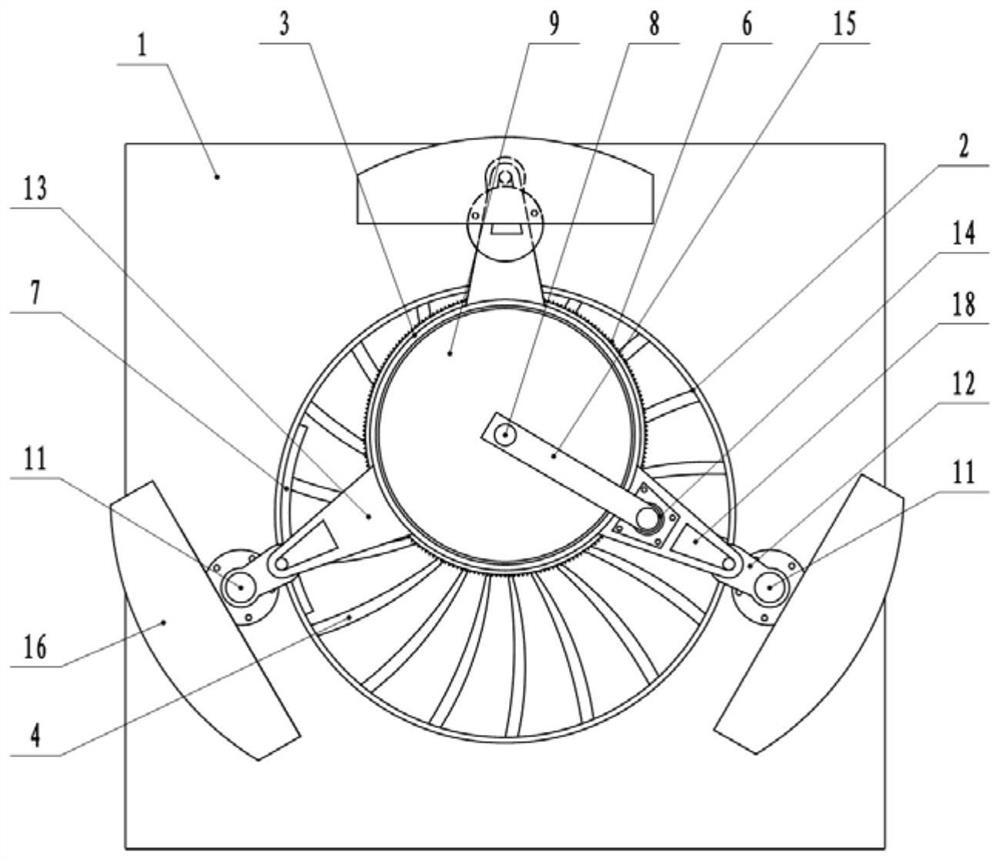

Tea leaf kneading machine

InactiveCN107996749AQuality improvementImprove work efficiencyPre-extraction tea treatmentEngineeringDrive motor

The present invention relates to a tea leaf kneading machine and belongs to the technical field of tea leaf processing devices. Tea leaves are added into a preliminary kneading device and enter between kneading belts under an action of a baffle plate, the kneading belts interact to knead the tea leaves, after the preliminary kneading, the tea leaves fall into a kneading cylinder by gravity, the tea leaves enter into a kneading disk via an inner tea leaf channel of a pressure cover, a hydraulic device presses the pressure cover via a hydraulic rod, a shaping arm is driven to operate by a driving motor and a driving wheel and drives the kneading disk on the kneading cylinder to move, the tea leaves are kneaded, the kneaded tea leaves fall on a conveyor belt via a material discharge mouth, and then the tea leaves are discharged from the conveyor belt. The preliminary kneading device uses the kneading belts as kneading devices, movement direction of the two kneading belts is opposite, by using functions between the kneading belts to conduct the preliminary kneading of the tea leaves, kneading speed is accelerated, kneading time is shortened, and the kneading work is line with paces ofother processes of tea making.

Owner:陈建峰

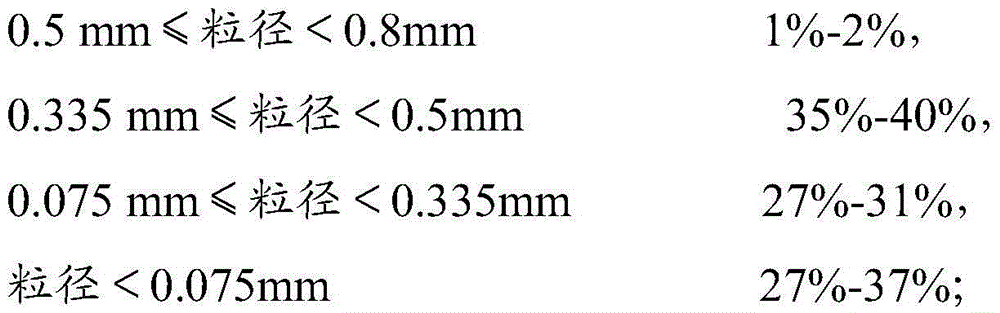

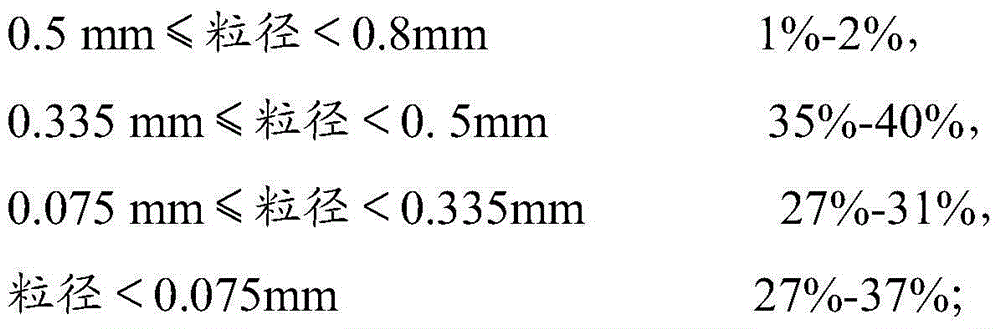

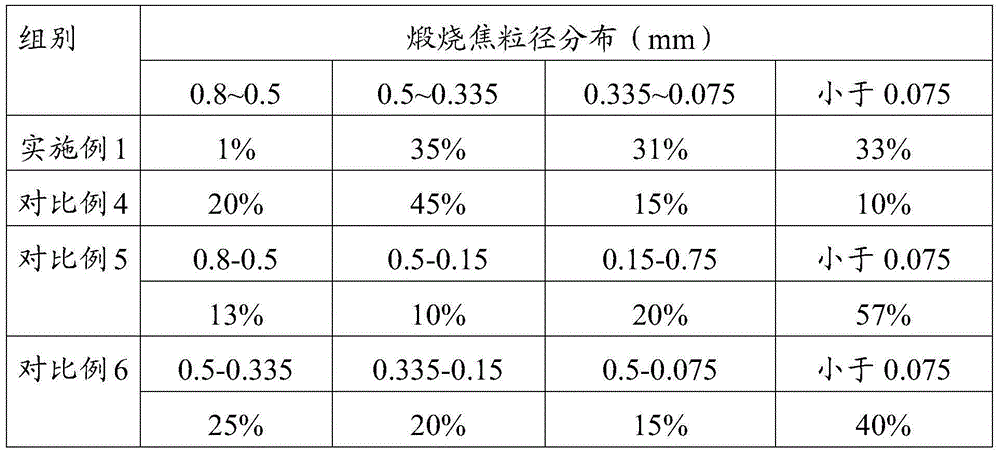

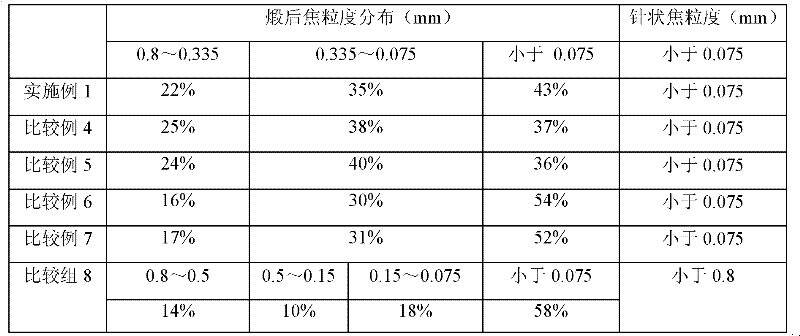

Graphite furnace lining used for high purity graphitization furnaces, and preparation method thereof

The invention discloses a graphite furnace lining used for high purity graphitization furnaces, and a preparation method thereof, and belongs to the technical field of graphite processing. The preparation method comprises steps of crushing, sieving, material preparing, dry blending, wet blending, moulding, primary roasting, primary dipping, secondary roasting, secondary dipping, tertiary roasting, and graphitization. In the raw materials of the graphite furnace lining, an aggregate is composed of calcined coke, pitch coke, and needle coke at a mass ratio of 80-82:10-15:5-8; wherein calcined coke is composed of particles with four following different particle size ranges: 0.5mm<=particle size<0.8mm, 0.335mm<=particle size <0.5mm, 0.075mm<=particle size<0.335mm, and particle size<0.075mm, and the weight amounts of the four particles account for 1 to 2%, 35 to 40%, 27 to 31%, and 27 to 37% respectively. Purity of the graphite furnace lining prepared via the preparation method is high; bulk density is large; porosity is low; ash content is low; oxidation resistance, compressive strength, and rupture strength are extremely excellent; and application requirements on high purity graphitization furnace linings are satisfied.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Blending tea and processing method thereof

ActiveCN109619221AImprove the tasteReduce caffeine levelsPre-extraction tea treatmentCaffeineChemistry

The invention discloses blending tea and a processing method thereof, and belongs to the field of tea processing. The blending tea is obtained by blending cleyera lipingensis green tea with black tea,green tea or dark green tea, wherein the cleyera lipingensis green tea is prepared by processing tender shoots of fresh cleyera lipingensis leaves and fresh leaves through a green tea processing method. According to the processing method, the cleyera lipingensis green tea is blended with after-fermentation dark green tea, the content of catechinic content in the fermented dark green tea can be increased, the content of caffeine can be lowered, the shortcoming of dark green tea of being bitter in taste is overcome, and the new tea product which has the advantages of being tolerant to storage,mellow in mouthfeel, capable of achieving an excellent afterwaste effect and sweet in smell is obtained. The blending tea is a new plant beverage on the market, other competitive products of the samekind do not exist, and the economic benefit of the blending tea is very obvious.

Owner:QINGYUAN POLYTECHNIC

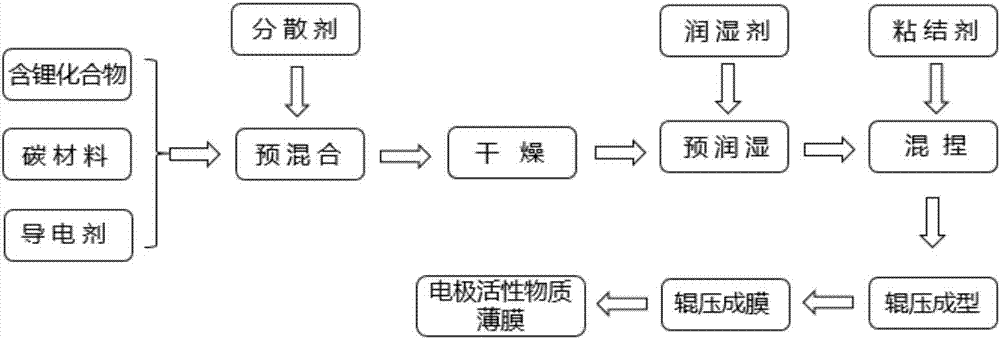

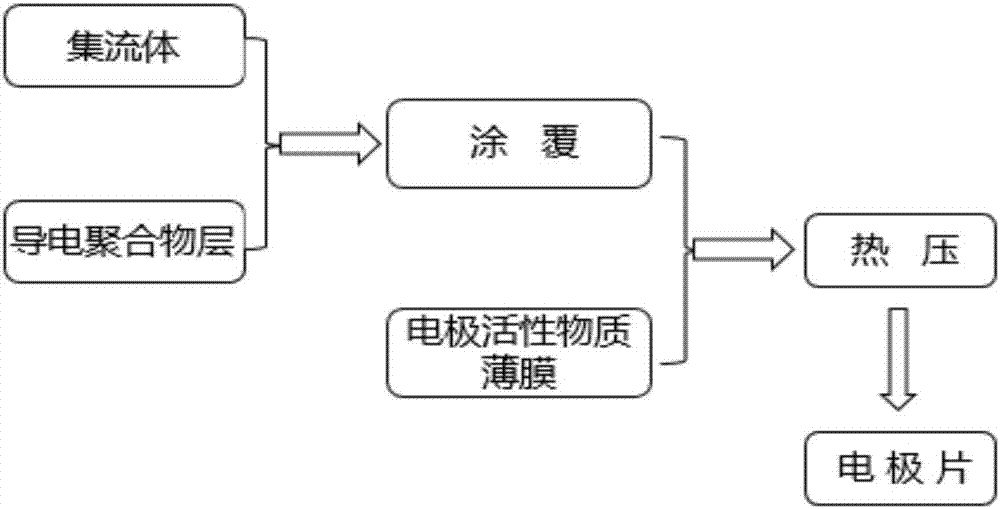

Hybrid chemical power supply device electrode and preparation method thereof

ActiveCN107086128AHigh tap densityIncrease energy densityHybrid capacitor electrodesHybrid/EDL manufactureState of artInternal resistance

The invention relates to a preparation method of an electrode of a hybrid chemical power device, which comprises the following steps: (1) Premixing of electrode active materials: uniformly mixing a lithium-containing compound, a carbon material and a conductive agent, and then kneading with a binder to obtain Agglomerated or powdered electrode active material raw materials; (2) preparation of electrode active material film: the agglomerated or powdered electrode active material raw material is passed through multi-stage rolling to obtain an electrode active material film of required thickness; (3) electrode active material film Forming: The thin film of electrode active material is supported on the current collector coated with the conductive polymer layer, and subjected to hot pressing treatment to obtain the electrode of the hybrid chemical power device. Compared with the prior art, the electrode prepared by the present invention has a compact structure, high tap density, high capacity, good consistency, and high reliability. This electrode is applied to hybrid chemical power devices and can significantly increase the electrode density. , Reduce internal resistance, improve life.

Owner:TONGJI UNIV

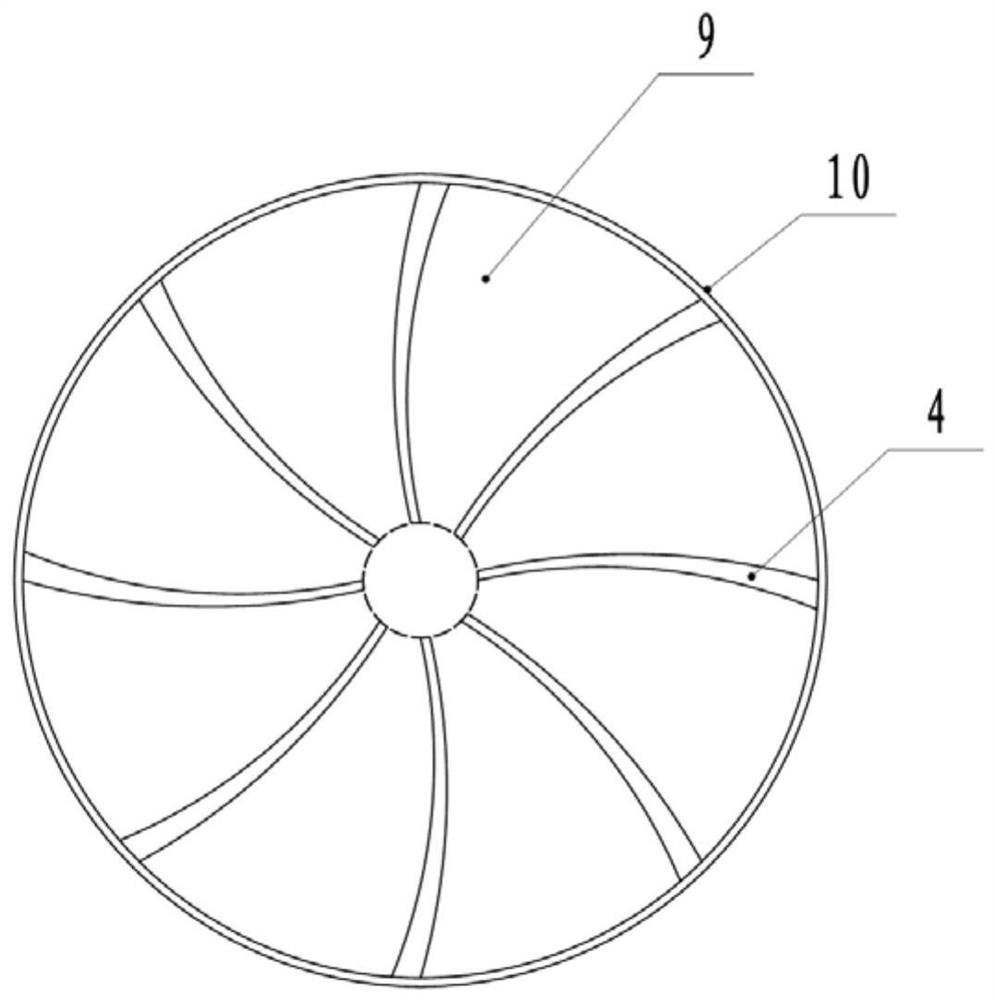

Organic tea leaf production system

PendingCN111869758AIncrease relative motion and frictionImprove the effectConveyorsPre-extraction tea treatmentTea leafThreaded rod

The invention relates to the field of tea leaf processing, and discloses an organic tea leaf production system. The organic tea leaf production system comprises a fixation device, a rolling device, afragrance improving device, a drying device and conveying devices arranged between adjacent devices, which are arranged in sequence, wherein the rolling device comprises a machine frame, and a rollingdisc, a kneading barrel, a driving mechanism and a pressurizing mechanism which are arranged on the machine frame; and a plurality of edge bones are arranged on the rolling disc. The organic tea leafproduction system is characterized in that a circle of limiting groove is formed in the outer wall of the kneading barrel, and the driving mechanism is connected to the limiting groove in a sliding mode; a circle of driving teeth are arranged at the lower part of the outer wall of the kneading barrel, and an arc-shaped driving rack capable of being meshed with the driving teeth is arranged on therolling disc; and the pressurizing mechanism comprises a supporting piece fixedly connected with the driving mechanism, a threaded rod is vertically and slidably connected to one end away from the driving mechanism, of the supporting piece, a gland is fixedly connected to the bottom end of the threaded rod, a pressing thread is arranged on the side wall of the gland, and an internal thread capable of being meshed with the pressing thread is arranged on the inner wall of the kneading barrel. Step-by-step pressurization can be achieved, and the rolling efficiency is improved.

Owner:道真仡佬族苗族自治县渝信有机茶叶有限公司

Making technology of spring tippy tea

InactiveCN105901185AIncrease damage rateEasy to knead into stripsPre-extraction tea treatmentTea flavoringProcess engineeringTea leaf

The invention relates to the field of tea processing, in particular to a making technology of spring tippy tea. The method comprises the procedures of picking, vacuum freezing, withering, leaf selecting, vacuum microwave fixing, spreading for cooling, rolling, deblocking, shaping and the like. According to the making technology, the traditional rolling time is shortened to 6-10 min from original 20-25 min, the spring tippy tea made in the time period is pure in taste, reduced in bitter taste and suitable for consumption of modern urban crowds, the appearance is light green in color and luster, full of fluff and more attractive, the commodity appearance aesthetic feeling is enhanced, market evaluation is good, the tea making yield per unit time is increased, and electric charge and labor charge are reduced.

Owner:YIDU YULU TEA CO LTD

Solid watercolor, solid watercolor grinding device and preparation method thereof

InactiveCN111205688AReduce moisture contentAdapt to stirringArtist's paintsStarch coatingsMetallurgyGlycerol

The invention belongs to the technical field of color pigments, and particularly relates to solid watercolor, a solid watercolor grinding device and a preparation method of the solid watercolor. The solid watercolor comprises, by weight, 5 to 10 parts of distilled water, 5 to 10 parts of a toner, 5 to 10 parts of glycerin, 20 to 40 parts of a filler, 1 to 2 parts of a preservative, 10 to 15 partsof Arabic gum, and 10 to 15 parts of yellow dextrin. The preparation method comprises the following steps: weighing the raw materials in parts by weight, grinding and kneading the weighed raw materials by virtue of the solid watercolor grinding device, extruding and drying so as to form the solid watercolor. The watercolor grinding device Disclosed in the invention can increase production efficiency, the production period of each color solid watercolor is shortened from original 4-5 months to 48 hours at present; and the maximum output of each batch of colors can reach 50,000 pieces, the increase of the output does not depend on the expansion of the production space and the increase of the time, but just increasing of the volume of kneading equipment, so that the production cost is saved,and the yield is increased efficiently.

Owner:SHUYANG PHOENIX ART PAINTS CO LTD

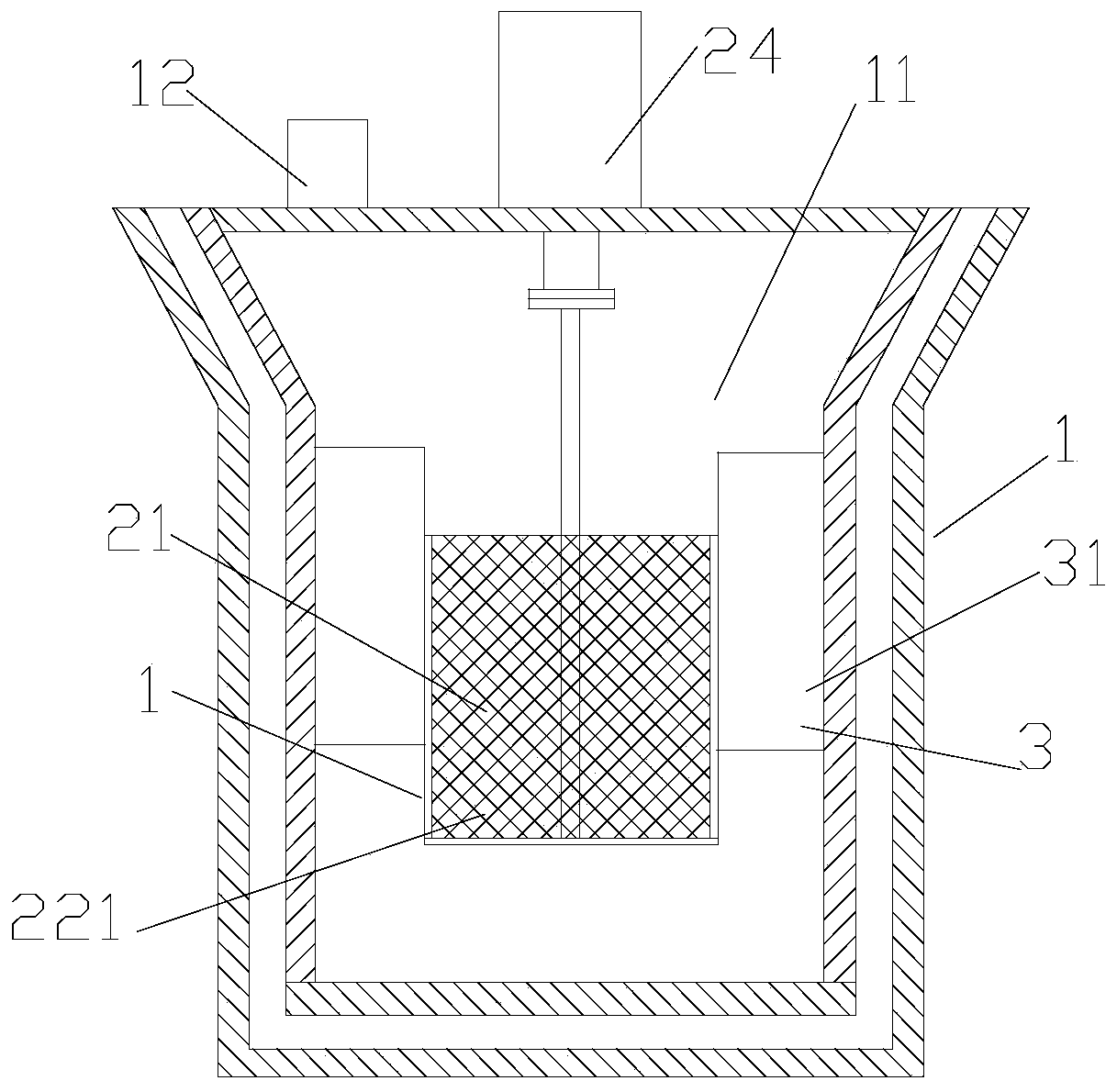

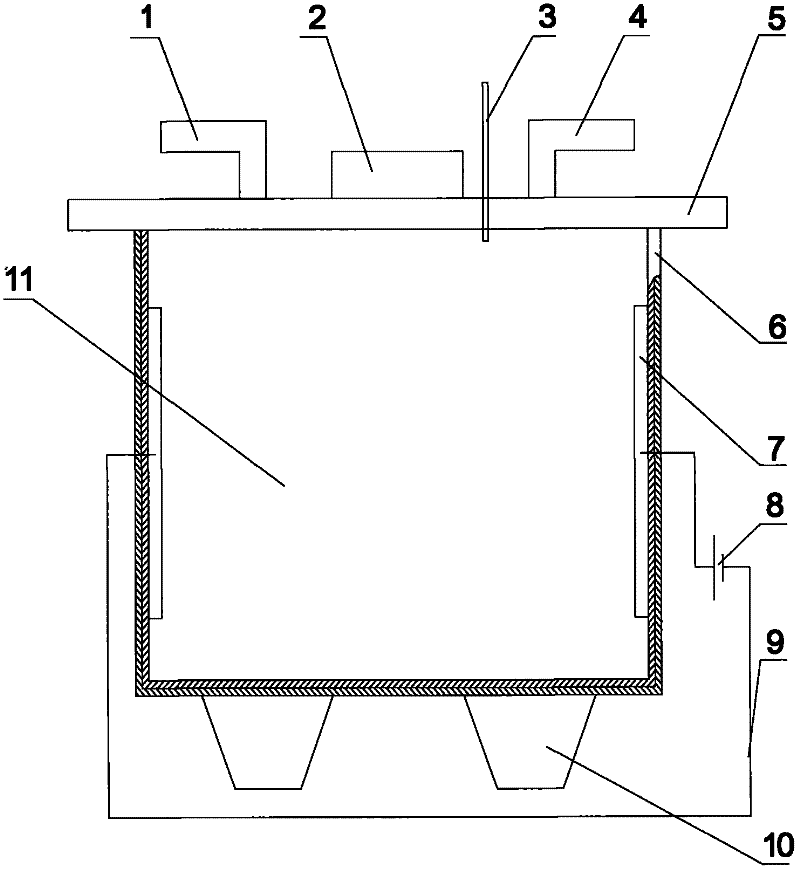

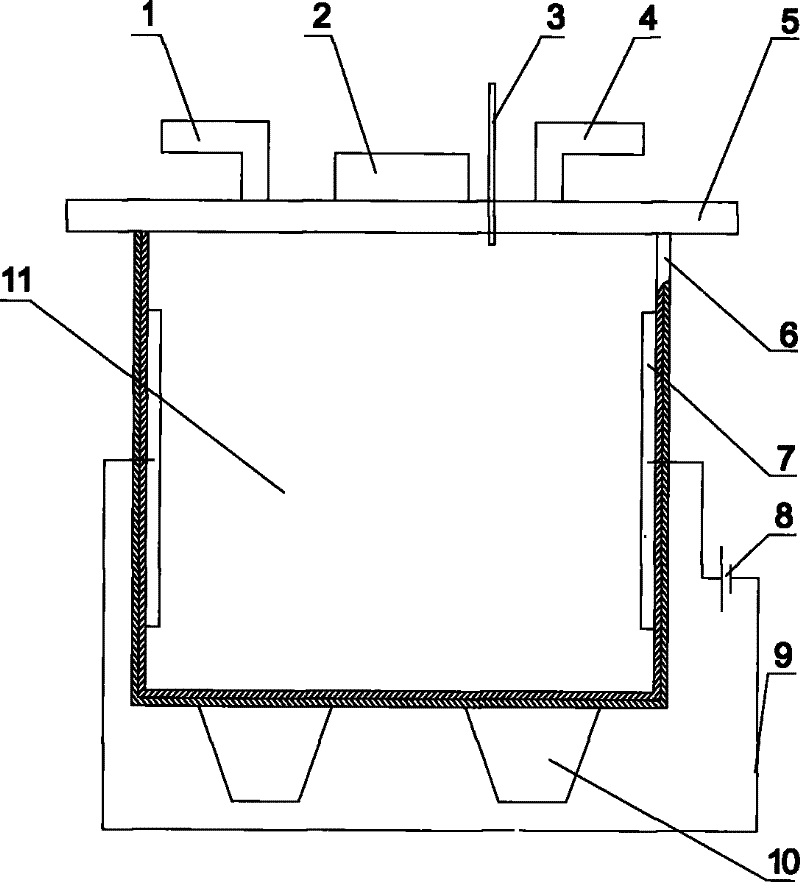

Dry material heater

The invention discloses a dry material heater, which consists of a top cap (5), a cavity (11), a feed opening (2), a discharge door (10), an electrode plate (7), a ventilating duct (1), a flue gas duct (4), an infrared thermometer (3) and the like. The dry material heater is characterized in that: the feed opening (2) is formed at the central position of the top cap (5); the infrared thermometer (3) is arranged beside the feed opening (2); the top cap (5) is connected with a cavity wall (6); the electrode plate (7) is fixed on the inner surface of the cavity wall (6); the discharge door (10) is arranged at the bottom of the cavity (11); and the ventilating duct (1) and the flue gas duct (4) are communicated with the cavity (11) through the top cap (5). Through the dry material heater, theheating temperature of a dry material can be accurately controlled, the energy consumption is reduced, the production efficiency is improved, and dust and flue gas pollution is reduced.

Owner:KAIFENG CARBON CO LTD OF CHINA PINGMEI SHENMA GRP

Health black tea teabag production method

InactiveCN106937692ASpeed up the oxidation processImprove catalytic performancePre-extraction tea treatmentTea flavoringFlavorAdditive ingredient

The present invention relates to a health black tea teabag production method, and belongs to the technical field of tea beverages. The health black tea teabag production method comprises: raw material weighing, raw material extraction, tea leaf shaking, withering, kneading, fermentation, drying, and crushing packaging. According to the present invention, the health black tea teabag product has high quality, and can maintain the nutrients of tea leaf and have health effect while the original flavor of black tea is not damaged; and the production method has characteristics of simple process and low production cost.

Owner:广西乐业县昌伦茶业有限责任公司

Black tea processing method capable of increasing cell breakage rate

InactiveCN106472721AIncreased damage rateSame starting point of fermentationPre-extraction tea treatmentChemistryCamellia sinensis

The invention discloses a black tea processing method capable of increasing a cell breakage rate. The black tea processing method comprises the following working procedures of picking fresh camellia sinensis leaves, performing withering, performing rolling, performing fermentation and performing drying, wherein before withering, a potassium silicate solution of which the concentration is 0.1-0.6mmol / L is sprayed on picked fresh leaves, and a liquor ratio is 100g to (1-5)ml. According to the black tea processing method disclosed by the invention, the cell injury rate during rolling can be increased, the rolling time can be shortened, consistent tea leaf fermentation starting points is guaranteed, and the condition that theaflavin and thearubigins are converted into theabrownin due to excessive fermentation is avoided. After the black tea prepared by the black tea processing method disclosed by the invention is brewed, tea soup is pleasant in fragrance, rich in taste and bright in color.

Owner:广西神海云峰农业综合开发有限公司

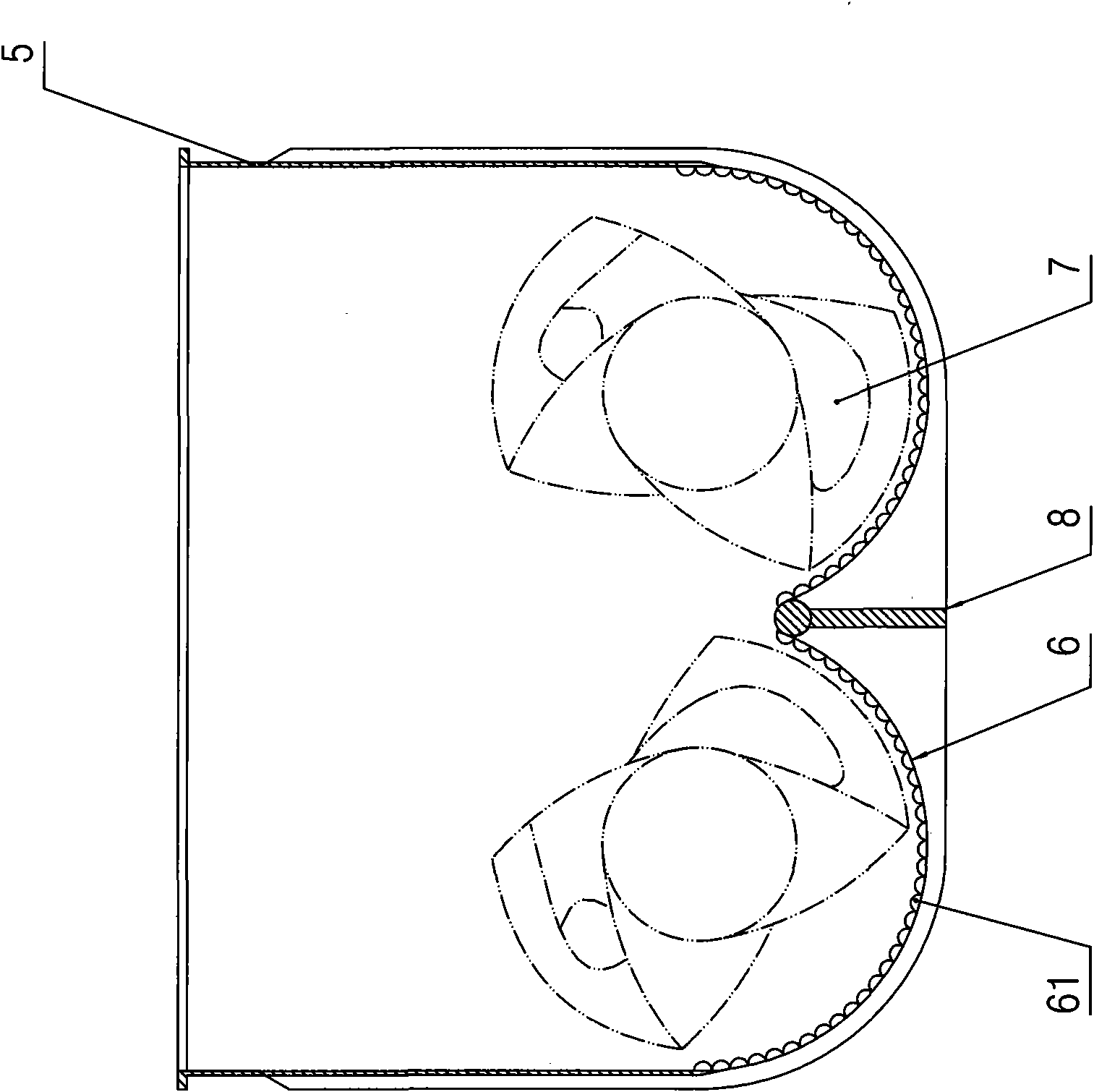

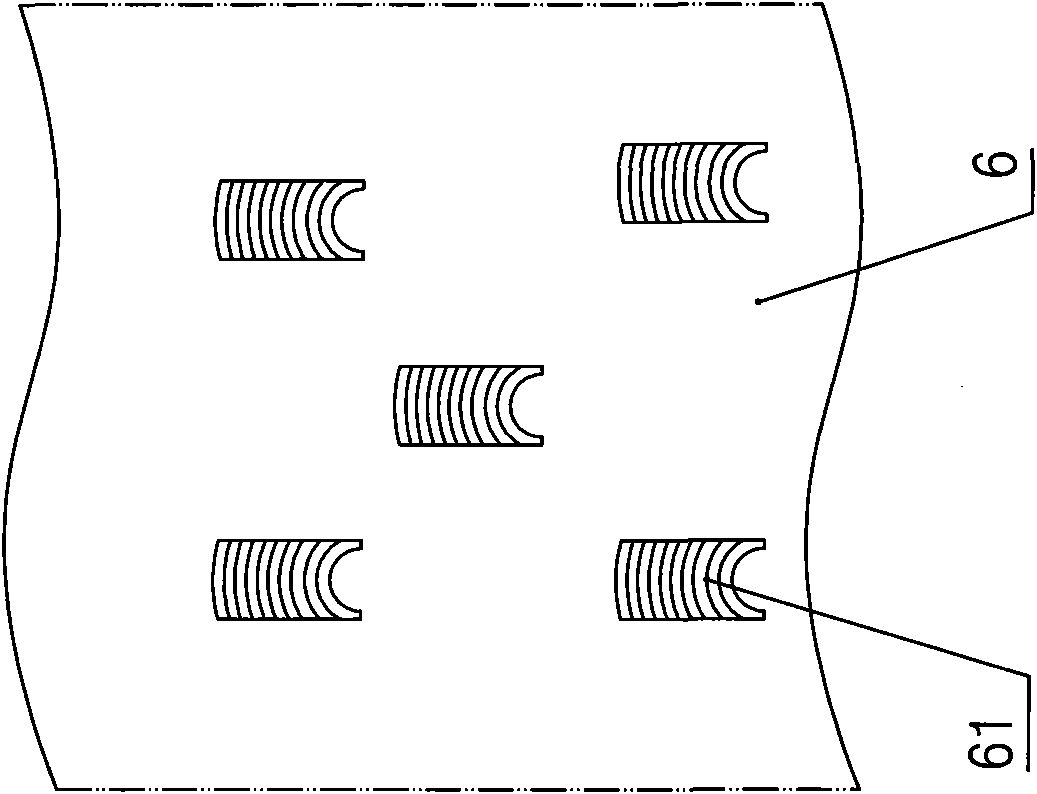

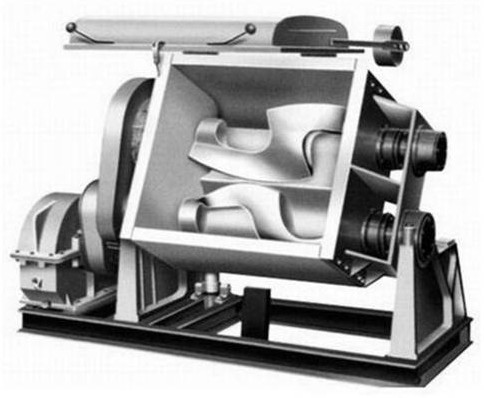

Kneading groove in kneading machine

The invention discloses a kneading groove in a kneading machine for improving shearing force to materials, which comprises a groove wall and a groove bottom, wherein the inner surface of the groove bottom is provided with a plurality of bosses, and a plurality of veins are arranged on the surface of each boss. The inner surface of the groove bottom of the kneading groove is provided with the plurality of bosses to increase the shearing force to the materials so as to achieve the aims of shortening the kneading time of silicone rubber and improving the kneading efficiency of the silicone rubber. In addition, the veins arranged on the surface of each boss can further increase the shearing force to the materials in the process of stirring so as to further shorten the kneading time of the silicone rubber, improve the kneading effect on the silicone rubber, and reduce about 5 percent of the energy consumption.

Owner:ZHANGJIAGANG LANHANG MACHINERY

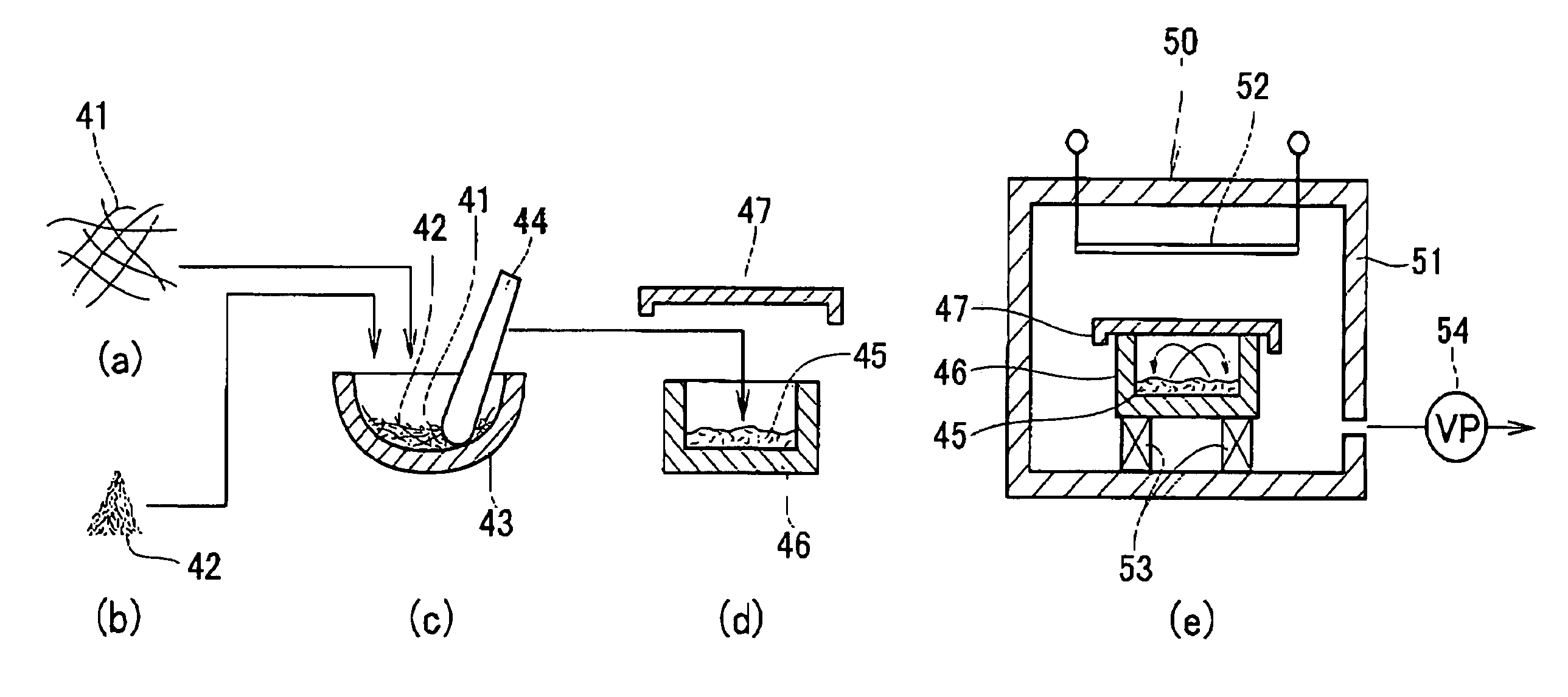

Method for manufacturing composite metal alloy and method for manufacturing article from composite metal

A method for manufacturing a composite metal alloy. An Mg material as an alloy base material and a carbon nanomaterial are mixed together to obtain a mixture in which the Mg material is covered with particles of the carbon nanomaterial. The mixture of the Mg material and carbon nanomaterial are sintered to obtain an Mg sintered compact including the carbon nanomaterial. The Mg sintered compact including the carbon nanomaterial is dissolved to obtain a melt of the composite metal alloy.

Owner:NISSEI PLASTIC IND CO LTD

Method for processing high-aroma black tea

InactiveCN106417707AIncreased damage rateSame starting point of fermentationPre-extraction tea treatmentBlack teaThearubigin

The invention discloses a method for processing high-aroma black tea. The method comprises the procedures of tea tree fresh leaf picking, withering, rolling, fermenting and drying. Before withering, a disilicate solution with the concentration being 0.1 mmol / L to 0.3 mmol / L is sprayed to picked fresh leaves, and the solid-liquid ratio is l00 g:(1-5) ml. According to the method, the cellular damage rate during rolling can be increased, the rolling time can be shortened, it is guaranteed that the tea fermentation starting point is consistent, it is avoided that theaflavin and thearubigins are converted into theabrownin due to excessive fermentation, and the black tea made through the method is fragrant in tea soup after being brewed, strong in taste and bright in color.

Owner:广西神海云峰农业综合开发有限公司

Rolling and shaping processing method of tea

InactiveCN107343548AEfficient CatalysisSpeed up decompositionPre-extraction tea treatmentDecompositionSolvent

The purpose of the invention is to provide a rolling and shaping processing method of tea. The rolling and shaping processing method of the tea comprises the following steps of: (1), putting well prepared raw tea leaf materials into a fixating machine so as to carry out fixation treatment; (2), performing rolling processing on the tea leaves fixated in the step (1) after completion of soaking, wherein a ferrugination solvent mixture is uniformly sprinkled onto surfaces of the tea leaves before the rolling processing, and the rolling processing is specifically composed of mechanical rolling and artificial rolling, namely preliminary rolling is performed first by using a rolling machine, and artificial rolling is performed then; and (3), performing drying treatment, namely carrying out steam-drying in a steam drying barrel. The rolling and shaping processing method of the tea is capable of effectively catalyzing tea polyphenols so as to effectively improving decomposition rate of the tea polyphenols; moreover, the mechanical rolling and the artificial rolling are combined so as to ensure shortened rolling time and improved rolling efficiency, and improve shaping effect of the tea leaves so as to improve quality of the tea.

Owner:HEFEI HAOWANG AQUACULTURE TECH CO LTD

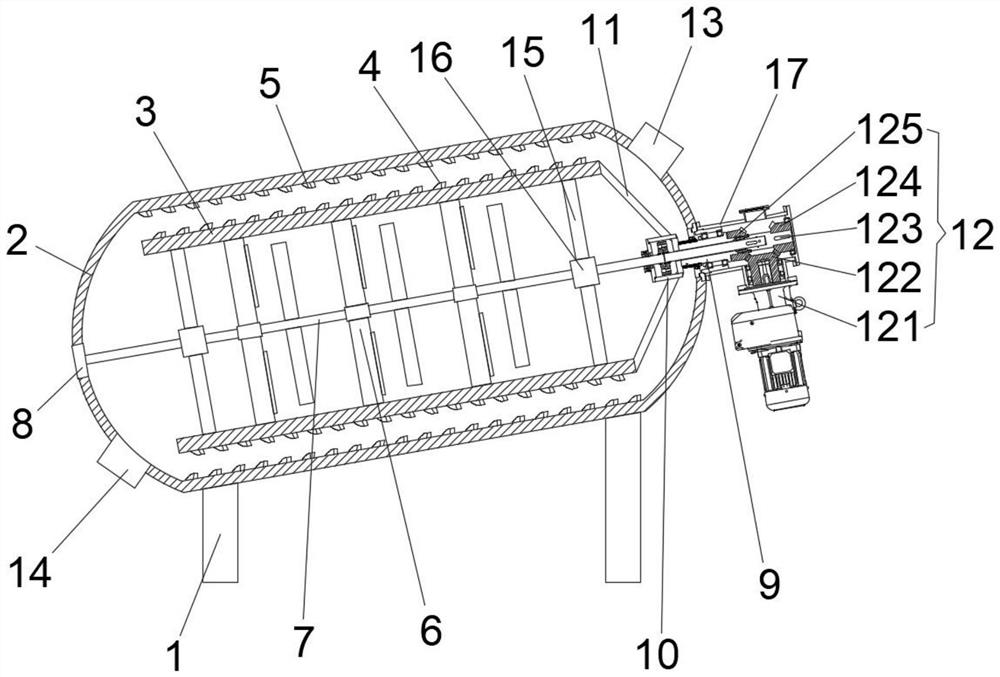

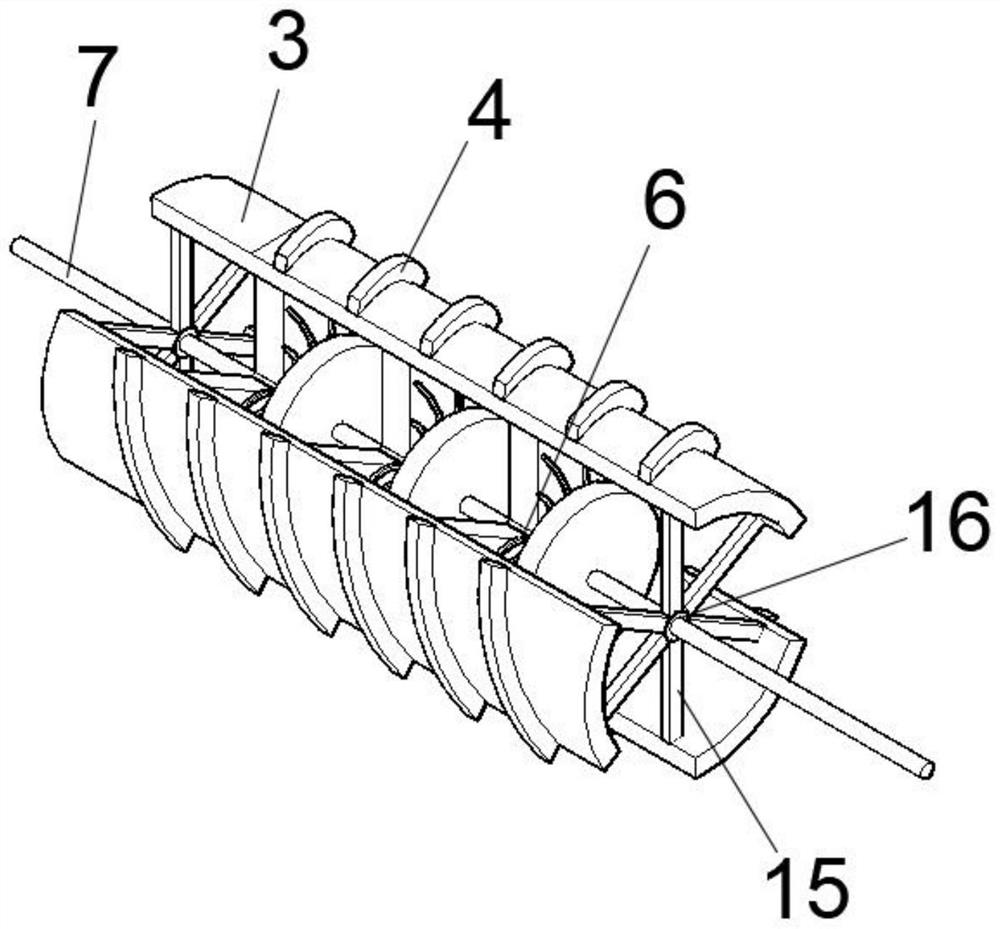

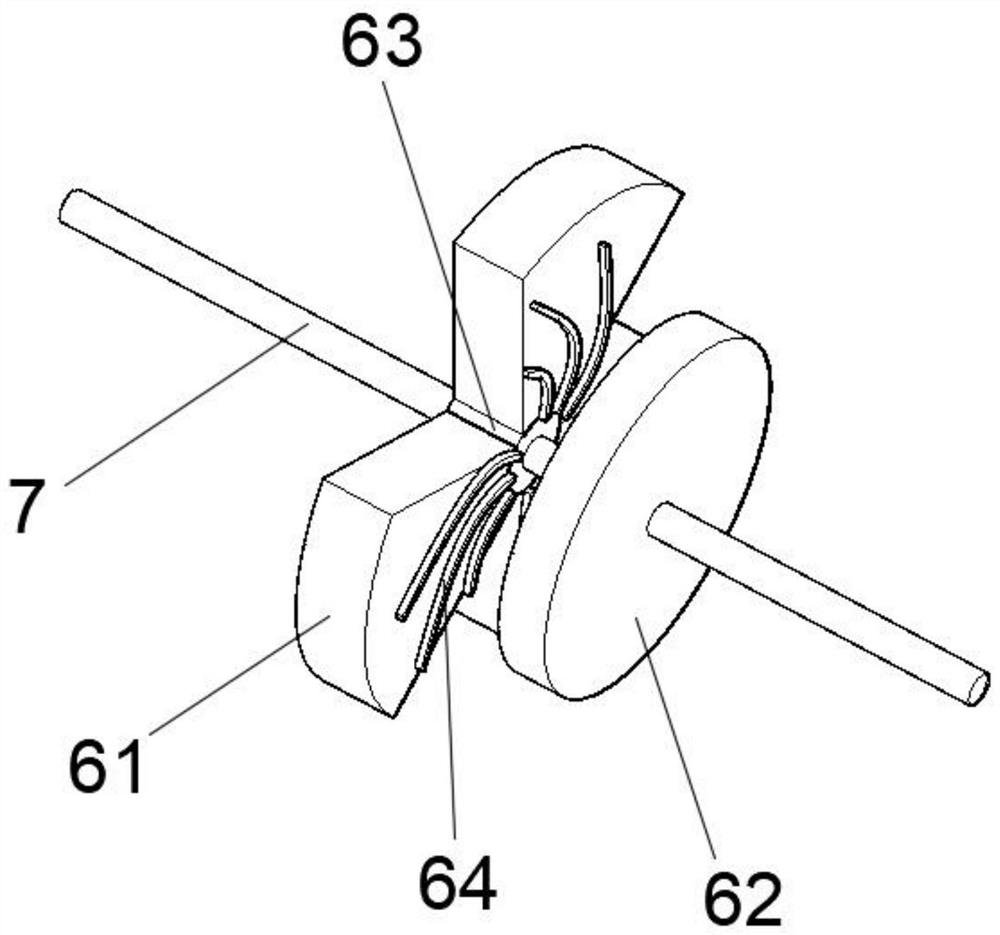

Horizontal tea twisting machine

PendingCN111772005AShorten kneading timeImprove rolling efficiencyPre-extraction tea treatmentEngineeringTea leaf

The invention discloses a horizontal tea twisting machine. The horizontal tea twisting machine comprises a rack and a twisting cylinder, wherein the bottom of the twisting cylinder is fixedly connected with the rack, arc plates are annularly arranged in the twisting cylinder at equal intervals, first twisting ribs are arranged on the outer sides of the arc plates, second twisting ribs are arrangedon the inner wall of the twisting cylinder, inner twisting assemblies are arranged in the arc plates, the inner twisting assemblies are connected with a main shaft, the inner walls of two ends of thearc plates are movably connected with the main shaft, one end of the main shaft is connected with the twisting cylinder through the rotating seat, the outer ring of the other end of the main shaft ismovably sleeved with the outer shaft, the end of the outer shaft is connected with the frame, the outer side wall of the frame is connected with the ends of the arc plates through connecting rods, the main shaft and the end of the outer shaft are connected with a power assembly, and a feeding hole and a discharging hole are formed in the two ends of the twisting cylinder; the twisting cylinder ishorizontally placed, and the main shaft drives the arc plates to rotate so as to drive the tea leaves to rotate, so that the first twisting ribs and the second twisting ribs act, the inner twisting assemblies perform dual twisting on the tea leaves, the twisting time is shortened, the twisting efficiency is high, the tea leaves are twisted thoroughly, and the twisting is uniform.

Owner:安徽省霍山县永宏茶业有限公司

Intermittent same-direction vacuum mechanical premixing preparation method for spaceflight ablation heat-proof chopped fiber/phenolic aldehyde premix

The invention provides an intermittent same-direction vacuum mechanical premixing preparation method for a spaceflight ablation heat-proof non-conductive chopped fiber / phenolic aldehyde premix. The method is characterized in that firstly, by using intermittent mechanical premixing, that is, multi-cycle short-time kneading, fibers can be completely infiltrated by resin, moreover, the uniformity of the premix can be ensured, and the problem that the fibers are damaged due to too long kneading time can be avoided; secondly, by using same-direction mechanical premixing, the collision intensity and collision frequency of dispersion system molecules are reduced, and phase separation, sedimentation, precipitation and the like are prevented; and thirdly, vacuum mechanical premixing is used, and after multi-cycle kneading, dealcoholization treatment is performed in a vacuum state, such that it is ensured that the glue content does not generate gradient changes when the premix is aired. According to the method, compared with a manual premixing method, the intermittent same-direction mechanical premixing method has the advantages that the number of operators is reduced by 71.4%; the resin content uniformity is superior to that of the manual premixing method; the mechanical property of a composite material is equivalent to that of a composite material obtained by premix mould pressing through the manual premixing method; and the premix has no glue content difference in a vertical direction.

Owner:北京元蛋复合材料有限公司

Health-care black tea and preparation method thereof

InactiveCN107019067ASpeed up the oxidation processImprove catalytic performancePre-extraction tea treatmentTea flavoringFlavorAdditive ingredient

The invention relates to health-care black tea and a preparation method thereof, and belongs to the technical field of tea beverages. The health-care black tea is prepared from the following raw materials in parts by weight: 80-90 parts of fresh leaf of Lingyun Baihao tea, 3-6 parts of emblic leafflower fruit, 1-3 parts of flos lonicerae and 5-10 parts of poria cocos. The black tea has high product quality and also has a health care efficacy; the prepared black tea can keep nutrition ingredients in the tea, the processing time of the black tea can be greatly shortened while the original flavor of the black tea is not damaged, and economic benefit is improved.

Owner:广西乐业县昌伦茶业有限责任公司

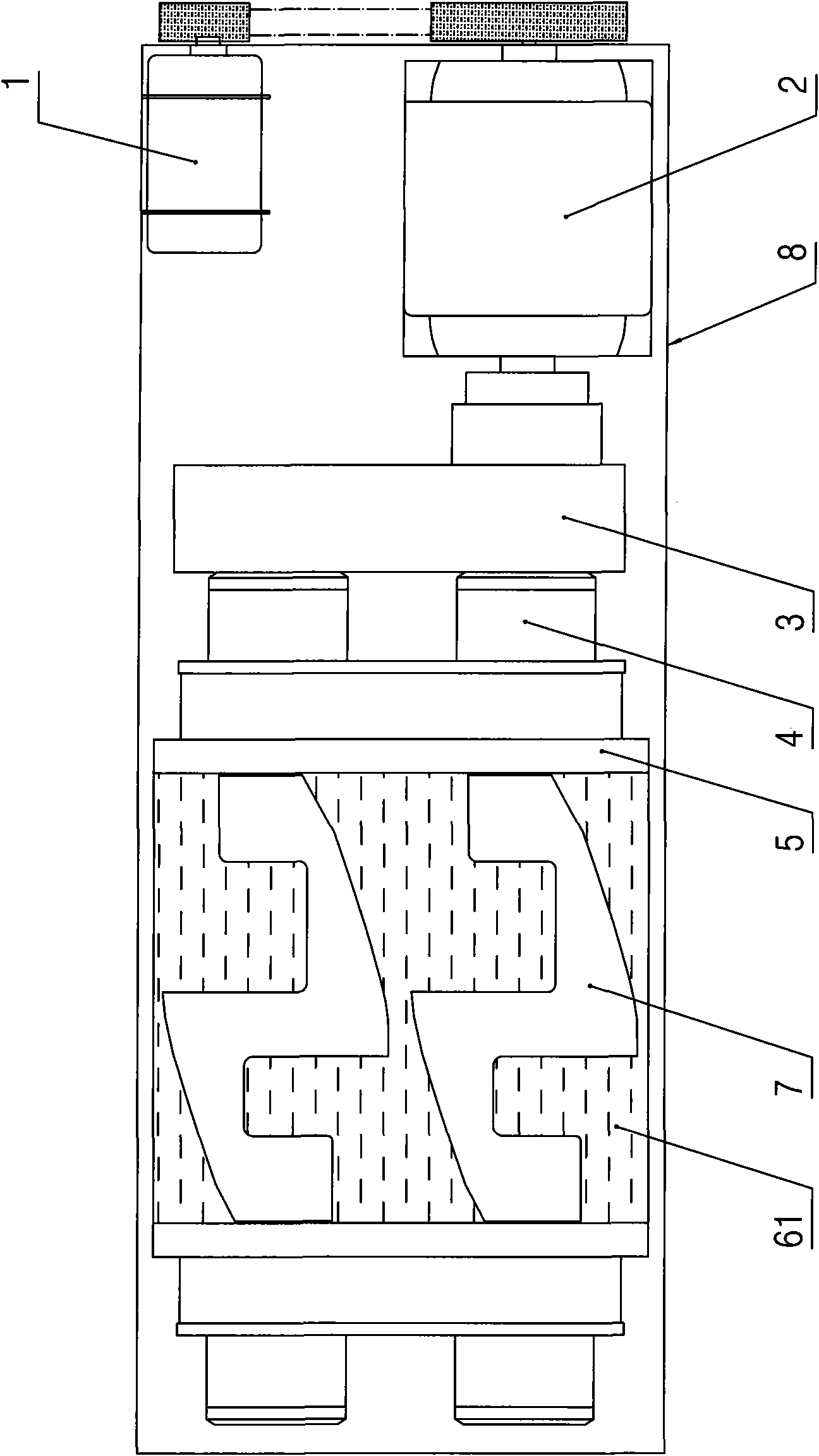

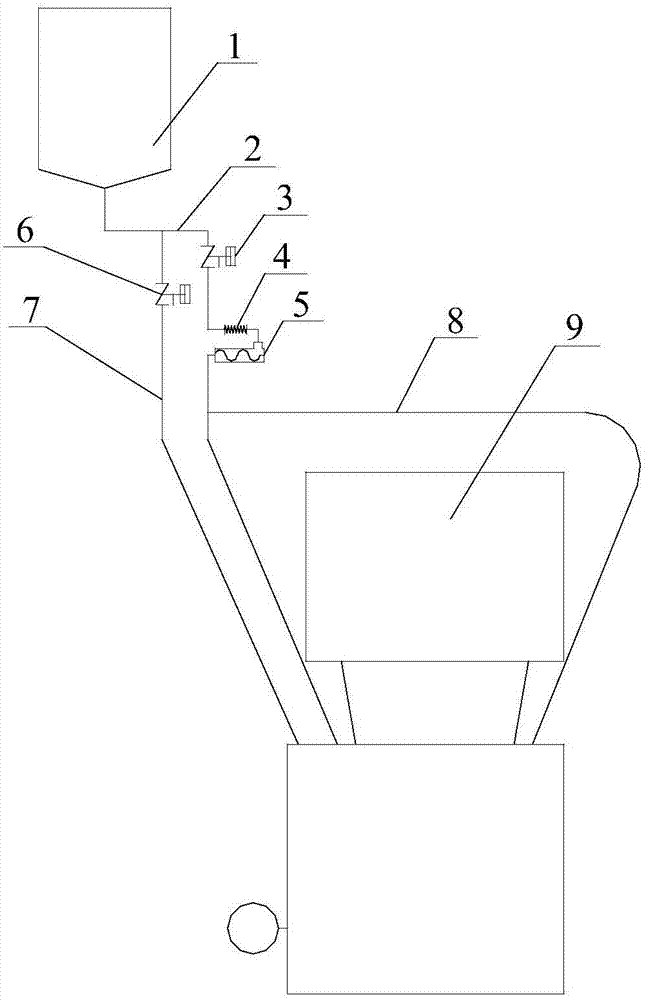

Multi-point spraying injection asphalt system of mixing and blending pot for carbon formation

InactiveCN107376765AIncrease kneading timeShorten kneading timeTransportation and packagingMixer accessoriesEngineeringHigh pressure

The invention discloses a multi-point spraying injection asphalt system of a mixing and blending pot for carbon formation. The system is characterized by comprising an oxygen cylinder (16) and a valve seat (17), wherein the valve seat (17) is arranged on the oxygen cylinder (16); an oxygen flow channel is formed in the oxygen cylinder (16); a pressure reduction valve and a flow control valve which are both communicated with an oxygen flow channel are respectively arranged on the valve seat (17); an inlet of the oxygen flow channel is positioned above the mouth of the oxygen cylinder (16); a respiration connector (4) is arranged on an outlet of the oxygen flow channel. The system is not only simple in structure and relatively low in cost, but also can conveniently reduce high-pressurized oxygen to low-pressure oxygen which is applicable to respiration by human bodies through the pressure reduction valve arranged on the valve seat, and can conveniently adjust the output oxygen flow rate through the flow control valve arranged on the valve seat, so that the system can be conveniently carried and used by common users and suitable for popularization and application.

Owner:BEIJING HUASUO TECH

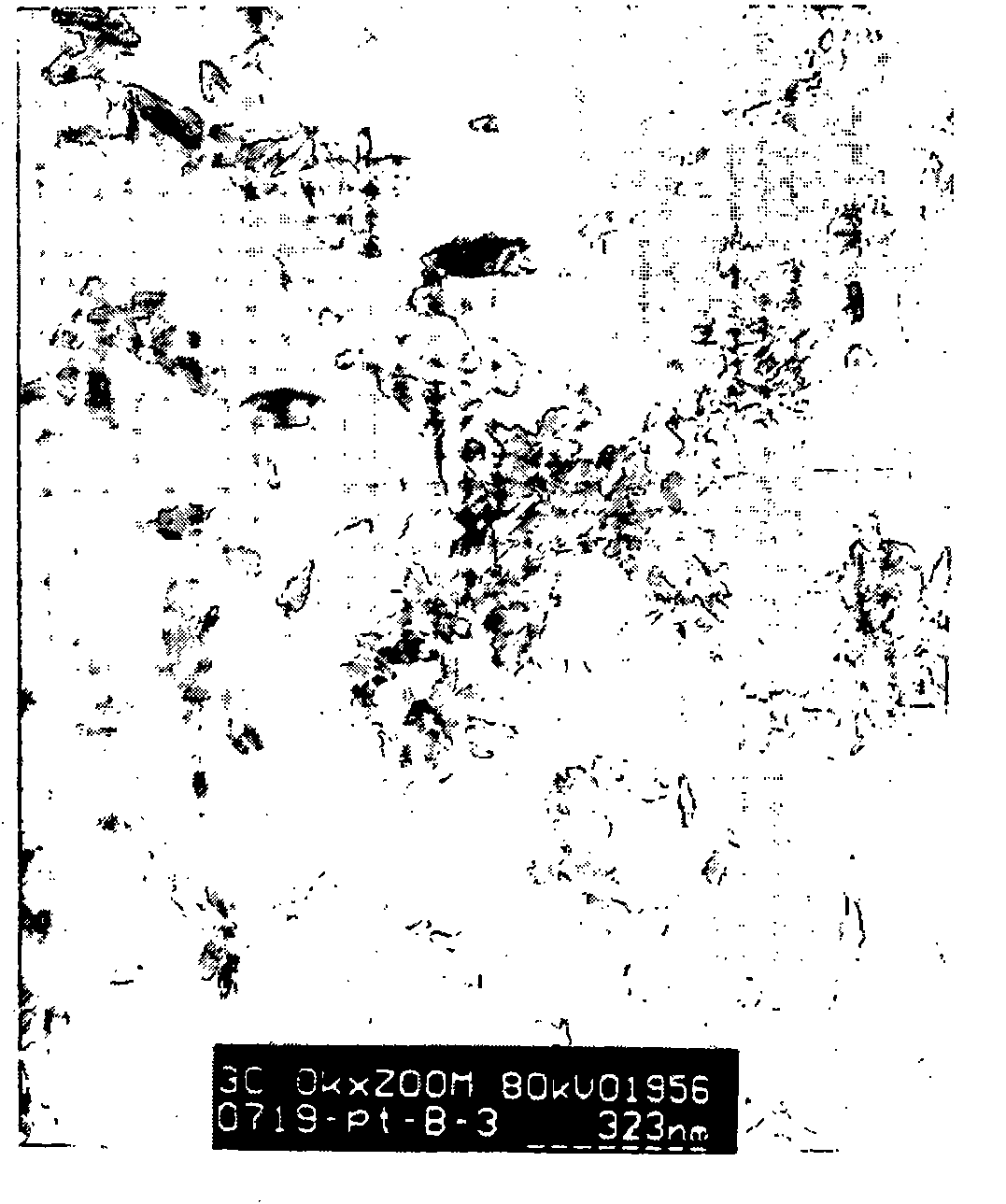

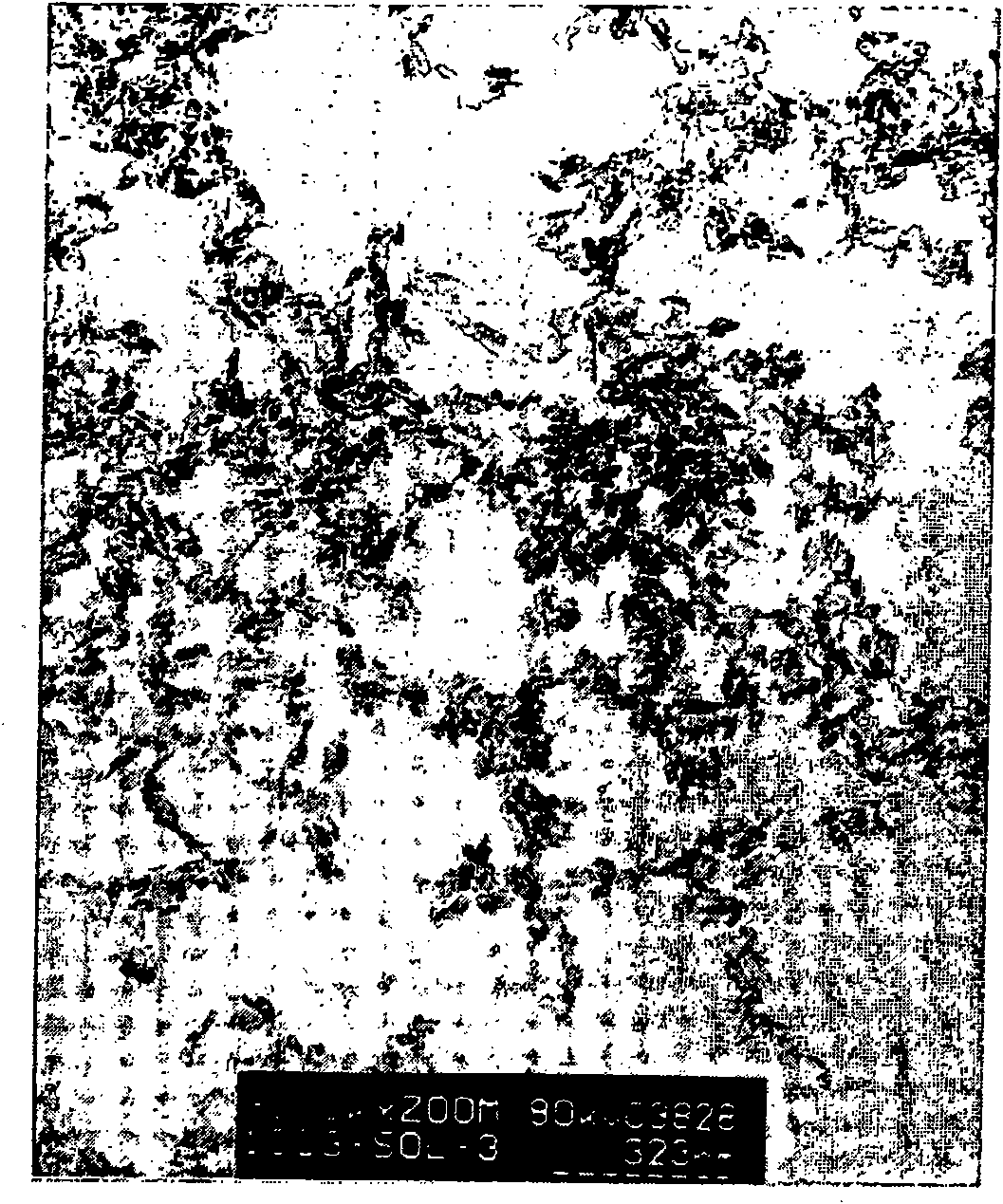

Heat accumulation and energy storage graphite material for solar thermal power generation and preparation method thereof

ActiveCN101948675BImprove thermal conductivityImprove heat storage capacityHeat-exchange elementsThermal expansionMaterials science

The invention relates to a heat accumulation and energy storage graphite material for solar thermal power generation and a preparation method thereof. The performance parameters of the graphite material meet the following requirements that: volume density is more than or equal to 1.75 g / cm<3>; electrical resistivity is less than or equal to 7.5 mu ohm m; ash content is less than or equal to 0.2 percent; rupture strength is more than or equal to 18.5 MPa; elastic modulus is less than or equal to 8.8 Gpa; and thermal expansion coefficient is less than or equal to 2.0*10<-6> / DEG C<-1>. The graphite material of the invention has the advantages of high thermal capacity, high heat conductivity, long service life, low cost and the like. In the preparation method, the focusing solar thermal power generation and heat accumulating material is prepared from raw materials by the steps of sieving, burdening, kneading, airing, vibration molding, baking, soaking, secondary baking, graphitizing and machining.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Preparation of epsilon copper phthalocyanine of small primary particle size and narrow particle size distribution by kneading

ActiveCN101918496ASmall granularityShorten kneading timePhotomechanical apparatusOrganic dyesInorganic saltsParticle-size distribution

A process of preparing copper phthalocyanine particles exhibiting an epsilon crystallographic form, comprising a kneading step by kneading at at least two different temperatures copper phthalocyanine particles wherein more than or equal to 50 wt % of the particles exhibit an alpha crystallographic form in presence of a liquid and of at least one inorganic salt.

Owner:SOLVAY SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com