Solid watercolor, solid watercolor grinding device and preparation method thereof

A grinding device and watercolor technology, which is applied in coatings, art paints, starch paints, etc., can solve the problems of long time, low efficiency, long production cycle, etc., to shorten the kneading time, shorten the production time, reduce the The effect of the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

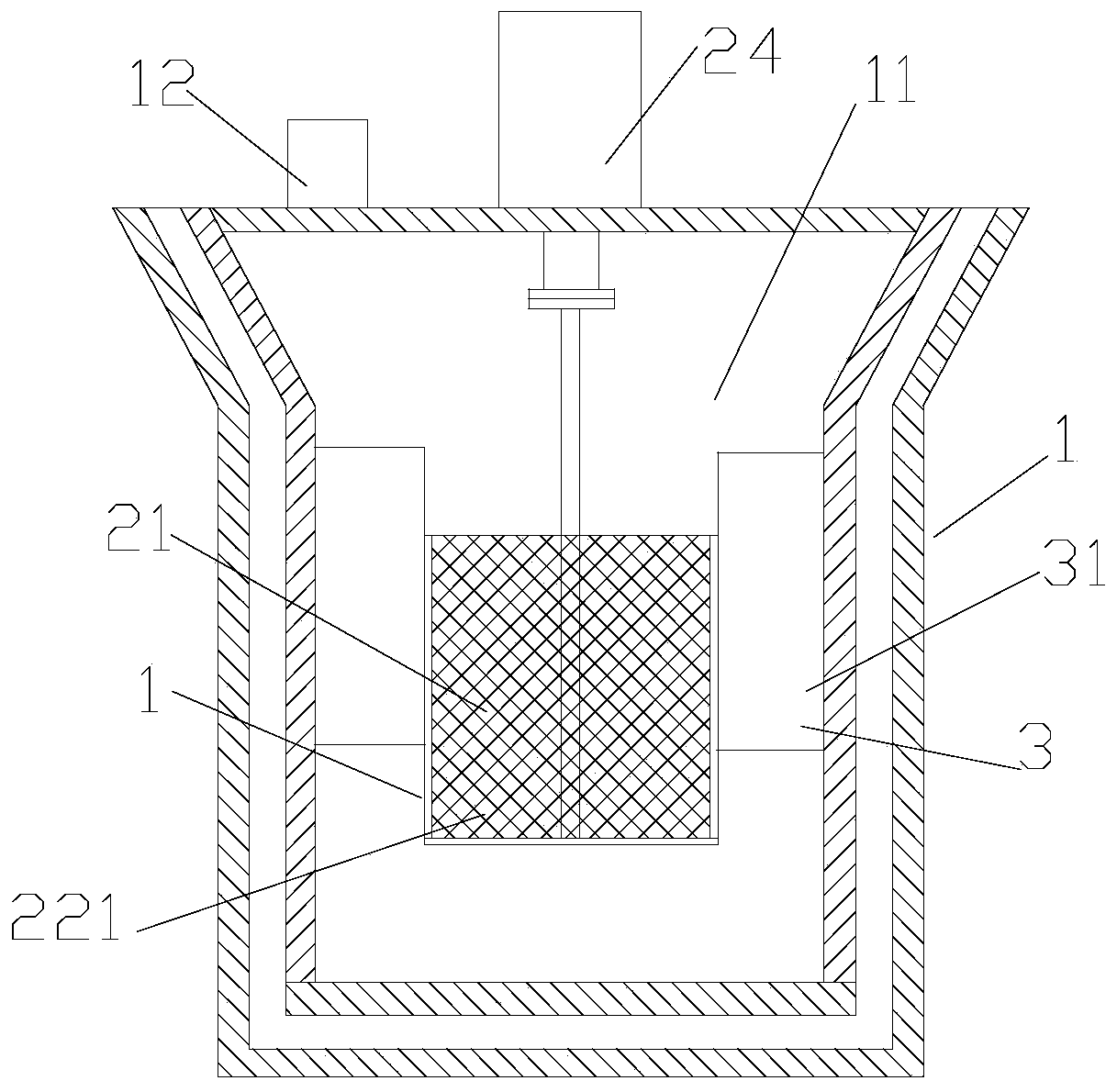

Image

Examples

Embodiment 1

[0032] A solid watercolor, comprising the following raw materials in weight percentage: 5-10 parts of distilled water, 5-10 parts of toner, 5-10 parts of glycerin, 20-40 parts of filler, 1-2 parts of preservative, and 10-15 parts of gum arabic 10-15 parts of yellow dextrin.

[0033] In this example, the preservative can be selected from Foshan Lanfeng Auxiliary Co., Ltd. to choose LY-Y301, which has broad-spectrum sterilization, long-term effect, does not contain formaldehyde, does not contain divalent salts, does not cross-link emulsion, is safe and environmentally friendly, and has a high concentration. It is completely harmless, discharges without residue, and will not cause cumulative pollution to the environment.

Embodiment 2

[0035] A solid watercolor, comprising the following raw materials in weight percentage: 8 parts of distilled water, 10 parts of toner, 10 parts of glycerin, 40 parts of filler, 2 parts of preservatives, 15 parts of gum arabic, and 15 parts of yellow dextrin.

Embodiment 3

[0037] A solid watercolor, comprising the following raw materials in weight percentage: 5 parts of distilled water, 8 parts of toner, 10 parts of glycerin, 35 parts of filler, 1.5 parts of preservative, 12 parts of gum arabic, and 10 parts of yellow dextrin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com