Hybrid chemical power supply device electrode and preparation method thereof

A chemical power source and hybrid technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc. problems, to achieve the effect of good consistency, high yield and reduced complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

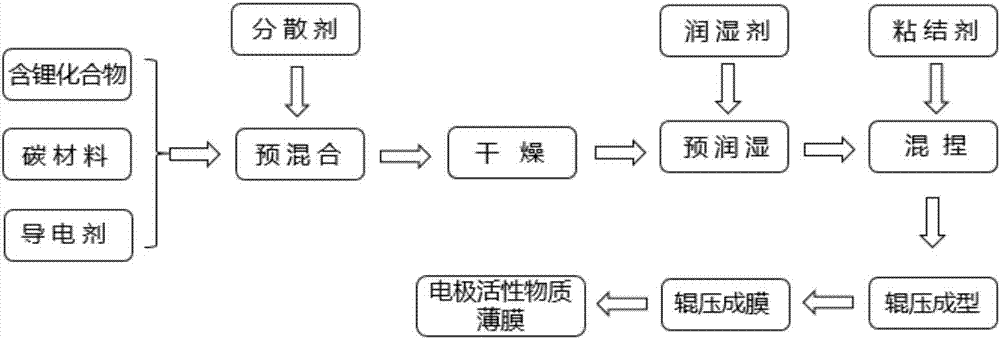

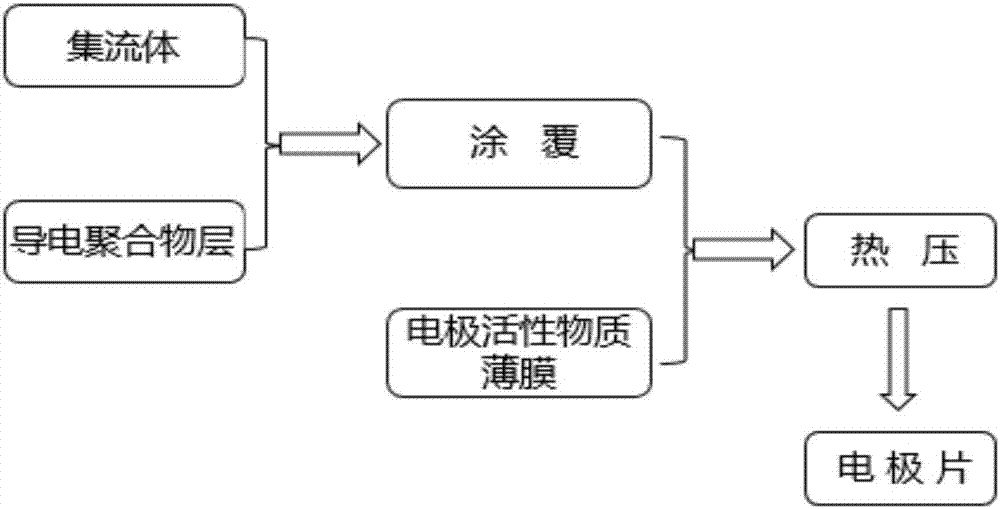

[0083] Step 1, lithium iron phosphate (LiFePO 4 ) is mixed with activated carbon according to the mass ratio of 2:8 to obtain a dry powder material;

[0084] Step 2, adding n-hexane as a dispersant, pre-mixing the dry powder material by ball milling, the speed of the ball mill is 1000r / min, the mixing temperature is 25°C, and mixing for 30 minutes;

[0085] Step 3, drying the pre-mixed slurry in step 2, removing the dispersant in the slurry, and obtaining a uniformly mixed dry material;

[0086] Step 4, adding toluene to the dry material, and pre-wetting with a ball mill;

[0087] Step 5, move the pre-wetted mixture into the kneading device, and add SBR particles (the ratio of the mass of SBR particles to the mass of the dry powder material is 8:92), and use the shearing and stretching action during high-speed rotation to make the material Fully contact with the binder to form a lump-shaped electrode active material raw material with a certain viscosity;

[0088] Step 6, pu...

Embodiment 2

[0093] Step 1, lithium cobalt oxide (LiCoO 2 ) is mixed with activated carbon according to the mass ratio of 25:75 to obtain a dry powder material;

[0094] Step 2, adding dichloromethane as a dispersant, and pre-mixing the dry powder material by ball milling, the speed of the ball mill is 1500r / min, the mixing temperature is 40°C, and mixing for 20 minutes;

[0095] Step 3, drying the pre-mixed slurry in step 2, removing the dispersant in the slurry, and obtaining a uniformly mixed dry material;

[0096] Step 4, adding ethanol to the dry material, and pre-wetting with a ball mill;

[0097] Step 5, move the pre-wetted mixture into the kneading device, and add the CMC solution (the ratio of the mass of CMC in the CMC solution to the mass of the dry powder material is 3:97), and utilize the shearing and stretching effects during high-speed rotation, Make the material fully contact with the binder to form a lump-shaped electrode active material raw material with a certain visco...

Embodiment 3

[0102] Step 1, lithium nickel manganese cobaltate (LiNi 1 / 3 mn 1 / 3 co 1 / 3 o 2 ) and activated carbon are mixed according to the mass ratio of 50:50 to obtain a dry powder material;

[0103] Step 2, add acetone, pre-mix the dry powder material by ball milling, the speed of the ball mill is 800r / min, the mixing temperature is 30°C, and mix for 10 minutes;

[0104] Step 3, drying the pre-mixed slurry in step 2, removing the dispersant in the slurry, and obtaining a uniformly mixed dry material;

[0105] Step 4, adding water to the dry material, and pre-wetting with a ball mill;

[0106] Step 5, move the pre-wetted mixture into the kneading device, and add PVDF emulsion (the ratio of the mass of PVDF in the PVDF emulsion to the mass of the dry powder material is 20:80), and use the shearing and stretching effect during high-speed rotation, Make the material fully contact with the binder to form a lump-shaped electrode active material raw material with a certain viscosity;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com