Kneading groove in kneading machine

A kneading machine and kneading tank technology, applied in the field of kneading machines, can solve the problems of much longer kneading time and low kneading efficiency of silicone rubber, so as to shorten the kneading time, improve the kneading effect, and increase the shear force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

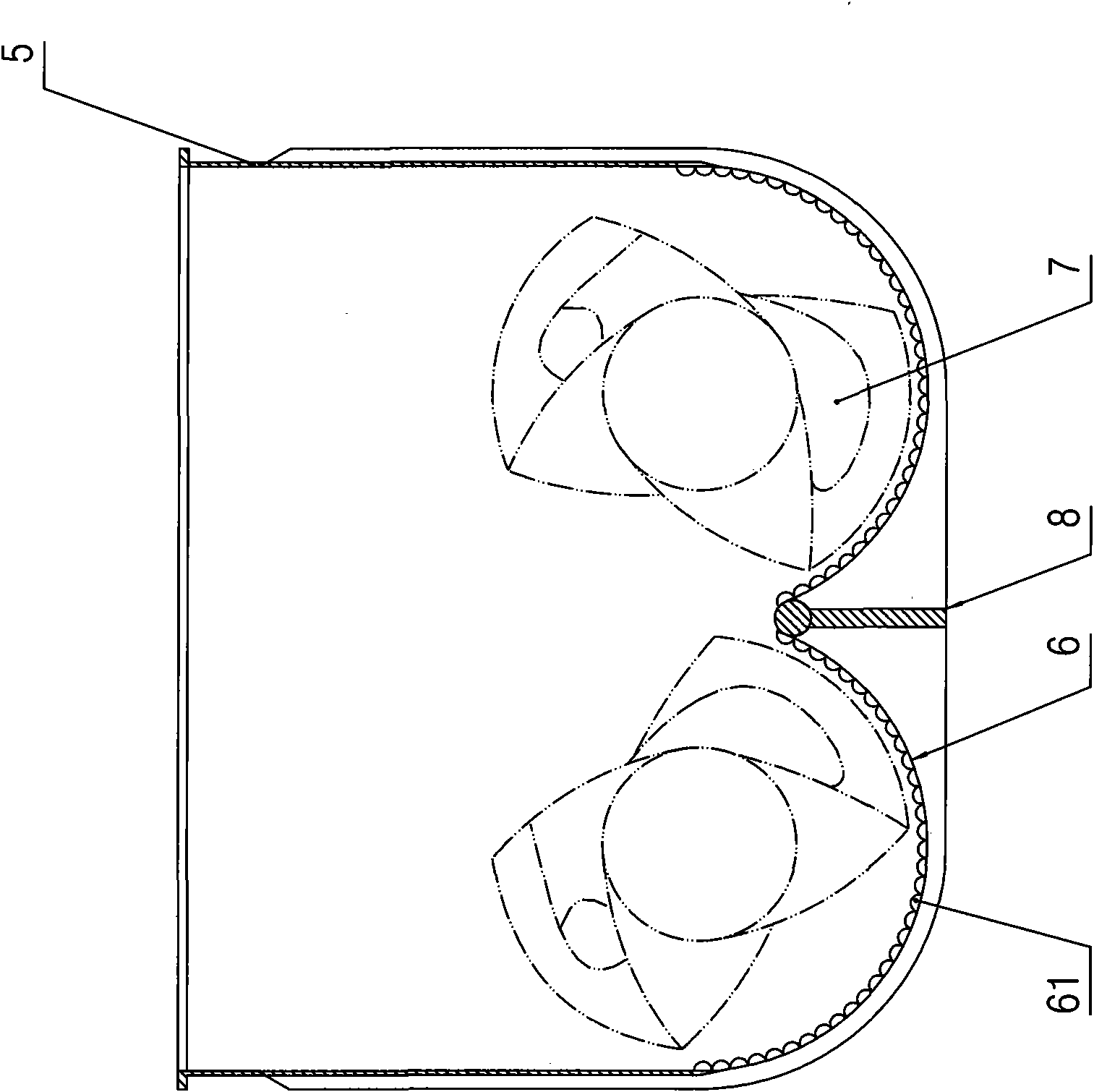

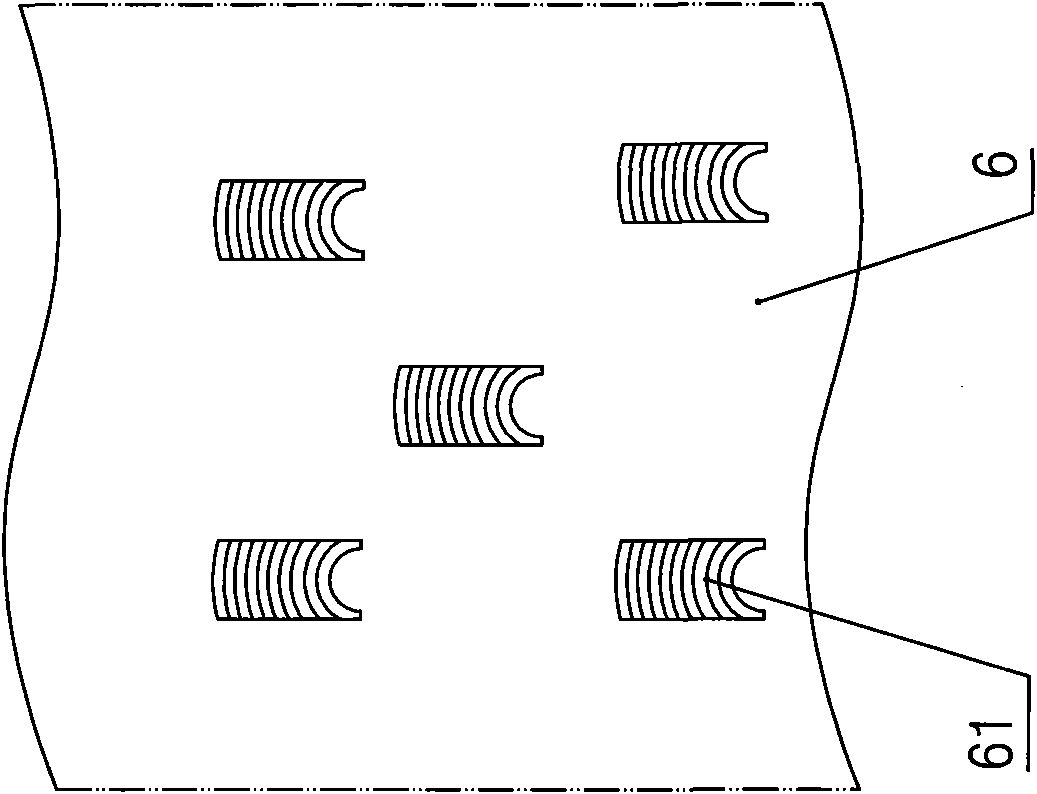

[0012] Such as figure 2 As shown, the kneading tank in the kneader of the present invention includes: a tank wall 5 and a tank bottom 6, and the inner surface of the tank bottom 6 is surfacing with several protrusions 61 for increasing the shear force; and each Multiple lines are arranged on the surface of each protrusion 61 to further increase the shearing force—see image 3 shown.

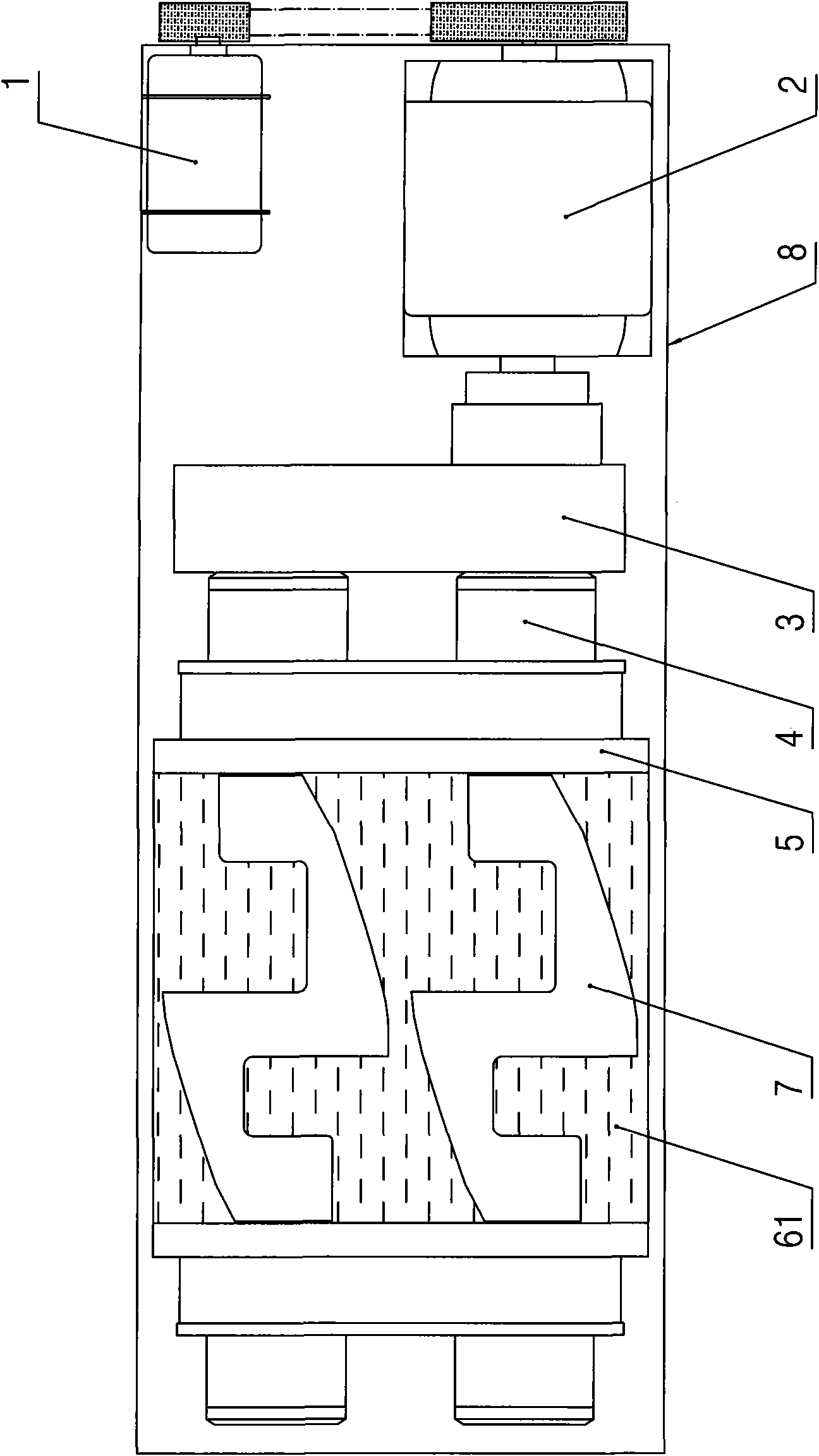

[0013] Such as figure 1 As shown, the kneader provided with the kneading tank of the present invention has the following working process: the motor 1 drives the reducer 2 to rotate, and the reducer 2 drives a pair of gear boxes through the gear box 3 and is respectively arranged in the frame 8 through the bearings 4. The stirring shaft 7 rotates, and the material is squeezed with the tank wall 5 and the tank bottom 6 of the kneading tank under the stirring of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com