Preparation of epsilon copper phthalocyanine of small primary particle size and narrow particle size distribution by kneading

A technology of copper phthalocyanine and particles, which is applied in the direction of organic dyes, photomechanical equipment, photoplate making process of patterned surface, etc., can solve the problems of crystal phase transformation and particle size reduction, multi-time, etc., achieve narrow size distribution, reduce The effect of kneading time and small primary particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

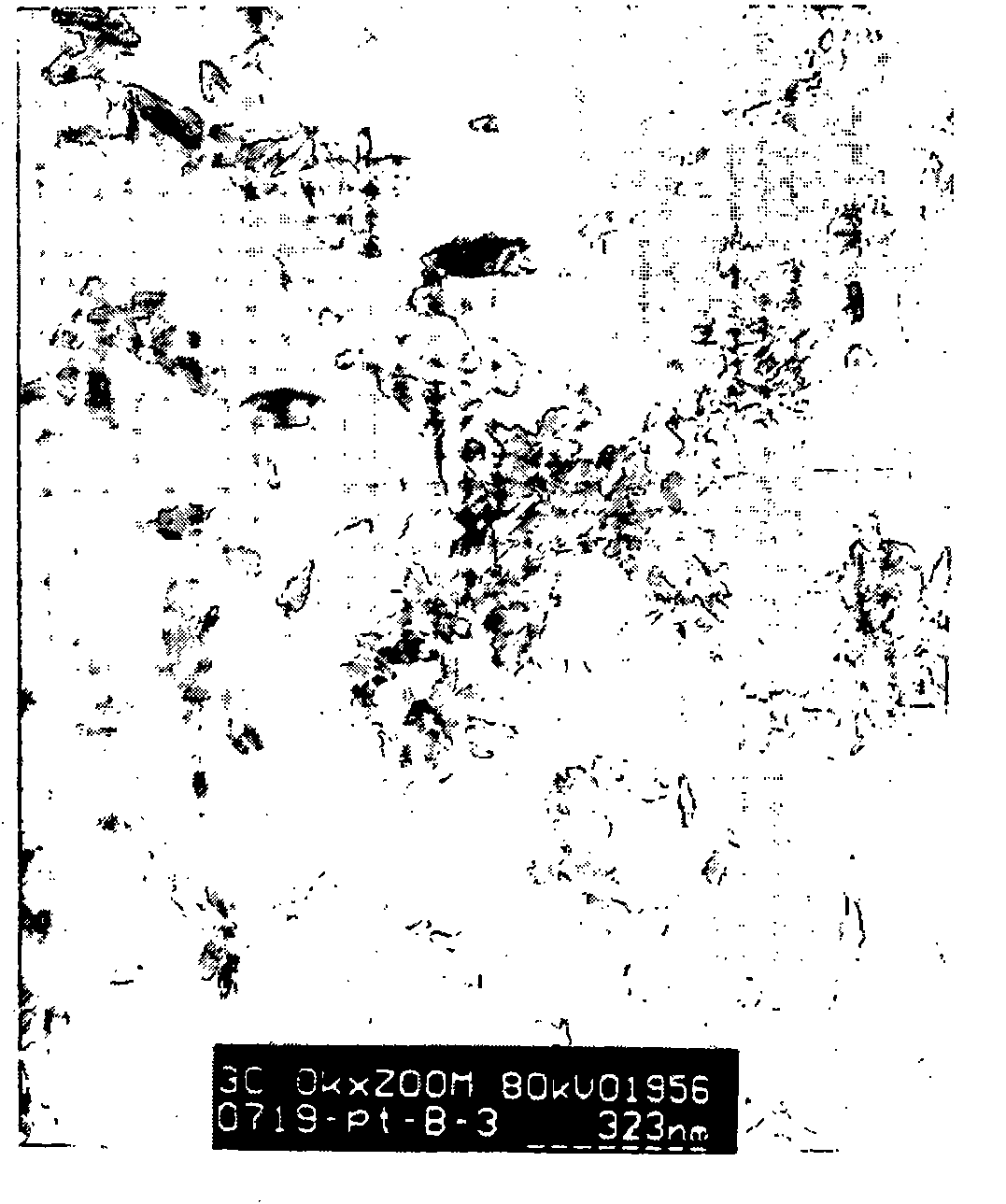

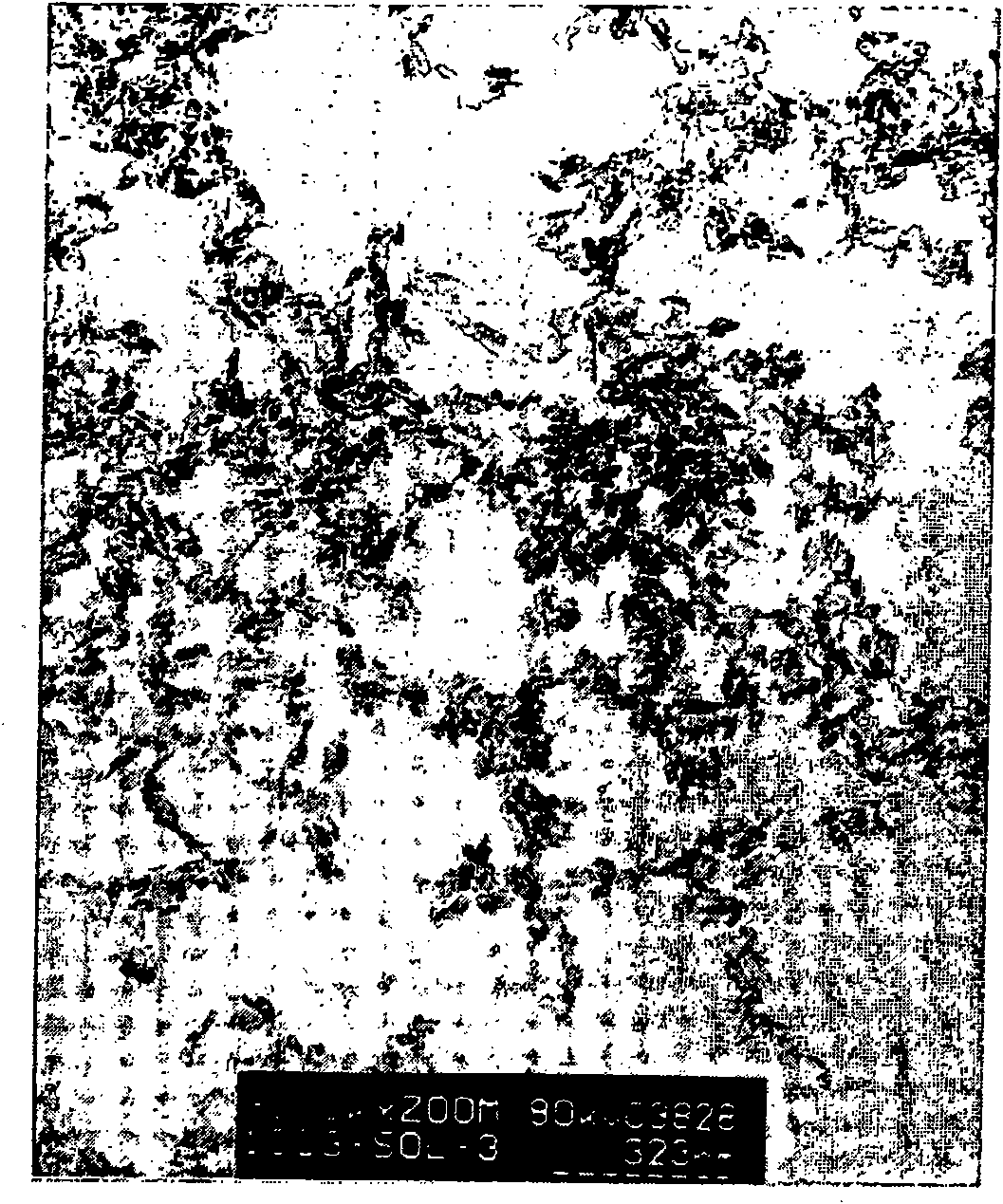

Image

Examples

example 1

[0067] The preparation of example 1.ε crystal form copper phthalocyanine

[0068] 1) Crystal phase transformation of copper phthalocyanine from β crystal form to α crystal form

[0069] 80 parts by weight of crude copper phthalocyanine were added to 800 parts by weight of 95 wt% sulfuric acid. Additionally, the resulting mixture was stirred for 3 hours to prepare a suspension or solution of sulfate in sulfuric acid. The suspension or solution was poured into twice as much 8 L of water to obtain an α crystal form copper phthalocyanine, which was then dried in hot air. After pulverizing the resulting solid, it was confirmed by XRD studies that nearly quantitative α crystal form copper phthalocyanine was obtained in terms of crystallization yield.

[0070] 2) Kneading copper phthalocyanine particles for crystal phase transformation from α crystal form to ε crystal form and particle size reduction

[0071] Add 50 parts by weight of the resulting copper phthalocyanine particles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com