Multi-point spraying injection asphalt system of mixing and blending pot for carbon formation

A kneading pot and asphalt technology, applied in the direction of mixer, mixing method, liquid and solid mixing, etc., can solve the problems of poor mixing effect, dispersing dry material particles, long time, etc., to shorten kneading time and increase intrusion Intensity, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

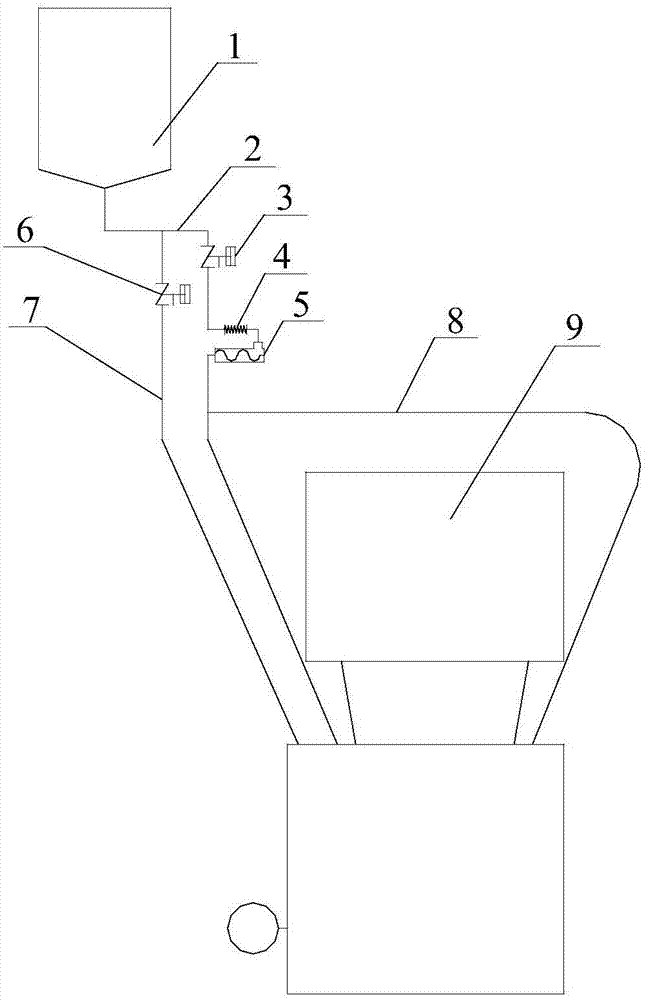

[0023] Such as figure 1 As shown, the kneading pot multi-point spray filling system for carbon molding of the present invention includes an asphalt tank 1 and a kneading pot 9. Two-layer double-layer kneading pot. The upper kneading pot is used for kneading the dry material, the dry material in the upper kneading pot is added to the lower kneading pot, and the high-temperature asphalt oil in the asphalt tank 1 is added to the lower kneading pot, the dry material can be mixed in the lower kneading pot Kneading treatment with high temperature asphalt oil.

[0024] In order to facilitate the high-temperature asphalt oil in the asphalt tank 1 to be quickly evenly added to the kneading pot 9 and mixed with the dry material, the asphalt tank 1 is provided with an asphalt tank discharge pipe 2, and the asphalt tank discharge pipe 2 is arranged on The discharge port at the bottom of the asphalt tank 1, and the discharge pipe 2 of the asphalt tank communicates with the asphalt tank 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com