Polypropylene cable sheath material for submersible pump and producing technology thereof

A technology of cable sheath material and polypropylene, which is applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of inability to realize automation and continuity, difficult to guarantee product quality, and serious dust pollution, so as to be beneficial to product quality and product quality. Effects of improving quality and reducing dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Each component name and each component parts by weight ratio are:

[0025] High flow homopolypropylene resin 100Kg

[0026] POE 8899 30Kg

[0028] IRGANOX 1010 0.5Kg

[0029] IRGANOX MD1024 0.2Kg

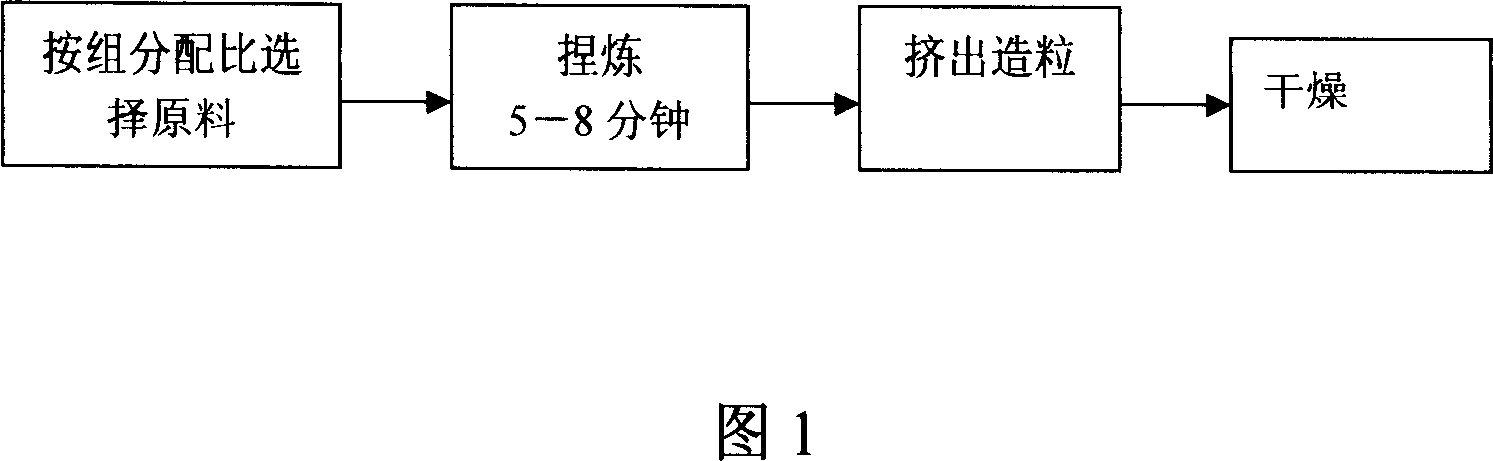

[0030] Production process: select raw materials according to the above-mentioned components and proportions, knead the raw materials in a turning kneader for 5-8 minutes, and use feeding extrusion granulation mixing type twin-screw extrusion granulation after kneading Extrude and granulate by machine, dry after granulation, and obtain polypropylene cable sheathing material for submersible oil pump.

[0031] Among them, the four temperature sections of the feeding extrusion granulation mixing type twin-screw extrusion granulator are: feeding section 180°C, mixing section 200°C, extrusion granulation section 210°C, head part 220°C.

Embodiment 2

[0033] Each component name and each component parts by weight ratio are:

[0034] High flow homopolypropylene resin 100Kg

[0035] POE 8899 50Kg

[0037] IRGANOX 1010 1.0Kg

[0038] IRGANOX MD1024 0.8Kg

[0039] Production technology is identical with embodiment 1.

Embodiment 3

[0041] Each component name and each component parts by weight ratio are:

[0042] High flow homopolypropylene resin 100Kg

[0043] POE 8899 50Kg

[0045] IRGANOX 1010 0.5Kg

[0046] IRGANOX MD1024 0.2Kg

[0047] Production technology is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com