Tea leaf kneading machine

A kneading machine and tea technology, which is applied in the field of tea processing equipment, can solve problems such as low kneading efficiency and long kneading time, and achieve the effects of improving quality, shortening kneading time, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

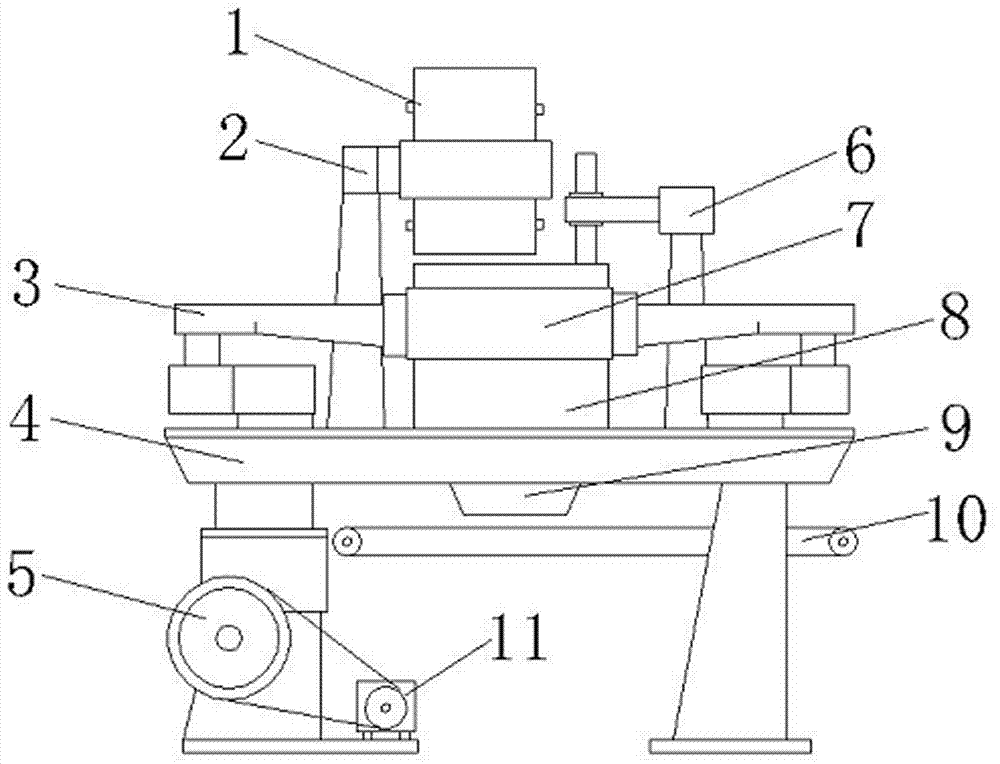

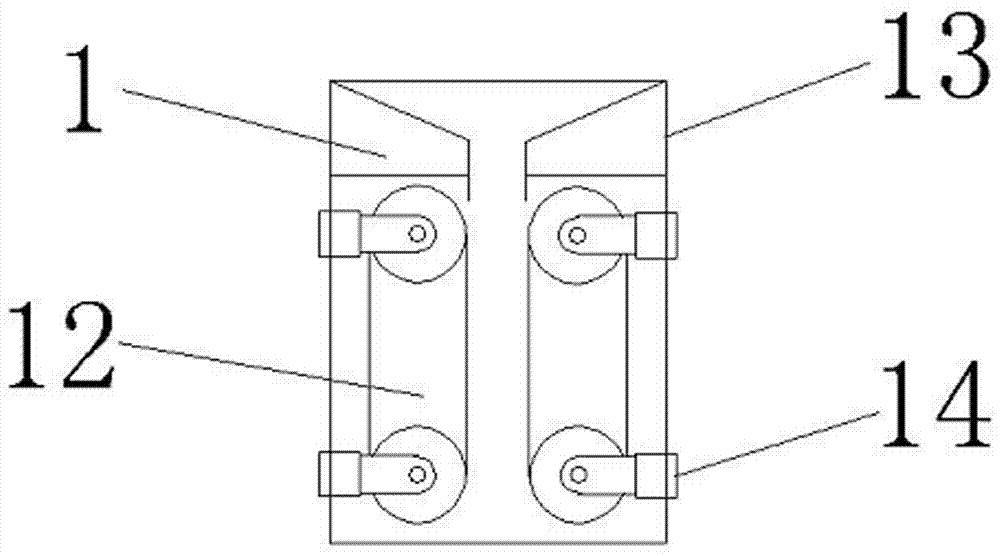

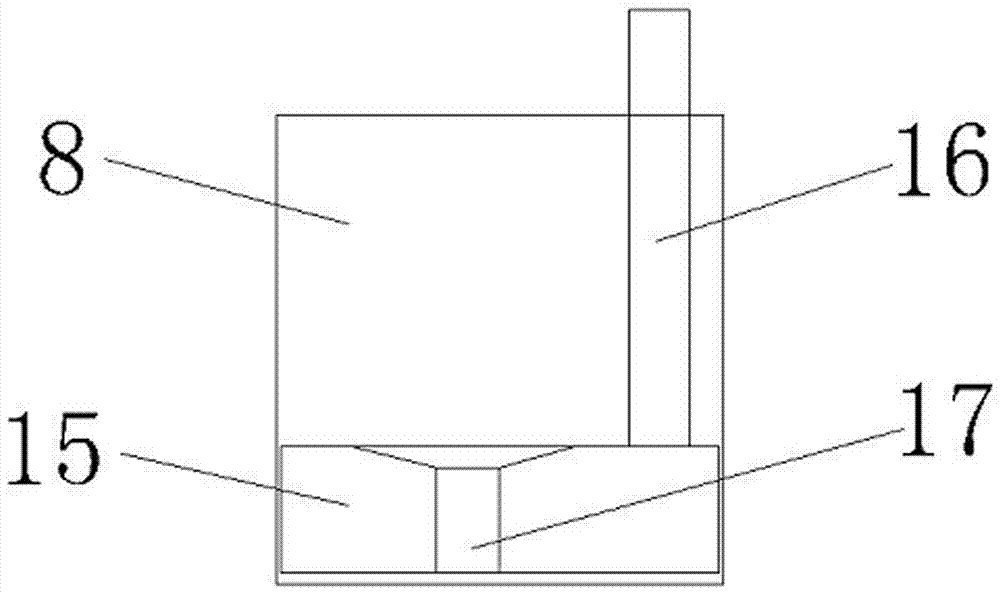

[0021] A kind of tea kneading machine, comprises primary kneading device 1, kneading barrel 8 and kneading plate 4, described primary kneading device 1 comprises baffle plate 13, below baffle plate 13 is kneading belt 12, and kneading belt 12 is provided with adjusting device 14 The primary kneading device 1 is fixed by the fixed bracket 2, the kneading cylinder 8 is located below the primary kneading device 1, and the kneading cylinder 8 is fixed on the kneading disc 4 through the fixed frame 7 and the rocker arm 3, and the inside of the kneading cylinder 8 is provided with a pressure cover 15 and A hydraulic rod 16, a tea channel 17 is opened inside the pressure cover 15, the pressure cover 15 is connected with the hydraulic device 6 through the hydraulic rod 16, a discharge port 9 is provided at the bottom of the kneading disc 4, and a conveyor belt 10 is arranged below the discharge port 9 , the bottom left of the conveyor belt 10 is provided with a drive wheel 5 and a driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com