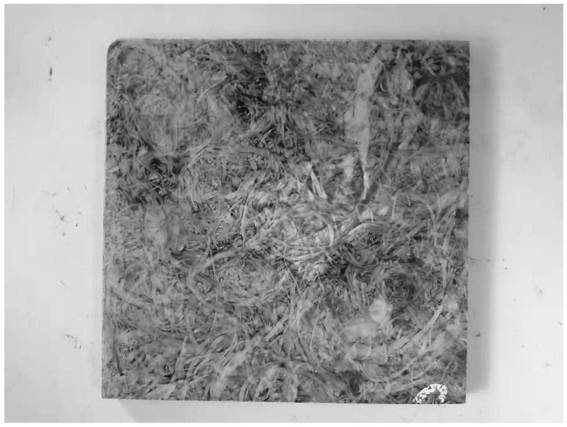

Intermittent same-direction vacuum mechanical premixing preparation method for spaceflight ablation heat-proof chopped fiber/phenolic aldehyde premix

A technology of chopped fiber and premix, applied in the field of composite materials, can solve the problems of low production efficiency, gradient change, high labor cost, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The high-silica short fiber / aminophenol aldehyde premix and its composite material described in this embodiment are prepared from high-silica short fiber, aminophenol aldehyde, and absolute ethanol.

[0029] The preparation method of the high silica chopped fiber / aminophenol aldehyde premix and its composite material described in the present embodiment is specifically as follows:

[0030] 1. Use (100-200) purpose copper or stainless steel filter to filter the resin;

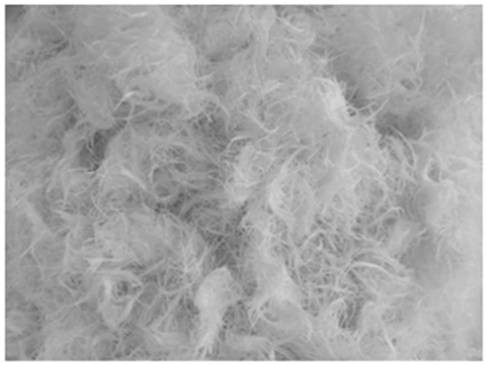

[0031] 2. The cut length of high silica fiber is 24mm, and heated in an oven at (120±5)°C for 4 hours;

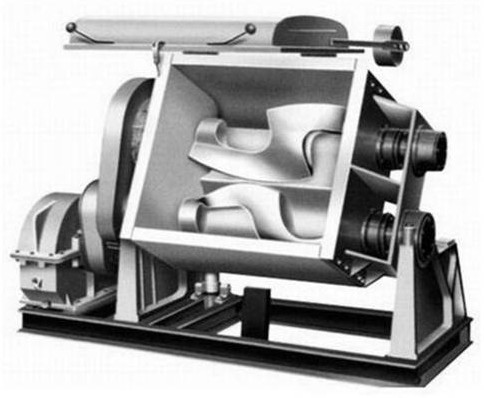

[0032] 3. Weigh (35.5-37.5) kg of aminophenol-formaldehyde resin and pour it into the kneader, add (23-25) L of absolute ethanol, and rotate forward (1-2) min to mix the resin solution evenly;

[0033] 4. Weigh (45±0.1)kg high silica glass fiber chopped strand;

[0034] 5. Spin yarn three times. First, put 15kg of high-silica glass fiber chopped strands evenly into all parts of the kneader, and turn ...

Embodiment 2

[0046] The high-silica chopped fiber / magnesium phenolic premix and its composite material described in this embodiment are prepared from high-silica chopped fiber, magnesium phenolic resin, and absolute ethanol.

[0047]The preparation method of the high silica chopped fiber / magnesium phenolic premix and composite material described in the present embodiment is specifically as follows:

[0048] 1. Use (100-200) purpose copper or stainless steel filter to filter the resin;

[0049] 2. The cut length of high silica fiber is 24mm, and heated in an oven at (120±5)°C for 4 hours;

[0050] 3. Weigh (44-47) kg magnesium phenolic resin and pour it into the kneader, add (19-22) L absolute ethanol, and rotate forward (1-2) min to mix the resin solution evenly;

[0051] 4. Weigh (45±0.1)kg high silica glass fiber chopped strand;

[0052] 5. Spin yarn three times. First, put 15kg of high-silica glass fiber chopped strands evenly into all parts of the kneader, and turn forward for 30s; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com