Dough kneading machine

A technology for dough kneading machine and noodle bowl, which is applied to dough mixers, structural parts of mixing/kneading machines, mixing/kneading with vertical installation tools, etc. Low problems, to achieve the effect of overcoming vibration, prolonging service life and improving dough kneading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

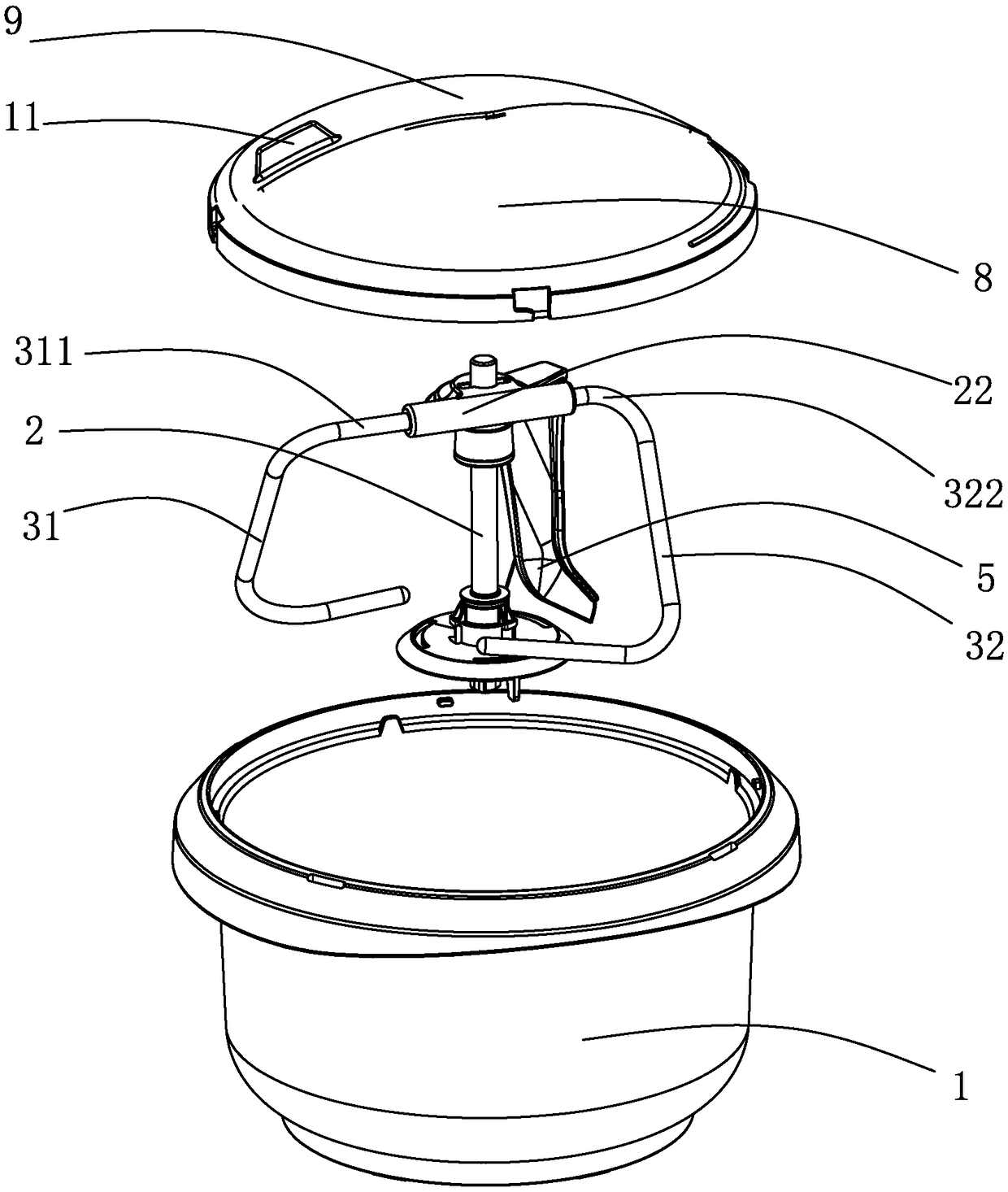

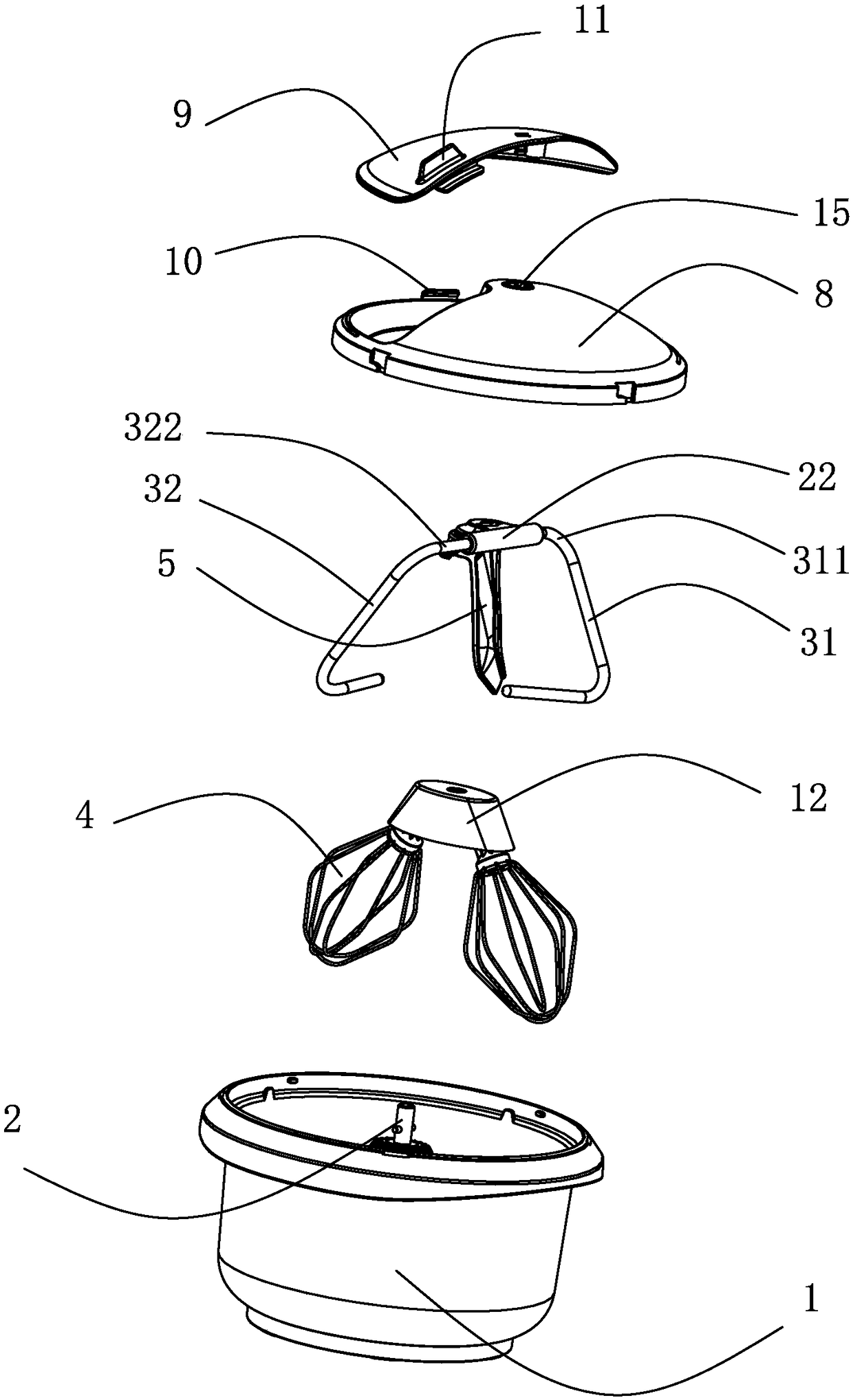

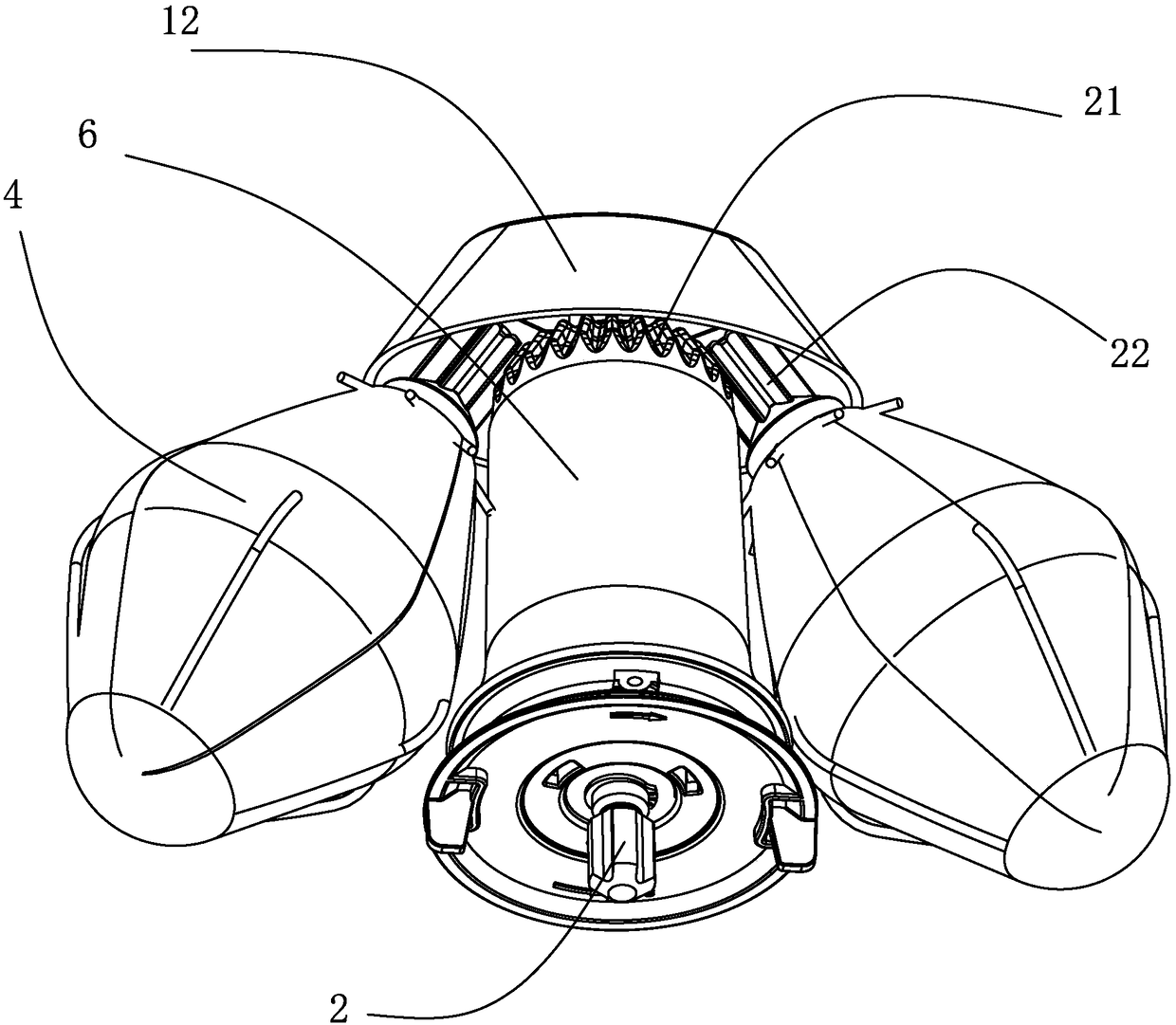

[0025] Such as Figure 1-Figure 8As shown, a kind of dough kneading machine provided by the present invention includes a dough kneading bowl 1 and a dough kneading assembly, a bowl cover is arranged on the kneading dough bowl 1, an integrally formed transmission shaft 2 is arranged in the kneading dough bowl 1, and the transmission shaft 2 vertically through the fixing hole at the bottom of the kneading bowl 1, and the lower end is connected with a drive motor, the upper end of the transmission shaft 2 is provided with a positioning protrusion 7, and the mounting frame 22 is provided with a positioning hole corresponding to the positioning protrusion 7. The kneading assembly includes a mounting frame 22 and a first connecting rod 311 and a second connecting rod 322 arranged at the two ends of the mounting frame 22, the length of the first connecting rod 311 is shorter than the length of the second connecting rod 322, and the first connecting rod The end of 311 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com