Kneading type garlic peeling machine

A garlic machine and rack technology, applied in the field of rubbing garlic peeling machines, can solve problems such as low efficiency and damage to garlic braids, and achieve the effects of not polluting the environment, high rubbing efficiency, and novel materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

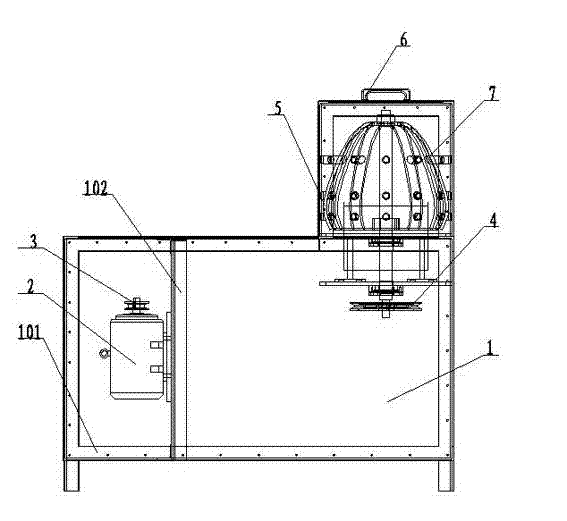

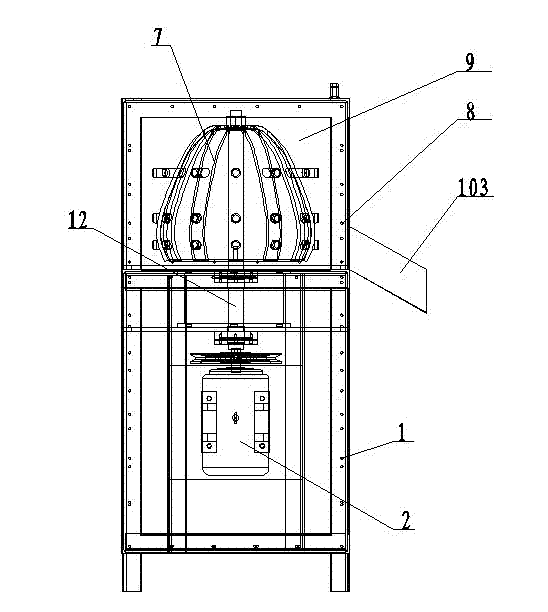

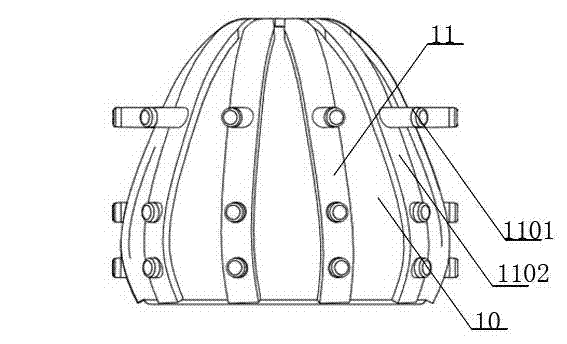

[0015] As shown in the figure, the specific implementation method is as follows:

[0016] A rubbing type garlic peeling machine, comprising a support device 1, a power unit and a peeling device, the power unit and the peeling device are respectively arranged at the two ends of the support device 1, and the described peeling device includes a garlic inlet 6, a garlic outlet The peeling chamber 9 of the mouth 8 and the debris outlet 5, and a rubbing mechanism 7 arranged in the peeling chamber 9, the rubbing mechanism 7 includes a rotating wooden wheel 10, a rotating shaft 12 and a ring 11, and the rotating shaft 12 To drive the rotating wooden wheel 10 to rotate, a plurality of rings 11 are provided and evenly distributed on the outer surface of the rotating wooden wheel 10. The rings 11 are composed of arc bars 1102 and protrusions 1101 installed on the arc bars 1102 , the length direction of the arc bar 1102 is consistent with the axial direction of the rotating shaft 12 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com