Low-temperature twisting device for tea leaves

A kneading device and low-temperature technology, which is applied in the field of tea kneading equipment, can solve the problems that affect green tea aroma, color quality, taste, heat cannot be dissipated to the outside, and reduce the quality characteristics of green tea, so as to improve the tea kneading efficiency, turn over well, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

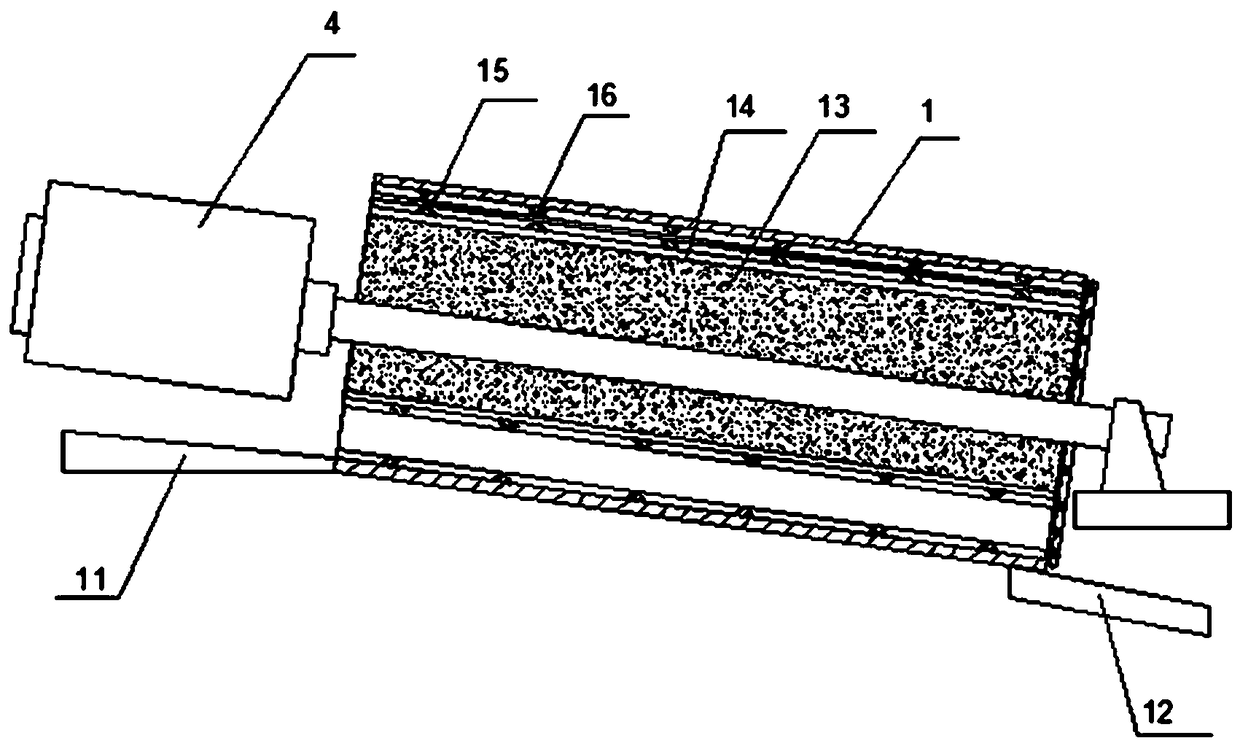

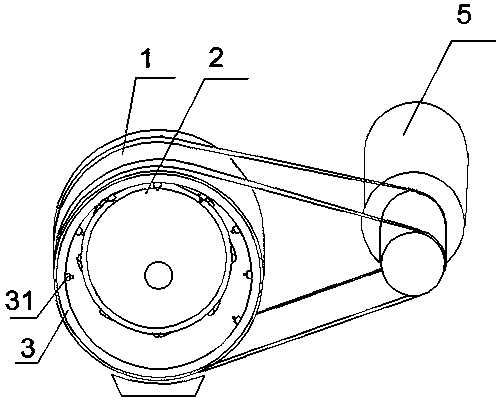

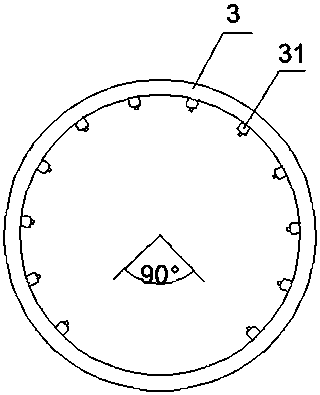

[0033] Such as Figure 1~3 As shown, a tea low-temperature rolling device includes a driving device 4, a rolling cylinder 1, and a rolling roller 2 arranged in the rolling cylinder 1 and moving in an eccentric circle along the axis of the rolling cylinder 1. Feed port 11 and discharge port 12, said kneading drum 1 is provided with an annular air supply pipeline 3 externally connected to the nitrogen generator near the end of discharge port 12, and said air supply pipeline 3 is provided with a plurality of kneading cylinder 1 Inclined nozzle 31; the kneading drum 1 is arranged obliquely.

[0034] The driving device 4 may be any one of a hydraulic pump, an air pump or a geared motor. The second driving device 5 is a geared motor.

[0035] The kneading barrel is provided with an eccentric shaft, the axis of the eccentric shaft is on the same straight line as the axis of the kneading disc, and the end of the eccentric shaft far away from the kneading barrel is connected to the d...

Embodiment 2

[0040] This embodiment is improved on the basis of Embodiment 1, and its improvement is that: the kneading roll 2 includes a roller 13 and an air pressure layer 14 sleeved on the roller 13; the rib 16 is arranged on Air pressure layer 14 surface.

[0041] The roller 13 is made of metal material or stone with high density and high hardness, preferably metal iron or granite.

[0042] The air pressure layer 14 is an air bag made of a polymeric organic material filled with gas, and the air pressure layer 14 is located between the roller 13 and the inner surface of the kneading cylinder 1, so that the roller 13 of strong hardness is not in contact with the kneading cylinder 1. The tea leaves on the air pressure layer 14 are in direct contact with the tea leaves, and the gas in the air pressure layer 14 is compressible. The air bag made of polymer organic material has a certain elasticity, so that in the process of rolling the tea leaves, the gas flows and compresses in the air pressu...

Embodiment 3

[0047] This embodiment is improved on the basis of Embodiment 1 or 2, and the improvement is that: the inner surface of the kneading drum 1 is provided with a number of ribs 15 arcuately extending from the inlet 11 to the outlet 12 The outer surface of the kneading roller 2 is provided with a plurality of ribs 16 arcuately extending from one end of the feed port 11 to one end of the discharge port 12 . The number of ribs 15 in the kneading cylinder 1 is 12-15; the number of ribs 16 on the kneading roller 2 is 8-10.

[0048] Preferably, the surface of the air pressure layer 14 is provided with several ribs 16 for increasing the surface friction of the air pressure disc, and the ribs 16 are just opposite to the extending direction of the ribs 15 on the kneading roller 2 .

[0049] Other parts in this embodiment are basically the same as those in Embodiment 1, so details will not be repeated one by one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com