Plateau brick machine

A plateau brick machine and unit technology, applied in the direction of ceramic molding machine, ceramic extrusion die, cement mixing device, etc., can solve the problem that the vacuum degree of mud material cannot meet the production requirements, cannot further exhaust gas, does not have exhaust function, etc. problems, to achieve the effect of improving product quality and yield, flexible adjustment of extrusion speed, and uniform kneading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

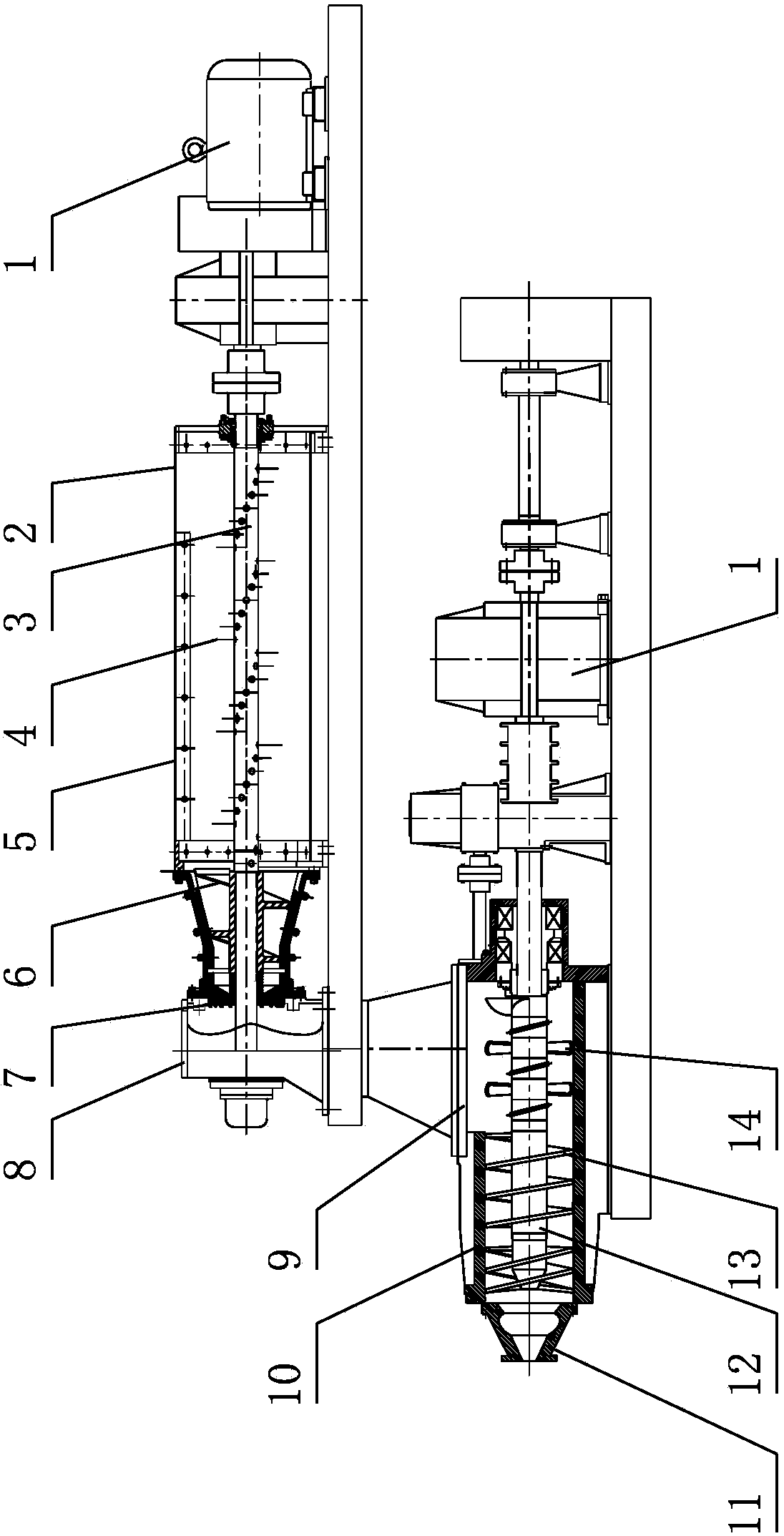

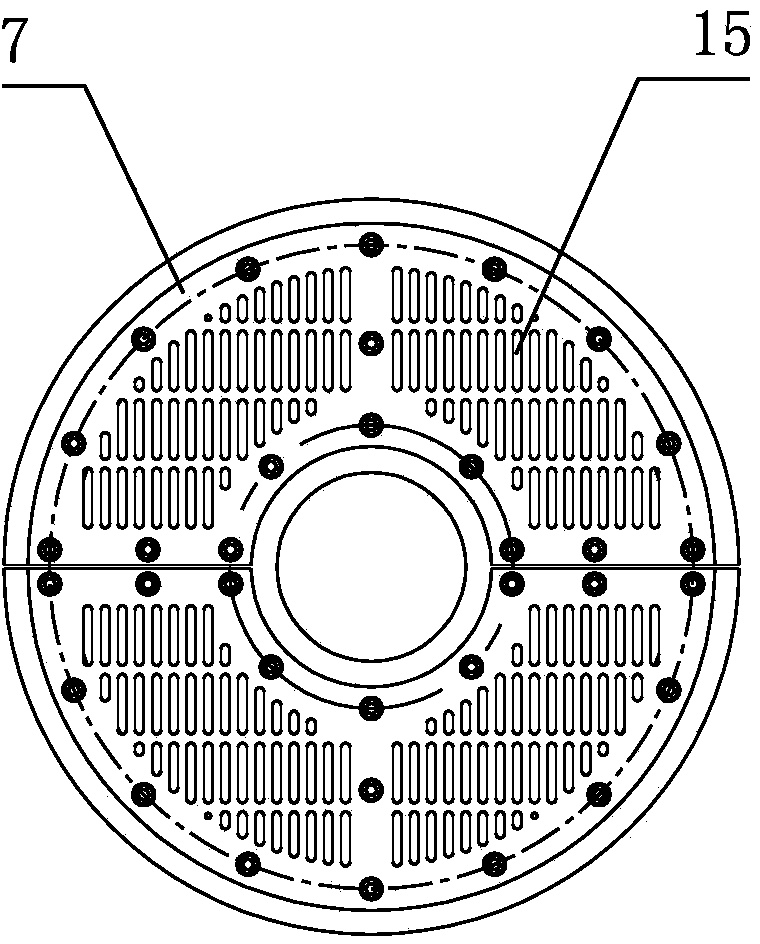

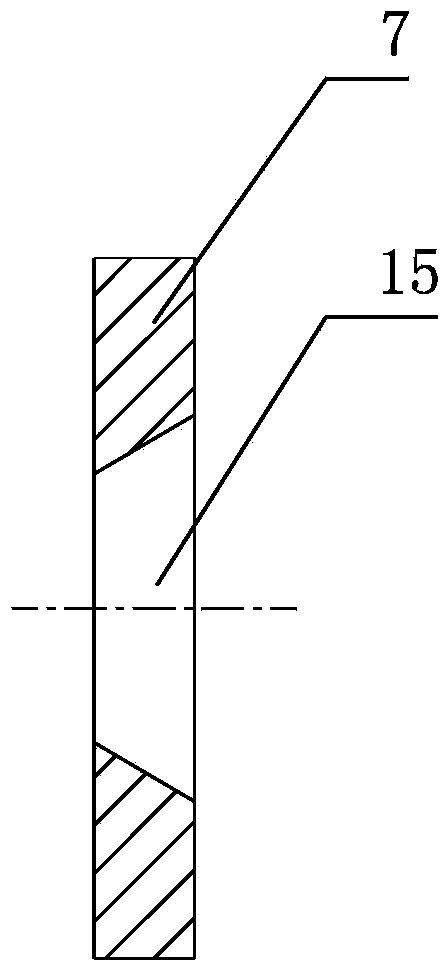

[0030] Such as Figure 1-5 As shown, the plateau brick machine of the present invention includes a superior unit and a lower unit, and the superior unit includes a mixing box 5, a blanking box 8 and a driving device 1, and the blanking box 8 is connected to the outlet end of the mixing box 5, and the dropping box A vacuum chamber is set in the material box 8, a feed inlet 2 is set at the rear of the stirring box 5, and a stirring propulsion assembly is arranged in the stirring box 5, and the stirring propulsion assembly includes the stirring shaft 5 and the stirring knife 4, the spiral twisting shaft installed on the stirring shaft 5 in turn. Knife 6, mixing knife 4 and stirring shaft 3 form a stirring part to stir the mud, and the spiral reamer 6 and stirring shaft 3 form a propulsion part to push the mud forward, and the stirring shaft 3 is connected to the driving device 1. A sieve plate 7 is installed at the discharge port of the stirring box 5, and several sieve holes 15 ...

Embodiment 2

[0036] Such as Figure 6 As shown, the mold base 11.3 is sequentially provided with the first compression cavity 11.2, the first expansion cavity 11.4, and the extrusion cavity 11.5 along the axial discharge direction. The first expansion cavity 11.4 is a gourd cavity or a waist drum cavity, and the extrusion cavity 11.5 The diameter gradually decreases along the axial discharge direction, and the rest are the same as in Example 1.

Embodiment 3

[0038] Such as Figure 7 As shown, the mold base 11.3 is sequentially provided with a first compression chamber 11.2, a first expansion chamber 11.4, a second compression chamber 11.7, a second expansion chamber 11.8, and an extrusion chamber 11.5 along the axial discharge direction. The diameters of the first compression chamber 11.2 and the second compression chamber 11.7 gradually decrease along the axial discharge direction, the first expansion chamber 11.4 and the second expansion chamber 11.8 are cylindrical cavities with equal diameters, and the extrusion chamber 11.5 is a cylinder with equal diameters cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com