Controllable-temperature tea stir-frying machine capable of fully rolling tea leaves

A technology for frying tea machine and tea leaves, which is applied in the direction of tea processing before extraction, etc., can solve the problem that the tea leaves cannot be fully rolled by a tea rolling device, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

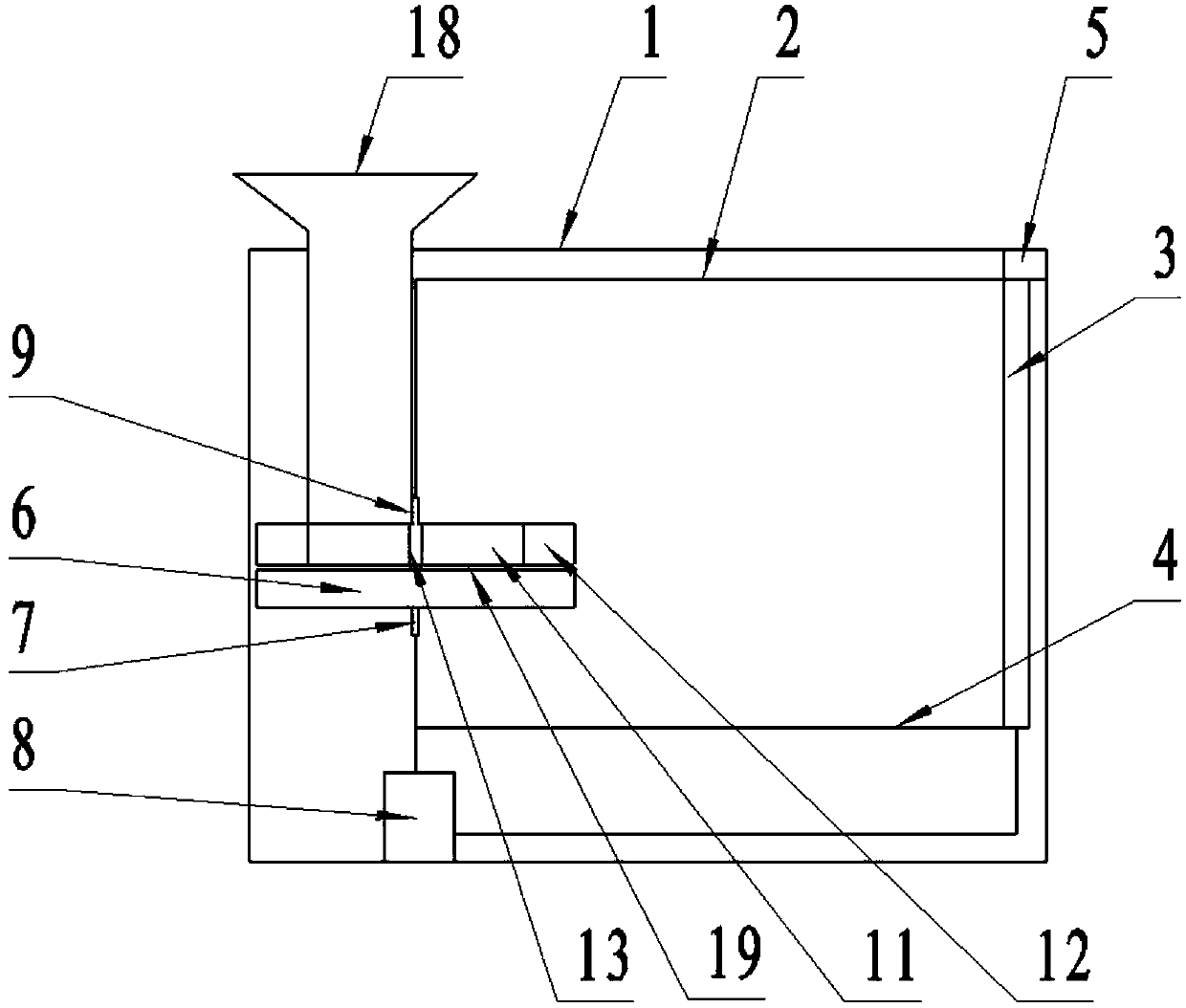

[0027] Such as figure 1 As shown, a temperature-controllable tea frying machine for fully kneading tea leaves includes an outer furnace body 1, an inner furnace body 2, a tea rolling device and a heater 3. The outer furnace body 1 is embedded with an inner furnace body 2, and the inner furnace body There is an opening on one side of the body 2, and half of the tea kneading device is located between the outer furnace body 1 and the inner furnace body 2 through the opening, and the other half is located in the inner furnace body 2. The tea kneading device includes a kneading platform 6 and a kneading platform 6 A plurality of kneading ends, a sieve plate 4 is provided under the tea kneader in the inner furnace body 2, a heater 3 is provided on the side opposite to the tea kneader between the outer furnace body 1 and the inner furnace body 2, and the heater 3 is connected to the temperature Sensor, the temperature sensor is provided with a temperature display instrument 5, the to...

Embodiment 2

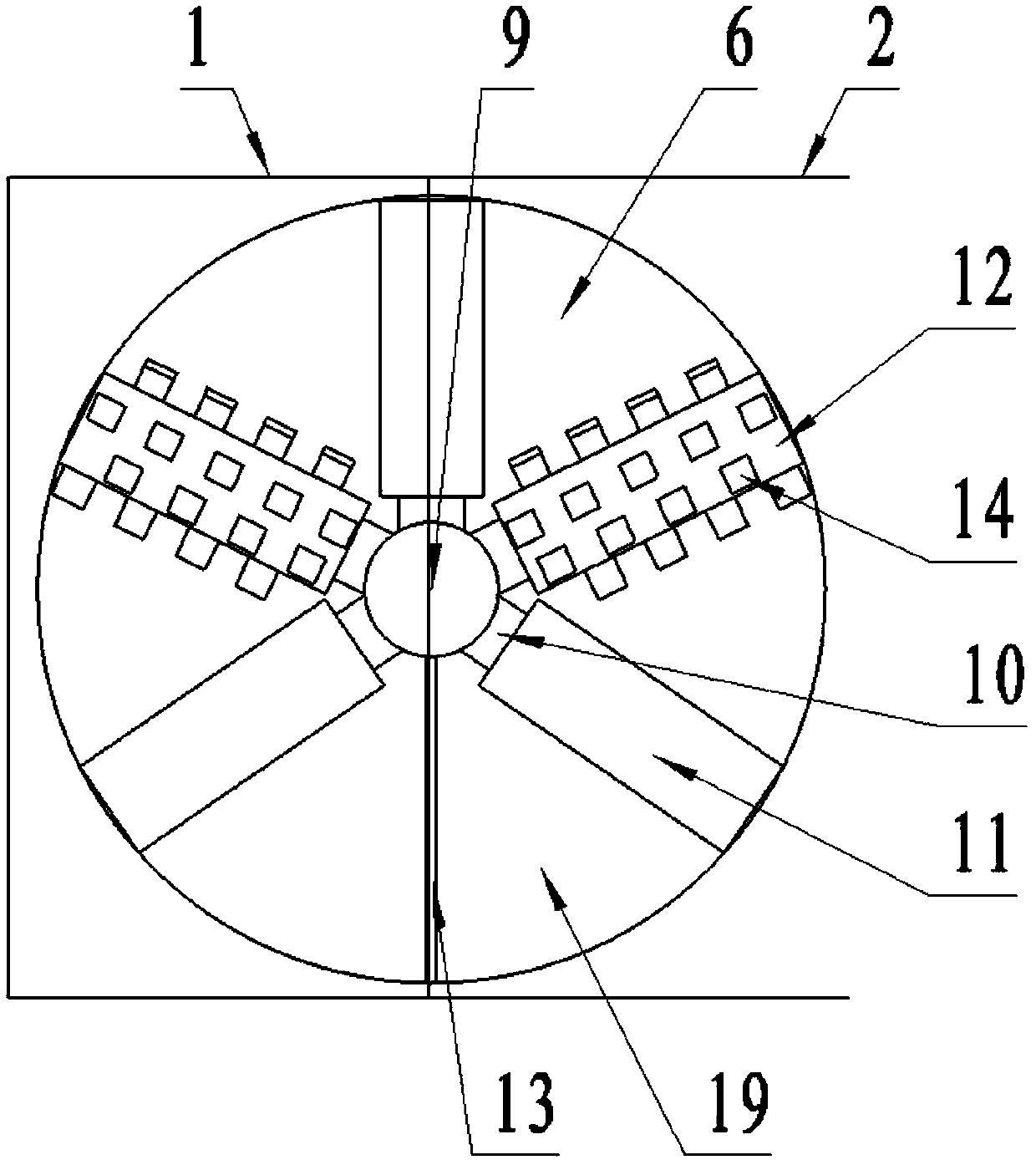

[0032] Such as figure 1 and figure 2 As shown, the lower end of the kneading platform 6 is provided with a support rod 7, one end of the support rod 7 is fixedly connected to the kneading platform 6, and the other end is connected to the first drive motor 8 positioned between the outer furnace body 1 and the inner furnace body 2, and the kneading A fixed rod 9 is arranged above the vertical direction of the center of the platform 6, and one end of the fixed rod 9 is fixed on the upper end of the inner furnace body 2 opening. Located on the same horizontal plane and parallel to the kneading platform 6.

[0033] The plurality of kneading ends are three kneading cylinders 11, two mixing cylinders 12 and a separation plate 13, and the three kneading cylinders 11 are evenly distributed on the kneading platform 6 at an angle of 120° to each other. The platforms 6 are in contact, two mixing drums 12 and a separating plate 13 are respectively located between two adjacent kneading d...

Embodiment 3

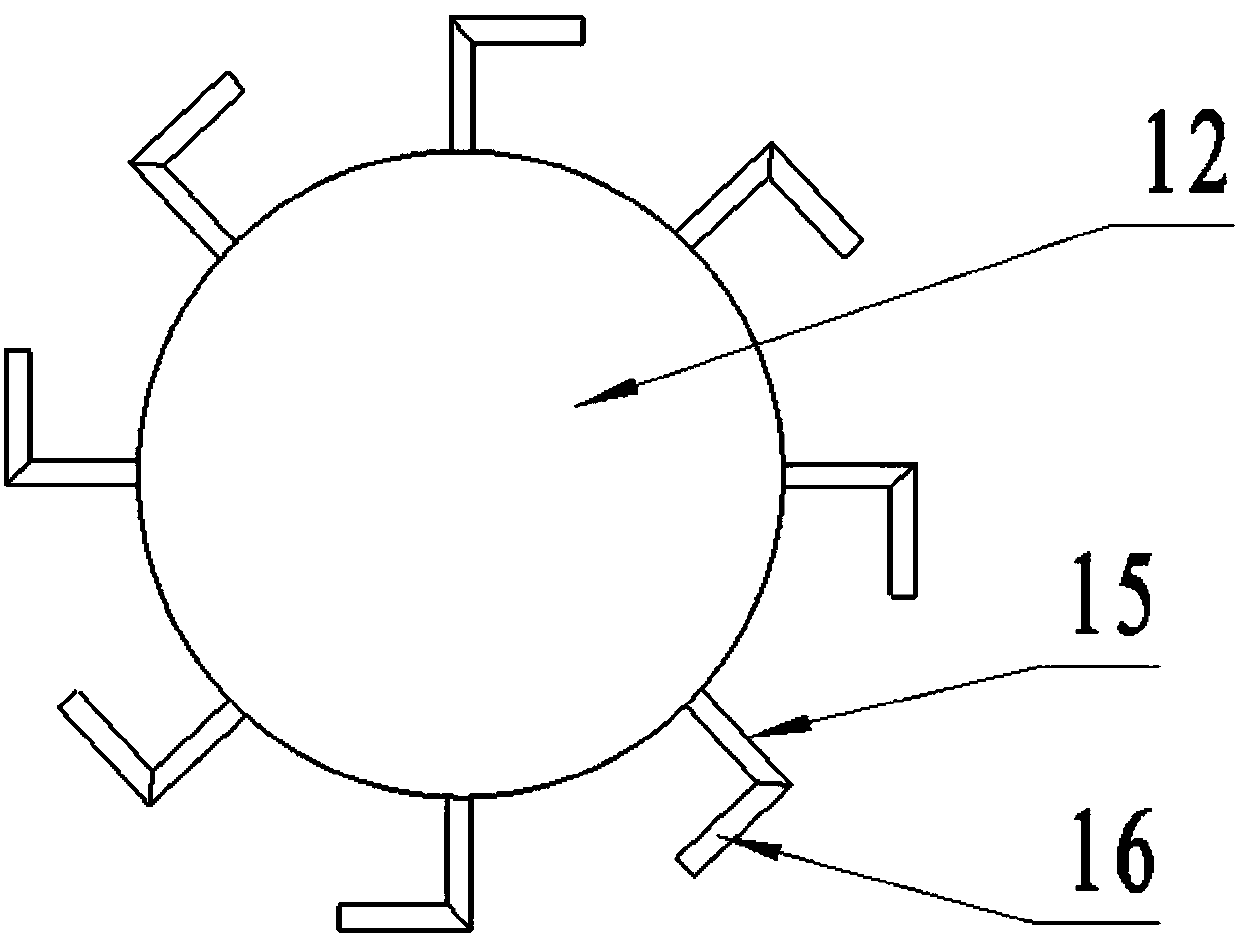

[0038] Such as image 3 and Figure 4 As shown, the kneading cylinder 11 and the mixing cylinder 12 are cylinders, and the side of the mixing cylinder 12 is evenly distributed with a plurality of scattered structures 14, and the side of the separating plate 13 near the kneading platform 6 is along the radial direction of the kneading platform 6. A brush belt 17 is provided, and one end of the brush belt 17 is in contact with the kneading platform 6 .

[0039] The breaking structure 14 comprises a first breaking plate 15 and a second breaking plate 16, one end of the first breaking plate 15 is fixedly connected to the outside of the mixing drum 12 and is perpendicular to the tangent at the junction of the mixing drum 12, the first The other end of breaking up plate 15 is connected with an end of the second breaking up plate 16, and the angle that the first breaking up plate 15 and the second breaking up plate 16 forms is toward the direction that mixing drum 12 rotates, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com