Pre-reactor main shaft spiral system for hydrogen fluoride

A pre-reactor and hydrogen fluoride technology, which is applied in the direction of fluorine/hydrogen fluoride, etc., can solve the problems of insufficient reaction, easy material jamming, and material return, and achieve the effects of improving production efficiency and product quality, increasing stirring strokes, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

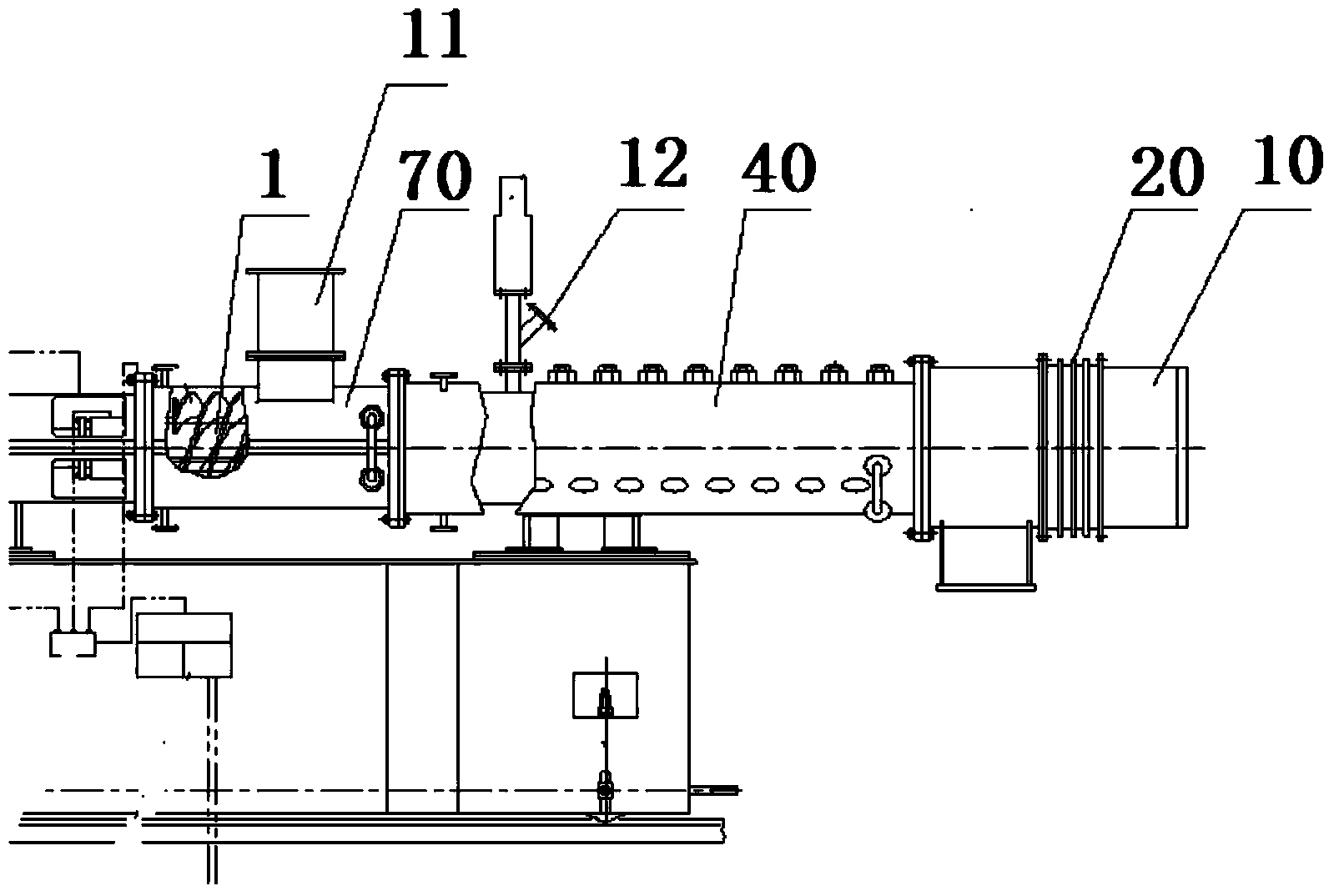

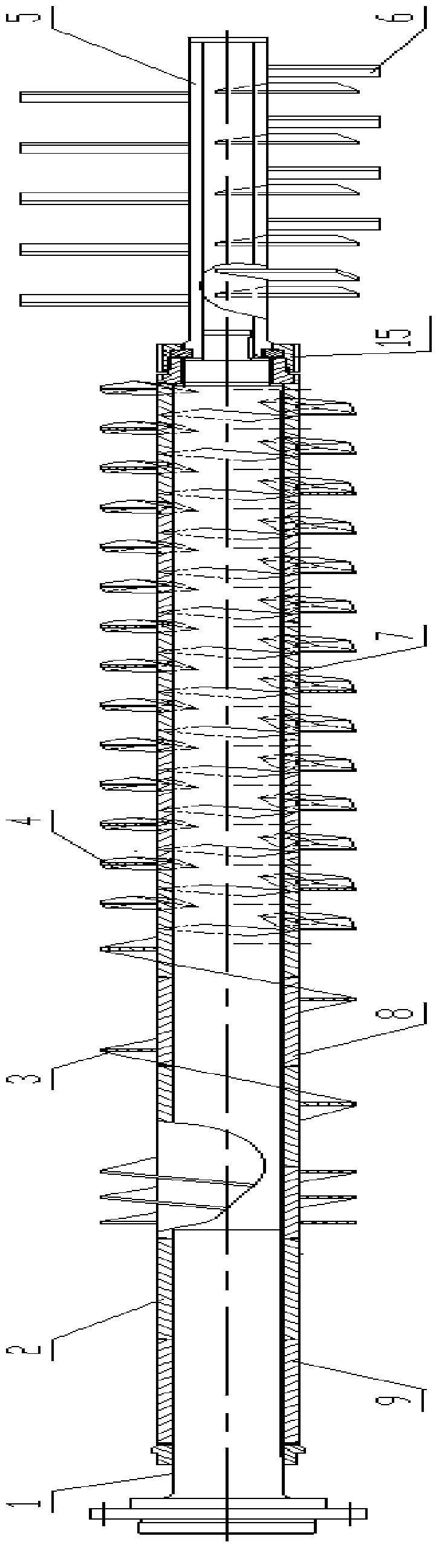

[0017] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-Figure 2 As shown, the present invention is applied to the equipment disclosed in Chinese Patent Application No. 201120249083.X, named "hydrogen fluoride pre-reactor", which comprises an extension section 10, an extension section compensator 20, a main reaction section 40, a feeding Section 70, screw spindle 1, etc.; feeding section 70 is provided with fluorite feeding port 11 and acid feeding port 12; hydrogen fluoride pre-reactor spindle screw system, including main shaft 1, stuffing box sleeve 2, fluorite feeding section paddle 3. The reaction section paddle 4, the extension section shaft 5, the extension section paddle 6, the reaction section shaft sleeve 7, the fluorite feeding section shaft sleeve 8, the bearing bush 9, and the fluorite feeding section paddle 3 is welded on On the shaft sleeve 8 of the fluorite feeding section, the paddle 4 of the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com