Tea airing equipment

A kind of equipment and cylinder technology, applied in the field of automation equipment, can solve the problem that tea is easily contaminated with dust, etc., and achieve the effects of small footprint, easy recovery, and little impact of bad weather

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

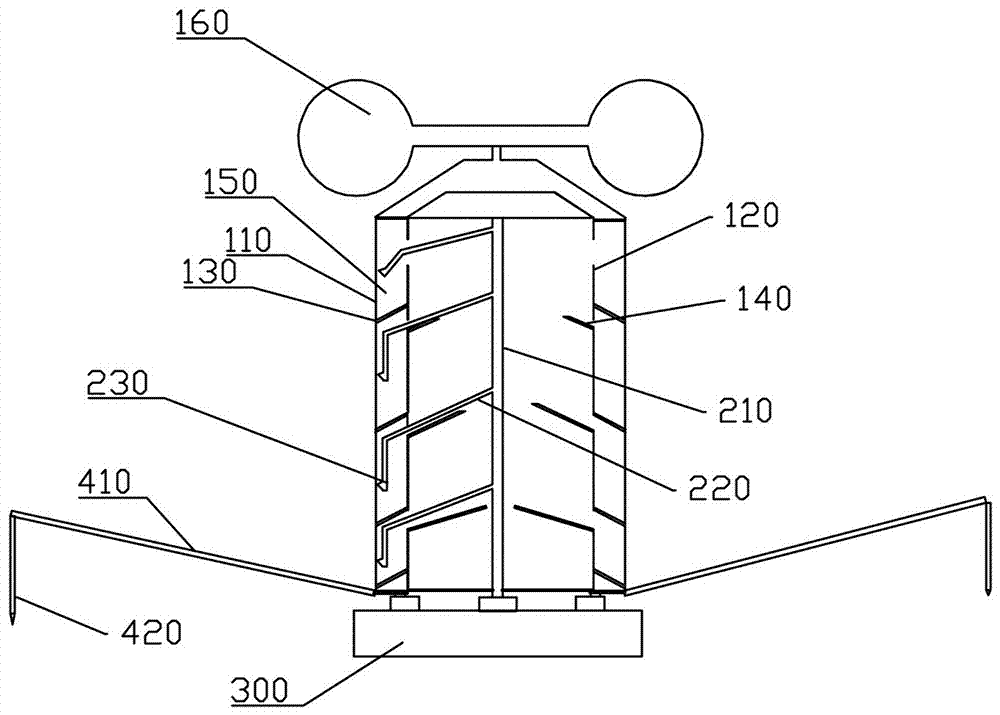

[0016] like figure 1 The shown tea drying equipment includes a cylinder body, a mounting base 300, a stirring mechanism and a protective cover. The cylinder body is horizontally rotatably connected to the mounting base 300, the stirring mechanism is set inside the cylinder body, and the protection sleeve is set outside the cylinder body; It includes a cylinder holder, a transparent outer cylinder shell 110 arranged outside the cylinder holder, an inner cylinder shell 120 arranged inside the cylinder holder, several layers of partitions 130 arranged between the outer cylinder shell 110 and the inner cylinder shell 120, and the The tea tray 140 on the inner wall of the inner cylinder shell 120, the outer cylinder shell 110, the inner cylinder shell 120 and the partition 130 form four tea drying chambers 150, the tea drying chamber 150 is provided with a tea inlet and a tea ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com