Noodle maker with good dough kneading effect

A noodle machine and noodle bucket technology, which is applied to dough mixers, dough extruders, structural components of mixing/kneading machines, etc., can solve problems such as uneven mixing, poor kneading effect, and inability to push into the extruding drum. , to achieve a good effect of kneading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

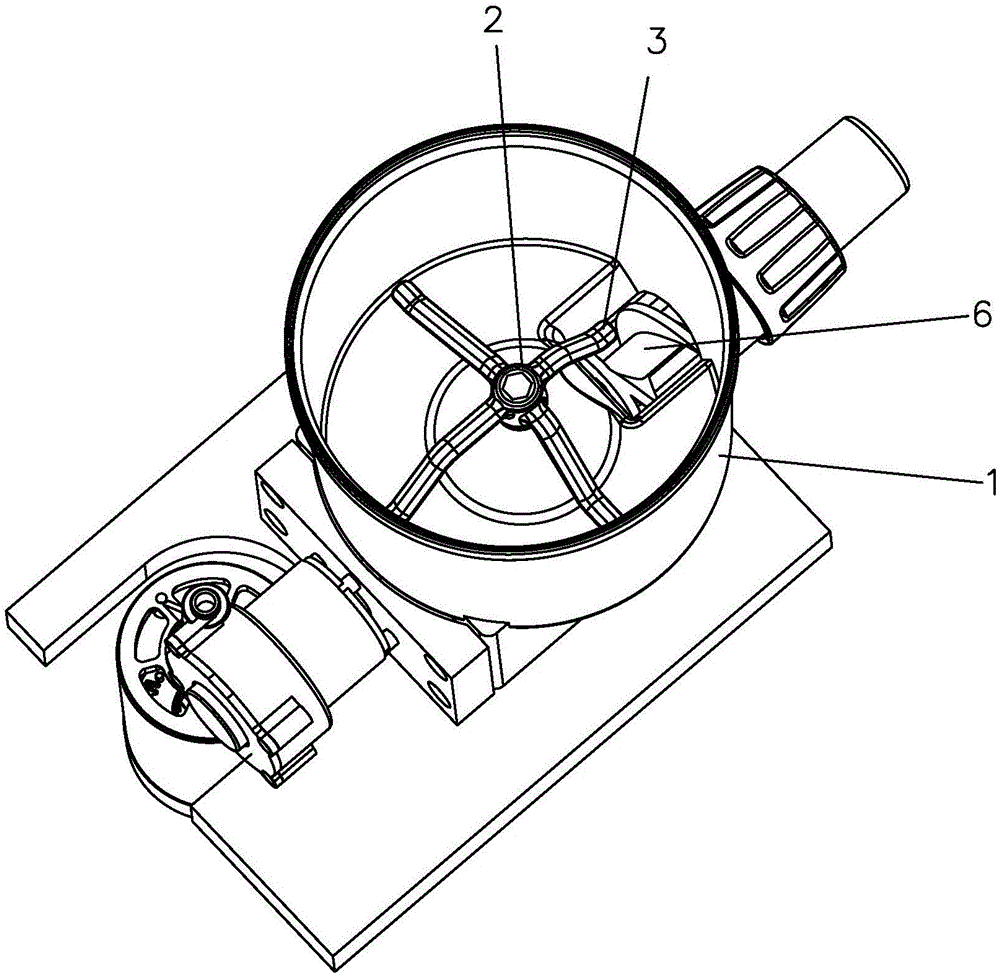

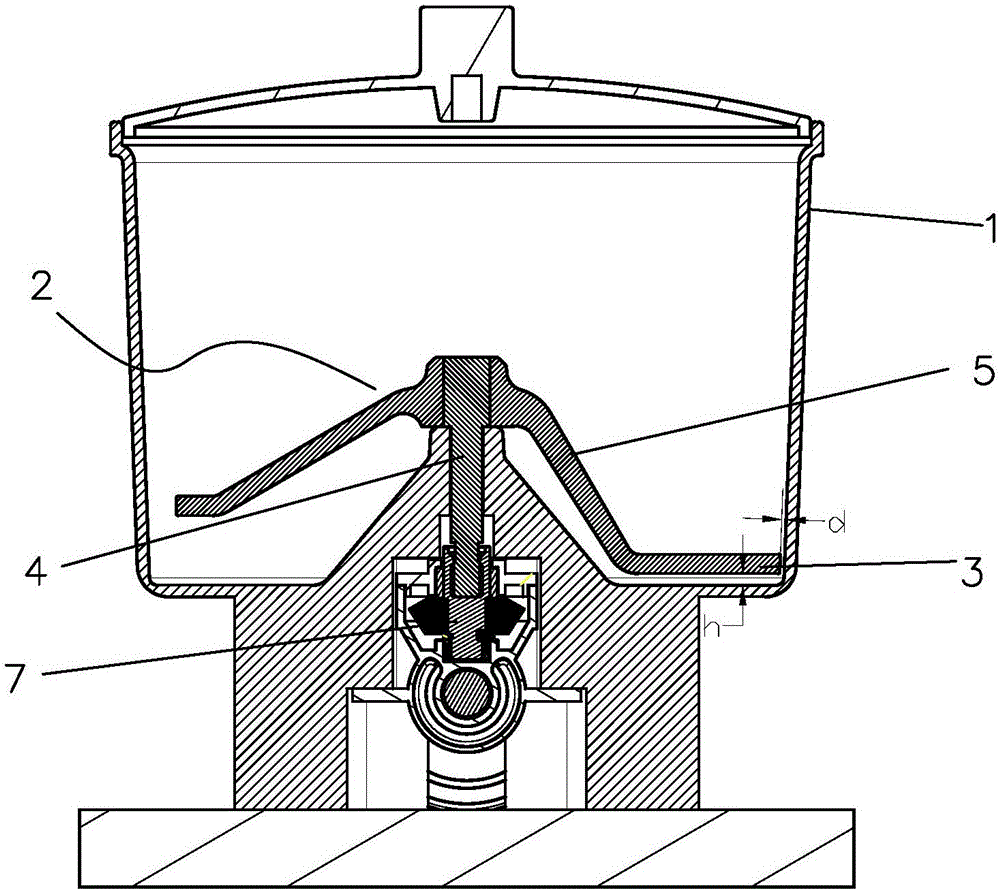

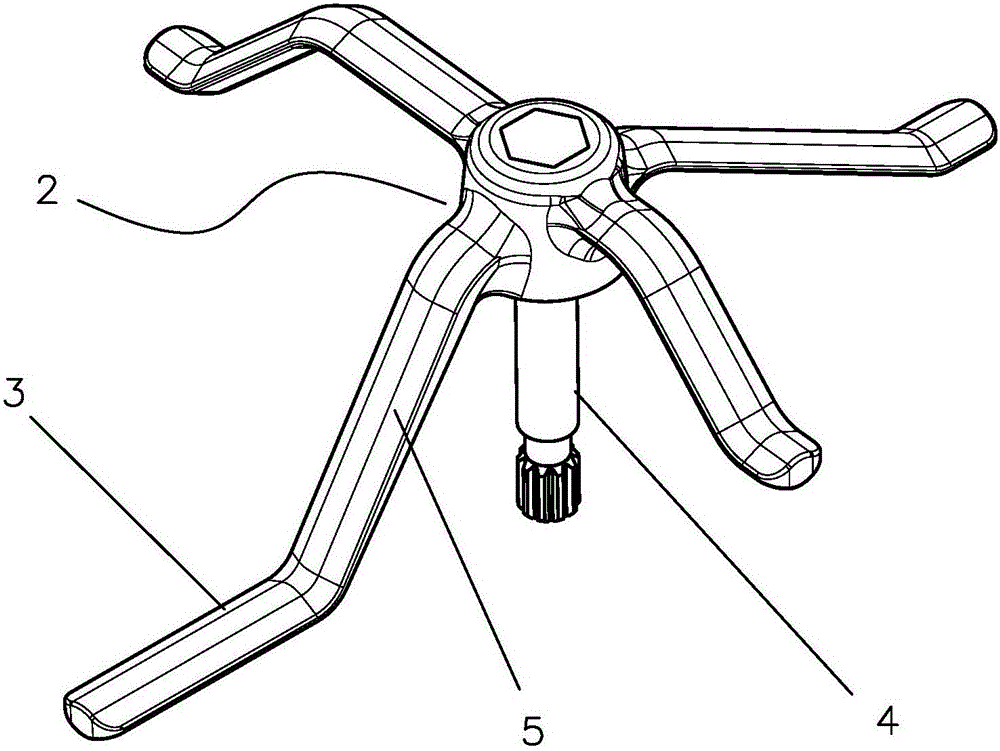

[0024] Such as Figure 1 to Figure 3 As shown, a noodle machine with good kneading effect comprises a kneading bucket 1, which is provided with a stirring device capable of rotating and kneading in the kneading bucket 1. The knife bar 4 that driving device 7 is connected, is connected with several knife teeth 2 on the said knife bar 4, and wherein at least one knife tooth 2 includes the extension section 5 that extends toward kneading dough barrel 1 bottom and is connected with extension section 5 and with The bent pushing surface 3, the lower end surface of the pushing surface 3 is parallel to the bottom surface of the dough kneading bucket 1, and the distance h between the lower end surface of the pushing surface 3 and the bottom surface of the kneading dough bucket 1 satisf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com