Pulverized coal molding method without binding agent and double-roller molding machine suitable for method

A binder-free, forming method technology, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of reduced calorific value of briquettes, limited sources of binders, complex process systems, etc., to achieve The effects of high pelleting strength, simplified raw coal preparation process, and simplified control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

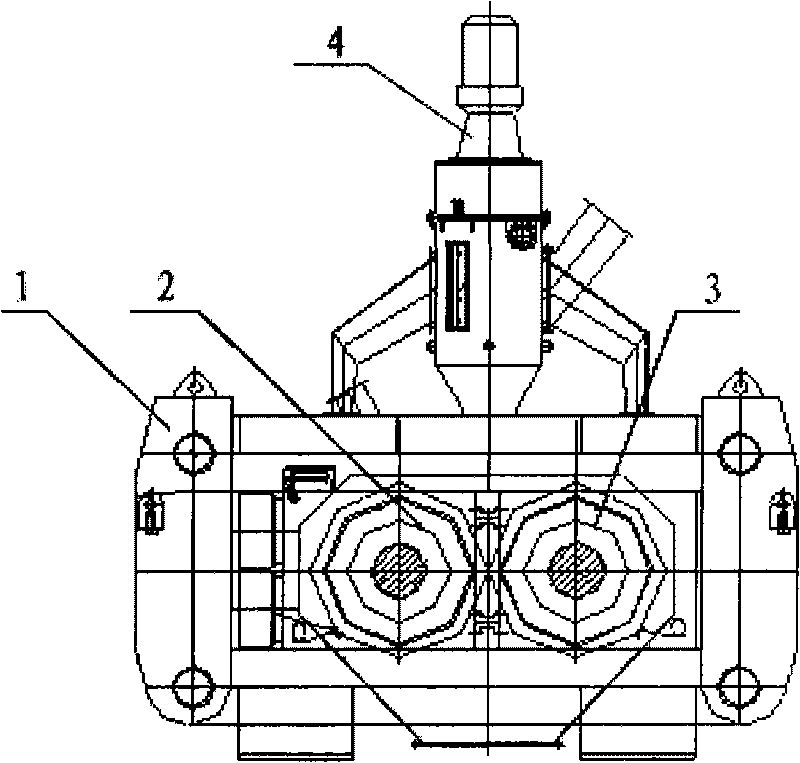

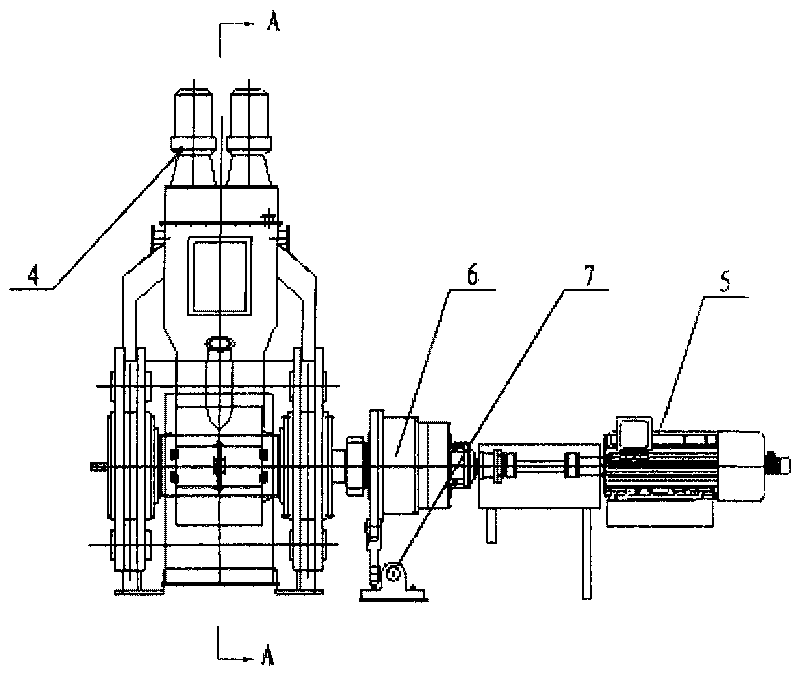

[0033] Below, combine figure 1 , 2 , the specific embodiment of the present invention will be described in detail.

[0034] The pulverized coal binder-free forming method of the present invention comprises the following steps: the first step is to screen out pulverized coal with a particle size of ≤6 mm through a screening device, and perform drying and dehydration treatment on the pulverized coal to control the moisture content to 2-15 mm; %; the second step, the pulverized coal obtained in the first step is fed between the roll gaps of the pair of rollers 2 and 3 of the pair of roll forming machines through feeder 4 (preferred screw feeder) forcibly compressed; the third step, The pair-roll forming machine operates, and the pair of rollers with dimples arranged on the circular surface of at least one roller continuously rotates, and the briquettes are compacted and formed through the dimples.

[0035] In the powdered coal binderless molding method of the present invention,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com