Automatic feeding device and kneading device for tea leaves

A technology of automatic feeding device and rolling device, applied in the direction of tea processing before extraction, etc., can solve the problems of increasing the workload and working time of operators, difficult to unify the quality of tea leaves, complicated weighing mechanism, etc., so as to save operating procedures and time. , the effect of saving manpower and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

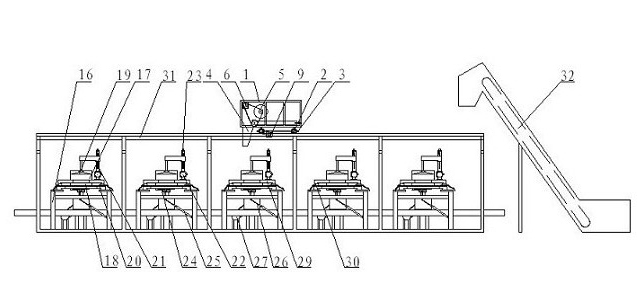

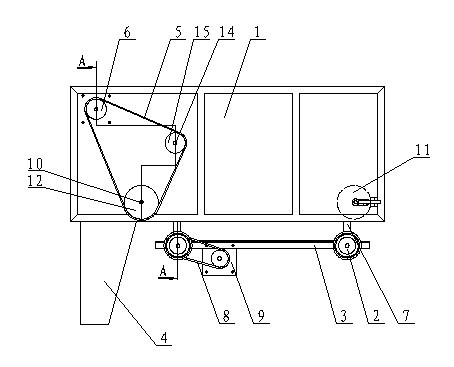

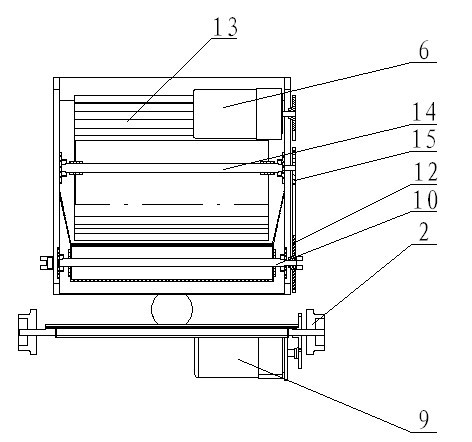

[0038] Embodiment 1: as figure 1 , 2 , shown in 3, a kind of tea feeding device, it comprises the charging box 1 that is used to dress tea, is provided with on the lower end surface of charging box 1 and is used for the vehicle frame 3 that has wheel 2 that is used for walking on track and is used for The outlet of the discharge is provided with a hopper 4 on the outlet, a tea transmission mechanism is arranged in the bottom of the charging box 1, and a leaf evener is arranged above the tea transmission mechanism. The tea transmission mechanism and the leaf evener All are connected with the motor 6 that is arranged on the charging box 1 by chain 5.

[0039] A weight sensor 7 is arranged on the vehicle frame 3, and the weight sensor 7 is connected with the lower end surface of the charging box 1, so that the tea leaves in the charging box 1 can be weighed more conveniently and accurately.

[0040] The wheels 2 are connected with the transmission motor 9 arranged on the vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com