Tea leaf fixation and rolling integrated device

A technology of greening device and rolling device, which is applied in the field of greening rolling device and tea processing device, which can solve the problems of low processing efficiency, prone to broken tea, difficult forming, etc., and achieve the effects of improving processing efficiency, shortening processing cycle and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

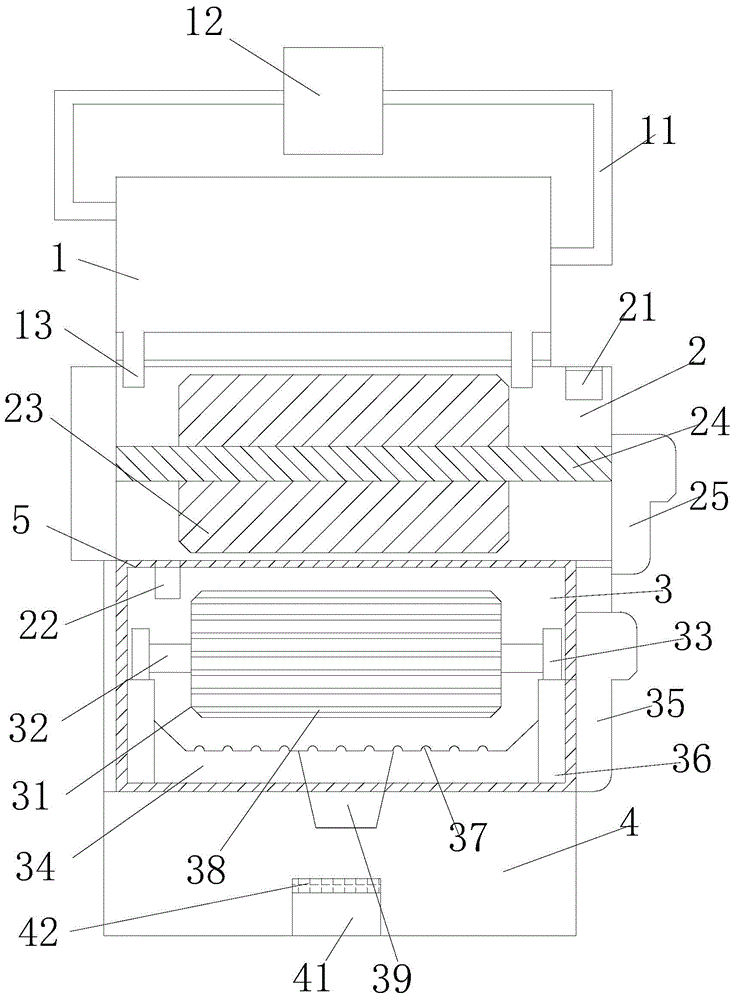

[0016] refer to figure 1 , an integrated device for fixing and rolling tea leaves according to the present invention, comprising a hot blast stove 1, a fixing device 2, a rolling device 3 and a combustion chamber 4. Air outlet pipe 11, described air outlet pipe 11 is connected with blower 12, and the lower end of hot blast stove 1 is provided with air inlet pipe 13, and described fixing device 2 is connected with hot blast stove 1 through inlet pipe 13, and described fixing device 2 is provided with rotating shaft inside 24. The rotating shaft 24 is provided with a guide vane plate 23 for rolling tea leaves, and the rotating shaft 24 is connected to the No. 1 motor 25 through transmission. Port 22, the discharge port 22 and the feed port 21 are provided with valves for switching, the kneading device 3 communicates with the greening device 2 through the discharge port 22, and the kneading device 3 includes a drum 31, a connecting bracket 36. No. 2 motor 35, kneading tank 34 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com