Garlic clove splitting device with screening function

A splitting and functional technology, applied in the direction of sieve, solid separation, grille, etc., can solve the problems that garlic cannot be split quickly and the effect is not ideal, and achieve the effect of increasing relative displacement and improving splitting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

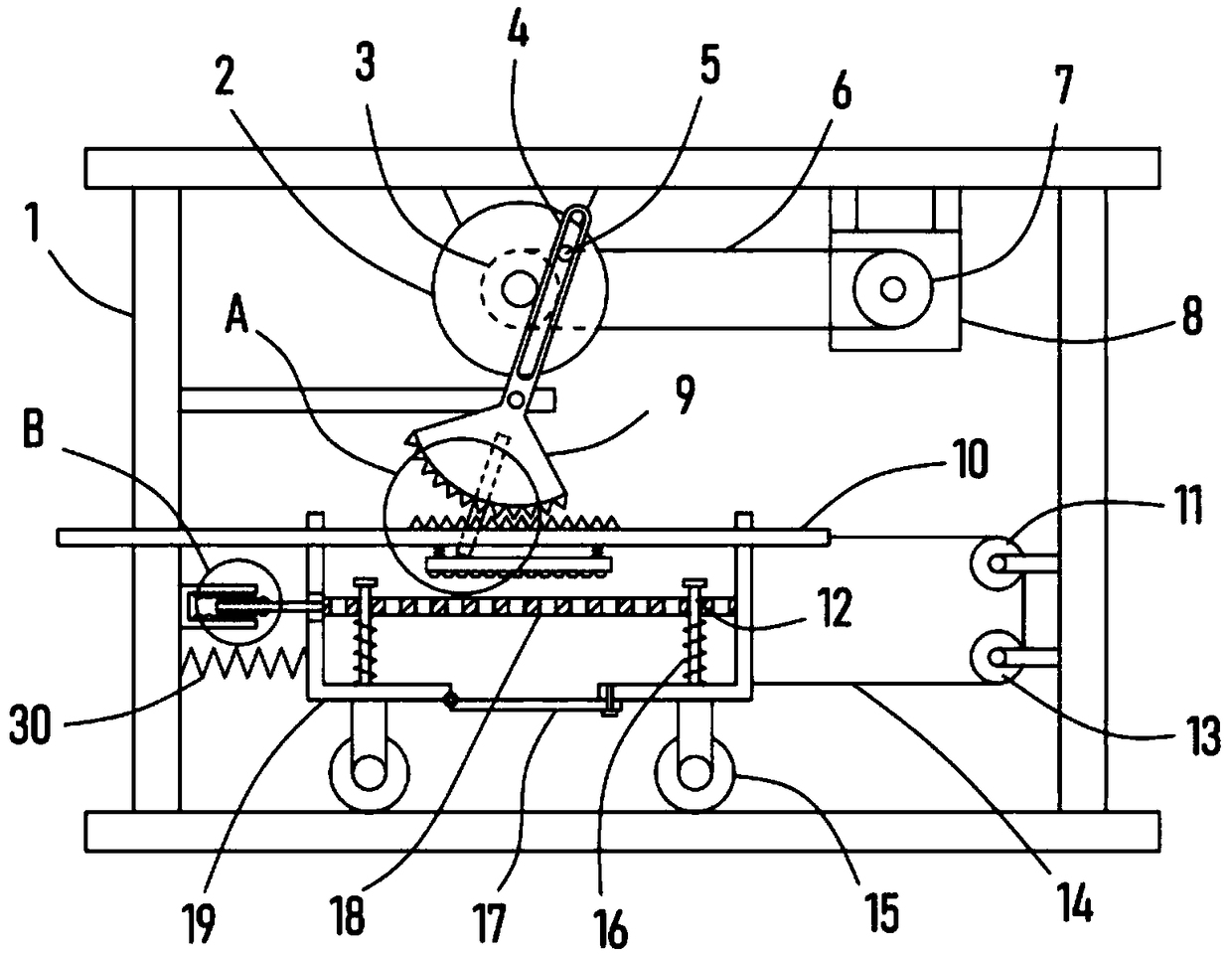

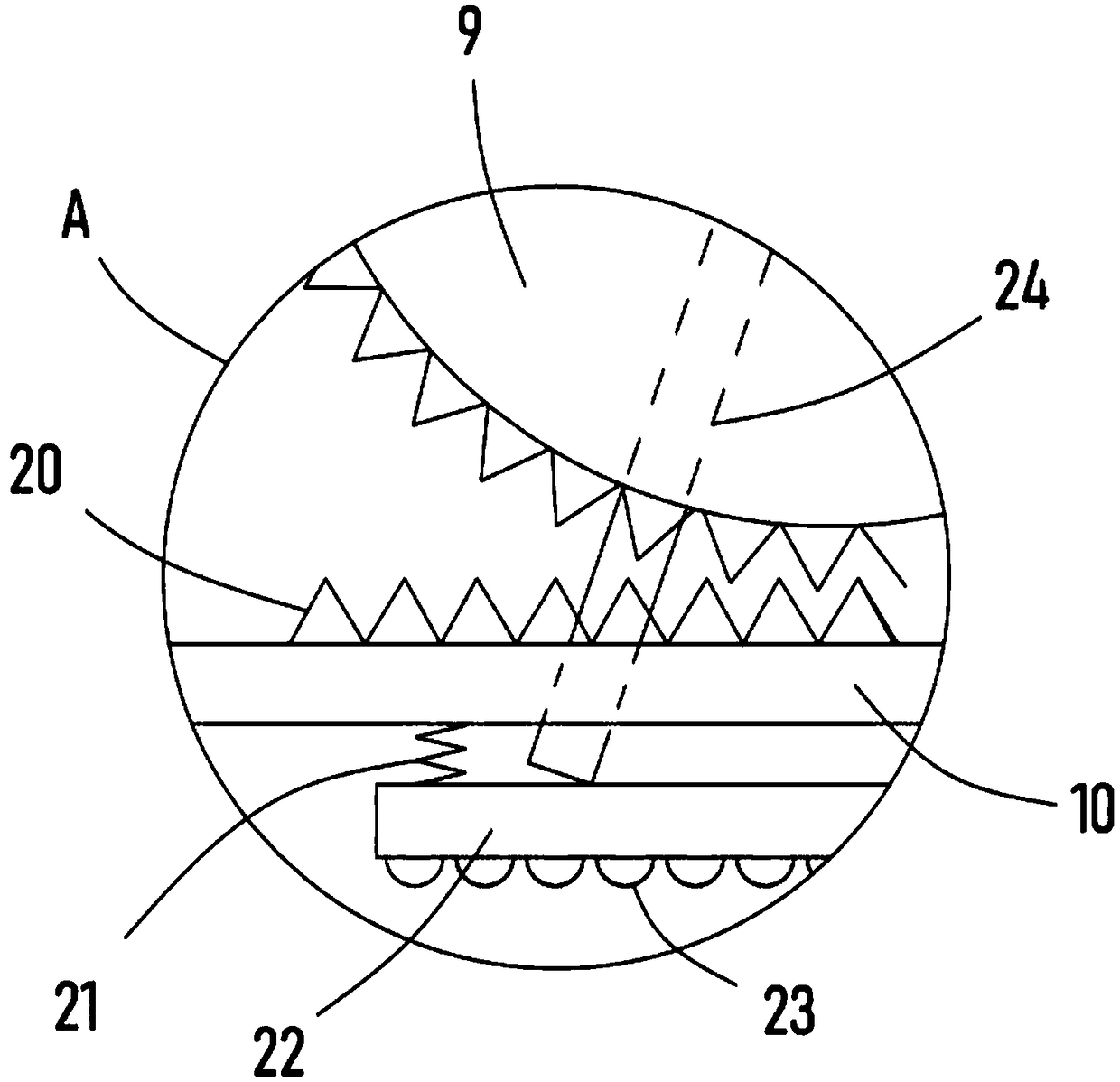

[0023] see Figure 1-5 , a garlic splitting device with screening function, comprising a supporting frame 1, a drive motor 8 is fixedly installed in the supporting frame 1, a splitting box 19 is arranged in the supporting frame 1, and a screening box is horizontally arranged in the splitting box 19 Plate 18, horizontal sliding type is installed with drive plate 10 on the flap box 19, and drive plate 10 bottom is provided with rubbing plate 22, and rubbing plate 22 bottoms are uniformly fixedly installed with several rubbing projections 23, between rubbing plate 22 and drive plate 10 Several telescopic springs 21 are fixedly installed between them, and a spur rack 20 is fixedly installed on the upper surface of the transmission plate 10, and a sector gear 9 that is meshed with and connected to the spur rack 20 is swingably provided on the top of the drive plate 10. 22 against the drive rod 24 .

[0024] Further, a runner 2 is rotatably arranged in the support frame 1 , and a c...

Embodiment 2

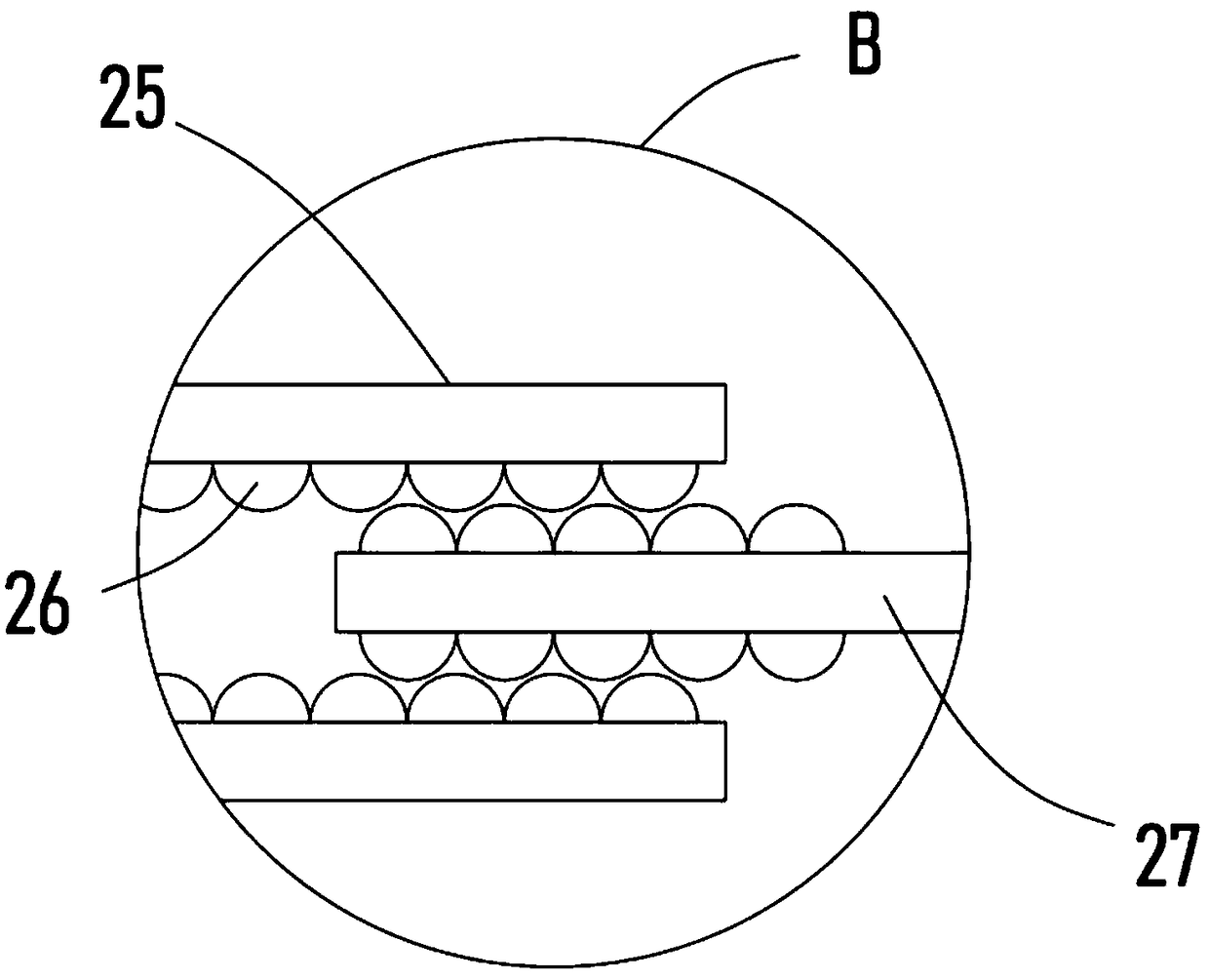

[0031] On the basis of Embodiment 1, in addition, a U-shaped plate 25 is fixedly installed on the inner side wall of the support frame 1, and an extension plate 27 that penetrates the split box 19 and extends into the U-shaped plate 25 is fixedly installed on the left side of the screening plate 18. , the surface of the extension plate 27 and the inner wall of the U-shaped plate 25 are all provided with a hemispherical transmission block 26 that abuts against each other, and the bottom of the split box 19 is rotatably provided with guide rollers 15 .

[0032] The lateral movement of the split box 19 realizes the left and right reciprocating motion of the extension plate 27, and then realizes its relative displacement with the U-shaped plate 25, and the relative movement of the U-shaped plate 25 and the transmission block 26 on the extension plate 27 realizes the expansion of the extension plate. The vibration of 27, and then realized the vibration of sieve plate 18, has promote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com