Tea leaf processing kneading device

A rolling device and tea technology, which is applied in tea treatment before extraction, etc., can solve the problems of tea product color, lack of taste, slow tea delivery speed, insufficient rolling, etc., to solve the trouble of manual feeding, high work efficiency, and full rolling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

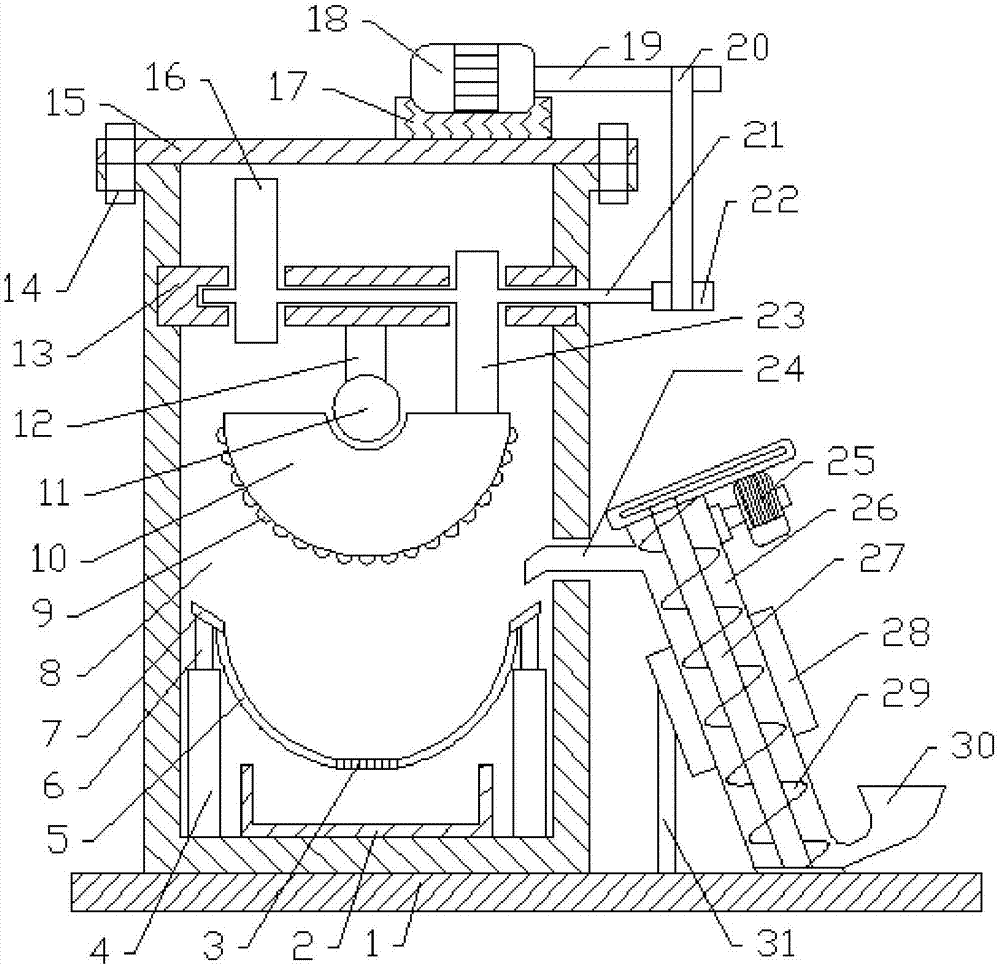

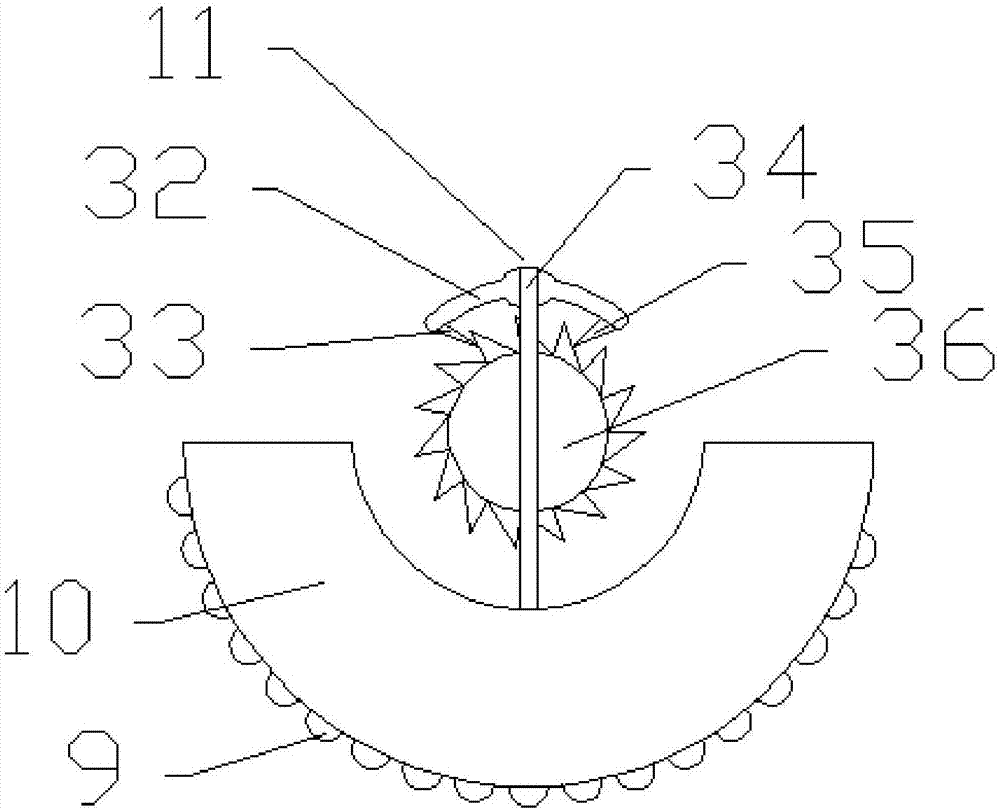

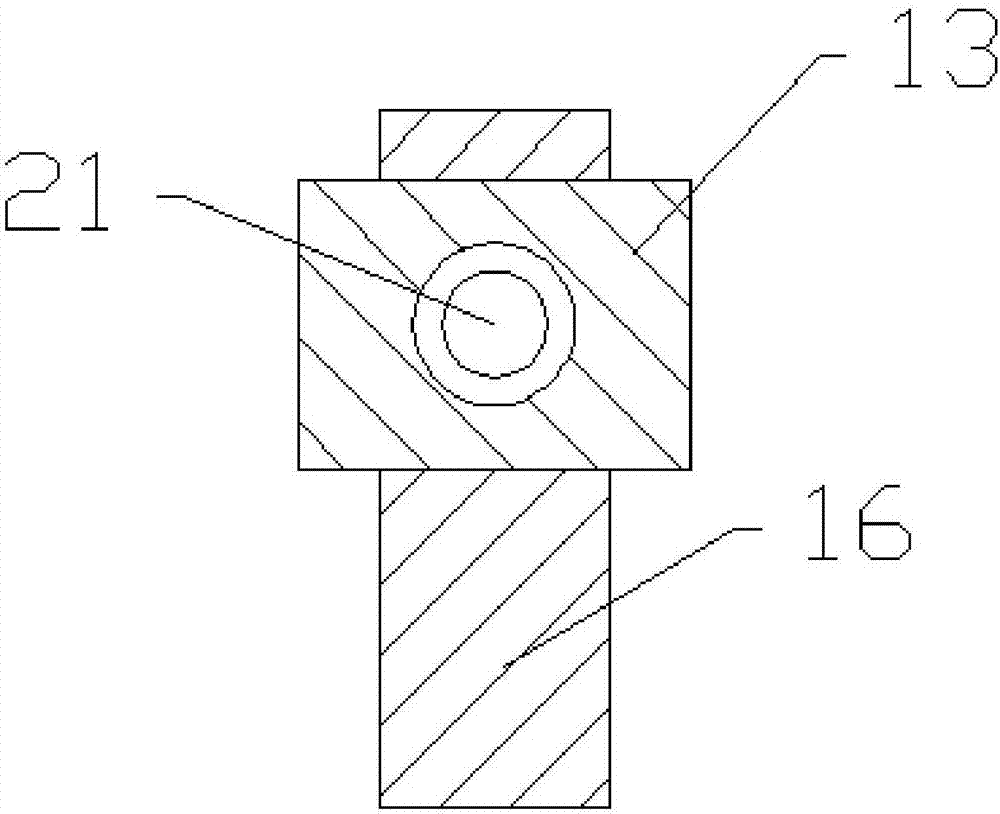

[0021] see Figure 1-4 , a tea processing and rolling device, including a base 1; the cross section of the base 1 is rectangular, made of gray cast iron, used to fix the device, and provide installation space for other components at the same time, the left side of the upper surface is fixed and kneaded Box 8; the upper cover plate 15 is placed above the kneading box 8; the upper cover plate 15 is fixed on the top of the kneading box 8 by bolts 14; Vertical through holes are arranged symmetrically on the left and right sides of 13, and the left and right through holes are connected to the left movable hammer 16 and the right movable hammer 23 respectively; the inside of the cross bar 13 is embedded with a rotating shaft 21; Dynamic hammer 23; the right end of rotating shaft 21 is welded coupling 22; the periphery of described coupling 22 is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com