Automatic impending twisting unit

A unit and automatic technology, applied in tea processing before extraction, etc., can solve the problems that kneading and sorting machines cannot realize continuous automatic kneading and sorting operations, the pressure of tea leaves cannot be well grasped, and it is difficult to finish kneading quickly, so as to reduce broken tea High efficiency, simple structure and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

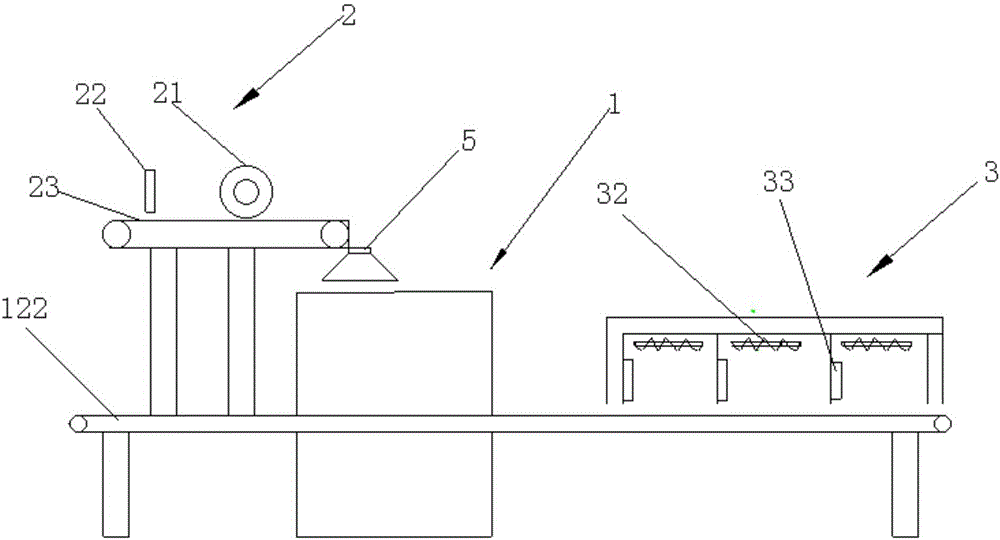

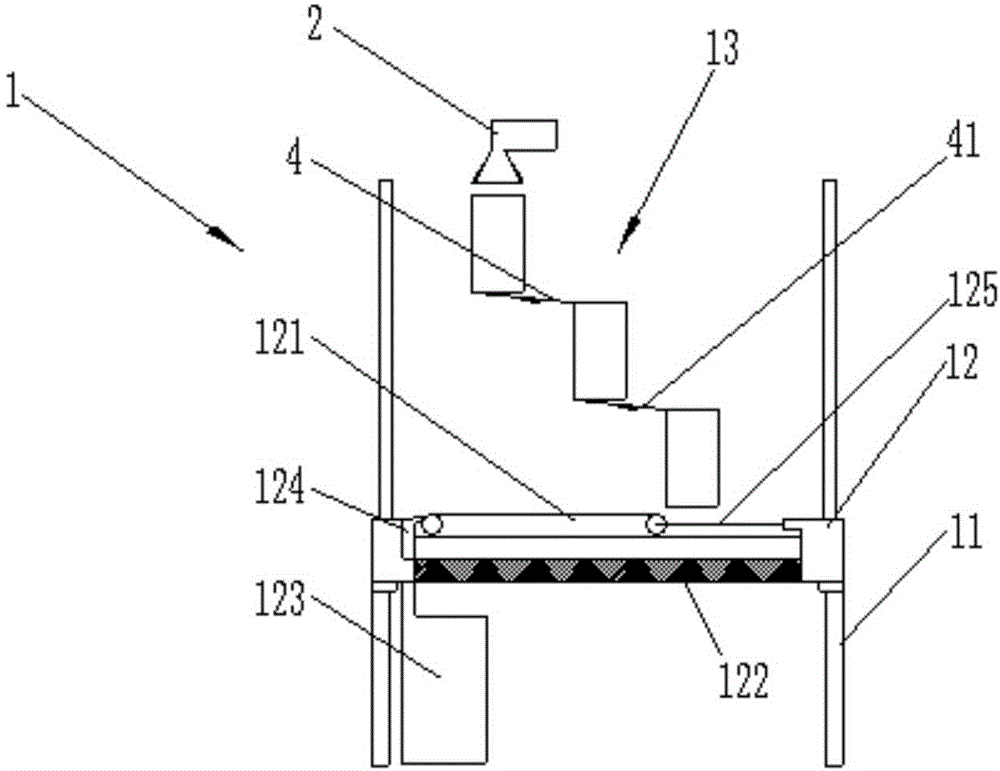

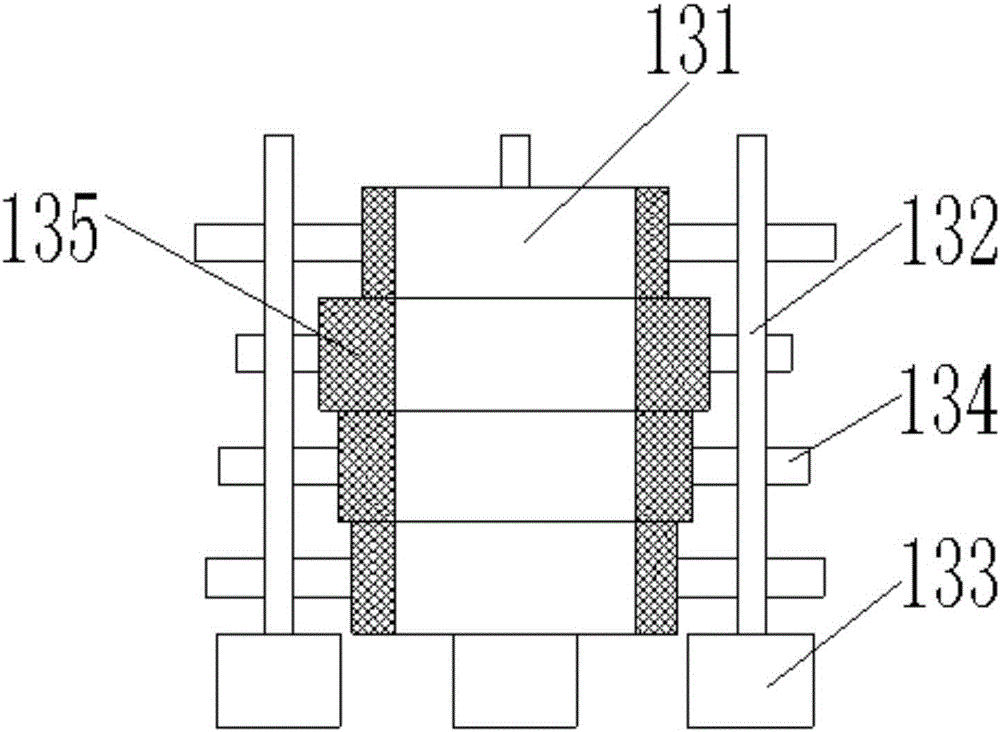

[0033] see Figure 1 to Figure 7 , an automatic non-ground kneading unit, comprising a kneading mechanism 1, a feeding mechanism 2, and a drying mechanism 3; the kneading mechanism 1 includes a bracket 11, a housing 12, and a drum 13 arranged inside the housing 12; the housing The body 12 is located above the bracket 11; the drum 13 includes a plurality of rotating drums 131 that are sequentially clamped up and down and rotate independently of each other and a plurality of driving motors 133 with rotating shafts 132; the uppermost opening of the rotating drum 131 is located at the discharge port 51 below, the outer surface of the drum 131 is covered with a rubber ring 135; in this embodiment, a plurality of drive motors 133 are evenly arranged on the outer circumference of the drum 131; thereby making the drum 131 run more stably; on the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com