Modularized multi-chamber continuous kneading machine

A multi-chamber, kneading machine technology, applied in the field of continuous kneading, can solve the problems of inability to provide large shear force, single equipment suitable for materials, less variable parameters of equipment, etc., to achieve flexible equipment, wide range of materials, no kneading dead end effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The modular multi-chamber continuous kneader described in this example is mainly used for kneading sodium sulfate powder with a solid content of 40% and a particle size of 350 μm and HTPB.

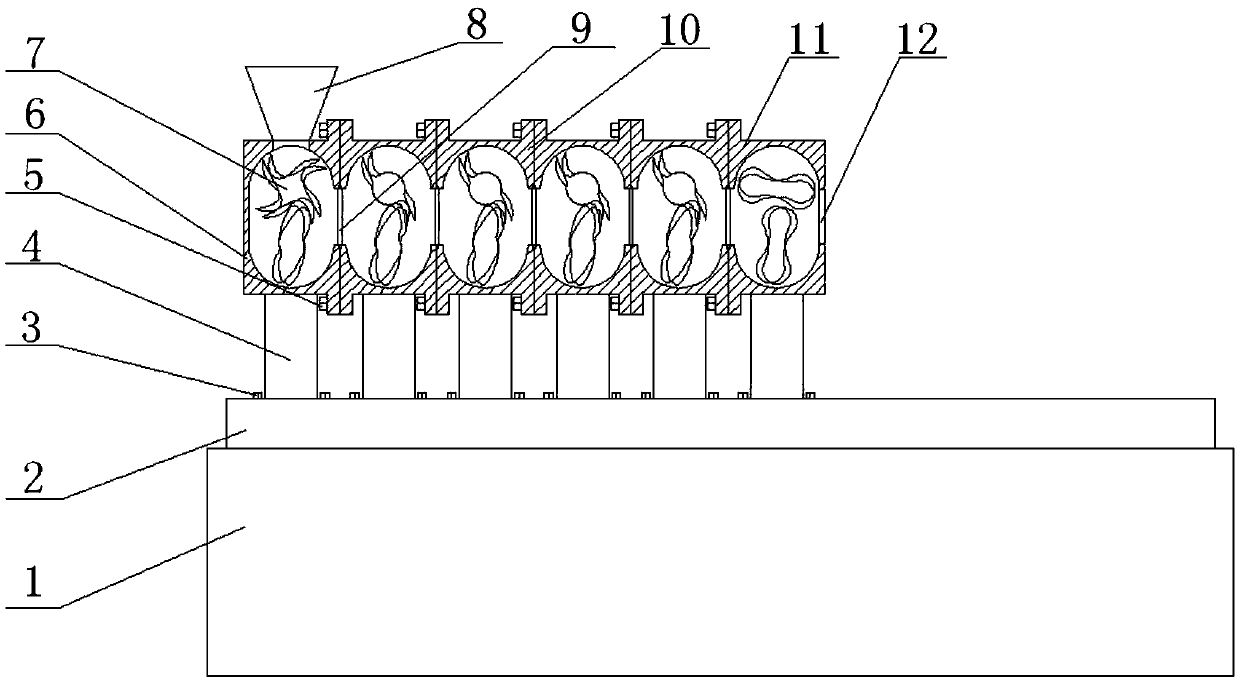

[0020] see figure 1 , the feed chamber 6, the kneading chamber 10, and the discharge chamber 11 are arranged in series, and the chamber and the chamber are fixed by connecting screws 5; the upper end of the feed chamber 6 has a feed port; the kneading chamber There are four chambers 10; a discharge port 10 is provided on the side of the discharge chamber 11.

[0021] see figure 1 , The sieve plates 9 are fixed by grooves between the 6 chambers, and the apertures of the sieve plates are 5mm, 4mm, 3mm, 2mm, and 1mm in sequence.

[0022] see figure 1 , the minimum gap between the blades 7 is 1mm; the blades 7 are twisted in the axial direction, wherein the blades located in the upper semicircle of the chamber are right-handed, and the blades of the lower semicircle are left-handed, ...

Embodiment 2

[0024] The modular multi-chamber continuous kneader described in this example is mainly used for kneading calcium carbonate powder with a solid content of 60% and a particle size of 1 μm with cellulose acetate in glycerol triacetate.

[0025] The feeding chamber 6, the kneading chamber 10, and the discharging chamber 11 are arranged in series, and the chamber and the chamber 6 are fixed by connecting screws 5; the upper end of the feeding chamber 6 has a feeding port; the kneading chamber There are 6 chambers 10; the side of the discharge chamber 11 has a discharge port; the kneading chamber 10 has a heating water jacket, and the heating temperature is 40 degrees Celsius.

[0026] The sieve plates 9 are fixed by grooves between the 6 chambers, and the apertures of the sieve plates 9 are 45 mesh, 100 mesh, 200 mesh, 400 mesh, 800 mesh, 1250 mesh, and 2500 mesh.

[0027] The minimum gap between the blades 7 is 0.5mm; the blades 7 are twisted in the axial direction, wherein the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com