Full-automatic non-demoulded glove cleaning machine

A cleaning machine, fully automatic technology, applied in the direction of household components, household appliances, other household appliances, etc., can solve the problems of demoulding failure, poor equipment adaptability, large demoulding force, etc., to achieve convenient and flexible use and high demoulding efficiency. , The effect of enhancing the demolding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

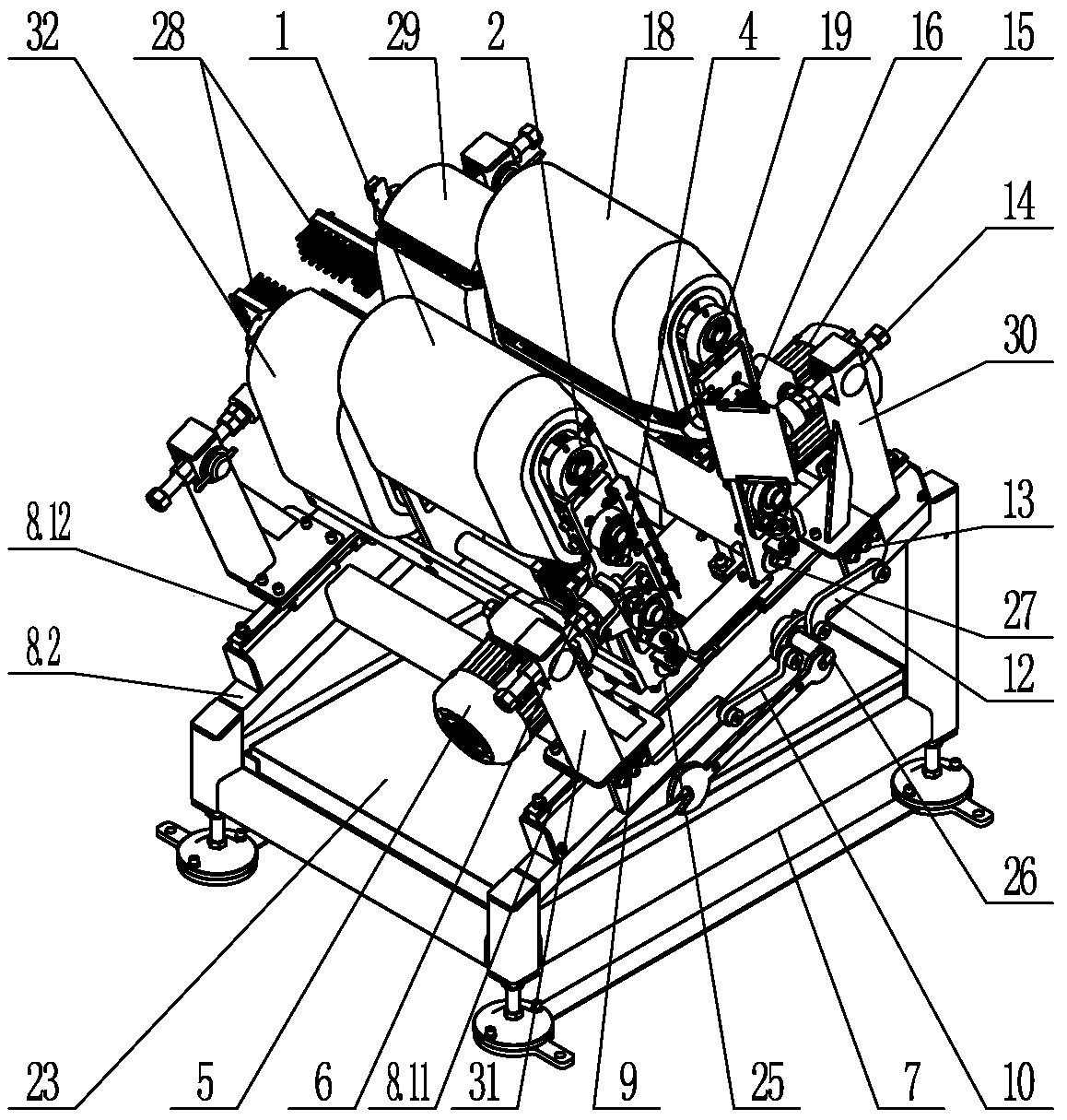

[0047] Such as figure 1 As shown, a full-automatic non-release glove cleaning machine according to the present invention includes a base 7, a sliding track device 8, a high-position demoulding assembly, a low-position demoulding assembly and a sliding drive assembly, and the sliding The rail device 8 is installed on the base 7, and the high-position demoulding assembly and the low-position demoulding assembly are installed on the sliding rail device 8, and both the high-position demoulding assembly and the low-position demoulding assembly include at least one set of brush functional groups. In this embodiment, both the high-position demoulding component and the low-position demoulding component include two brush functional groups.

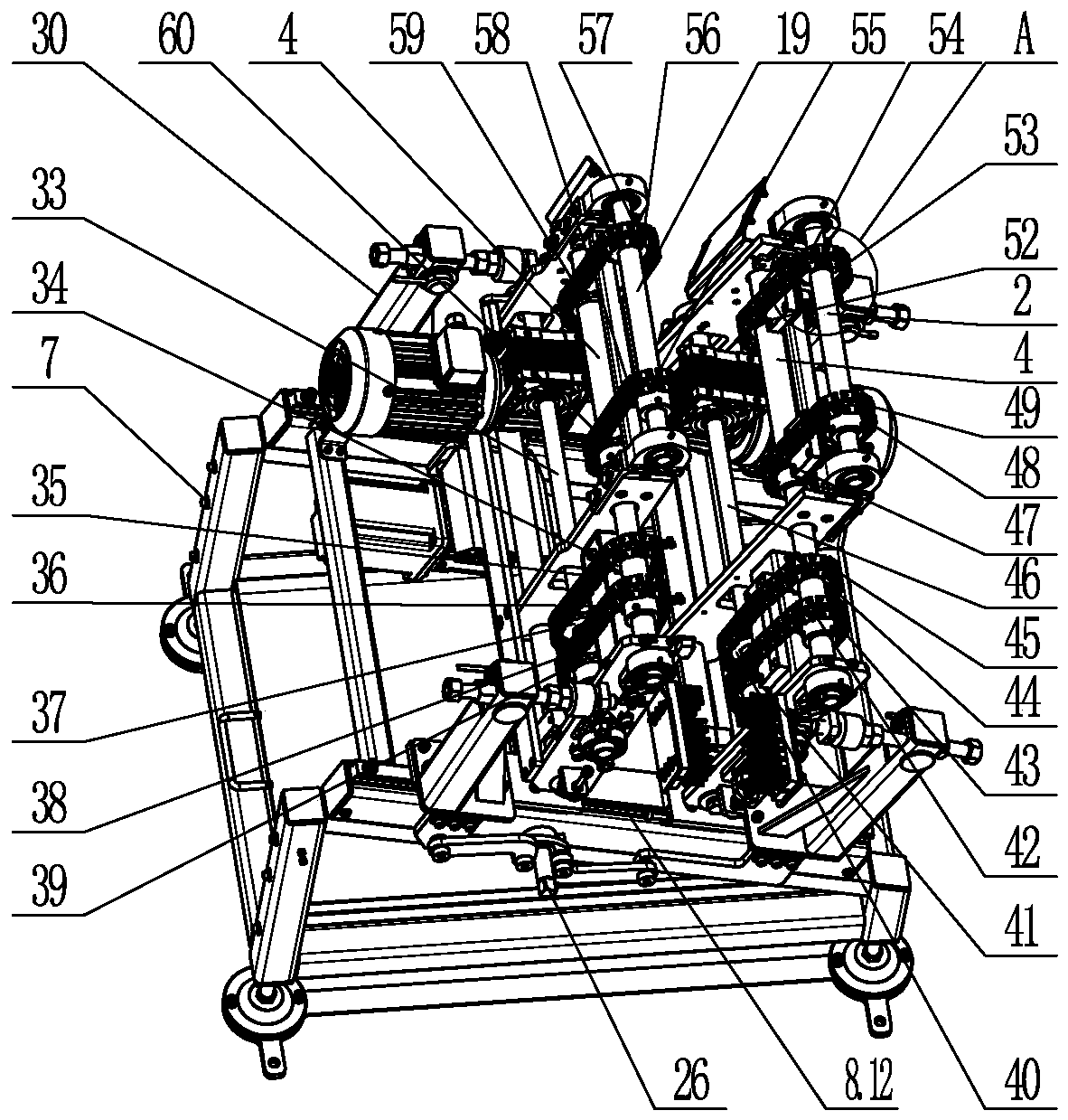

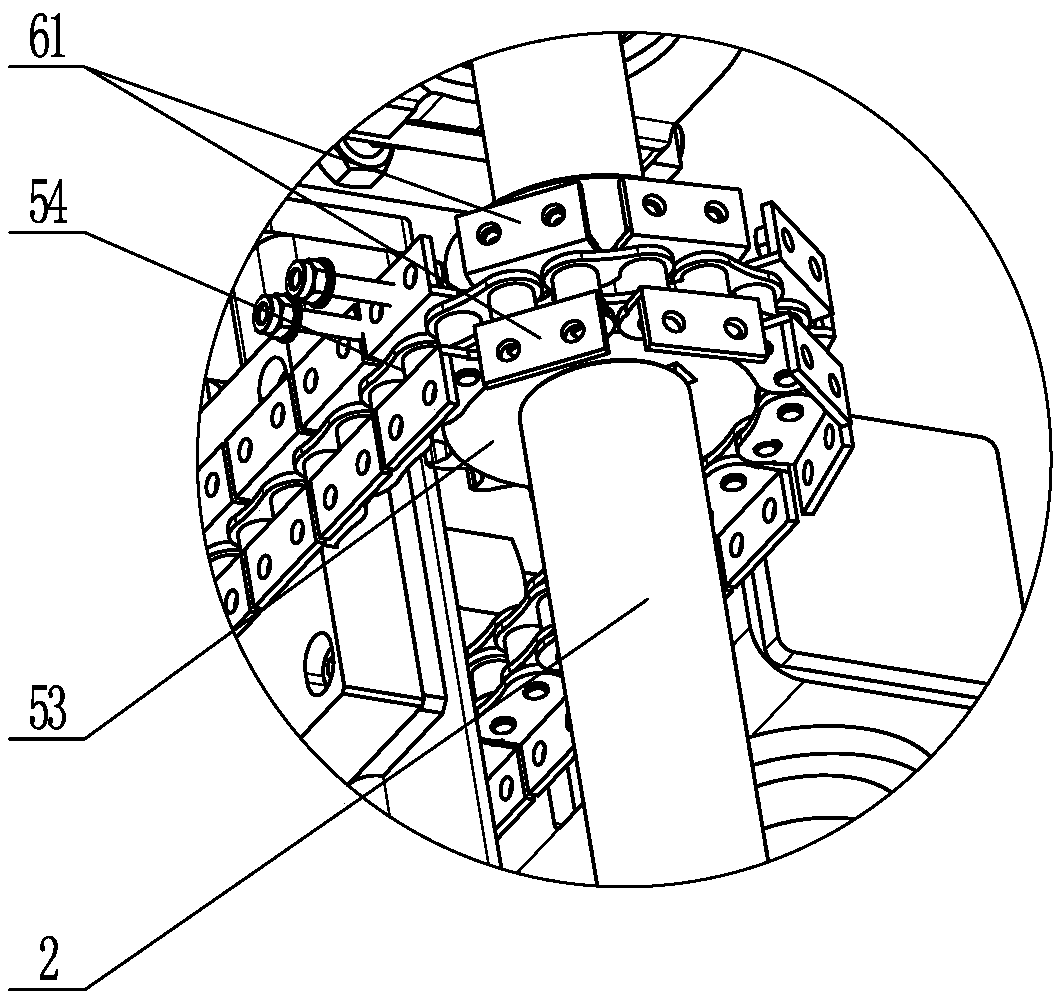

[0048] Such as figure 2 and 4 As shown, the brush function group of the high-position demoulding assembly is called a high-position brush function group, and the high-position brush function group includes a high-position brush bracket 17, a hig...

Embodiment 2

[0068] The difference between this embodiment and Embodiment 1 is that the high-position demoulding assembly only includes one to two sets of high-position upper annular brush mechanisms 18, and does not include the high-position lower annular brush mechanism 29; The lower upper annular brush mechanism 1 with the same number of components also does not include the lower lower annular brush mechanism 32 .

[0069] In this embodiment, the high-position upper annular brush mechanism 18 and the low-position upper annular brush mechanism 1 can use the same scrubber structure as in Embodiment 1, or can be set as a strip structure.

[0070] The ring-shaped brush mechanism 18 on the high position of the strip structure is specifically set as follows:

[0071] Install the high position first lower pulley on the shaft 16 in the high position, install the high position first upper pulley on the high position installation shaft 19, and set the high position upper ring wool on the high pos...

Embodiment 3

[0077] The difference between this embodiment and embodiment one and embodiment two is:

[0078] The sliding drive assembly includes a high-position drive cylinder and a low-position drive cylinder. Both the high-position drive cylinder and the low-position drive cylinder are installed on the track support 8.2. Hinged low slider 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com