Early-strength concrete for non-steam autoclaved PHC pipe piles

A PHC pipe pile and concrete technology, applied in the field of concrete, can solve the problems of low strength guarantee rate, increase production process, high production investment, etc., achieve the effect of improving workability and compressive strength, outstanding comprehensive effect, and improving early strength

Active Publication Date: 2013-02-20

CCCC THIRD HARBOR ENG +2

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Autoclave curing is the process that consumes the most energy and time. Generally speaking, every 1m of autoclaved curing 3 Concrete consumes about 25kg of oil (according to an oil-fired boiler as an example); the whole process of autoclave curing takes 10 to 20 hours, which takes a lot of time

In addition, autoclave curing requires an autoclave, and the production investment is relatively high; the temperature of the PHC pipe pile is very high when it comes out of the kettle, and if it is not effectively cooled, the temperature difference is enough to cause cracks in the concrete of the pile body, which will affect the durability of the PHC pipe pile. bring adverse effects

In short, the use of high-pressure steam curing process will consume a lot of energy, increase the production process, take up a lot of production time, and will also have an impact on the quality control of PHC pipe piles

In the early 1990s, many pipe pile factories did not have autoclave equipment, and the method of immersing pipe piles in a pool after initial curing and demoulding was used to produce PHC pipe piles. In fact, the test data that the concrete strength grade reached C80 was also obtained. But after all, the strength guarantee rate is low, so in the mid-1990s, autoclaves were added one after another. After adding finely ground quartz sand and dry-discharged fly ash, autoclaves are even more indispensable.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0042] Example 1 Concrete mix ratio research

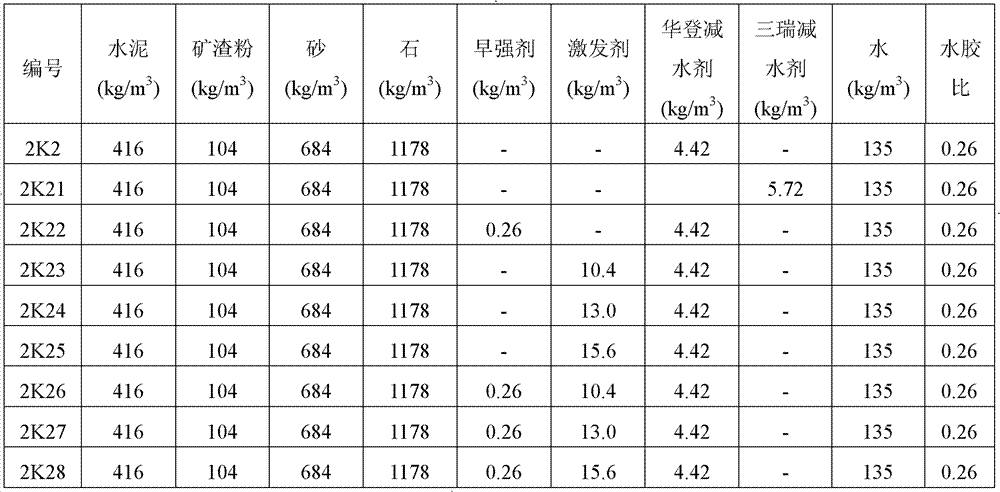

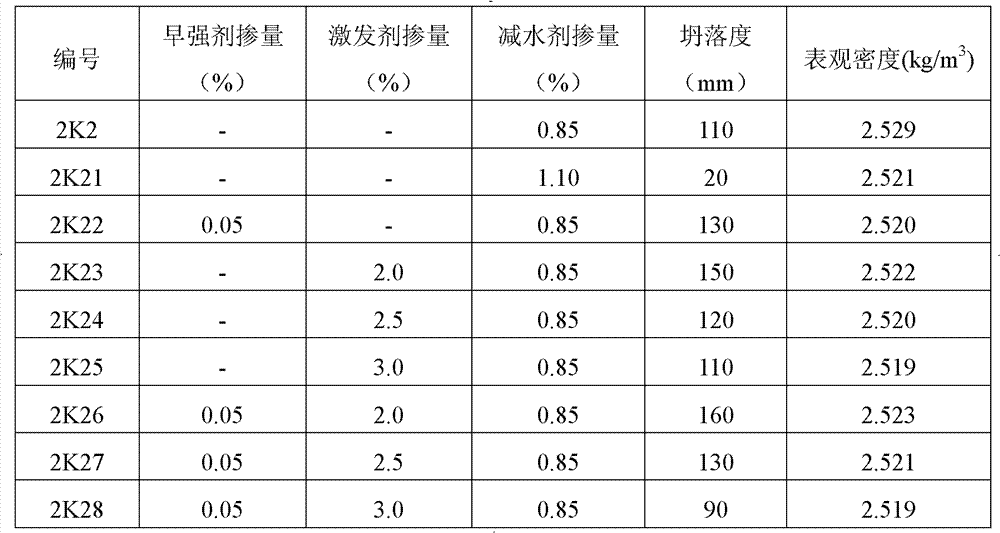

[0043] Prepare and compare concrete according to the following table, and the mix ratio design is shown in Table 1-1.

[0044] Table 1-1 Concrete Mix Design

[0045]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| sand rate | aaaaa | aaaaa |

Login to View More

Abstract

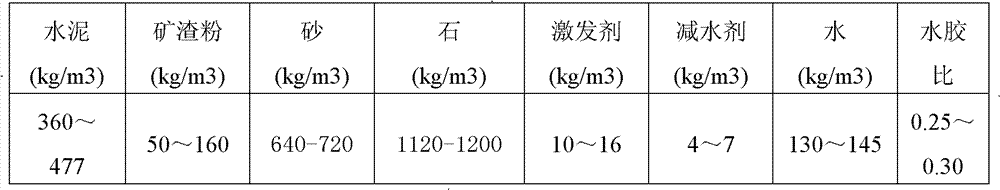

The invention discloses early-strength concrete for non-steam autoclaved PHC pipe piles. The concrete / m3 is prepared from the following raw materials: 360-477kg of Portland cement, 50-160kg of granulated blast furnace slag powder, 640-720kg of fine aggregates with fineness modulus of 2.5-3.0, 1120-1200kg of coarse aggregates with maximum grain size being not more than 25mm, 10-16kg of anhydrous gypsum, 4-7kg of high efficiency water reducing agents and 130-145kg of water. The concrete is used for preparing the PHC pipe piles and can meet the compression strength requirement of C80 concrete for non-steam autoclaved PHC pipe piles in a shorter time.

Description

technical field [0001] The invention relates to concrete, in particular to early-strength concrete for pressure-free steamed PHC pipe piles. Background technique [0002] PHC pipe piles are widely used in large-scale projects such as industrial and civil buildings, municipal engineering, port terminals, and sea-crossing bridges because of their excellent mechanical properties, short pile-making cycle, and low price. With the rapid development of infrastructure construction such as port projects and cross-sea bridges, the demand for PHC piles is increasing year by year. requirements. The production of PHC pipe piles is a process of high energy consumption. "Energy saving and emission reduction" is a national development strategy. The energy consumption and pollution in the production process of PHC pipe piles should be continuously reduced; the owner requires that on the basis of continuously improving the performance of PHC pipe piles, it should Low price; at the same time...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B28/08

Inventor 王成启王春明周郁宾

Owner CCCC THIRD HARBOR ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com