Concrete, preparation method of concrete, precast pile and preparation method of precast pile

A technology of concrete and prefabricated piles, which is applied in the field of concrete, prefabricated piles and prefabricated piles. It can solve the problems of difficult reuse, high steam cost and high steam pressure, and achieve the goal of reducing steam pressure, reducing pollution and improving bonding ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

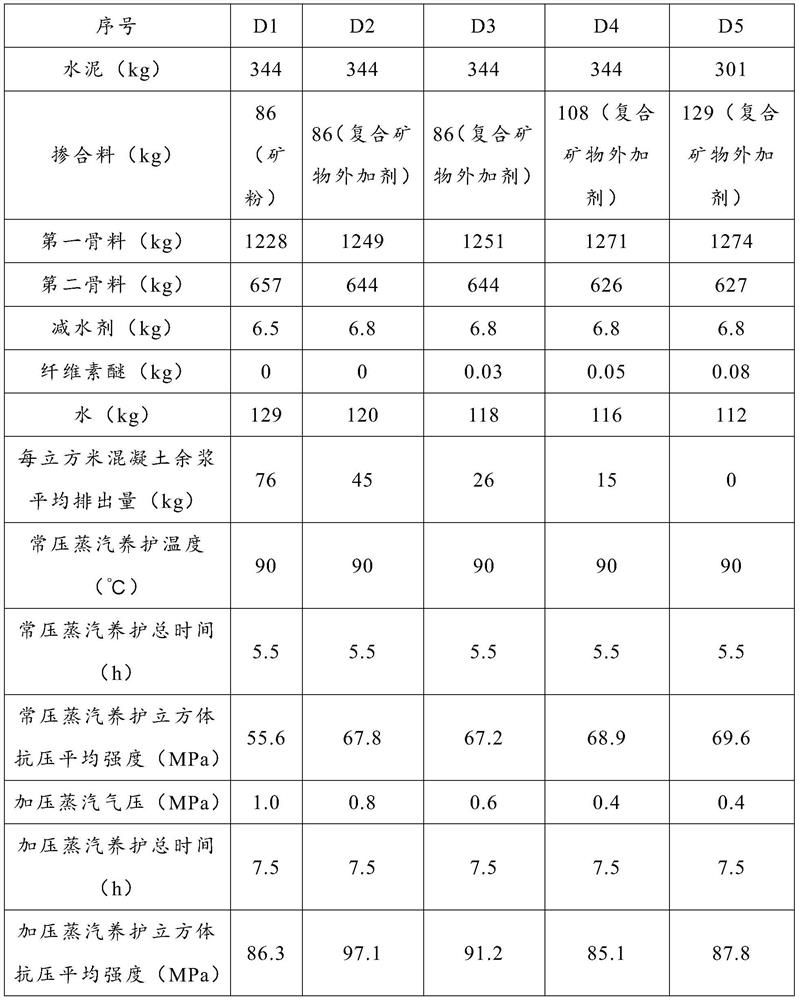

Examples

Embodiment Construction

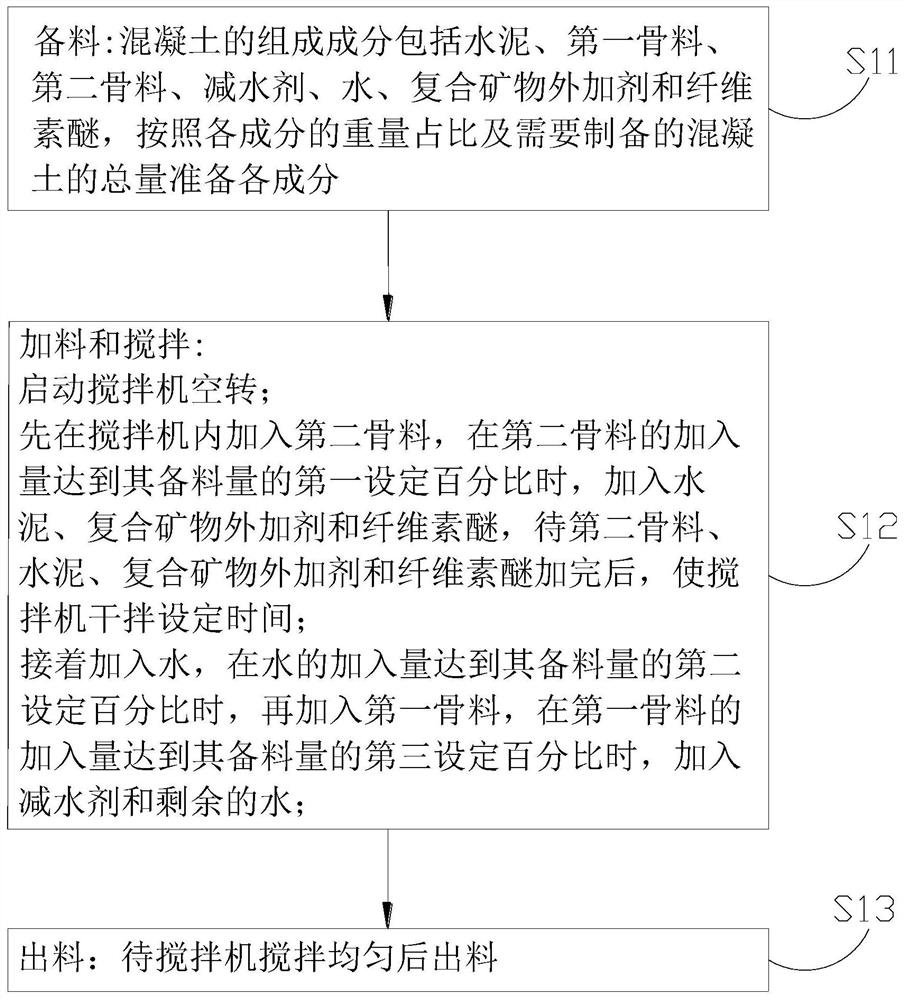

[0022] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0023] The present invention provides a concrete which includes components: cement, a first aggregate, a second aggregate, a water reducing agent and water, wherein the particle size of the first aggregate is larger than the particle size of the second aggregate. The first aggregate is called coarse aggregate, and the second aggregate is called fine aggregate. It can be understood that coarse and fine are a relative concept here.

[0024] Coarse aggregates usually include crushed stone. In specific applications, continuous graded crushed stone with a particle size of 5-25mm can be selected, and its related parameters meet the following requirements: crush value 6%, needle-flaky 3%, mud content Not more than 0.2%. Of course, in practical a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com