Floating floor device applied to water body ecological restoration

A technology of ecological restoration and floating bed, which is applied in biological water/sewage treatment, water/sludge/sewage treatment, horticulture, etc. It can solve the problems of poor anti-pollution source impact ability and large seasonal influence, and achieve easy maintenance and easy disassembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

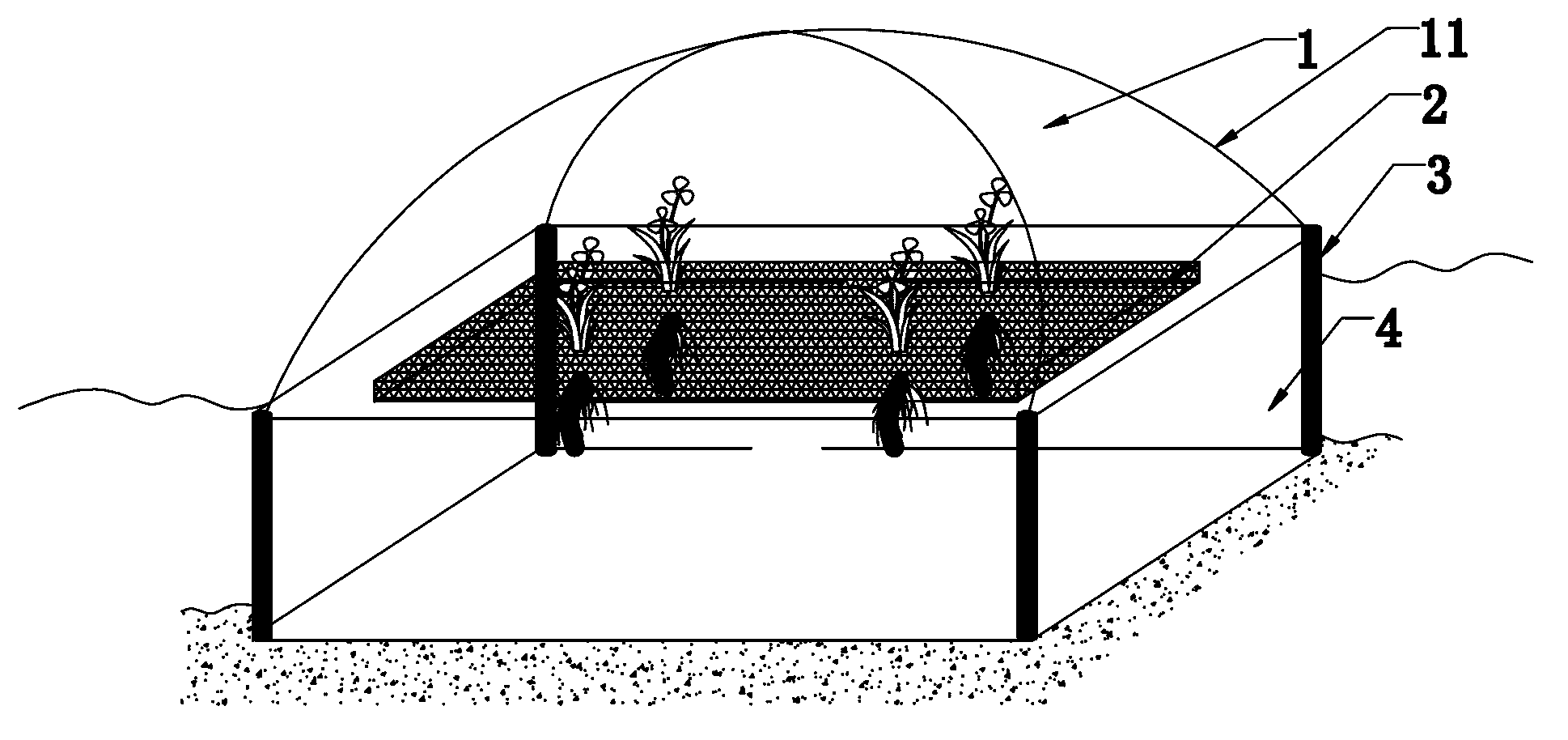

[0012] Such as figure 1 As shown, a floating bed device for ecological restoration of water bodies includes a light-transmitting heat-insulating cover 1 , control piles 3 , heat-insulating enclosures 4 and a floating bed 2 . Among them, the light-transmitting heat preservation cover body 1 is made of transparent pp plastic film with a thickness of 6 mm. The middle of the plastic film is a closed air layer, so that the heat insulation effect of the air layer and the light transmission effect of the transparent plastic can make the heat preservation The cover has the functions of heat preservation and light transmission. There is a support rod 11 in the heat preservation cover, which plays a supporting role. The support rod 11 is inserted into the jack on the upper end of the control pile 3, so that the heat preservation cover 1 is fixed above the control pile 3 , the support bar 11 of heat preservation cover body 1 is provided with two, and material is stainless steel, and diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com