Preparation process of an environment-friendly urea-formaldehyde ketone-based modified furan casting resin

A urea-formaldehyde-ketone-based, preparation process technology, applied in the direction of casting molding equipment, manufacturing tools, casting molds, etc., can solve the problems of high production cost and use cost, increased raw material consumption cost, easy delamination, etc., to reduce consumption cost, The effect of improving quality defects and enhancing solid permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

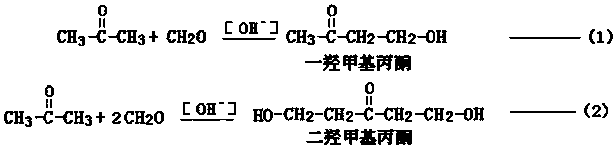

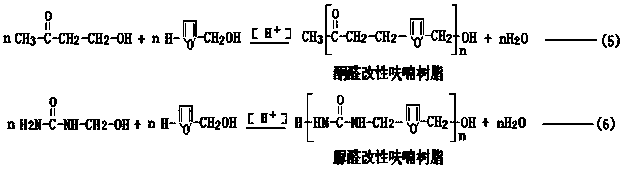

Method used

Image

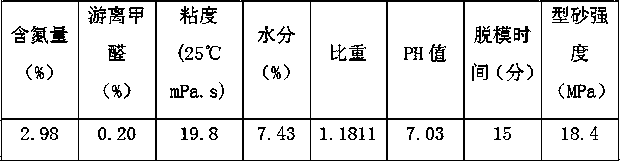

Examples

Embodiment 1

[0037] (1) Put 245g of formaldehyde (37% formaldehyde content) in a device equipped with a three-necked flask, stirring, and coiled condenser, add 56g of acetone, and catalyst A to adjust the pH of the material. The pH is controlled within the range of 9.5 to 1.0.

[0038] (2) Addition reaction for 90 minutes at material temperature 80±2℃.

[0039] (3) After the reaction time is up, add 60g of urea, and react for 60 minutes at the material temperature of 80-85°C.

[0040] (4) After the reaction time is up, add 300 g of furfuryl alcohol, add 6 g of catalyst B, control the pH value in the range of 4.0-4.5, and perform the polycondensation reaction for 60 minutes at the material temperature of 100±2°C.

[0041] (5) After the reaction time is up, reduce the temperature of the material to below 85°C, add 3.0g of catalyst C, control the PH value within the range of 7.5-8.0, add 5g of urea, add reaction at 80-85°C for 30 minutes .

[0042] (6) After the reaction time is up, add 1.5 g of melam...

Embodiment 2

[0048] (1) In a 2000L enamel reactor, put 440kg of formaldehyde (37% formaldehyde content), add 100kg of acetone, add catalyst A to adjust the pH value of the material, and the pH value is controlled within the range of 9.5 to 1.0.

[0049] (2) Addition reaction for 90 minutes at material temperature 80±2℃.

[0050] (3) After the reaction time is up, add 108g of urea, and add reaction for 60 minutes at the material temperature of 80-85°C.

[0051] (4) After the reaction time is up, add 540g of furfuryl alcohol, add 11kg of catalyst B, control the PH value in the range of 4.0-4.5, and conduct the polycondensation reaction for 60 minutes at the material temperature of 100±2°C.

[0052] (5) After the reaction time is up, reduce the temperature of the material to below 85℃, add 5.5kg of catalyst C, control the PH value in the range of 7.5-8.0, add 10kg of urea, add reaction for 30 minutes at the material temperature of 80-85℃ .

[0053] (6) After the reaction time is up, add 3 kg of melami...

Embodiment 3

[0060] (1) Put 980kg of formaldehyde (37% formaldehyde content) into a 5000L enamel reactor, add 224kg of acetone, add catalyst A to adjust the pH value of the material, and the pH value is controlled within the range of 9.5 to 1.0.

[0061] (2) Addition reaction for 90 minutes at material temperature 80±2℃.

[0062] (3) After the reaction time is up, add 240g of urea, and add reaction for 60 minutes at the material temperature of 80-85°C.

[0063] (4) After the reaction time is up, add 1200g of furfuryl alcohol, add 24kg of catalyst B, control the PH value in the range of 4.0-4.5, at (5) material temperature 100±2℃, polycondensation reaction for 60 minutes.

[0064] (5) After the reaction time is up, reduce the material temperature to below 85°C, add 12kg of catalyst C, control the PH value in the range of 7.5-8.0, add 20kg of urea, and add reaction at 80-85°C for 30 minutes.

[0065] (6) After the reaction time is up, add 6 kg of melamine, and react for 30 minutes at a material temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com