Magneto-optic imaging nondestructive testing device

A magneto-optical imaging and non-destructive testing technology, which is applied in the direction of measuring devices, optical testing flaws/defects, material magnetic variables, etc., can solve the problems of not being able to determine the internal thermal state of the workpiece, requiring couplants, and expensive prices, etc., to achieve non-contact Non-destructive testing, safe and reliable operation, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] The present invention uses the Faraday magneto-optical effect principle: when a beam of polarized light passes through the medium, if there is an external magnetic field in the beam propagation direction, the polarized light will be deflected when it passes through the polarization plane, and the deflection angle depends on the strength of the magnetic field.

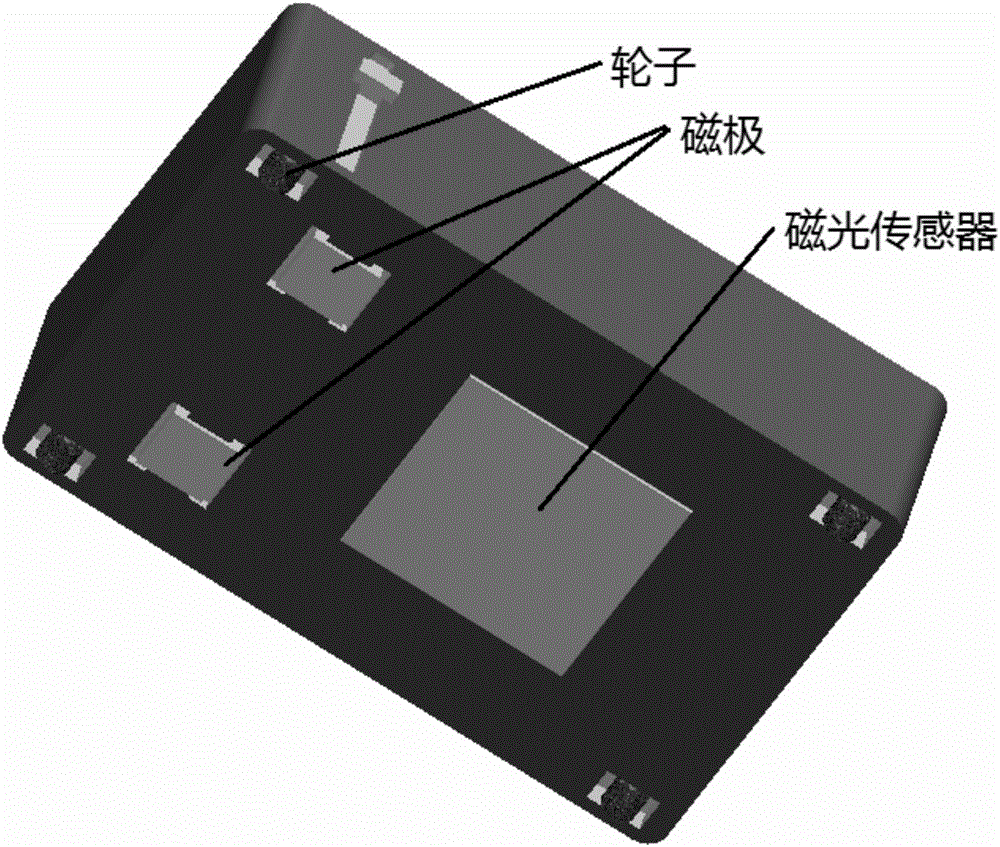

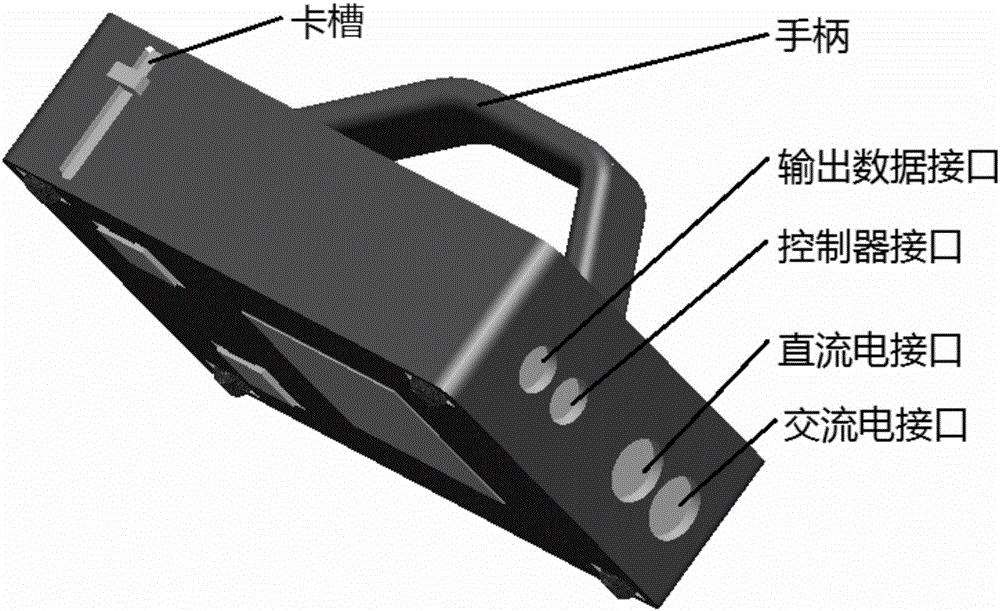

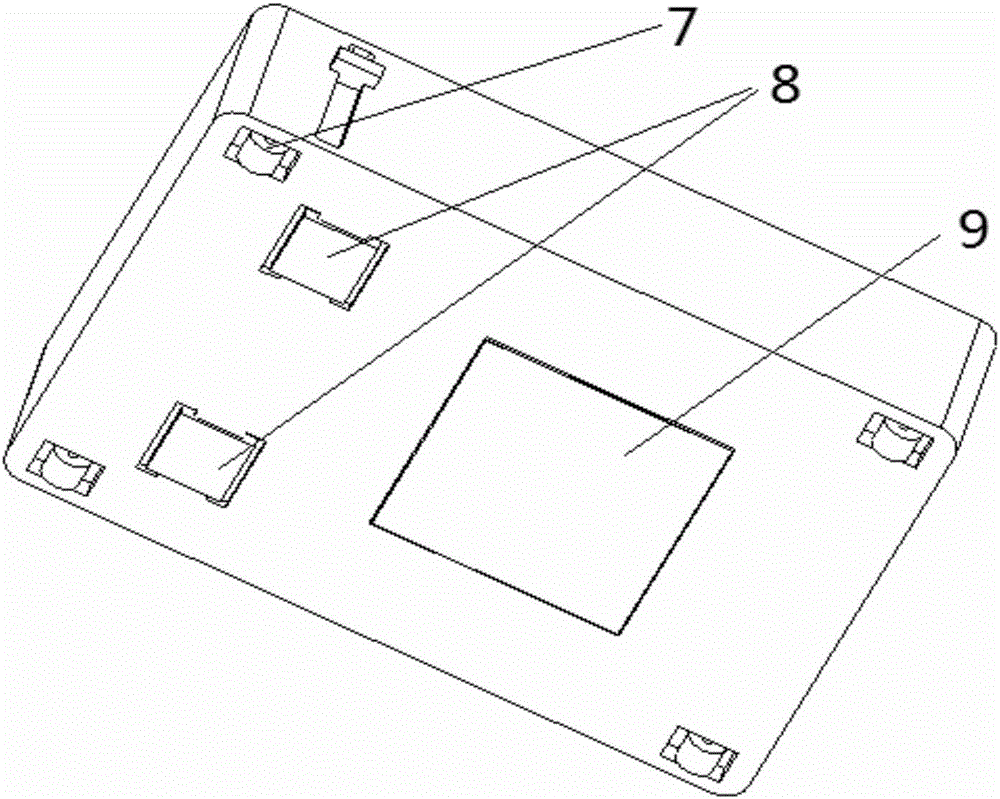

[0026]The invention applies the magneto-optical imaging technology, and the electromagnet is excited by a magnetic field generator with a constant current or an alternating current to induce a magnetic field on the workpiece, and the distribution of the magnetic field will be distorted at the defect of the workpiece, causing the vertical magnetic field component there to occur. changes, and correspondingly changes the induced magnetic field. The magneto-optical imaging sensor produces a magneto-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com