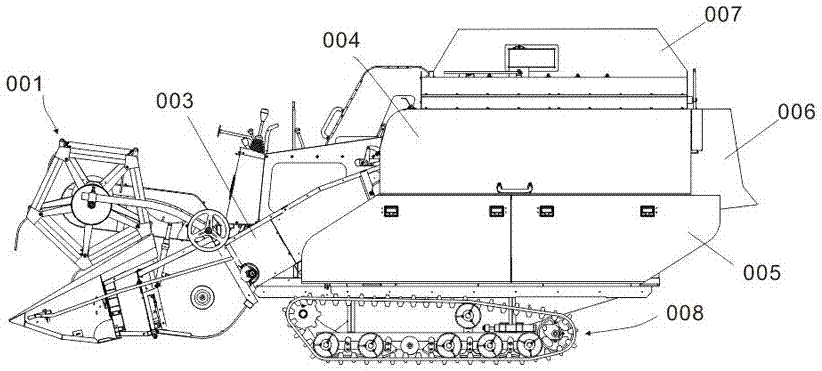

Combined harvester for cereals

A combine harvester and millet technology, which is applied in the field of crop harvesting, can solve the problems of high maintenance cost and inconvenient disassembly and assembly, and achieve the effect of improving the cleaning rate, reducing the entrainment loss rate, and avoiding clogging and accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

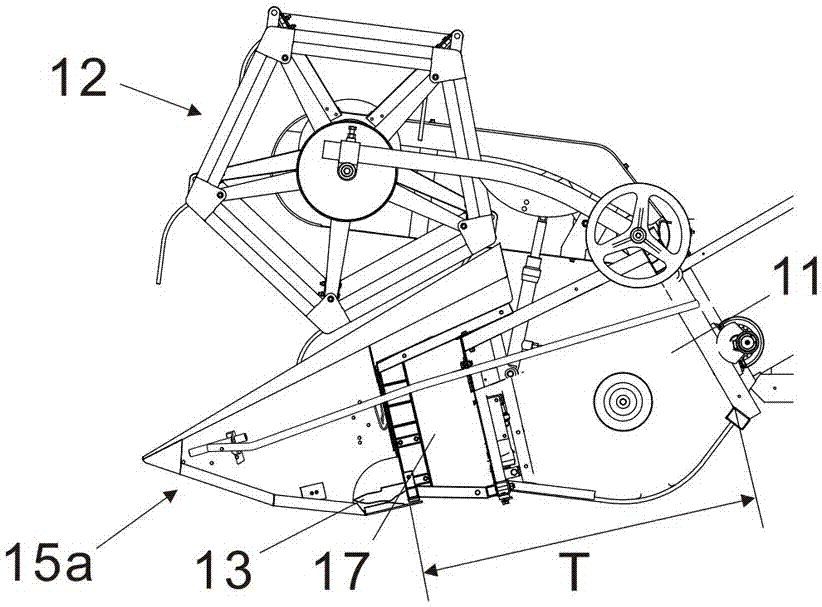

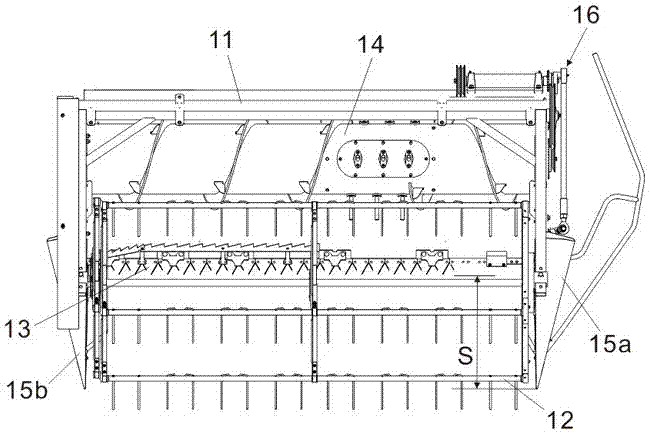

[0053] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0054] Because millet is a small crop, compared with wheat, rice, and corn, the grain quality is small, and the thousand-grain weight is only 2.4-3.5g, and there is a main stem in the middle of the ear, on which there are first-level branches, and second-level branches are produced on the first-level branches. Branches and three-level branches, each level of branch is a small yard, there are many grains on it, some as many as two or three hundred grains, if the threshing device of the traditional full-feed combine harvester is slightly modified to threshing, it will cause Grain yards and stalks are not easy to separate, grains are not easy to clean, large damage, high loss rate of entrainment cleaning and other major defect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com