Patents

Literature

42results about How to "Shorten withering time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Red tea processing method

ActiveCN102630769APromote oxidationPromote transformation formationPre-extraction tea treatmentFlavorBlack tea

The invention discloses a red tea processing method, which comprises the following steps of: withering: placing fresh tealeaves into a blowing-type withering groove to be withered; green rolling: guiding withered tealeaves into a green rolling machine to be rolled until the tealeaves turn from green to dark, the edge of each tealeaf turns red, the tealeaves are moisturized when being touched by hand, the greenness disappears and the floral fragrance spreads; kneading: guiding the green-rolled fresh tealeaves into a kneading machine to be kneaded; fermenting: filling the kneaded tealeaves after be de-blocked into a fermenting disc or a clean bamboo basket, and stopping the fermentation until floral and fruity flavor radiates; primary drying: pouring the fermented tealeaves into a single-layer drying machine to be primarily dried; re-kneading: guiding hot tealeaves into the kneading machine to be re-kneaded; re-drying: guiding the re-kneaded tealeaves after being de-blocked into the drying machine to be re-dried; sufficient drying: placing the tealeaves into a tea fragrance enhancer to be slowly dried at a low temperature; spreading for cooling: placing the dried tealeaves into a bamboo disc to be spread and cooled to the normal temperature; and screening: screening the cooled tealeaves to remove broken pieces.

Owner:桂东县玲珑王茶叶开发有限公司

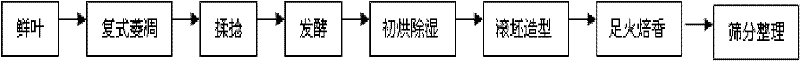

Method for processing high-fragrance curly black tea

InactiveCN102511572ARapid termination of enzyme activityOvercome the defect of not being brightPre-extraction tea treatmentBlack teaHot Temperature

The invention discloses a method for processing high-fragrance curly black tea. The method comprises the following steps of: selecting a fresh one-bud two-leaf raw material of black tea, sequentially performing composite withering, twisting, fermenting, primary drying for dehumidifying, rolling, shaping, baking for getting fragrance over complete fire, screening, finishing, and thus obtaining thehigh-fragrance curly black tea. By adopting composite withering, high-temperature quick drying for dehumidifying and low-temperature slow baking treatment over the complete fire, the fragrance of theblack tea is remarkably improved, and the finished tea is compact and curly as snails and has black, bright and gold color; by sensory change of water losing weight parameter and leaf phase of the tea blank of each processing stage, the processing procedure of the black tea is controlled; and the method is easy and convenient to operate and easy to master, and is a black tea processing method convenient to popularize and apply.

Owner:TEA RES INST ANHUI ACAD OF AGRI SCI

Processing method of black tea

The invention discloses a processing method of black tea. The processing method comprises the following steps of: withering, rolling, fermenting, performing incipient drying, performing full drying to extract fragrance, and performing the incipient drying on a tea base; washing tender shoots and leaves of persimmon, spreading, performing microwave fixing, gently rubbing, drying, performing fine grinding, leaching, performing micro-filtration, concentrating, spraying and drying; and dissolving contents of persimmon leaves in water for preparing a saturated solution, atomizing the tea leaves, performing the incipient drying and performing the full drying. The withering in the processing method disclosed by the invention is adopted outdoors and indoors, temperature and humidity are controlled, and natural withering is combined with rocking withering, so that the withering time is shortened, and the uniformity and the quality of the withered leaves are improved; a new process of continuously pressurizing and continuously depressurizing is adopted in rolling so as to be conductive to formation and enhancement of color and luster of the tea leaves, liquor color and taste; new equipment for microwave incipient drying, ultraviolet microwave drying and full drying is used in the drying process, so that the quality of the black tea is greatly improved; the saturated solution of the contents of the persimmon leaves is directly atomized in the incipient drying process flow of the black tea; and the compound way is simple to operate, the distribution of the substances is uniform, the absorption is fast, and the continuous production is convenient.

Owner:CHIZHOU SHUANGYUAN TEA

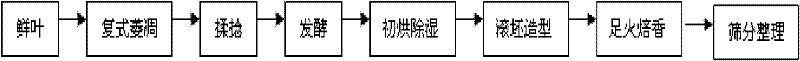

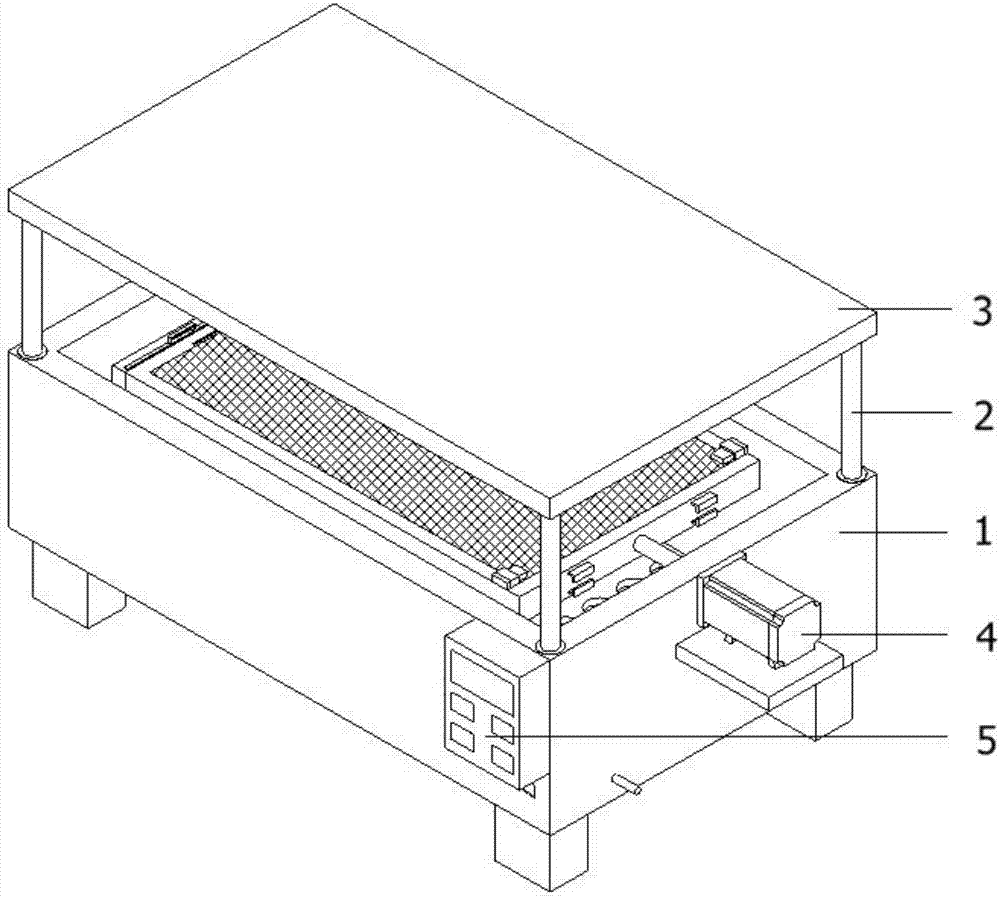

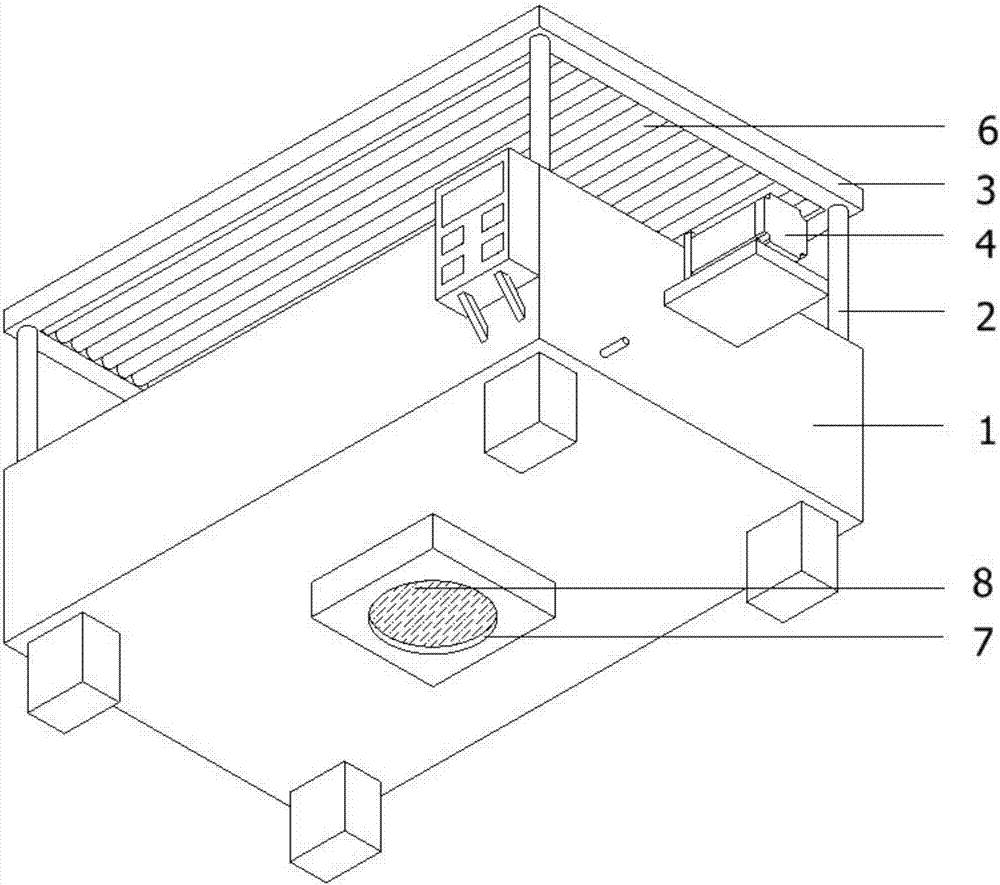

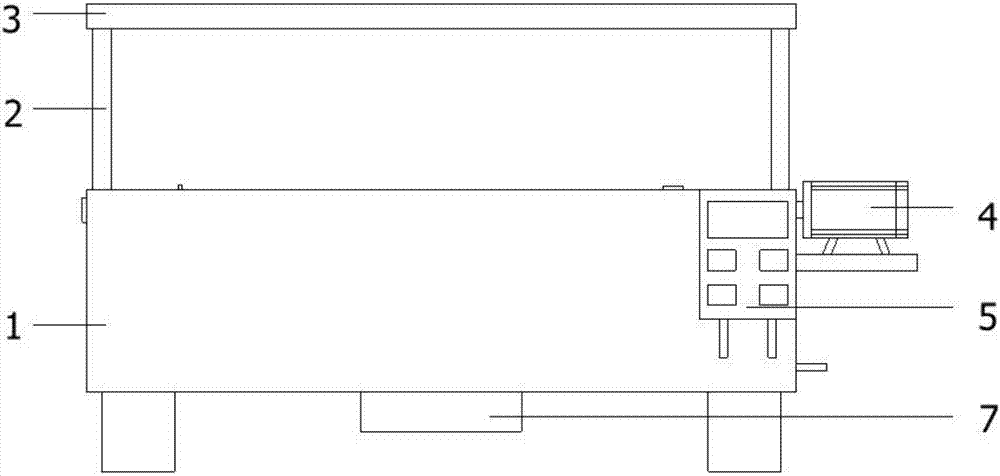

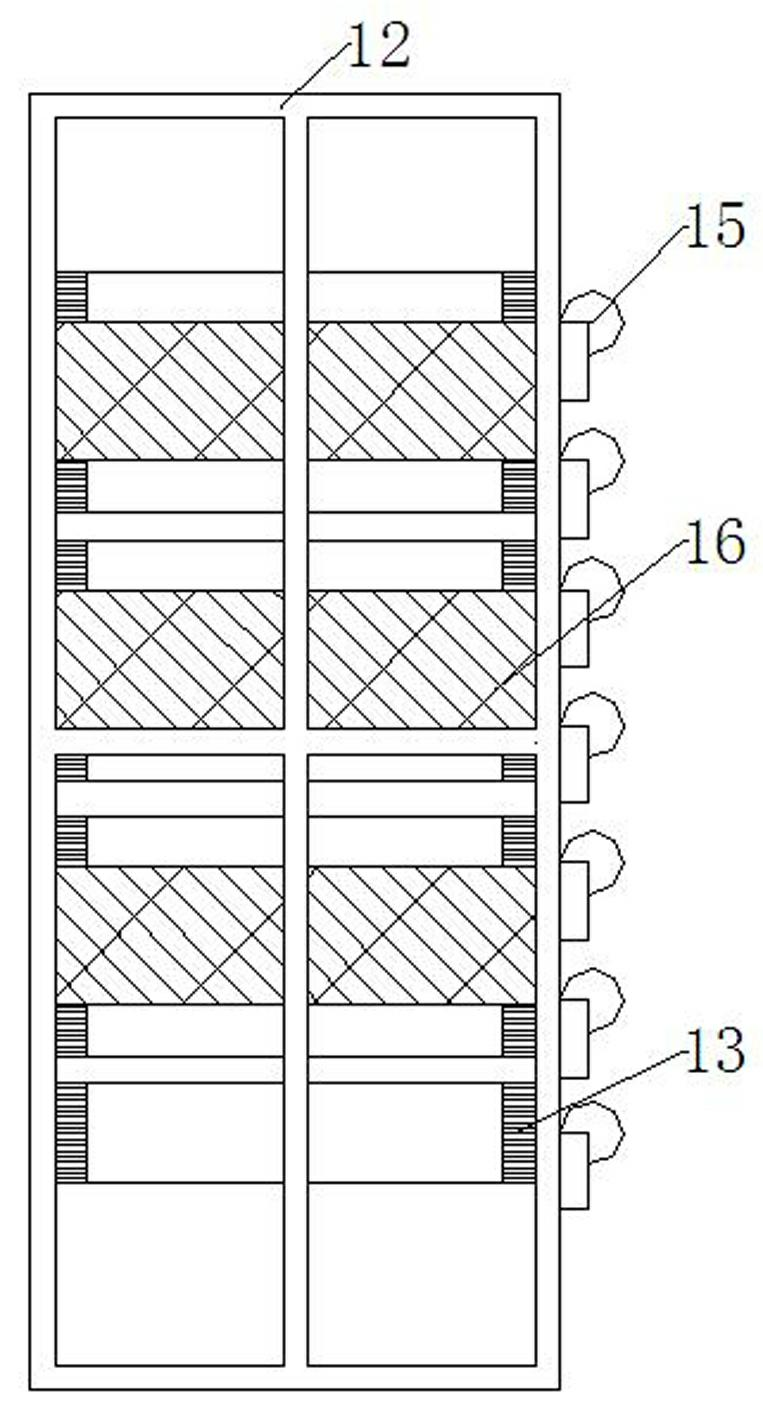

Low-temperature withering device for tea leaves

InactiveCN102835487AShorten withering timeImprove tea production efficiencyPre-extraction tea treatmentControl systemCapillary Tubing

The invention relates to a low-temperature withering device for tea leaves, which mainly comprises a shell, a CPU (central processing unit) control system, a compressor, a capillary tube, a condenser, a radiator, electron temperature probes and a fan. The shell of the whole withering device is of a cabinet type structure; 4-6 layers of interlayers are arranged at the upper part of the shell and are used for placing the tea leaves; the electron temperature probes are uniformly arranged on the interlayers and are used for detecting the temperature of each interlayer; the compressor, the capillary tube, the condenser, the radiator and the fan are arranged at the lower part of the shell; the condenser is positioned above the radiator; the capillary tube is positioned between the condenser and the radiator; and the temperature in the whole withering device is controlled at 8 DEG C. According to the low-temperature withering device provided by the invention, the time for the tea leaves to wither is greatly shortened, the efficiency for making tea is improved, the risk of nonuniform quality of high-end brand-name tea is reduced, the quality of the tea leaves is improved, and the competition of the tea leaves in the market is enhanced.

Owner:贵州怡壶春生态茶业有限公司

Method for preparing Maofeng tea by using non-whitened-stage fresh tea leaves

ActiveCN104585370ADark green colorIntegrity guaranteedPre-extraction tea treatmentEconomic benefitsProcessing cost

The invention belongs to the technical field of tea processing, and particularly relates to a method for preparing Maofen tea by using non-whitened-stage fresh tea leaves. The finished tea is prepared according to the steps of selecting materials, withering, inactivating enzyme, regaining moisture, twisting, dewatering, shaping, drying, scenting, and winnowing. According to the method, high quality of the finished product is ensured at all the stages due to the adoption of refine processing technology, so that the processing time and processing cost of Zhen'an white tea are greatly reduced, the production efficiency is improved, simultaneously the finished product processed according to the method has the unique characteristics of tight, thin curled and uniform shape, green color, durable clean aroma and fresh taste, and the economic benefit of the finished product is improved; and meanwhile, the problem of waste of non-whitened-stage Zhen'an fresh tea leaves is solved, and the economic benefit is improved.

Owner:ZHENGAN JINLIN TEA IND +1

Processing method of white tea

InactiveCN107873867AReduce color changeImprove distributionPre-extraction tea treatmentTemperature controlAmino acid content

The invention provides a processing method of white tea and belongs to the technical field of tea processing. The processing method provided by the invention comprises the steps of picking fresh leaves, carrying out sun withering, carrying out rapid leaf cooling, carrying out slight rocking on green leaves, carrying out temperature-controlled withering, slowly drying at low temperature and packaging and also comprises an aerobic micro fermentation step between the steps of constant temperature withering and slowly drying at low temperature, wherein the aerobic micro fermentation comprises thesteps that withered leaves are put into a bamboo dustpan and natural aerobic micro fermentation is carried out indoors for 0.5-1.0 hour. The white tea produced according to the processing method provided by the invention is strong in fragrance and mellow in taste, faint scent is lasting, taste is fresh, mellow and delicious, aftertaste is sweet, tea soup is lubricating and sweet when entering themouth, soup color is olivine and bright, and the white tea is durable and can be brewed for multiple times and has the characteristic of relatively high amino acid content.

Owner:南宁茗韵茶业有限公司

Process for preparing honeyed black tea

InactiveCN105309655AShorten withering timeSpread evenlyPre-extraction tea treatmentBrilliant RedBlack tea

The invention discloses a process for preparing honeyed black tea. The process comprises the following steps: 1, fresh leaf picking; 2, withering, 3, rolling in three times, 4, primary fermentation: putting rolled leaves into a fermentation tank, keeping the temperature to be 26-29 DEG C, conducting spraying fermentation, keeping the humidity to be 90-92%, automatically turning once every 15 min, adding honey water in a spraying manner before turning, and automatically stopping turning after uniform mixing, wherein the fermentation time is 3 h; 5, drying: drying by adopting a drying machine, wherein the drying temperature is 40-50 DEG C, the air speed is 1 m / s, and the drying time is 2-3 h; 6, secondary fermentation: putting the dried tea leaves in a ventilated fermentation room for storage for 3-4 d, and conducting secondary fermentation under the natural condition; 7, aroma extraction. The prepared black tea is brilliant red and bright in tea color and has a strong honey aroma.

Owner:GUANGXI ZHAOPING NINGXIANGCUI TEA FACTORY

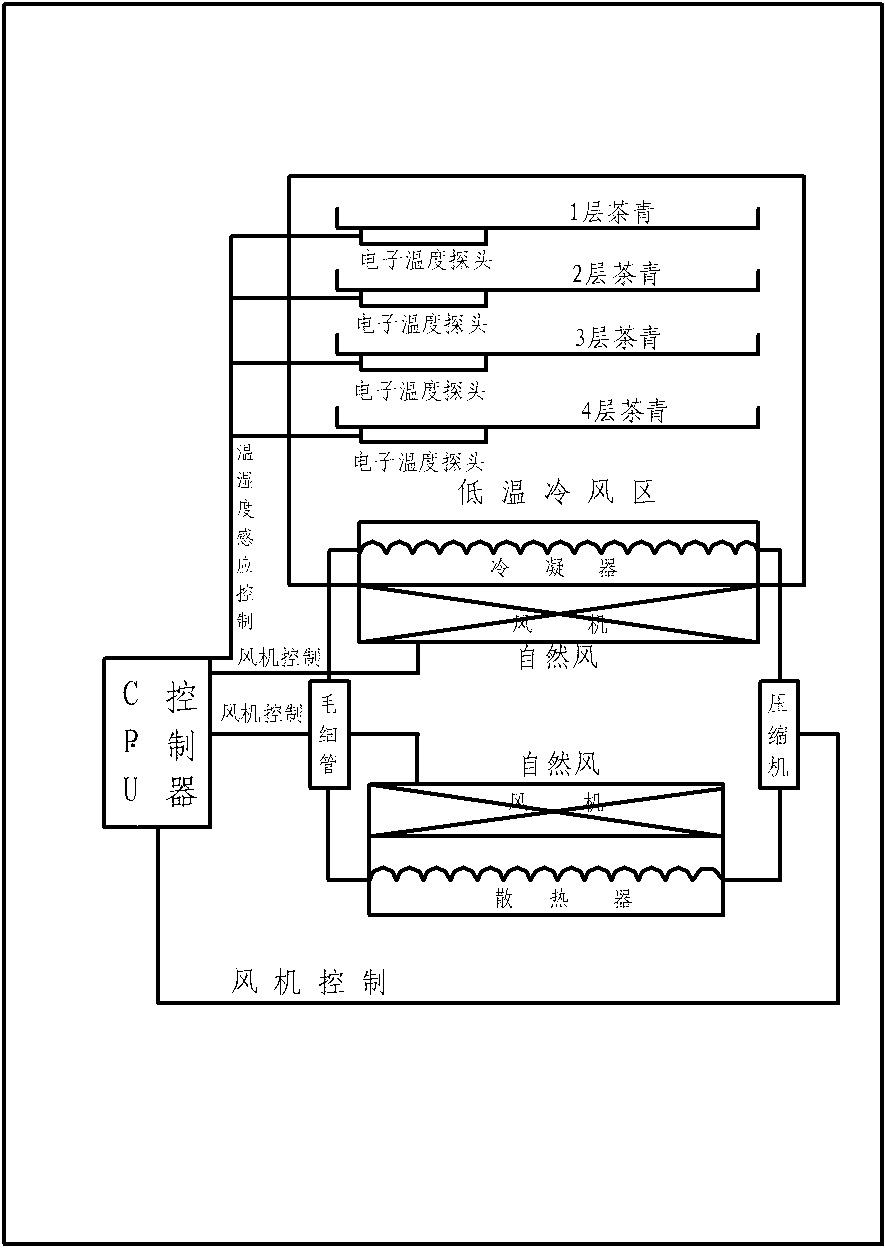

Preparation method of sweet and fragrant particle black tea

The invention discloses a preparation method of sweet and fragrant particle black tea. Conventional fresh tea leaves are taken as a raw material, wherein each fresh tea leaf comprises one sprout and one leaf; the hot air type deterioration method is utilized to deteriorate the fresh tea leaves; the three-step twisting method is adopted to twist the tea leaves; then, space heating fermentation is performed; finally, the sweet and fragrant particle black tea is obtained through shaping and drying. The black tea disclosed by the invention contains rich inclusions in high content; with adoption of the preparation method, the quality and economic benefits of the tea are effectively improved.

Owner:厦门清雅源科技有限公司

Processing method of Guanyin black tea having aroma

ActiveCN107865125AReduce color changeImprove distributionPre-extraction tea treatmentClimate change adaptationTemperature controlBlack tea

The invention provides a processing method of Guanyin black tea having aroma, and belongs to the technical field of processing of tea leaves. The processing method comprises the following steps of selecting Tieguanyin tea trees, picking fresh leaves, performing sunning with soft sunlight, performing cooling, rocking the cooled leaves for the first time, shining the rocked leaves, and performing rocking for the second time; and performing temperature-controlled withering in an air conditioning room, performing rolling, performing deblocking, performing fermentation, performing drying with a first fire, performing drying with a full fire, performing aroma increasing and performing packing. The made Guanyin black tea is tight and thin in strips, the soup color is red and bright, the taste ismellow, fresh and brisk, the Guanyin black tea has special aroma of Guanyin tea, and sweet aroma of black tea, and the Guanyin black tea is long in fragrance and rich in Guanyin tea fragrance.

Owner:南宁茗韵茶业有限公司

Preparation process for white tea

InactiveCN104757149AImprove the richness and mellowness of the tastePromote formationPre-extraction tea treatmentWater contentFood science

The invention discloses a preparation process for white tea. The preparation process comprises the steps of a picking step, a withering step, a rolling step and a drying step. The preparation process is characterized in that the withering step is a warm withering step which is specifically characterized in that fresh tea leaves are uniformly spread in a withering trough for withering, the thickness is 1-1.5 centimeters, the withering temperature is controlled at 30 DEG C-36 DEG C, the withering time is 4-6 hours, the tea leaves are withered until the leaves are shrunk, the leave texture is soft, and stalks are not broken when bent, faint fragrance is generated, and the water content is 65-70%. According to the white tea, the trabes are tight in appearance, the color is silvery, the pekoe is revealed, the liquor color is yellow and bright, the fragrance is strong and durable, the taste is strong, fresh and mellow, and infused leaves are tender, even and bright.

Owner:成都市碧涛茶业有限公司

Method for low-temperature withering tea leaves

InactiveCN102813019AShorten withering timeImprove tea production efficiencyPre-extraction tea treatmentCold airPhysical chemistry

Owner:贵州怡壶春生态茶业有限公司

Preparation method of flower-fragrance white tea

InactiveCN106954690AShorten withering timeSuit one's needsPre-extraction tea treatmentSweetnessChemistry

The invention relates to the technical filed of tea processing, and specifically relates to a preparation method of flower-fragrance white tea. The preparation method of the flower-fragrance white tea comprises the following steps of: withering fresh tea leaves in the sun, carrying out slight shaking, carrying out indoor micro-domain-regulated withering, carrying out vibration-waving, carrying out high-temperature preliminary drying, carrying out rolling when the tea leaves are still hot, carrying out drying, and then, carrying out selecting and weeding so as to prepare the flower-fragrance white tea. The invention has the following beneficial effects: the white tea prepared by the preparation method of the flower-fragrance white tea disclosed by the invention is semi-rolled stripes with slightly shrunken folds on leaf blades which are dark green with brown in color and luster; the white tea is obvious in flower fragrance and free of grassy smell, as well as sweet and mellow in flavor; the tea soup is dark yellow in color and clear; and the tea leaves are complete and translucent. Compared with prior art, the preparation method of the flower-fragrance white tea disclosed by the invention shortens withering time of the white tea, overcomes influence of bad weather, and improves product quality; moreover, the processes of shaking and waving are integrated so as to improve aroma of the product, and the process of high-temperature preliminary drying is combined so as to eliminate the grassy smell, as well as improve the sweetness and the mellowness. The strip shape of the white tea is tighter compared with conventional technology, and the prepared white tea is mellow in flavor and stronger in aroma, and thus, demands of the market and the consumers are satisfied.

Owner:TEA RES INST OF FUJIAN ACADEMY OF AGRI SCI

Withering method of Gongfu black tea

InactiveCN106343048AAccelerate dehydrationWither evenlyPre-extraction tea treatmentBlack teaTea leaf

The invention provides a withering method of Gongfu black tea. The method comprises the following steps: 1) picking tea tree fresh leaves, putting on a withering rack, and withering for 1.0-1.5 hours, wherein the withering thickness is 0.5-2.5cm, and the leaves are stirred 3-4 times in the withering process; 2) withering the tea leaves in a withering machine with cold air for 50-70 minutes, wherein the tea leaf spreading thickness is 30-40cm; 3) withering with hot air for 30-40 minutes, wherein the hot air temperature is 35-40 DEG C; 4) withering with cold air for 30-50 minutes; 5) withering with hot air for 70-90 minutes, wherein the hot air temperature is 35-40 DEG C; 6) shutting down for 50 minutes; and 7) withering with hot air for 110-130 minutes, wherein the hot air temperature is 35-40 DEG C, and the tea leaves are stirred every 15 minutes in the whole withering process. The method can accelerate the water loss of the fresh leaves and accelerate the conversion of substances in the fresh leaves, and the tea leaves can be withered uniformly and sufficiently. Meanwhile, the method greatly shortens the withering time.

Owner:柳城县国营伏虎华侨农场茶厂

White tea and processing method thereof

InactiveCN106106861APromote formationMellow tastePre-extraction tea treatmentClimate change adaptationEconomic benefitsBud

The invention provides white tea with flower and fruit fragrance and a processing method thereof. Compared with the traditional white tea, fresh leaves of a bud with two leaves or a bud with three leaves of Chuntaoxiang tea, Jinmeigui tea and Ziguanyin tea instead of Fuding Dabaicha, Zhenghe Dabaicha, Fuding Dahaocha or Caicha are selected as raw materials, a step of green-making in the sunlight, a step of piling of fresh leaves after green-making in the sunlight, a step of modeling and a step of moisture regaining are added to the processing method, so that withering time is greatly shortened, the utilization rate of tea making equipment and factories is effectively improved, the cost is reduced, the economic benefit is increased, the characteristic of the traditional white tea is kept on the quality of the finished tea, in addition, the flower and fruit fragrance is strong and high, the taste is mellow, the appearance is compact, the white tea is resistant to brewing, and the white tea product is enriched, and can better meet the requirements of consumers.

Owner:FUAN KEMING AGRI DEV

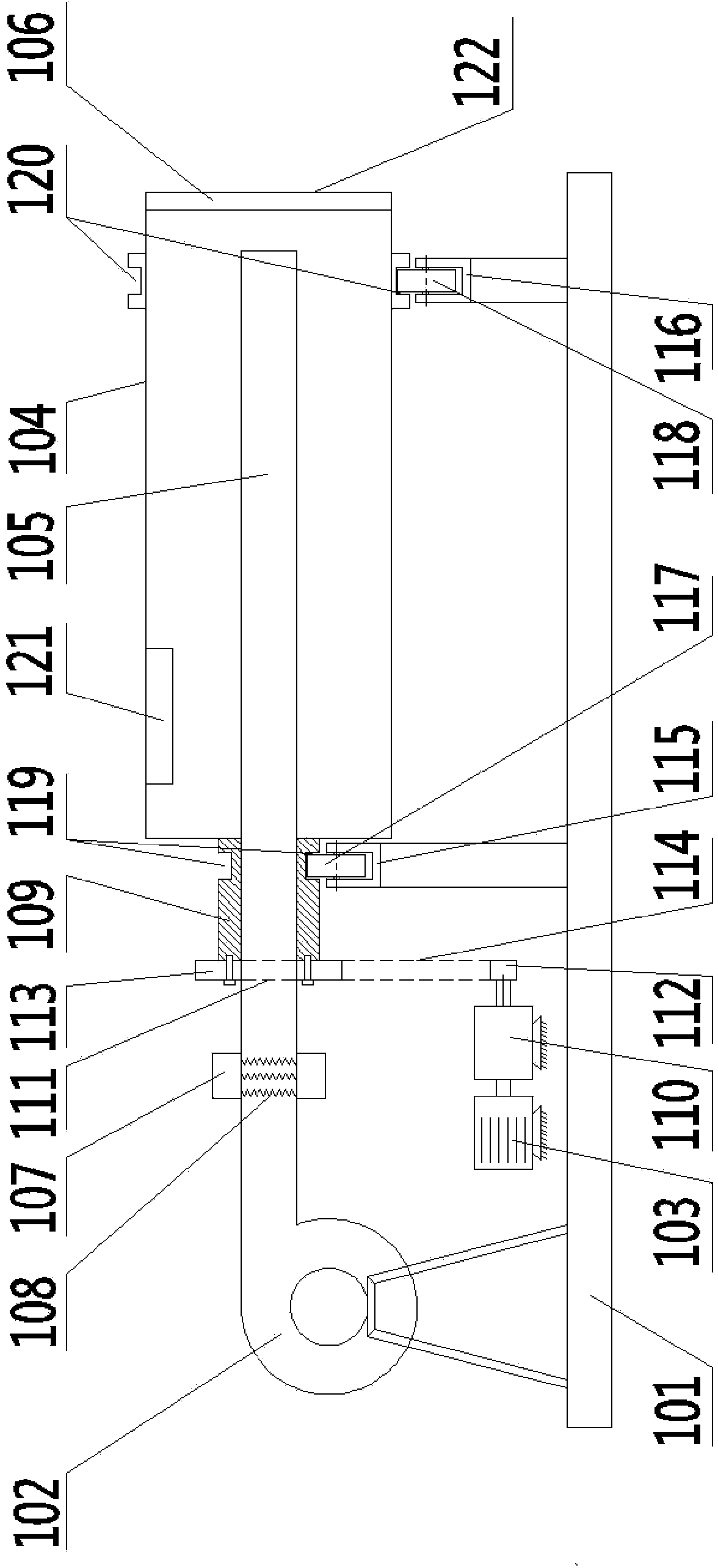

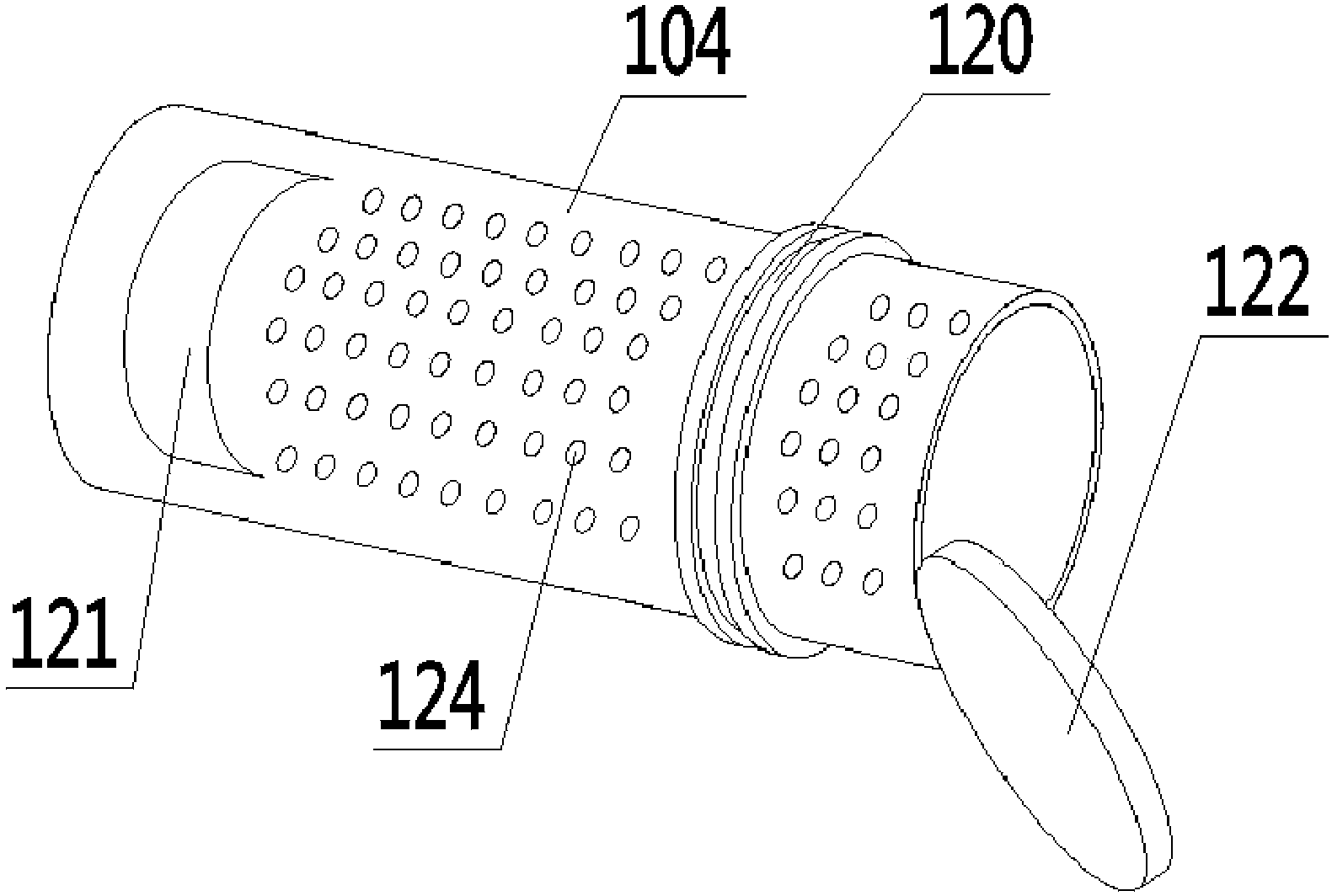

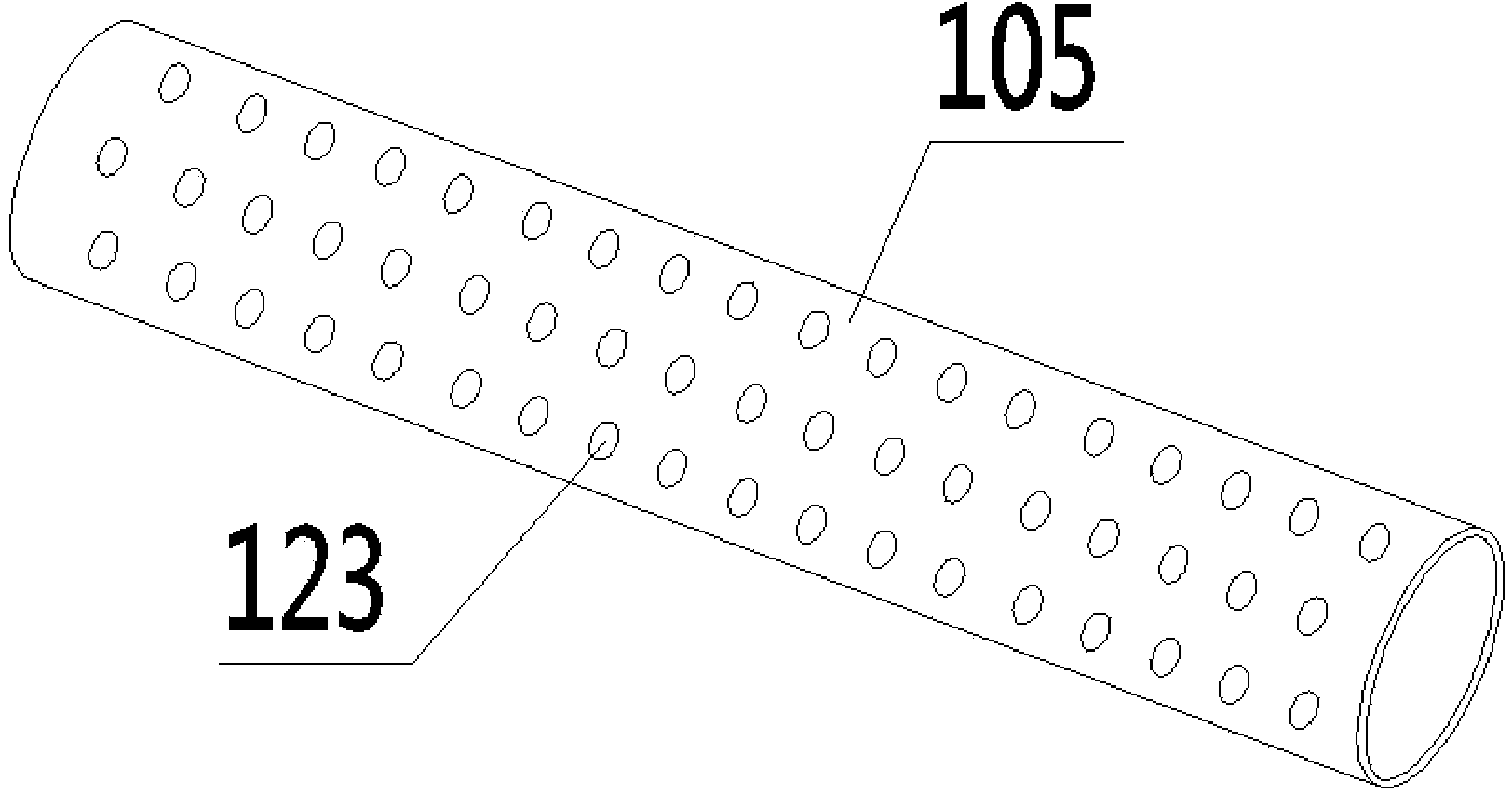

Withering machine

InactiveCN104171085AAvoid spreadingSmall footprintPre-extraction tea treatmentElectric machineryMotor drive

The invention provides a withering machine belonging to the technical field of tea making. The withering machine comprises a rack, a fan, a motor and a rotatable rotary roller, wherein the fan is arranged at one end of the rack, the rotary roller is arranged at the other end of the rack, an air duct is connected to an air outlet of the fan, the air outlet of the fan corresponds to an air inlet of the air duct, an opening is formed in one end of the rotary drum, the air duct extends into the rotary roller by virtue of the opening, the motor is in transmission connection with the rotary roller, and the rotary roller is provided with a door. According to the withering machine, the rotary roller is arranged and the air duct connected with the fan extends into the rotary roller, air generated by the fan enters the rotary roller by virtue of the air duct, the motor drives the rotary roller to rotate around the air duct, and tea is arranged in the rotary roller, and is withered along with the rotation of the rotary roller. According to the withering machine provided by the invention, the occupation area is reduced, the withering speed is increased, and the withering time is shortened.

Owner:GUIZHOU JIUDING MACHINERY

Processing technology of white tea

The invention discloses a processing technology of white tea in the field of processing of tea leaves. The processing technology comprises the steps of performing picking, performing withering, performing shaping and performing drying, in the step of withering, placing picked leaves in outdoor environment of 25-30 DEG C, performing natural withering, after natural withering, enabling a plurality of infrared lamp tubes to be fixed to the inside wall of a withering box, enabling an air inlet to the formed in the bottom of the withering box, enabling an air outlet to be formed in the top of the withering box, enabling the air outlet to be connected with an exhaust fan, performing rotary withering on the naturally-withered leaves in the withering box, controlling and maintaining the temperature of the withering box to be 32-45 DEG C, controlling the rotating speed of a screen mesh to be 6r / min, and controlling the rotary withering time to be 1-2h. Compared with a conventional technology, the adopted technology provided by the invention has the advantages that the withering is more uniform, the withering efficiency is higher, and the preserved white fine long hair is more complete. After the processed white tea is brewed, tea soup is delicately fragrant, slightly sweet and slightly fragrant, the soup color is light, the white fine long hair is rich in fragrance, the taste is fresh, mellow and delicious, and the quality is better than that of traditional products.

Owner:正安县吐香茶业有限责任公司

Natural rosin black tea production process

The invention discloses a natural rosin black tea production process. The natural rosin black tea production process comprises the following steps: fresh leaf picking; withering; rolling by the three-step method; fermentation for 8-10 h in a fermentation room at the temperature of 25-30 DEG C and the humidity of 90-95 percent; primary drying; secondary fermentation; secondary drying till the water content of tea leaves is 10-12 percent; primary mixing of tea leaves and pine needle by performing repeated multi-layer stacking according to the weight ratio (pine needles to the tea leaves) of (1-2):6 in such a way that the tea leaves and the pine needle are placed layer by layer; third-time fermentation; third-time drying. After a natural rosin black tea produced by the method is brewed, the tea soup is red and bright, has a unique fresh rosin flavor and can meet the many-flavor demands of tea lovers.

Owner:GUANGXI ZHAOPING NINGXIANGCUI TEA FACTORY

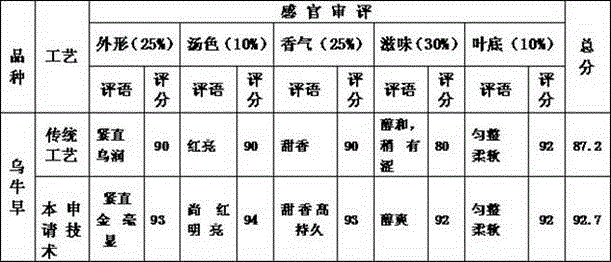

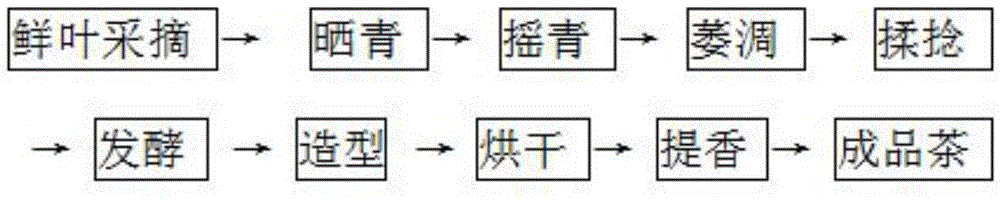

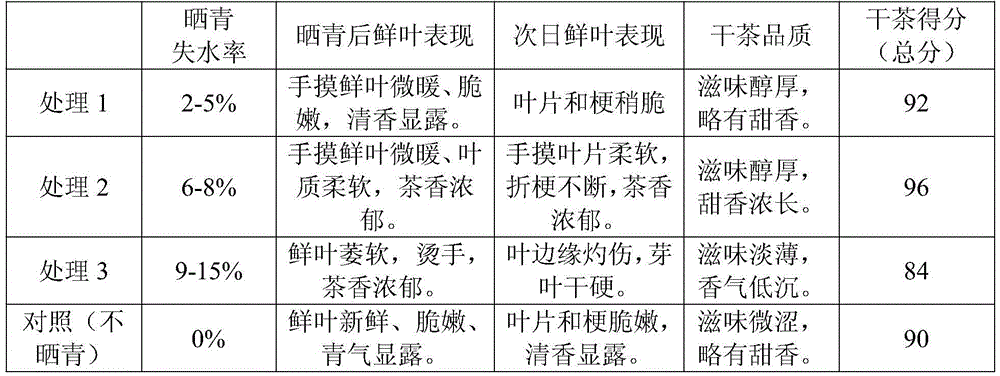

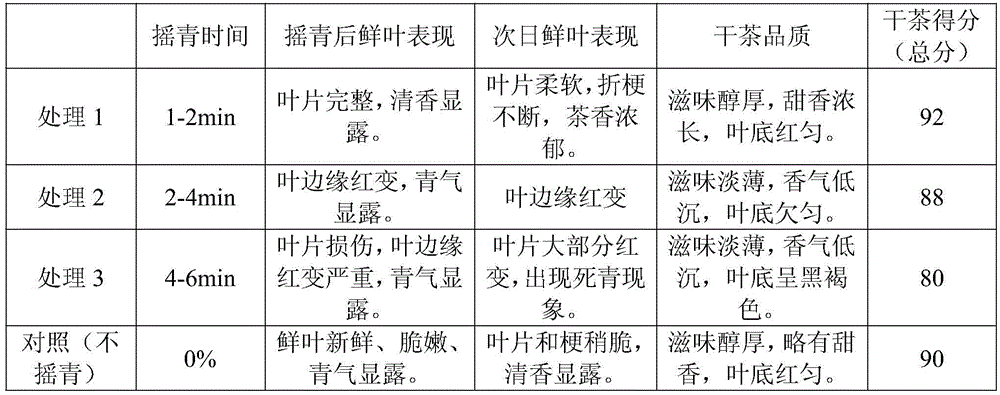

Processing method of Wuniuzao black tea

InactiveCN106234656ABright red soupMellow tastePre-extraction tea treatmentClimate change adaptationTemperature controlShoot

The invention discloses a processing method of Wuniuzao black tea. The preparation method comprises the following technological processes: raw material picking, sun-drying, withering, rolling, fermentation, drying, flavour-distilling and the like. Fresh Wuniuzao tea leaves picked after early spring are used as the raw material. By adding the sun-drying process into a traditional black tea process and through temperature control and humidity control of the fermentation process, fermentation is more complete, mouthfeel of the tea product is more mellow and brisk, and traditional fermentation time is shortened. The produced Wuniuzao black tea has tight and straight strip-shaped appearance and has clearly visible tender tea shoots; the tea liquor color is red and bright; the taste is mellow and brisk; tea fragrance has high level and is lasting; and infused leaves are soft and even.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

Processing method of chestnut-fragrance Guanyin green tea

InactiveCN107668228AImprove distributionPromote formationPre-extraction tea treatmentTemperature controlAir conditioning

The invention provides a processing method of chestnut-fragrance Guanyin green tea, and belongs to the technical field of processing of tea leaves. The processing method comprises the following stepsof picking fresh leaves, performing sunning, performing light rocking of the leaves, performing fixation, performing cooling on the leaves, performing rolling, performing deblocking, performing bakingfor the first time, performing strip tidying, performing drying and performing packing, and also comprises the step of performing quick cooling on the leaves between the step of performing sunning and the step of performing light cooking of the leaves, the step of performing temperature-controlled withering between the step of performing light rocking of the leaves and the step of performing fixation, the step of performing aerobic wetting between the step of performing cooling on the leaves and the step of performing rolling, and the step of performing aroma increasing between the step of performing drying and the step of performing packing, wherein the step of performing quick cooling on the leaves is performed in the manner of placing the sunned tea leaves in an air conditioning room,and performing standing for cooling the leaves; the step of performing temperature-controlled withering is performed in the manner of placing the tea leaves after being rocked in the air conditioningroom for standing; the step of performing aerobic wetting is performed in the manner of placing the cooled tea leaves in the room, and performing natural aerobic wetting; the step of performing aromaincreasing is performed in the manner of placing the dried tea leaves in an aroma-increasing machine, and performing uniform aroma increasing. The Guanyin green tea has the characteristics of being rich and obvious chestnut fragrance, being fresh and smooth in taste, yellowish green and bright in soup color, and convenient to store.

Owner:南宁茗韵茶业有限公司

Gold dragon tea processed by adopting Wuniuzao tea and preparation method thereof

InactiveCN105454484AShorten withering timeIncrease contentPre-extraction tea treatmentMineralogyRaw material

The invention discloses a preparation method of gold dragon tea processed by adopting Wuniuzao tea, which comprises the following steps: harvesting raw materials, sunning, rocking of green leaves, withering, rolling, straight-bar shaping, drying and fragrance extraction. The invention also provides the gold dragon tea processed by adopting the Wuniuzao tea. The preparation method is scientific, reasonable, simple and perfect and realizes normalized and large-scale production of Wuniuzao tea, so as to meet the requirement of tea lovers on excellent tea quality.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

Tea withering, spreading and transmitting frame

The invention discloses a transmission frame for tea withering and spreading, which includes a transmission frame body, a hook and a ring buckle. The transmission frame body and the lamp board are movably connected by four telescopic rods, and the inner wall of the bottom of the lamp board is inlaid with LEDs. As for the panel light, the wind collecting housing corresponds to the position of the tea placing device. The tea leaves withering and spreading transmission frame is provided with a rotatable and adjustable tea placement device. Tea leaves that need to wither can be placed inside the upper and lower ends of the tea placement device. The control box controls the motor to start and controls the tea placement device to rotate 180°, so that The tea leaves in the tea storage device are subjected to direct LED panel light and hot air heating and withering treatment. After repeated double withering treatment through multiple rotations, the tea changing process can be accelerated, the withering time can be shortened, and the work efficiency can be improved. The tea leaves in the device are uniformly and fully withered to ensure the quality of the tea leaves after withering.

Owner:贵州沁园茶业有限责任公司

Dynamic withering method of black tea

InactiveCN106387111AChange the internal material structureAccelerate chemical changesPre-extraction tea treatmentBlack teaEngineering

The present invention relates to the field of tea processing and particularly relates to a dynamic withering method of black tea. The dynamic withering method of the black tea is as follows: black tea fresh leaves are placed in a withering trough and the withering trough is intermittently moved; airflow is blew into the withering trough when the withering trough is stopped and the airflow conducts the dynamic withering of the black tea fresh leaves in the withering trough; and wherein the temperature of the airflow is 28-32 DEG C. The provided dynamic withering method of the black tea enables the black tea fresh leaves in the withering trough to conduct the movement, at the same time the blew airflow at the specific temperature is combined, and the black tea fresh leaves are subjected to the dynamic withering. The dynamic withering method changes the intrinsic material structures in the black tea, speeds up the chemical changes of the intrinsic materials in the tea leaves, completes the required leaf phase standard in advance, shortens the withering time, and improves work efficiency. The color, fragrance and taste of the finally prepared black tea are obviously better than those of traditional black tea.

Owner:GUIZHOU ZHOUYIQING BIOTECH

Chrysanthemum tea and processing method thereof

InactiveCN109619239AInhibit oxidative decompositionUndamagedTea substituesMicrowaveChrysanthemum Flower

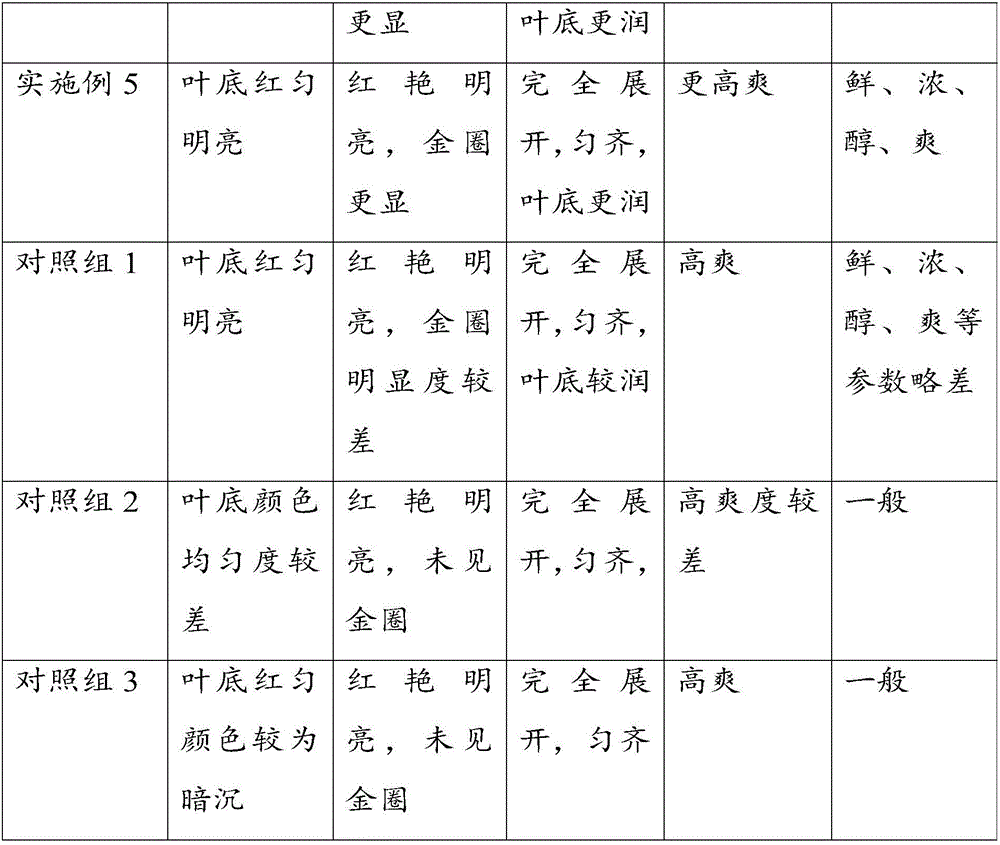

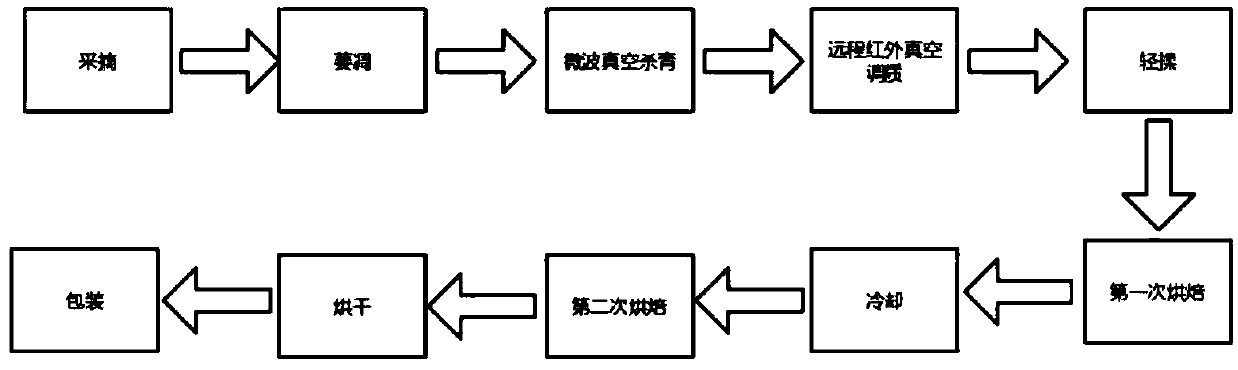

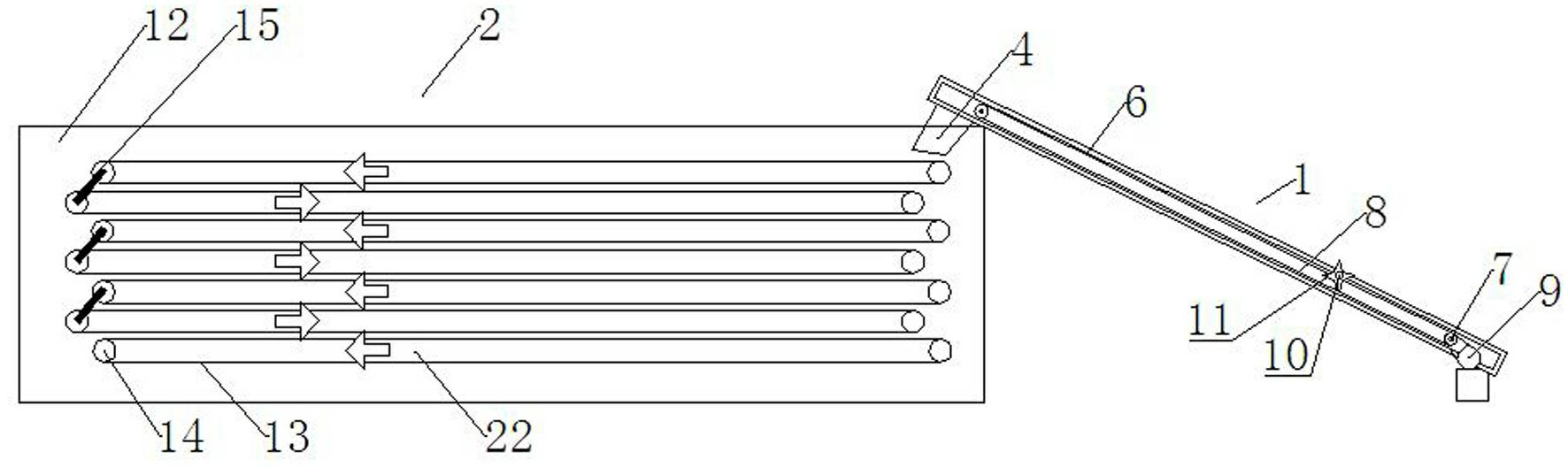

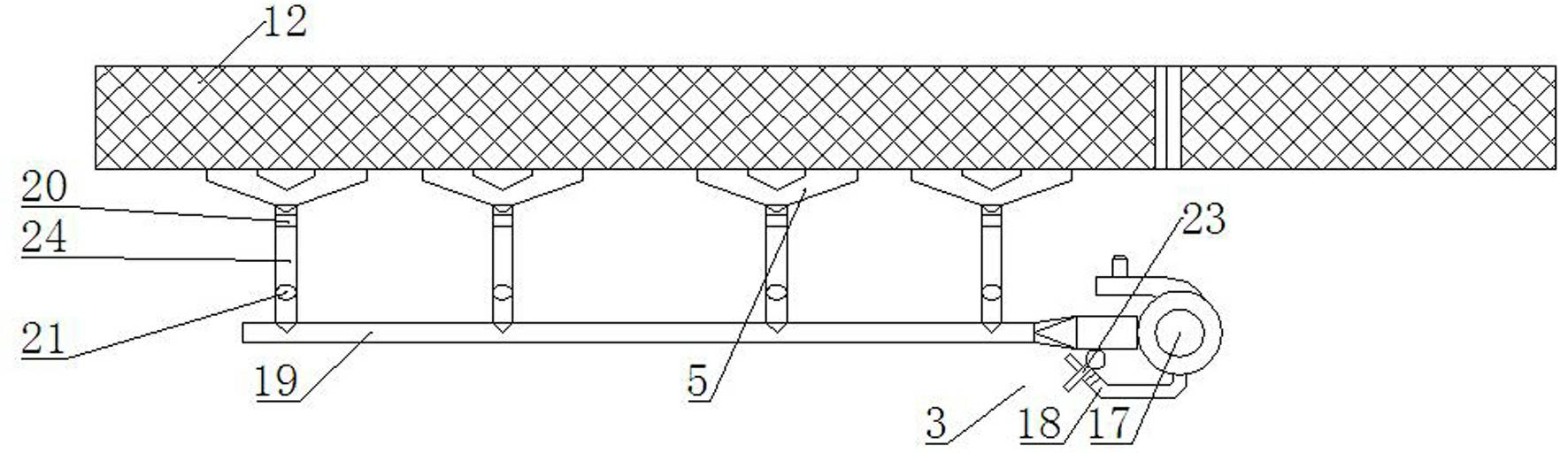

The invention relates to the technical field of tea processing, in particular to chrysanthemum tea and a processing method thereof. The processing method comprises the following steps of 1, picking; 2, withering; 3, microwave vacuum fixation; 4, remote infrared vacuum air conditioning; 5, light rolling; 6, primary baking; 7, cooling; 8, secondary baking; 9, drying; 10; drying. On the premise thatbeneficial components in chrysanthemum flowers are not reduced, the processing method can improve the level and taste of the chrysanthemum tea, so that the chrysanthemum tea good in color, fragrance,taste and shape is provided.

Owner:JIXI COUNTY HANHUI AGRI DEV

White tea-withering machine

InactiveCN102524443AShorten withering timeReasonable structural designPre-extraction tea treatmentProcess engineeringHot blast

The invention discloses a white tea-withering machine, which comprises a conveyer, a circulator and a temperature regulator, one end of the conveyer is connected with the circulator through a feed hopper, and the temperature regulator is connected with the circulator through branch hot blast pipes. Because the white tea-withering machine has the structure, the structural design of the white tea-withering machine is reasonable, and the white tea-withering machine is convenient to operate, shortens the white tea-withering time, and increases the working efficiency.

Owner:福建省天湖茶业有限公司

Black tea withering method

InactiveCN106387103AAccelerate dehydrationWither evenlyPre-extraction tea treatmentCold airBlack tea

The invention provides a black tea withering method. The black tea withering method comprises the following steps: 1), picking fresh tea leaves from tea trees, placing the picked tea leaves on a withering shelf, wherein the withering thickness is 0.5-3.5 centimeters and the withering time is 1.5-2.5 hours, and turning the tea leaves for 4-5 times during withering; 2) placing the tea leaves in a withering machine, wherein the spreading thickness of the tea leaves is 40-60 centimeters, and withering the tea leaves by using cold air for 30-45 minutes; 3), carrying out withering by using hot air for 60-80 minutes, wherein the temperature of the hot air is 35-40 DEG C; 4), carrying out withering by using cold air for 50-70 minutes; 5), carrying out withering by using hot air for 30-50 minutes, wherein the temperature of the hot air is 35-40 DEG C; 6) stopping the withering machine for 1 hour; and 7), carrying out withering by using hot air for 130-150 minutes, wherein the temperature of the hot air is 35-40 DEG C. The tea leaves are turned once every 15 minutes during the whole withering processes. The black tea withering method has the advantages of accelerating water loss of the fresh leaves, speeding up internal substance transformation in the fresh tea leaves and so on. By adopting the black tea withering method disclosed by the invention, the tea leaves are uniformly and fully withered; moreover, the withering time is greatly reduced.

Owner:柳城县国营伏虎华侨农场茶厂

Processing method of white tea with clean aroma

InactiveCN108576281AAvoid damagePromote formationPre-extraction tea treatmentClimate change adaptationAnti virusAmino acid content

The invention relates to the technical field of tea processing, in particular to a processing method of a white tea with a clean aroma. The method comprises the following steps: (1) picking, (2) sunshine withering, (3) fermentation, (5) withering, (6) stoving, and (8) packaging. The white tea produced by the method is mellow in fragrance, lasting in clean aroma, fresh, mellow and tasty in taste and sweet in aftertaste. Tea soup is smooth and sweet in mouth, and soup color is yellowish green and bright, and the white tea is durable in brewing, is high in amino acid content, also contains activeenzymes necessary for human body, and has good anti-virus immune functions.

Owner:思南梵众白茶开发经营有限公司

Low-temperature withering device for tea leaves

InactiveCN102835487BShorten withering timeImprove tea production efficiencyPre-extraction tea treatmentControl systemCapillary Tubing

The invention relates to a low-temperature withering device for tea leaves, which mainly comprises a shell, a CPU (central processing unit) control system, a compressor, a capillary tube, a condenser, a radiator, electron temperature probes and a fan. The shell of the whole withering device is of a cabinet type structure; 4-6 layers of interlayers are arranged at the upper part of the shell and are used for placing the tea leaves; the electron temperature probes are uniformly arranged on the interlayers and are used for detecting the temperature of each interlayer; the compressor, the capillary tube, the condenser, the radiator and the fan are arranged at the lower part of the shell; the condenser is positioned above the radiator; the capillary tube is positioned between the condenser and the radiator; and the temperature in the whole withering device is controlled at 8 DEG C. According to the low-temperature withering device provided by the invention, the time for the tea leaves to wither is greatly shortened, the efficiency for making tea is improved, the risk of nonuniform quality of high-end brand-name tea is reduced, the quality of the tea leaves is improved, and the competition of the tea leaves in the market is enhanced.

Owner:GUIZHOU YIHUCHUN ECOLOGICAL TEA CO LTD

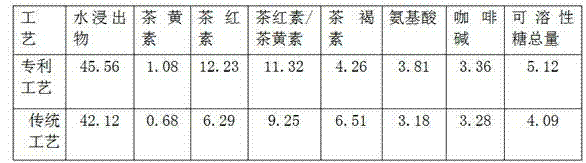

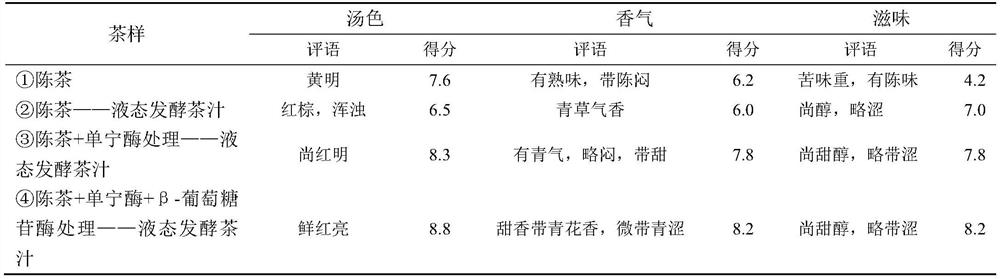

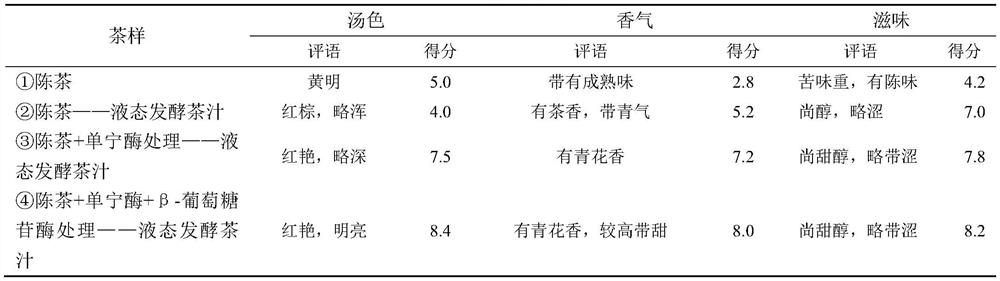

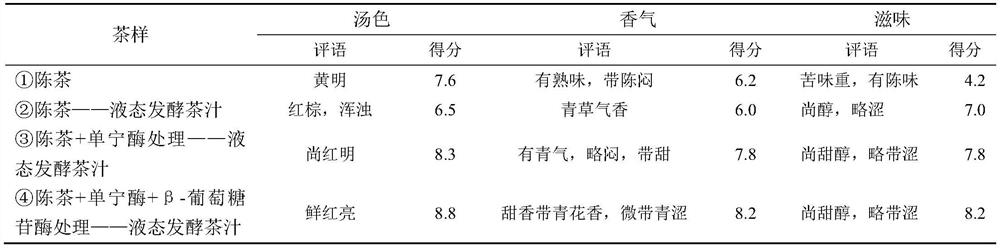

Method for performing liquid fermentation on black tea juice by using green and aged tea

PendingCN114304328AImprove flavor qualityPromote formationPre-extraction tea treatmentTea extractionBiotechnologyTheaflavin

The invention discloses a method for liquid-state fermentation of black tea juice by using aged green tea and belongs to the technical field of tea processing. The method comprises the following process steps: mixing green aged tea with hot water, and carrying out water bath extraction; adding tannase into the catechin crude extract to carry out water bath enzymolysis; freezing and withering the fresh tea leaves; performing homogenization treatment on the frozen withered leaves; pouring the homogenate into the primary enzymolysis catechin crude extract, adding beta-glucosidase, carrying out secondary enzymolysis treatment, and carrying out fermentation treatment; and performing microwave treatment on the fermentation liquor, filtering, and cooling to room temperature. A traditional black tea processing technology is combined with a liquid fermentation technology, and the fermentation process is further treated by two enzymes, so that the aged gas of the aged tea can be reversed, the residual catechin is fully utilized, the content of flower fragrance and fruit fragrance components is remarkably increased, the content of theaflavin in tea juice is increased, and the overall flavor quality of the aged tea is improved; after the black tea juice is diluted by 5 times, the tea fragrance is prominent, the blue and white fragrance is prominent, the liquor color is red and bright, and the taste is sweet and mellow.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

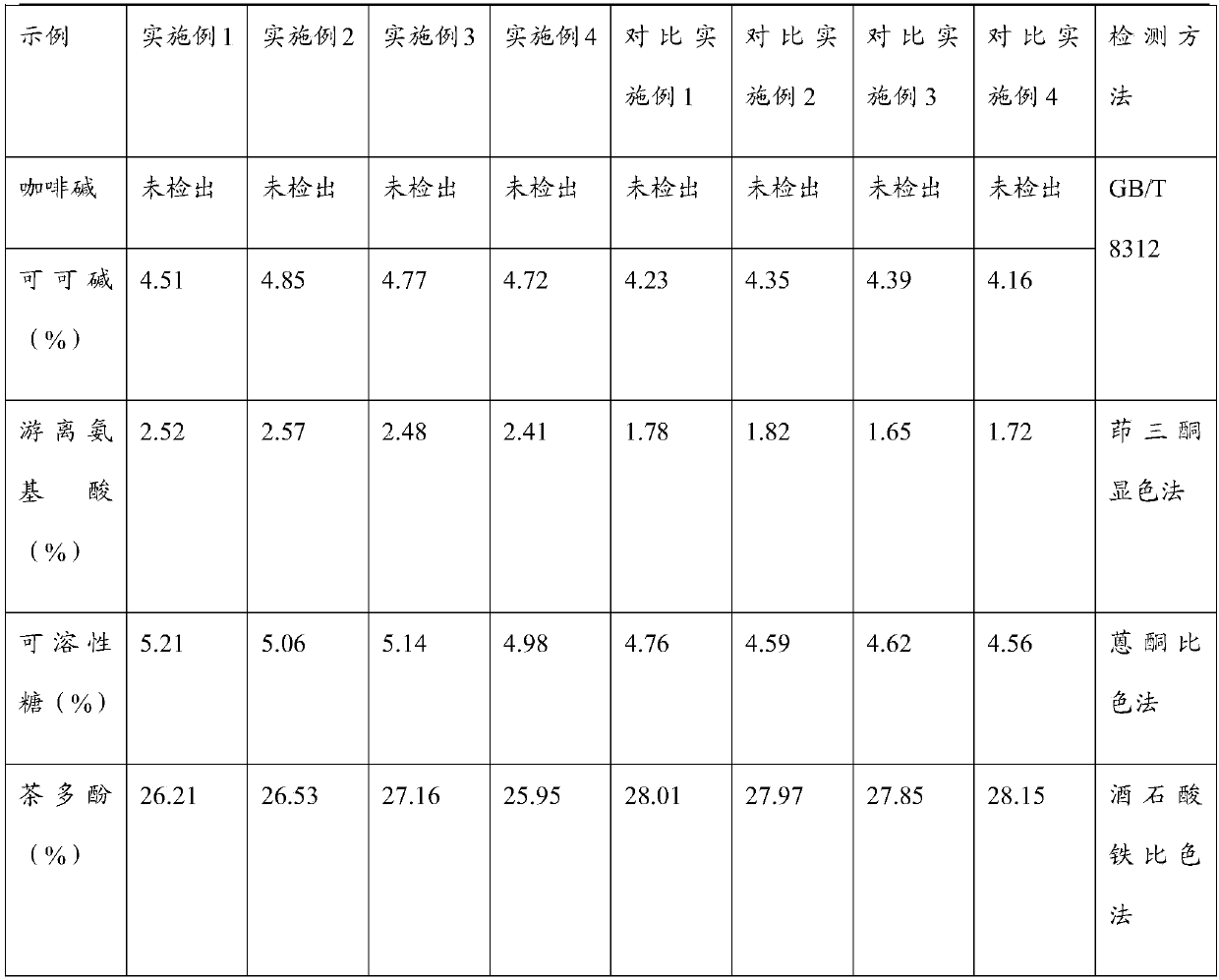

Caffeine-free cocoa white tea and preparation method

The invention discloses caffeine-free cocoa white tea and a preparation method. The preparation method comprises steps as follows: withering, enzyme deactivation, cooling, twisting, drying and the like. According to the preparation method, fresh raw materials have the water content of 40%-50% in short time by controlling the illumination intensity, the withering time is greatly shortened, caffeine, amino acid and soluble sugar can be better protected, and the prepared tea has rich glossiness, tastes mellow, has higher aftertaste and strong aroma and meets demands of consumers in the market.

Owner:GUANGDONG TAKSON FOOD PROCESSING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com