Method for performing liquid fermentation on black tea juice by using green and aged tea

A technology for liquid fermentation and green stale tea, applied in the direction of tea extraction and pre-extraction tea treatment, can solve the problems of loss of typical quality and flavor characteristics, deterioration of tea quality, color and aroma changes, etc., to improve the overall flavor quality, increase content, The effect of red and bright soup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

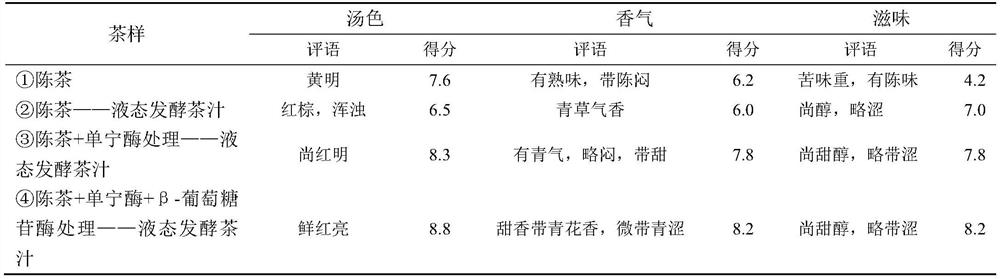

Embodiment 1

[0026] Embodiment 1: A kind of method utilizing green old tea liquid fermentation black tea juice

[0027] (1) The raw material of fresh leaves is Longjing 43 fresh leaves (autumn tea) with one bud and four leaves in mid-October. The fresh leaves are frozen and withered, frozen at -20°C for 4 hours, and thawed for 1 hour;

[0028] (2) Put 4 g of green aged broken tea (20 mesh) into a conical flask, pour 200 mL of hot water at 85°C for 20 min, and prepare a crude catechin extract;

[0029] (3) Add 8mg (addition amount w / w is 0.2%), 5000U / g tannase to the crude catechin extract obtained in step (2), and enzymolyze 7.5min at 50°C to obtain enzymolyzed catechin crude extract;

[0030] (4) Weigh 6 g of the frozen withered leaves obtained in step (1) for homogenization treatment, 300 mL of water, level 2, 30s×4;

[0031] (5) Pour the homogenate obtained in step (4) into the crude extract of enzymolysis catechin, add 1g, that is, 0.25% (w / v) β-glucosidase, at 35°C, add 0.2% ferment...

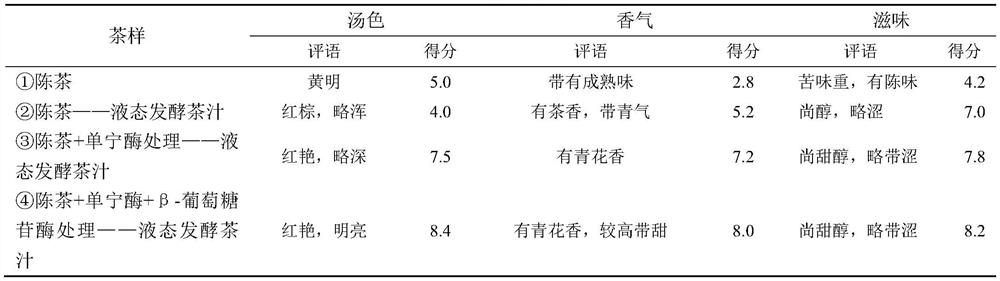

Embodiment 2

[0035] Embodiment 2: A kind of method utilizing green old tea liquid fermentation black tea juice

[0036] (1) The raw material of fresh leaves is Longjing 43 fresh leaves (winter tea) with one bud and two leaves in mid-December. The fresh leaves are frozen and withered, frozen at -20°C for 24 hours, and thawed for 1 hour;

[0037] (2) Put 4 g of green aged broken tea (20 mesh) into a conical flask, pour 200 mL of hot water at 85°C for 20 min, and prepare a crude catechin extract;

[0038] (3) Add 8mg (addition amount w / w is 0.2%), 5000U / g tannase to the crude catechin extract obtained in step (2), and enzymolyze 7.5min at 50°C to obtain enzymolyzed catechin crude extract;

[0039] (4) Weigh 6 g of the frozen withered leaves obtained in step (1) for homogenization treatment, 300 mL of water, level 2, 30s×4;

[0040] (5) Pour the homogenate obtained in step (4) into the crude extract of enzymolysis catechin, add 1g, that is, 0.25% (w / v) β-glucosidase, at 35°C, add 0.2% fermen...

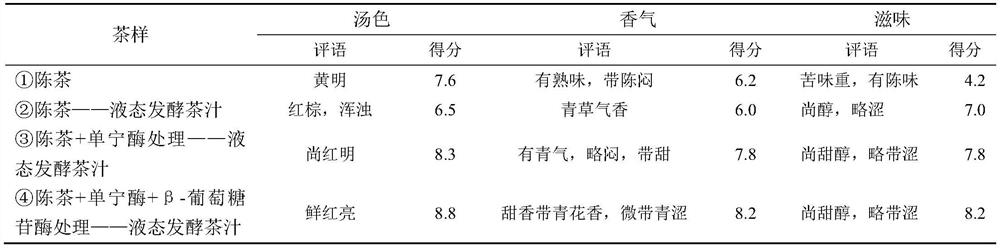

Embodiment 3

[0044] Embodiment 3: A kind of method utilizing green old tea liquid fermentation black tea juice

[0045] (1) The raw material of fresh leaves is Longjing 43 fresh leaves (winter tea) with one bud and two leaves in mid-December. The fresh leaves are frozen and withered, frozen at -20°C for 4 days, and thawed for 1 hour;

[0046] (2) Put 4g of low-grade green tea into a conical flask, pour 200mL of 85°C hot water for extraction for 20min, and prepare a crude catechin extract;

[0047] (3) Add 8mg (addition amount w / w is 0.2%), 5000U / g tannase to the crude catechin extract obtained in step (2), and enzymolyze 7.5min at 50°C to obtain enzymolyzed catechin crude extract;

[0048] (4) Weigh 4 g of the frozen withered leaves obtained in step (1) for homogenization treatment, 200 mL of water, level 2, 30s×4;

[0049] (5) Pour the homogenate obtained in step (4) into the crude extract of enzymolysis catechin, add 1g, that is, 0.25% (w / v) β-glucosidase, at 35°C, add 0.2% fermentatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com