Processing method of Wuniuzao black tea

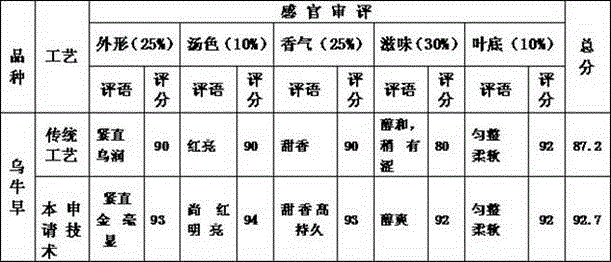

A processing method and technology of Wu Niu Zao, applied in the direction of pre-extraction tea treatment, climate change adaptation, etc., can solve the problems of insufficient deep-level development and utilization of tea, bitter taste, unstable product quality, etc., to achieve pleasant aroma, The taste is mellow and thick, and the effect of saving withering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The processing method of Wuniuzao black tea is characterized in that it comprises the following steps:

[0036] (1) Picking of raw materials: pick the fresh leaves of Wuniu Zaocha tree in late March as raw materials, and the picking standard is one bud and one leaf;

[0037] (2) Drying: spread the fresh leaves thinly on the dustpan with a thickness of 1-2cm; at 17:00 in the afternoon, place them outdoors for 20 minutes when the sunlight is weak;

[0038] (3) Withering: thinly spread the sun-dried green leaves in step (3) on a dustpan for indoor withering, the thickness of the spread leaves is 1-2cm, and the withering time is 13 hours;

[0039] (4) Kneading: Put the withered leaves in step (4) into the tea kneading machine and knead for 40 minutes; the specific operation is: knead for 25 minutes in empty space, 5 minutes with light pressure, 5 minutes with medium pressure, 8 minutes with heavy pressure, and then Knead on empty for 2-3 minutes. .

[0040] (5) Fermentat...

Embodiment 2

[0048] The processing method of Wuniuzao black tea is characterized in that it comprises the following steps:

[0049] (1) Picking of raw materials: pick the fresh leaves of Wuniu Zaocha tree in mid-May as raw materials, and pick one bud and one leaf as standard;

[0050] (2) Drying: spread the fresh leaves thinly on the dustpan with a thickness of 1-2cm; place them outdoors for 15 minutes at 17:40 in the afternoon when the sunlight is weak;

[0051] (3) Withering: thinly spread the sun-dried green leaves in step (3) on a dustpan for indoor withering, the thickness of the spread leaves is 1-2cm, and the withering time is 13 hours;

[0052] (4) Kneading: put the withered leaves in step (4) into the tea kneading machine and knead for 40-50 minutes; the specific operation is: first empty kneading for 25 minutes, light pressing for 5 minutes, then medium pressure kneading for 5-8 minutes, heavy pressing 8~10 minutes, then empty knead for 2-3 minutes.

[0053] (5) Fermentation: Unb...

Embodiment 3

[0058] The processing method of Wuniuzao black tea is characterized in that it comprises the following steps:

[0059] (1) Picking of raw materials: the fresh leaves of Wuniu Zaocha tree in late August are picked as raw materials, and the picking standard is one bud and one leaf;

[0060] (2) Drying: Spread the fresh leaves thinly on the dustpan with a thickness of 1-2cm; at 17:30 in the afternoon, place them outdoors for 10 minutes when the sunlight is weak;

[0061] (3) Withering: thinly spread the sun-dried green leaves in step (3) on a dustpan for indoor withering, the thickness of the spread leaves is 1-2cm, and the withering time is 14 hours;

[0062] (4) Kneading: put the withered leaves in step (4) into the tea kneading machine and knead for 40-50 minutes; the specific operation is: first empty kneading for 25 minutes, light pressing for 5 minutes, then medium pressure kneading for 5-8 minutes, heavy pressing 8~10 minutes, then empty knead for 2-3 minutes.

[0063] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com