Patents

Literature

43results about How to "Tight and thin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Roasted famous high-quality green tea and production process thereof

InactiveCN102669313AGuaranteed qualityPromote hydrolysisPre-extraction tea treatmentTemperature controlGreen tea

The invention relates to roasted famous high-quality green tea and a production process thereof, belongs to the technical field of tea processing, and provides a production process of roasted famous high-quality green tea to effectively improve quality of the green tea. The production process includes steps of fresh tea leaf fixation, shaping and drying. Fresh tea leaves are further cured before fixation by placing the fresh tea leaves in a precision temperature control device at the set temperature of 35DEG C to 36 DEG C for 2-4 hours of curing.

Owner:中国测试技术研究院生物研究所

Technique for processing black tea

The invention relates to a technique for processing black tea, comprising the following steps of picking mono-bud-trilobate fresh tea leaves as raw materials; spreading and airing the fresh leaves for 1-2 hours, and shriveling; spreading the aired tea leaves uniformly on a shriveling trough with the thickness of 3-4 cm and the shriveling time of hours 2-3 hours, and rolling the tea leaves until the weight loss rate of the tea leaves reaches 35-38 percent; rolling for 90-120 minutes, and putting the tea leaves into a dynamic steaming machine; regulating the steaming temperature in the dynamic steaming machine to 200-210 DEG C, and steaming at high temperature for 20-30 minutes; uniformly mixing the high-temperature steamed tea leaves with water with the mass ratio of 38 percent, putting the mixture on a fermentation bed, and fermenting for 3-5 hours at the fermentation room temperature of 24-25 DEG C, the humidity of 89-93 percent and the leaf temperature of 26-33 DEG C; putting the fermentation product into a dryer, carrying out first drying at the temperature of 120-130 DEG C, spreading and airing the tea from the dryer in time, and carrying out secondary drying on the tea at the temperature of 100-110 DEG C after water in the tea is uniformly distributed; and finally, obtaining finished tea by distilling flavor for one hour.

Owner:贵州贵天下盛兴茶业有限公司

Processing method of green tea

ActiveCN102960482APromote sustainable developmentImprove tree down ratePre-extraction tea treatmentGreen teasProcess engineering

The invention provides a processing method of green tea, which is used for solving the problem of bitter taste of a large amount of green tea produced in Sichuan province. The processing method of the green tea is characterized by comprising the following steps of: picking fresh leaf, tedding green leaves, deactivating enzymes, rolling, conducting first-step roasting, conducting secondary rolling, conducting deblocking, conducting second-step roasting, spreading and airing, roasting to be dry, spreading and airing, and drying and extracting flavor, wherein twice rolling processes are carried out by hot rubbing. According to the processing method of the green tea, the bitter taste of the large amount of the green tea produced in the Sichuan province can be effectively reduced, the quality of tea leaves can be improved, and the heavy, mellow, fresh and brisk degrees can be increased; and the good foundation is established for expanding the tea markets of Sichuan and promoting the export of the tea in Sichuan.

Owner:YIBIN CHUANHONG TEA IND GRP

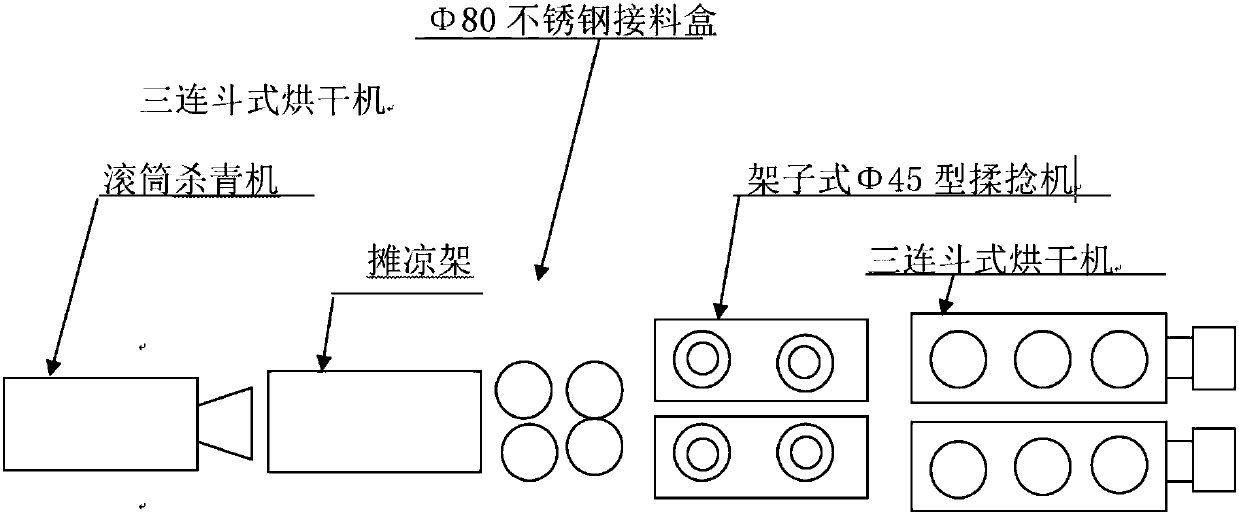

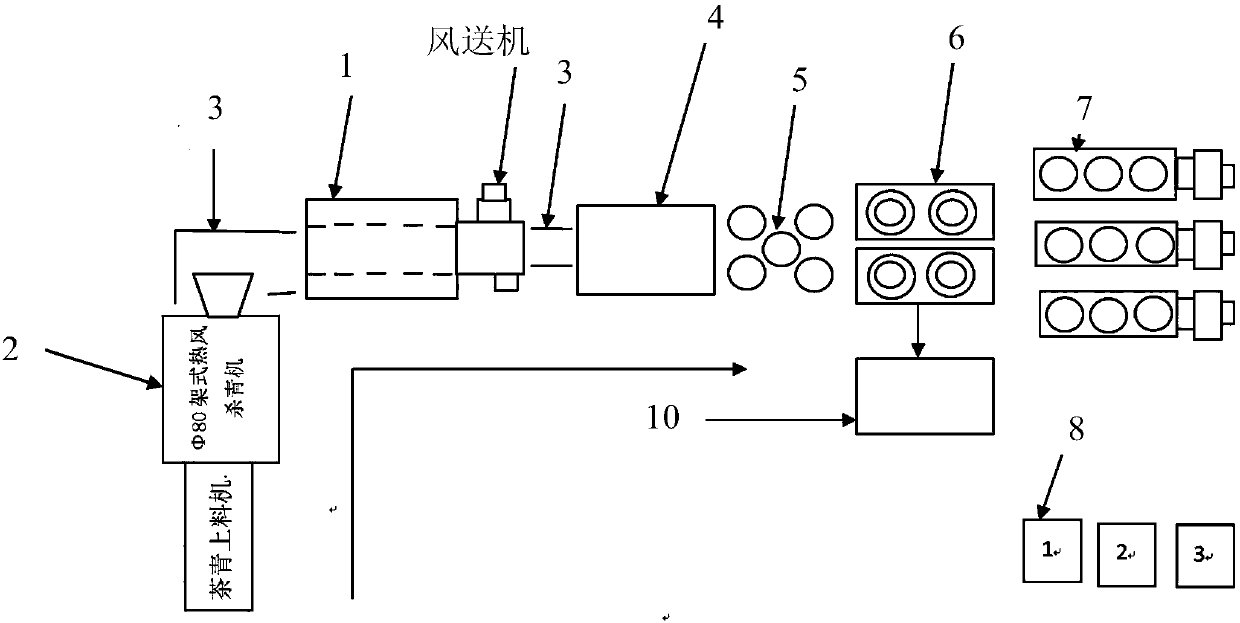

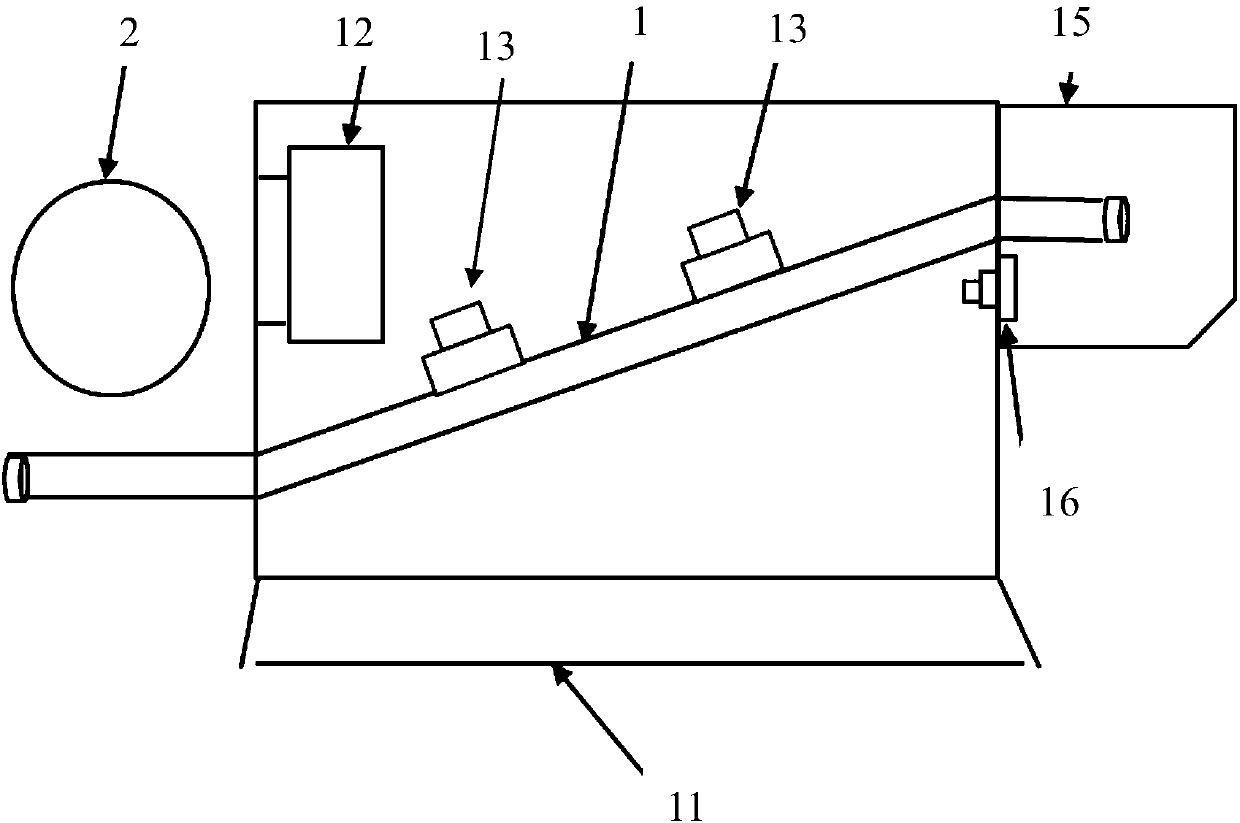

Mechanized method for processing styliform green tea

InactiveCN101366419AThe shape is tight, thin, round and straightBright green colorPre-extraction tea treatmentGreen teaEnzyme

The invention belongs to the technical field of tea manufacture, in particular to a method for mechanically processing acicular green tea. The method is characterized in that fresh green tea leaves are prepared into tea with acicular shape through spreading, enzyme deactivating, tightening, sorting, solidifying, drying, flavoring and other steps. The acicular well-known tea has the characteristics of tight, thin, round and straight strips, shape similar to pine straw, bright and green color and luster, silver tip exposedness, pure fragrance, fresh and rich taste, tender green and bright liquor color, tender and uniform leaves and the like. The tea quality can completely reach the level of manually processing, and the method is applicable to mechanical processing production.

Owner:HUAZHONG AGRI UNIV

Pericarpium citri reticulatae dark green tea and processing method thereof

ActiveCN102960491AUnique tasteGreat tastePre-extraction tea treatmentPericarpium citri reticulataeGreen tea

The invention provides pericarpium citri reticulatae dark green tea and a processing method thereof aiming at the problem of single type of dark green tea. The pericarpium citri reticulatae dark green tea provided by the invention comprises dark green tea and pericarpium citri reticulatae and is prepared according to the mass ratio of the dark green tea and the pericarpium citri reticulatae of 1:(0.35-0.45). The processing method of the pericarpium citri reticulatae dark green tea comprises the steps of scenting the dark green tea and the pericarpium citri reticulatae which are prepared primarily, and then uniformly mixing the scented dark green tea and pericarpium citri reticulatae particles according to the mass ratio of 15:(0.8-1). The pericarpium citri reticulatae dark green tea has the superior advantages of the dark green tea and the pericarpium citri reticulatae and has the double health protection effects. According to the pericarpium citri reticulatae dark green tea, the types of the dark green tea are added, and a new road is searched for the tea industry.

Owner:YIBIN CHUANHONG TEA IND GRP

Method for processing strip green tea

The invention discloses a method for processing strip green tea, wherein an artificially assisted shaping and flavoring process is added into the common green tea processing method, so that the shape of tea leaves is tight, thin, round, straight and uniform, and is of a great visual art value; meanwhile, the full conversion and polymerization of the contents and the flavor components are promoted, thus the specific quality characteristics of strong flavor, pure taste and refreshing property are achieved.

Owner:成都市碧涛茶业有限公司

Processing method of Congou black tea

InactiveCN104430993AStrong tendernessRich in endoplasmPre-extraction tea treatmentOrange FlavorBlack tea

The invention discloses a processing method of Congou black tea. Common fresh tea leaves are taken as raw materials and the processing method comprises the following steps of cold air withering, hot air withering, spreading, rolling, fermenting and drying. According to the invention, the original technology of Congou black tea is inherited, improved and innovated, so that the problems of low efficiency and high quality fluctuation of Congou black tea in the production process are solved effectively; the prepared Congou black tea is thin and fine, shows peak seedlings, is smooth in color, has bright red and yellow soup color, is mellow in taste, has heavy sweet orange flavor, is bright red in leaf bottom, and lays a good foundation for occupying the tea leaf market for the Congou black tea.

Owner:YIBIN CHUANHONG TEA IND GRP

Straight-strip-type Maofeng and preparation method thereof

PendingCN107439717AEasy to loseDissipate evenlyPre-extraction tea treatmentFragrance extractionGreen tea

The invention relates to the technical field of process of tea leaves, and particularly relates to straight-strip-type Maofeng and a preparation method thereof. The preparation method comprises the following steps: picking fresh leaves, spreading, carrying out fixation, carrying out cooling resurgence, rolling for the first time, carrying out dynamic water loss, rolling for the second time, deblocking, tidying tea strips, tedding, drying for the first time, tedding, drying for the second time, tedding, drying for the third time, sieving and carrying out infrared fragrance extraction. The straight-strip-type Maofeng adopts the processes of multi-time molding, multi-section drying, quick cooling and the like, the produced tea strips are tight, straight and green, the inside fragrance is lasting and shows chestnut fragrance, the soup is yellowish green and bright, the taste is mellow and sweet after drinking, and leaf bottom is uniform; furthermore, the preparation method is simple, has the advantages that the quality of Maofeng type green tea is improved, the optimization of large-scale green tea is realized, and also has important significance on industry transformation and upgrading.

Owner:四川省农业科学院茶叶研究所 +1

Summer black tea production technology

InactiveCN103828947ATight and thinBlack and oily in colorPre-extraction tea treatmentCooking & bakingEconomic benefits

The invention relates to a summer black tea production technology and especially relates to a technology for preparing black tea from summer raw materials. Summer raw materials harvested in June, July, and August are selected, the summer raw materials are re-withered by specific processes of the technology in specific time, the re-withered summer raw materials are rolled, the rolled summer raw materials are re-fermented by specific processes of the technology in specific time, and the re-fermented materials are subjected to unique production processes such as gross fire, complete fire and long-time re-baking. The produced black tea strips are tightly shrunk, are fine and have a black color, oily touch, and sugar and honey fragrances. The soup of the summer black tea has a bright red color, a mellow and mild taste, no bitter taste, and even and orderly tea bottom. The summer black tea production technology reduces a bitter taste of the summer black tea, realizes a sweet taste of the summer black tea and improves economic benefits of the summer black tea.

Owner:LISHUI AGRI SCI

Method for making naked green tea

The invention relates to a method for making tea, and in particular relates to a method for making naked green tea. The method comprises the following steps: 1) spreading green tea leaves; 2) removing water; 3) kneading; 4) performing primary baking; 5) finely kneading, namely, finely kneading the primarily baked tea leaves by using a fine kneading machine, setting the temperature at 70 DEG C, feeding 5kg of the leaves, and kneading for 30-40 minutes so as to obtain the tea leaf bars which are compact, fine, round and straight, like pine needles in shape and green and smooth in color, taking out the tea leaves, and spreading out for 30 minutes; 6) drying and enhancing the fragrance, namely, drying till the moisture content is 5-6% and subsequently enhancing the fragrance. Compared with a conventional green tea making process, the method for making the baked green tea, which is provided by the invention, additionally adopts a fine kneading procedure for enabling the bars to be fine and compact, fixing the fresh and green color and promoting the formation of fragrance and taste of green tea, and thus the made baked green tea has the advantages that the tea bars are fine, round and straight, the tea leaves are resistant to water soaking, the leaves are long-lasting in fragrance, the buds and the leaves are complete, the tea can be stored, the color is green and smooth, and the like.

Owner:谢荣富

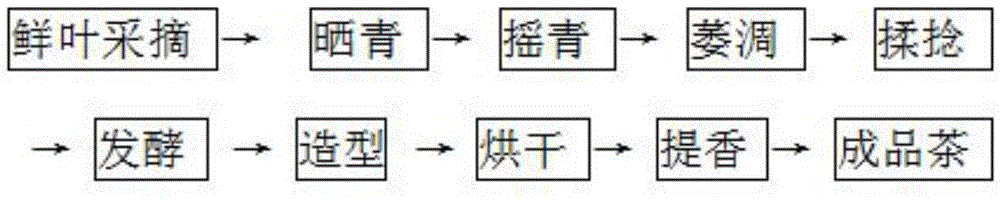

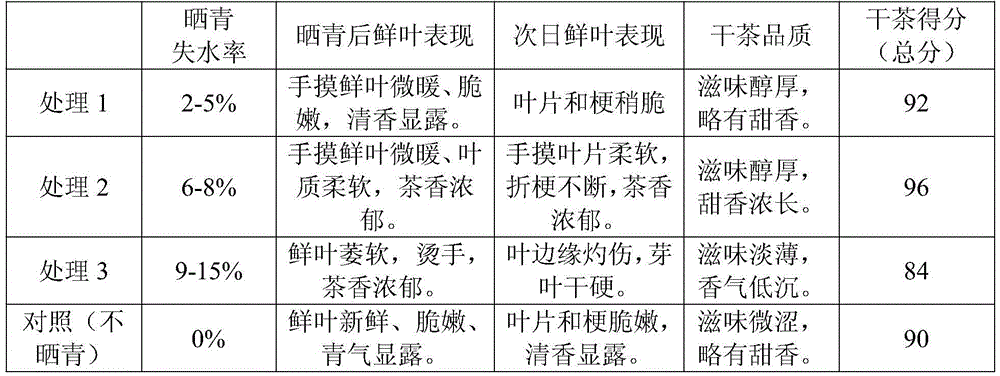

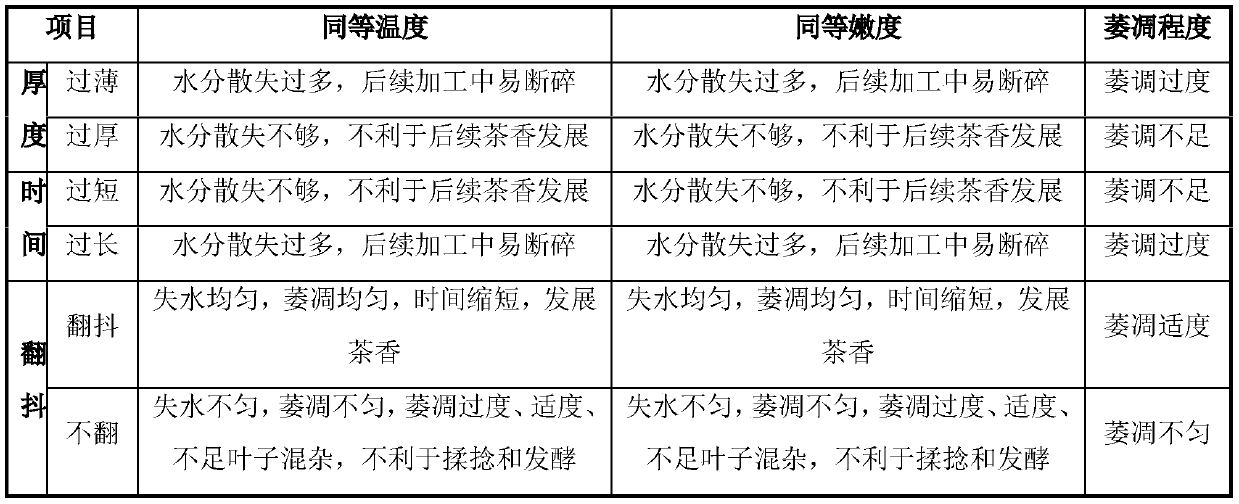

Processing method of Guanyin black tea having aroma

ActiveCN107865125AReduce color changeImprove distributionPre-extraction tea treatmentClimate change adaptationTemperature controlBlack tea

The invention provides a processing method of Guanyin black tea having aroma, and belongs to the technical field of processing of tea leaves. The processing method comprises the following steps of selecting Tieguanyin tea trees, picking fresh leaves, performing sunning with soft sunlight, performing cooling, rocking the cooled leaves for the first time, shining the rocked leaves, and performing rocking for the second time; and performing temperature-controlled withering in an air conditioning room, performing rolling, performing deblocking, performing fermentation, performing drying with a first fire, performing drying with a full fire, performing aroma increasing and performing packing. The made Guanyin black tea is tight and thin in strips, the soup color is red and bright, the taste ismellow, fresh and brisk, the Guanyin black tea has special aroma of Guanyin tea, and sweet aroma of black tea, and the Guanyin black tea is long in fragrance and rich in Guanyin tea fragrance.

Owner:南宁茗韵茶业有限公司

Preparation method of scented tea

InactiveCN104585372ASoup color transparentStrong tastePre-extraction tea treatmentQuality characteristics

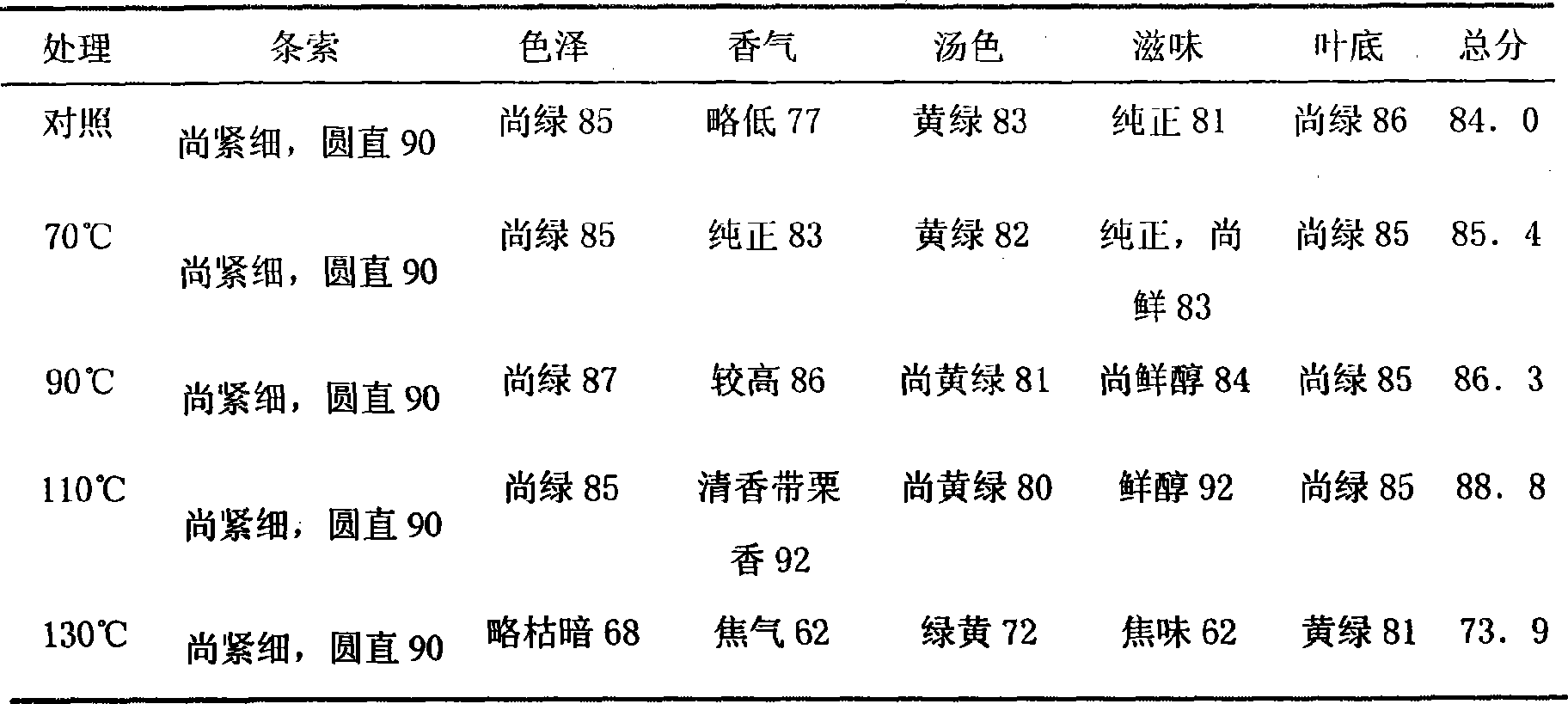

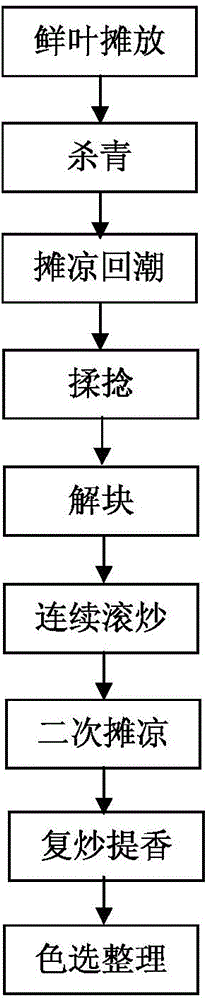

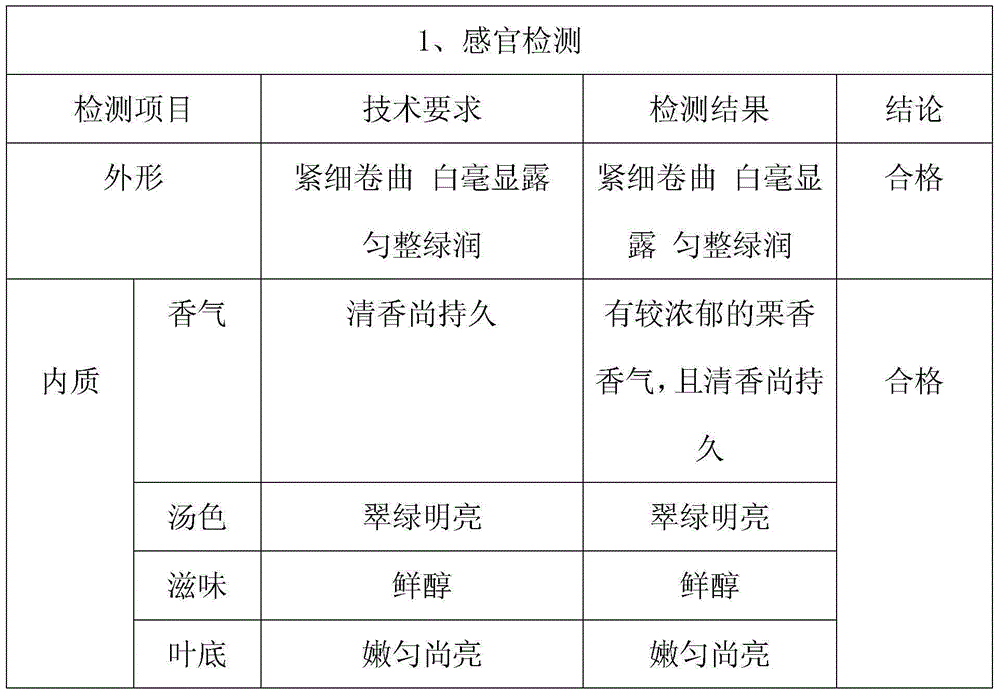

The invention discloses a preparation method of scented tea. The method comprises the following steps: spreading fresh leaves; carrying out fixation; cooling and dampening; rolling, deblocking, and continuously rolling and frying; cooling for the second time, re-roasting, extracting fragrance, carrying out color sorting and arrangement. According to the scented tea obtained by the preparation method, strips are tight, fine and curly, the soup is clear, the fragrance is intense and lasting, the taste is thick and cool, and the brewed leaf is green and clear, and the scented tea has the quality characteristics of tight strip, green color, intense fragrance and thick taste.

Owner:松阳县农业局 +1

Process for making green tee

InactiveCN105104599AInhibits enzymatic oxidationAccelerate evaporationPre-extraction tea treatmentWater contentSizing

The invention discloses a process for making green tee, which comprises steps: 1 deterioration; 2 de-enzyming; 3 cool sharing; 4 softening; 5 rolling; 6 secondary de-enzyming; 7 first baking; 8 secondary cool sharing; 8 secondary baking; 9 sizing; and 10 packaging warehousing. Green tee which is prepared through the process for making the green tee is strong in chestnut aroma, long in duration time of aroma, is below 5% in water content of tea, low in water content, long in retention time, verdant in color, uniform and tidy in shape, revealed in pekoes, crimp in trabs and excellent in quality of tee, fresh and pure in taste, sweet, clear in liquor color, light, green and bright in infused leaves, and can achieve grades above one or more.

Owner:GUIDING YIFENG TEA IND CO LTD

Green tea processing technology

The invention relates to a green tea processing technology, and belongs to the tea processing technology. The green tea processing technology includes the following steps: spreading and drying picked fresh tea leaves in air, and freezing for 6 to 24 hours under the condition of the temperature of -20 to 6 DEG C; firstly withering the frozen tea leaf raw material for 6 hours; after withering is completed, measuring and calculating the water content in the tea leaf raw material, and calculating the time required for drying the tea leaf raw material; and drying the tea leaf raw material in a vacuum microwave device, drying until the water content of the tea leaf raw material is 3% to 6%, and thus obtaining the green tea finished product. The green tea prepared by the technology is tight and slender in strip ropes, jade green in color and luster, green yellow, bright and clear in liquor color, and rich in nutrition, has pekoe revealed, also can be brewed with cold or hot purified water, and has lasting tea aroma.

Owner:贵州都云毛尖茶叶有限公司

Processing method of summer raw material tea

ActiveCN105166103AReduce bitternessImprove palatabilityPre-extraction tea treatmentHydrolysisCatechin

The invention relates to a processing method of a summer raw material tea. The processing method comprises the steps of performing fixation; rolling tea leaves on which fixation is performed; drying the rolled tea leaves for the first time; sufficiently drying the tea leaves dried for the first time; and after the fixation, braising the tea leaves in an insulation can at the temperature of 36-42 DEG C, which is performed between the step of the fixation and the step of rolling the tea leaves on which fixation is performed, or / and between the step of rolling the tea leaves on which fixation is performed and the step of drying the rolled tea leaves for the first time, or / and between the step of drying the tea leaves for the first time and the step of sufficiently drying the dried tea leaves. According to the processing method disclosed by the invention, dehydrated summer raw material teas are loaded into the insulation can to be braised at a high temperature while the dehydrated summer raw material teas are hot, so that the degradation of tea polyphenol is facilitated, and particularly the hydrolysis of ester catechins and the hydrolysis of saccharide and protein are facilitated; therefore, the bitterness of a summer tea is reduced, mellow and refreshing taste is formed, the bitterness of the processed tea leaves is obviously reduced, the palatability is strengthened, and the tea forming rate is increased.

Owner:CHONGQING ACAD OF AGRI SCI

Manufacturing method of orange black tea

InactiveCN110892929AStrong tendernessRich in endoplasmPre-extraction tea treatmentTea flavoringBiotechnologySugar

The invention belongs to the field of tea processing, and specifically relates to a manufacturing method of orange black tea. The orange black tea is composed of the following components in parts by weight: 3-8 parts of tangerine, and 10-17 parts of black tea. According to the present invention, by inheriting, improving and innovating the process of black tea preparation, the problems of low efficiency and large quality fluctuation in the production process of black tea are effectively solved; and the prepared orange black tea has a compact appearance, a fine peak seedling, an oily color, a bright red and yellow soup, a sweet and mellow taste, a strong aroma of orange sugar, and a bright and red leaf bottom, and the method lays a good foundation for the development of the orange black teamarket.

Owner:贵州省黎平县蝉之声农业发展有限公司

Preparation method for flower fragrance black tea

InactiveCN104304520APromote generationChen Xiang outstandingPre-extraction tea treatmentBlack teaEngineering

The present invention provides a preparation method for flower fragrance black tea. The method comprises the following steps: at first, picking and collecting needed fresh flowers, washing and drying the flowers after removing impurities, bagging dried flowers into cloth bags, placing the cloth bags into a steam cabinet, covering the cloth bags with a layer of breathable spacer fabric; uniformly paving withered tea leaves on the breathable spacer fabric to steam for 3-5 hours; taking out the tea leaves, air-drying the tea leaves, mixing tea fruits with tea stalks, adding water to the mixture, and decoct the mixture into tea soup; pour the tea soup into the tea leaves according to a certain ratio, uniformly stirring the tea leaves, and fermenting the tea leaves for 2-4 hours; and placing the fermented tea leaves into corresponding molds to mold by steaming, and carrying out drying and packaging to obtain finished products. The scheme effectively promotes the transformation of tea leaves contents and the generation of tea leaf fragrant molecules, and ensures that the black tea has quality characteristics of a significant aging flavor, light natural flower fragrance, a thick and mellow taste, smoothness, sweetness and pleasure.

Owner:湖南益阳香炉山茶业股份有限公司

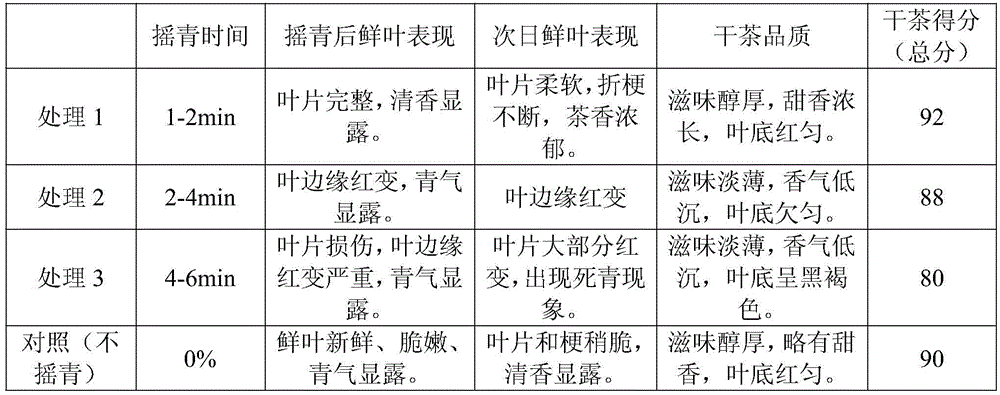

High-aroma Maojian and processing technology thereof

InactiveCN107348027AEfficient volatilizationEffective penetrationPre-extraction tea treatmentCooking & bakingSweetness

The invention provides high-aroma Maojian and a processing technology thereof. The processing technology comprises the following steps of performing spreading for cooling, performing rocking of green tea leaves, performing fixation, performing screening, performing moisture regain, performing rolling, performing baking, performing trimming, performing strip tidying and preparing finished products. The high-aroma Maojian is obtained through the processing technology. The high-aroma Maojian is fine and round in dried tea strips, slightly tippy, high in aroma, rich in flower aroma, clear, fresh, green and bright rather than turbid in tea soup color, mellow, fresh and refreshing in taste, obvious in sweetness after taste, and uniform and consistent in leaf bases, and the sense organ enjoyment of people when the people drink the high-aroma Maojian is greatly improved.

Owner:信阳市农业科学院

Method for semi-manually and semi-mechanically processing Xinyang Maojian tea leaves

InactiveCN105104586AStable qualityTight and thinPre-extraction tea treatmentChemistryEpigallo-catechin gallate

The invention belongs to the technical field of green tea processing, and concretely provides a method for semi-manually and semi-mechanically processing Xinyang Maojian tea leaves. The method comprises the following steps: processing fresh leaves; deactivating enzymes through a continuous roller enzyme deactivating machine; rolling through using a rolling machine; carrying out hot rolling and stir-frying strip forming by using a small Xinyang Maojian tea stir-frying strip forming machine; manually finishing strips; and drying by using charcoal fire. The method allows Xinyang Maojian tea obtained through the method to reach traditional Xinyang Maojian tea quality and dry tea to have stable quality and fine profile, and has the advantages of labor intensity reduction, production efficiency increase, production cost reduction, and large-scale standardized production of the Xinyang Maojian tea.

Owner:XINYANG AGRI & FORESTRY UNIV

Black tea oxygen introducing fermentation processing method and device

InactiveCN104824187AGuarantee product qualityShorten processing timePre-extraction tea treatmentBlack teaWater vapor

Owner:GUIZHOU TEA RES INST

Gold dragon tea processed by adopting Wuniuzao tea and preparation method thereof

InactiveCN105454484AShorten withering timeIncrease contentPre-extraction tea treatmentMineralogyRaw material

The invention discloses a preparation method of gold dragon tea processed by adopting Wuniuzao tea, which comprises the following steps: harvesting raw materials, sunning, rocking of green leaves, withering, rolling, straight-bar shaping, drying and fragrance extraction. The invention also provides the gold dragon tea processed by adopting the Wuniuzao tea. The preparation method is scientific, reasonable, simple and perfect and realizes normalized and large-scale production of Wuniuzao tea, so as to meet the requirement of tea lovers on excellent tea quality.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

Ilex latifolia thunb black tea and processing method thereof

ActiveCN111418668AReduce bitternessStable tastePre-extraction tea treatmentClimate change adaptationBlack teasTea leaf

The invention relates to Ilex latifolia thunb black tea and a processing method thereof, and belongs to the field of tea processing. The processing method of the Ilex latifolia thunb black tea comprises the following steps: withering fresh leaves, splicing the fresh leaves, performing primary rolling, performing primary fermentation, performing primary baking, performing secondary rolling, performing secondary fermentation and performing drying to obtain the Ilex latifolia thunb black tea. According to the ilex latifolia thunb black tea prepared by the method, the tastes of congou black tea and small-leaf ilex latifolia thunb are well fused together, the bitter tastes of the congou black tea and the small-leaf ilex latifolia thunb are reduced, and the Ilex latifolia thunb black tea has thefresh and sweet fragrance of the congou black tea and sweet aftertaste of the small-leaf ilex latifolia thunb and has a stable taste.

Owner:YIBIN SHUANGXING TEA IND

Pericarpium citri reticulatae dark green tea and processing method thereof

ActiveCN102960491BUnique tasteGreat tastePre-extraction tea treatmentPericarpium citri reticulataeGreen tea

Owner:YIBIN CHUANHONG TEA IND GRP

Compound tae and preparation method thereof

The invention provides compound tea and a preparation method thereof, and belongs to the fields of tea leaves and a processing method thereof. The compound tea comprises the following components in parts by weight: 100-200 parts of Fuyun No.6, 20-30 parts of semen platycladi and 20-30 parts of lupulus. In the preparation process, the preparation method comprises the following steps of tedding fresh leaves of Fuyun No.6, carrying out enzyme fixation, rolling and baking, spraying semen platycladi on tedded and baked lupulus after being prepared into an extracting solution, and then baking together with Fuyun No.6. The compound tea prepared by the invention can keep the original fragrance of tea leaves, and can overcome the problems that the existing green tea easily irritates the stomach and causes insomnia so as to induce a weak body and the like.

Owner:吴苏文

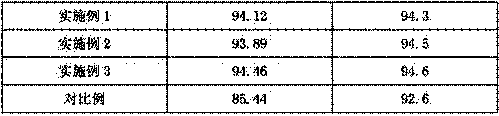

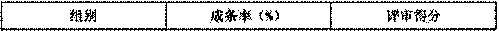

Rolling method for Maojian tea

The present invention discloses a rolling method for Maojian tea, and the the rolling method includes the following specific steps: putting enzyme-denatured leaves of Maojian tea raw materials into arolling barrel of a rolling machine, and making the amount of leaves thrown into the rolling barrel being natural filling; making the rolling time being 14-20 minutes; carrying out pressurizing in thefollowing order when rolling tea leaves: non-pressure rolling 1-2 minutes, light-pressure rolling 3-4 minutes, slightly heavy-pressure rolling 3-5 minutes, non-pressure rolling 1-2 minutes, slightlyheavy-pressure rolling 4-5 minutes and non-pressure rolling 2 minutes. The rolling pressure in the invention adopts a progressive pressurizing method, which is different from a rolling method of "light-heavy-light", the progressive pressurizing method is to slowly pressurize the tea leaves according to the forming law of the tea leaves to make the tea leaves gradually formed, and then to pressurize and tighten tea strips to make the tea leaves tightened, slender, elegant and beautiful. The principle process of the progressive pressurizing method for rolling is: non-pressure, light pressure, slightly-heavy pressure and non-pressure. The rolling rate reaches 94.46% by adopting the progressive pressurizing method.

Owner:黄桂兰

A kind of preparation method of black tea

ActiveCN104054857BIncrease productivityTight and thinPre-extraction tea treatmentBlack teaFermentation

The invention discloses a method for making black tea, which comprises the following steps: withering of fresh leaves, rolling, fermenting, cooling down, drying and refrigerating. This method is easy to control the degree of withering, and the rolling time is short, which improves the production efficiency of tea leaves, and the prepared black tea has tight and thin strands, dark and lustrous color, full of luster, with the fragrance of green grass, bright leaf bottom, good quality and easy to brew. The color of the tea soup produced is red and bright, which is another good choice for the production method of tea drinks.

Owner:贵州省凤冈县浪竹有机茶业有限公司

A kind of processing method of raw material tea in summer

ActiveCN105166103BReduce bitternessImprove palatabilityPre-extraction tea treatmentBiotechnologyTea catechin

The invention relates to a processing method of a summer raw material tea. The processing method comprises the steps of performing fixation; rolling tea leaves on which fixation is performed; drying the rolled tea leaves for the first time; sufficiently drying the tea leaves dried for the first time; and after the fixation, braising the tea leaves in an insulation can at the temperature of 36-42 DEG C, which is performed between the step of the fixation and the step of rolling the tea leaves on which fixation is performed, or / and between the step of rolling the tea leaves on which fixation is performed and the step of drying the rolled tea leaves for the first time, or / and between the step of drying the tea leaves for the first time and the step of sufficiently drying the dried tea leaves. According to the processing method disclosed by the invention, dehydrated summer raw material teas are loaded into the insulation can to be braised at a high temperature while the dehydrated summer raw material teas are hot, so that the degradation of tea polyphenol is facilitated, and particularly the hydrolysis of ester catechins and the hydrolysis of saccharide and protein are facilitated; therefore, the bitterness of a summer tea is reduced, mellow and refreshing taste is formed, the bitterness of the processed tea leaves is obviously reduced, the palatability is strengthened, and the tea forming rate is increased.

Owner:CHONGQING ACAD OF AGRI SCI

A kind of processing method of granule flower fragrance type Huangdan black tea

ActiveCN105746739BFloralMellow tastePre-extraction tea treatmentClimate change adaptationBlack teaGreen tea

The invention discloses a processing method of granular flower-fragrance Huang Dan black tea. The method includes the steps of fresh tea leaf picking, sunning, light rocking, withering, rolling, fermentation, fixation, piling, shaping, unpiling, secondary piling, secondary shaping, secondary unpiling, drying, fragrance increasing and the like .The fresh leaves of the Huang Dan tea plants are taken as the raw materials, the sunning, rocking and shaping processes of oolong and the fixation process of green tea are combined with the traditional black tea processes, and accordingly the degree of bitterness is reduced; a shaping machine is utilized to tightly roll the big leaves into strips which are then made into granules, and accordingly the Huang Dan black tea is tighter, finer and more attractive in appearance, easy to pack, mellow in taste and strong in flower fragrance.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

Tea leaf processing technology and processing equipment thereof

InactiveCN107771971ASolve the problem of easy yellowingTroubleshoot technical issues with ZoomPre-extraction tea treatmentRoom temperatureEngineering

The invention relates to a tea leaf processing technology and processing equipment thereof. The method comprises the following steps: cooling tea leaves of which water is removed at the temperature of120-180 DEG C to the temperature of 1-5 DEG C within 10-15 seconds through an air cooler room; moisturizing the cooled tea leaves; twisting the tea leaves moisturized in the step two and heating thetwisted tea leaves to the normal temperature; and cooling the normal-temperature tea leaves twisted in the step three to the temperature of 1-5 DEG C in an air-cooling box. A water-removing machine, the air cooler room, a moisturizer, a collecting box, a twisting machine and the air-cooling box of the tea leaf processing equipment are successively connected through a conveyer. The technical problem that during processing by a traditional process, the tea leaves become yellow and brown easily is solved. In addition, feasible specific implementing equipment is provided.

Owner:贵州名仕农业旅游科技有限公司

A kind of production technology of summer heat black tea

InactiveCN103828947BTight and thinBlack and oily in colorPre-extraction tea treatmentCooking & bakingBlack tea

The invention relates to a summer black tea production technology and especially relates to a technology for preparing black tea from summer raw materials. Summer raw materials harvested in June, July, and August are selected, the summer raw materials are re-withered by specific processes of the technology in specific time, the re-withered summer raw materials are rolled, the rolled summer raw materials are re-fermented by specific processes of the technology in specific time, and the re-fermented materials are subjected to unique production processes such as gross fire, complete fire and long-time re-baking. The produced black tea strips are tightly shrunk, are fine and have a black color, oily touch, and sugar and honey fragrances. The soup of the summer black tea has a bright red color, a mellow and mild taste, no bitter taste, and even and orderly tea bottom. The summer black tea production technology reduces a bitter taste of the summer black tea, realizes a sweet taste of the summer black tea and improves economic benefits of the summer black tea.

Owner:LISHUI AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com