Rolling method for Maojian tea

A Maojian tea and kneading machine technology, which is applied in tea treatment before extraction, can solve the problem of low processing rate and achieve the effect of light green and bright soup color, tight and thin appearance, and good process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

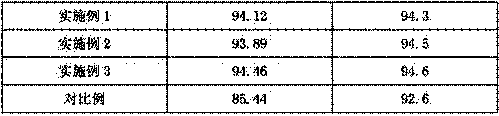

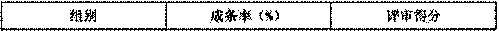

Examples

Embodiment 1

[0020] The specific steps of the method for rolling and twisting Maojian tea of the present invention are as follows:

[0021] Put the final leaves into the kneading barrel of the kneading machine, and the amount of leaf throwing is based on the degree that the kneading barrel is naturally filled; the kneading time is 16min; when kneading, press in the following order: no pressure kneading 1min→light pressing kneading 4min→slightly heavy pressing kneading 3min→No pressure kneading for 2min→Slightly heavy pressure kneading for 4min→No pressure kneading for 2min.

[0022] The rolling and twisting machine is 6CR30 type.

[0023] The pressure-free parameter is the position where the cover of the kneading machine is flush with the upper edge of the kneading barrel.

[0024] The parameter of light pressing is that the handle of the kneading machine rotates 4-5 times in a clockwise direction, and the kneading cover drops 1.6-2cm from the edge of the barrel.

[0025] The parameter of a littl...

Embodiment 2

[0028] The specific steps of the kneading method of the present invention are as follows:

[0029] Put the raw materials of Maojian tea into the kneading bucket of the kneading machine, and the amount of leaf throwing is based on the natural filling kneading bucket; the kneading time is 18min; when kneading, press in the following order: no pressure kneading 2min→light pressing kneading 3min→ Slightly press and twist for 5min→no pressure for 1min→slightly press for 5min→no pressure for 2min.

[0030] The said kneading machine is type 35.

[0031] The pressure-free parameter is the position where the cover of the kneading machine is flush with the upper edge of the kneading barrel.

[0032] The parameter of light pressing is that the handle of the kneading machine rotates 4-5 times in a clockwise direction, and the kneading cover drops 1.6-2cm from the edge of the barrel.

[0033] The parameter of a little heavier pressure is that the knob of the kneading machine rotates 8-9 times in a ...

Embodiment 3

[0036] The specific steps of the method for rolling and twisting Maojian tea of the present invention are as follows:

[0037] Put the raw leaves of Maojian tea into the kneading barrel of the kneading machine, and the amount of leaf throwing is based on the natural filling of the kneading barrel; the kneading time is 17min; when kneading, press the following sequence: no pressure kneading 1min→light pressing kneading 4min→ Slightly press and twist for 4min→no pressure for 1min→slightly press for 5min→no pressure for 2min.

[0038] The rolling and twisting machine is 45 type.

[0039] The pressure-free parameter is the position where the cover of the kneading machine is flush with the upper edge of the kneading barrel.

[0040] The parameter of light pressing is that the handle of the kneading machine rotates 4-5 times in a clockwise direction, and the kneading cover drops 1.6-2cm from the edge of the barrel.

[0041] The parameter of a little heavier pressure is that the knob of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com