Patents

Literature

67results about How to "Bright green soup" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for cultivating tea

InactiveCN1663350ARich biodiversityImprove the ecological environmentCultivating equipmentsDry seasonTea plantation

The invention discloses a method for cultivating tea comprising the steps of, tea plantation sun screening, planting deciduous arbor around the tea plantation and between the tea trees, covering the tea plantation through rice straw and planting bean green manure, applying special-purpose fertilizer for organic tea, inoculating beneficial soil organisms and soil creatures including right amount of earthworm, finally carrying out irrigation through mini- sprinkling irrigation system in high temperature dry seasons.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

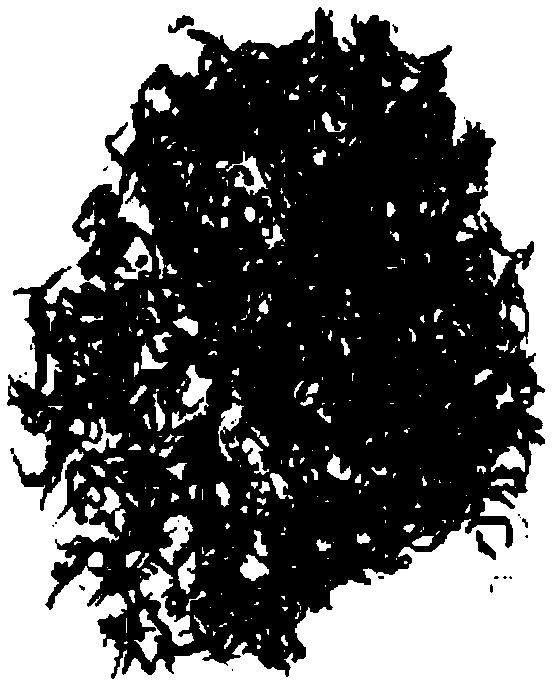

Green tea and processing method thereof

ActiveCN104186736AImprove freshnessImprove quality foundationPre-extraction tea treatmentGreen teasProcess engineering

The invention relates to a processing method of green tea. The processing method comprises the processing steps of raw material selection, picking, spreading, fixation, spreading, rolling, shaping, baking and the like, wherein the types of selected raw materials are strictly controlled to be Nanjiang #1, Zaobaijian #5 or Fuding Dabai tea; the raw materials are required to be picked in a harmless ecological tea garden at the elevation of 550-650m in sunny days in the middle of March under the temperature of 20-25 DEG C. The processing method is executed by the processing technologies such as high-quality raw material selection and optimized spreading, so that the quality of the green tea is improved.

Owner:CHONGQING YUNLING TEA IND TECH

Control method of weed in tea garden

InactiveCN101379926ASmall temperature fluctuationsHinder photosynthesisFertilising methodsWeed killersAlligatorTea leaf

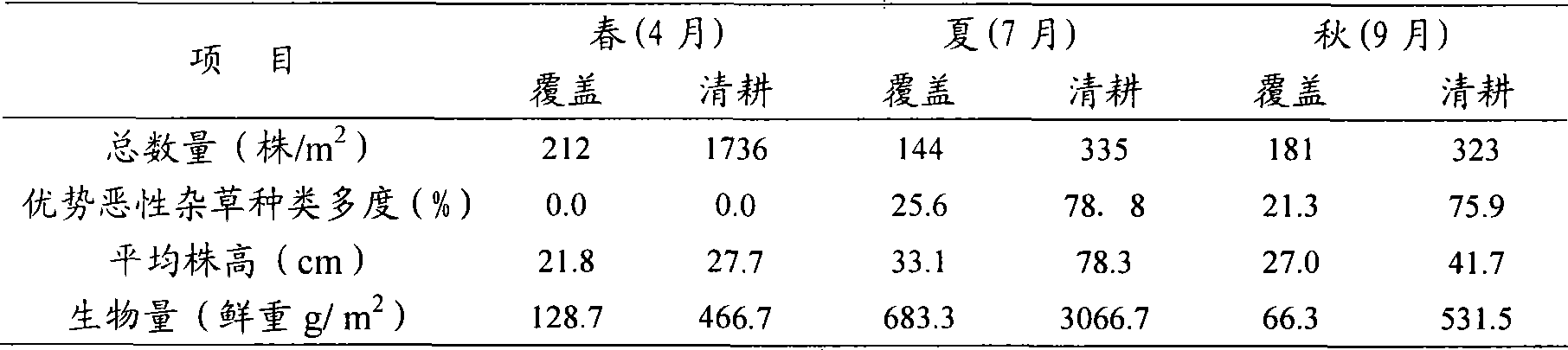

The invention discloses a method for controlling weeds in a tea garden, which comprises the following steps: first, plowing is carried out on the ground between tea plant rows in winter to remove root systems of the weeds such as nutgrass flatsedge, alligator alternanthera, greenbrier, chinaroot greenbrier, cogongrass, smartweed, lygodium and the like; a high-quality organic fertilizer is applied in spring: a certain amount of rape seed cake fertilizer is broadcast; the ground is covered with rice straws in spring: after the rape seed cake fertilizer is broadcast, all tea plant rows in the garden are immediately evenly covered with a certain amount of the rice straws; the high-quality organic fertilizer is applied in summer: a proper amount of the rape seed cake fertilizer is broadcast at a certain time; and the ground is covered with the rice straws in summer: after the rape seed cake fertilizer is broadcast, all tea plant rows are immediately evenly covered with a certain amount of the rice straws. The method enriches biodiversity of the tea garden, improves the ecological condition of the tea garden, increases tea yield, improves the quality of tea leaves; in addition, the method has the advantage of simple operation, is easy to be accepted by tea growers and has great popularization and application prospect.

Owner:HUNAN XIANGFENG TEA

White tea processing method

InactiveCN101658212AUniform whole rateImprove qualityPre-extraction tea treatmentMoisture regainTea leaf

The invention discloses a white tea processing method. The method comprises the following steps: fresh tea leaves spreading to cool; water removal; moisture regain; light kneading: light kneading on fresh tea leaves in a kneading machine for 20-30 min after moisture regain; pressurization for 4-6min in mid-process; strip arrangement; shaping and drying. The light-kneading procedure is added to theprocedures of the original fresh tea leaves spreading, water removal, moisture regain, strip arrangement, shaping and drying, so the quality of the white tea is obviously improved, i.e. wrinkled andcompact strips are luster, green and bright in water, good and lasting in aroma, cool and heavy in taste, and the like. The tea manufacture process is convenient to operate. The tea leaf block is reduced after being lightly kneaded, so the strip management, shaping and drying procedures are favorable, the fine package and the storage and transportation are convenient, and the appearance is improved. The light kneading procedure is added into the original manufacture procedures, the crushing rate of the white tea is uniform, the tea water is golden, and the quality of the white tea is more perfect. The invention takes the tea leaves contacting the cover plate of the kneading machine as reference to guarantee the moderate kneading pressure, therefore guaranteeing the kneading effect.

Owner:JIANGSU YIYUAN TEA

Manufacturing method of Jinshan green-buds tea leaves

The invention discloses a manufacturing method of Jinshan green-buds tea leaves, and provides the complete manufacturing method from a cultivating process to a processing process, wherein the cultivating process comprises selection and reclamation of garden plot, selection and breeding of tea seedlings and garden management, and the processing process is from plucking and selecting of raw materials to picking, rejecting and warehousing finally. The finished product of the processed tea leaves is flat, firm and sharp in shape, bright green in color, tippy in state, uniform in size, brisk and mellow in taste, light green and bright in tea soup color, and the elaborate tea leaves with fine work, high quality and prominent characteristic meet demands of tea fans with high-quality requirements.

Owner:句容谷歌庄园现代农业科技发展有限公司

Processing method of tippy tea

The invention discloses a processing method of tippy tea, which comprises the following steps: selecting medium and small-sized leaves of which the length is 1.7cm-3.2cm, wherein each medium and small-sized leaf comprises one single bud or one bud and one leaf; spreading and greening the leaves, removing water, and conveying and quickly cooling the water-removing leaves simultaneously; naturally regaining the moisture of the leaves in the conveying process, and automatically putting the moisture-regaining leaves into a twisting machine through a conveying and lifting machine; twisting, conveying and lifting the leaves: twisting the leaves until the twisted leaves are basically in strip shapes, have verdant leaf color, soft strips and slight fragrance and are sticky; mechanically conveying the leaves uniformly; preliminarily baking the leaves, and conveying and quickly cooling the preliminarily baked leaves simultaneously; spreading and airing the leaves from bottom to top in a blowing way on a spreading and airing platform; and forming, thinning and drying the leaves. The invention realizes the purpose of mechanically, continuously and cleanly processing the tippy tea, and simultaneously improves the quality and the yield of the processed products.

Owner:都匀供销茶叶有限责任公司

Honeysuckle green tea and production method thereof

ActiveCN104222399AAvoid destructionOvercome the problems of dull color and poor product qualityTea extractionMicrowaveBud

The invention relates to a honeysuckle green tea and a production method thereof. The method comprises picking honeysuckle buds of the three-green period, radiating the buds through a film with infrared rays of the rate of power of 5kW for 20-30 seconds and then water-removing the buds through microwaves for 2 minutes at a temperature of 80-90 DEG C, and during the microwave water-removing process, adjusting the moisture removal according to the color and the water content of the water-removed buds; timely blowing and cooling the water-removed buds for 20-30 minutes; rolling the buds for 8-10 minutes in a gentle and short-time mode; drying the buds through microwaves for 2-3 minutes at a temperature of 80-85 DEG C; flavoring the buds for 30-60 minutes to obtain the honeysuckle green tea. The honeysuckle green tea comprehensively improves the appearance and the color as well as internal qualities such as fragrance and taste of honeysuckle substituting tea and accordingly is a novel honeysuckle green tea product integrating high quality, health care and ornamental value.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Green tea preparation method

InactiveCN104663934AHigh nutritional valueNo pollution in the processPre-extraction tea treatmentNutritive valuesBud

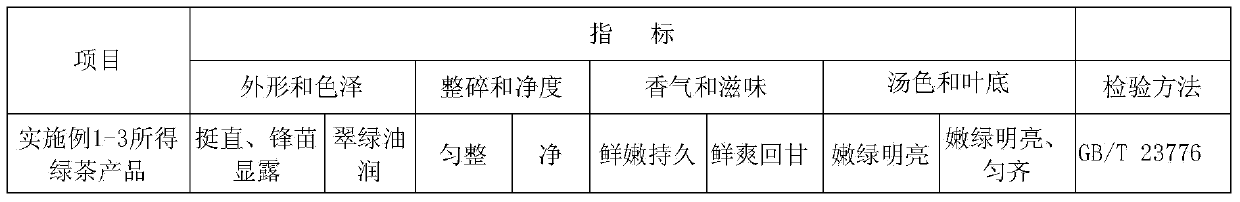

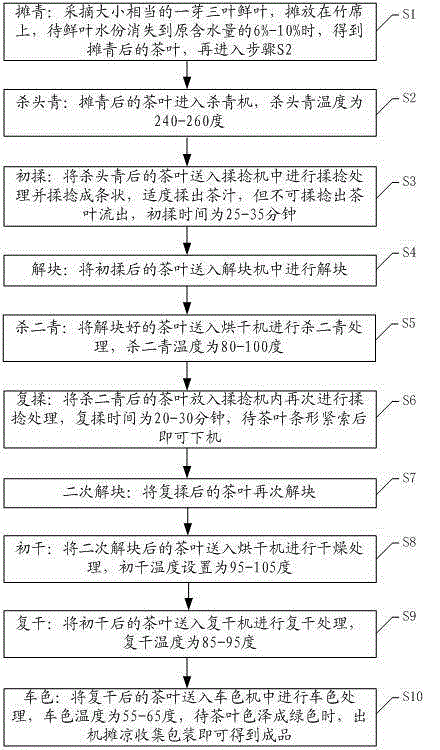

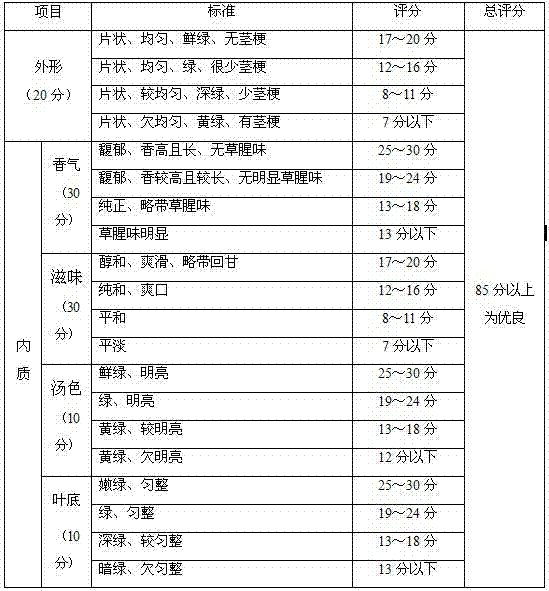

The invention provides a green tea preparation method. The method comprises the following steps: sequentially performing tea leaf spreading, primary de-enzyme, primary rolling, unblocking, secondary de-enzyme, secondary rolling, secondary unblocking, primary drying, secondary drying and polishing on fresh leaves of a picked bud with three leaves with the same sizes; collecting and packaging the leaves to obtain a finished product. Green tea prepared by using the method is high in nutritive value, pollution-free and additive-free. The liquor color of the tea leaves is green and bright, the fragrance is clean and lasting, and the taste is mellow and strong.

Owner:曾次炎

Method of improving black tea quality

InactiveCN103053716AStrong stress resistanceSolid appearancePre-extraction tea treatmentDiagnostic Radiology ModalityBlack tea

The invention relates to a method of improving black tea quality, in particular to a method and a production technique of utilizing optimizing raw materials combination and polymorphic biological enzymes to improve the quality of the traditional black tea. Production cycle is reduced and the quality of the black tea can be improved. Geoherbalism and functionality of black tea products can be guaranteed. Applicability of the black tea products can be enlarged. A defect of similar product modality can be overcome.

Owner:贺志弘 +2

Preparation method of low grass flavor mulberry leaves and products thereof

The invention discloses a preparation method of low grass flavor mulberry leaves and products thereof. The preparation method is simple and composed of the following steps: picking up fresh mulberry leaves, spreading out the fresh mulberry leaves to form a layer with the thickness of 10-15cm, airing the fresh mulberry leaves, until the water content is 68-72 wt%, so as to form pre-processed mulberry leaves; fixing the mulberry leaves at 280-330 DEG C for 0.5-1.5 minutes; dropping the temperature of the mulberry leaves to 20-30 DEG C; drying the mulberry leaves at 90-130 DEG C, until the water content is 15-20 wt%; rolling, sieving, and collecting the mulberry leaf flaps; finally drying the mulberry leaf flaps at 80-120 DEG C, until the water content is 2-7 wt%, so as to form the low grass flavor mulberry leaves. The low grass flavor mulberry leaves are formed into the flap shape, and fresh green without bones and muscles; the tea soup smells fragrant, looks fresh green and bright, and tastes smooth and cool, and leaf bases are clear green and regular, thus the low grass flavor mulberry leaves are very popular among consumers.

Owner:SOUTHWEST UNIVERSITY

Method for making flat green tea

ActiveCN102696794AReduce breakage rateImprove integrityPre-extraction tea treatmentGreen teasEngineering

The invention discloses a method for making flat green tea. The method comprises the steps of spread cooling of fresh leaves, green killing, spread cooling, reshaping, spread cooling and air drying, fragrance increasing and handpicking, wherein at the spread cooling and air drying step, the reshaped tea leaves are taken out of the pan and uniformly spread in a spread cooling slot, the thickness of the tea leaves is 1 to 2cm, the air is continuously blown to dry the tea leaves until the water content of the tea leaves reaches 8 to 9 percent, and finally the spread cooling and air drying process is completed. By the spread cooling method of air-blow drying, the water content of the tea leaves is greatly lowered, therefore the method has the advantages that (1) by the processing method, the broken tea and tea dust generated in the drying process are reduced, and the breaking rate of bud-tea shoot tips is lowered, so that the integrity of the bud-tea is improved; (2) the processing cost is lowered by nearly 25 percent and the energy is saved by nearly 30 percent; and (3) the color of green tea is brightened, and because the spread cooling and air drying process is adopted in the drying process, the color of green tea is kept all the time, and the influence of fluctuating temperature in the drying process on the quality of tea leaves is completely avoided.

Owner:湄潭银柜山茶业有限公司

Production method of green tea low in cost, green and high in aroma

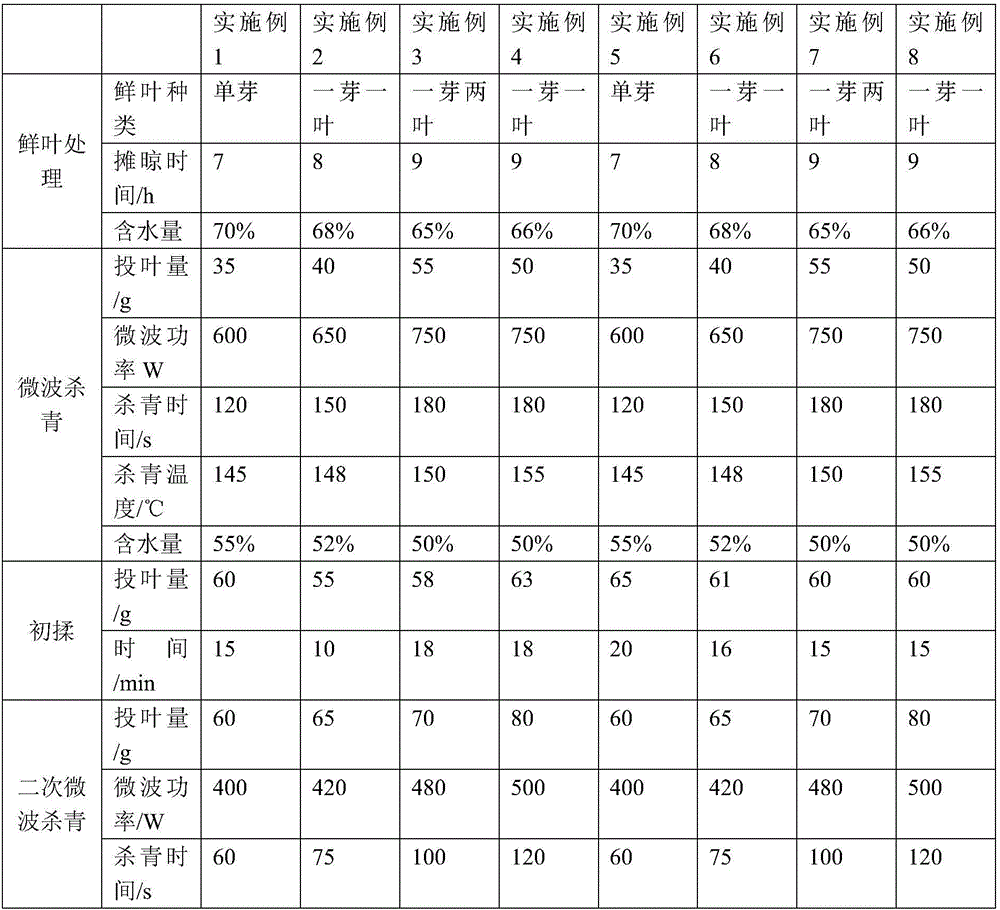

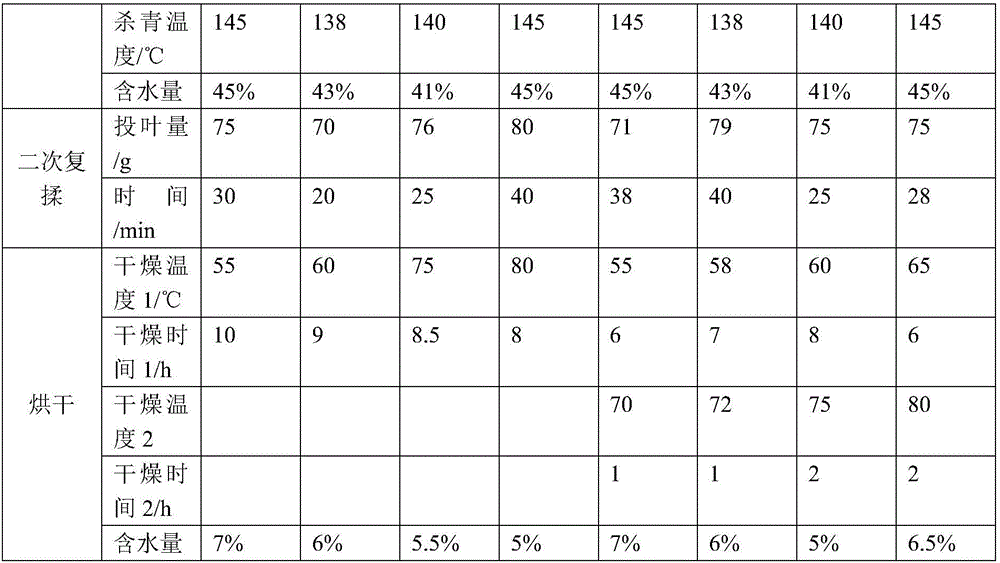

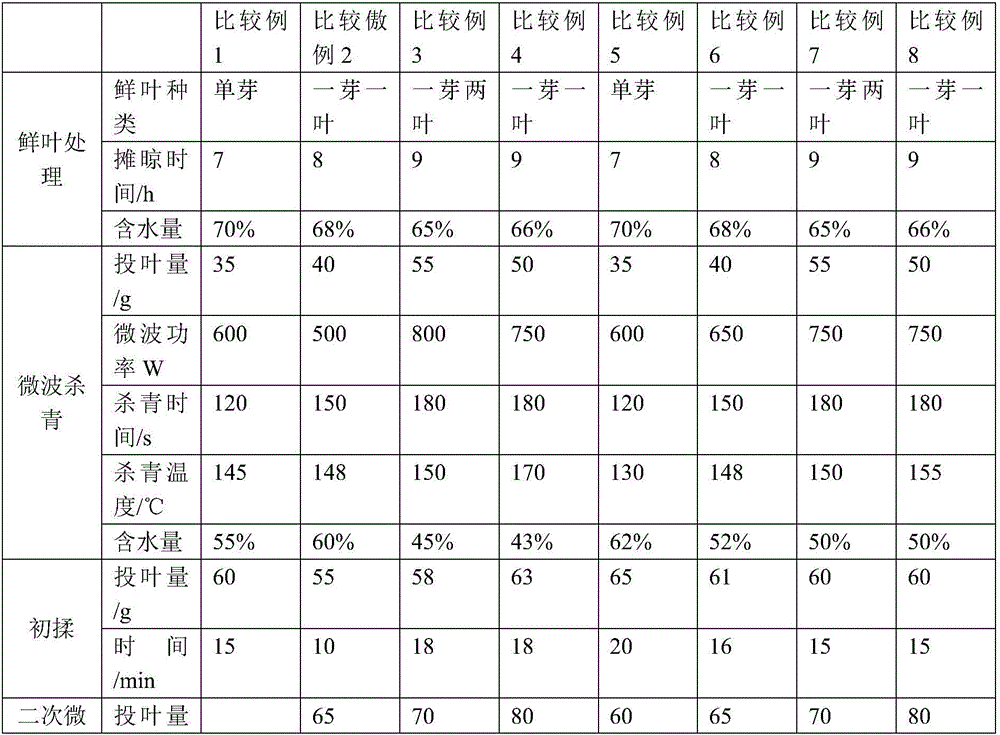

The invention discloses a production method of green tea low in cost, green and high in aroma. The production method comprises the following steps of (1) performing spreading for cooling: taking fresh tea leaves, and spreading the taken tea leaves for cooling for 7-9 hours so that the water content is reduced to 65-70%; (2) performing microwave fixation: performing microwave fixation on the fresh leaves which are spread for cooling in the step (1) so as to obtain fixation leaves of which the water content is 50-55%: (3) performing primary rolling: performing primary rolling on the fixation leaves; (4) performing secondary microwave fixation: performing microwave supplementary fixation on the primary fixation leaves once again so as to obtain secondary fixation leaves of which the water content is 40-45%: (5) performing secondary re-rolling: performing secondary rolling on the secondary fixation leaves so as to obtain shaping leaves; and (6) performing vacuum drying: performing vacuum drying on the shaping leaves after the secondary re-rolling so as to obtain the green tea of which the water content is 5-7% finally. The green tea is emerald green and compact in shape, tender green and bright in soup color, fresh, refreshing and mellow in taste, tender green and bright in leaf bases, strong in fragrance, and fresh and tender.

Owner:东莞市哥布林文化传媒有限公司

Tea processing method

The invention relates to the method for preparing nutritious buck wheat milk tea beverage which comprises the steps of fresh leaf processing, water-removing, airing, sorting the strips, shaping, spreading, drying, refining and fragrance extracting.

Owner:刘晓海

Pine needle powder green-keeping and fresh-keeping treatment method and pine needle health protection tea

ActiveCN103444927ARetain chlorophyll contentExtended shelf lifePre-extraction tea treatmentBiotechnologyChlorophyllin

The invention relates to a preparation method of Chinese herbal medicine tea and in particular relates to a pine needle powder green-keeping and fresh-keeping treatment method and pine needle health protection tea. According to the pine needle powder green-keeping and fresh-keeping treatment method, pine needles after being soaked and cleaned are dried by adopting a two-step method, a de-enzyming temperature in a de-enzyming step is 150 DEG C, de-enzyming time is 1-2 minutes, colour of the pine needles is changed into natural bright green after de-enzyming is finished, and more chlorophylls are reserved owning to shorter de-enzyming time; besides, the pine needles are cured, so that further bitterness is further reduced; in a low-temperature roasting step, a roasting temperature is 80-90 DEG C, and roasting time is 17-20 minutes, so that pharmaceutical ingredients in the pine needles can be effectively dissolved out after pine needle tea is made, and nutritional ingredients of the pine needle powder made by utilizing the pine needle powder green-keeping and fresh-keeping treatment method are effectively reserved.

Owner:吴杨森

Processing method of green tea with sweet aftertaste

InactiveCN108124982AImprove flavor qualityDark green oily colorPre-extraction tea treatmentEmeraldGreen tea

The invention provides a processing method of green tea with sweet aftertaste. The method comprises technological steps as follows: 1), fresh tea leaves are spread for airing; 2), the spread green tealeaves obtained in step 1) are subjected to fixation processing; 3), the spread tea leaves obtained in step 2) are subjected to carding processing; 4), the tea leaves subjected to carding in step 3)are subjected to rolling processing; 5), the rolled tea leaves obtained in step 4) are subjected to shaping processing; 6), the shaped tea leaves obtained in step 5) are subjected to primary drying processing; 7), the primarily dried tea leaves obtained in step 6) are fried to dry by a continuous fry-drying machine. According to the technical scheme, the produced green tea with the sweet aftertaste is high in flavor quality and has blackish green and lubricant color, strong mellow and refreshing taste and obvious sweet aftertaste, the aroma is tender, strong and long-lasting, and the soup color is emerald green and bright. By means of organic combination, improvement and perfection of a traditional technology and a special technology, the green tea with the sweet aftertaste, which is affordable and has strong and mellow aftertaste and strong and long-lasting aroma, is provided for customers.

Owner:都匀市高寨水库茶场有限公司

Autumn green-tea production method

InactiveCN101422202AImprove soil fertilityRich biodiversityPre-extraction tea treatmentFertilising methodsFertilizerChemistry

The invention discloses a method for producing green tea in autumn, which comprises the following steps: a special fertilizer for organic tea is applied; mechanical picking or labor picking with limitation is carried out and the picking strength is to cut 1 / 2 of new shoot growing in autumn; a trellis is put up in the tea garden and a shading net is covered to conduct shading; low temperature (24 DEG C to 26 DEG C) drying is carried out; green removing is carried out when the temperature of the inlet barrel of a fixation machine is 195 DEG C to 215 DEG C, the air temperature at the tea inlet is 100 DEG C to 110 DEG C and the temperature of the outlet barrel is 145 DEG C to 155 DEG C; and drying and shaping are conducted in a curing machine, the temperature is controlled to be the temperature of the air intake at the beginning, tea is thinly laid in a plate made of bamboo sheets to be cooled until the surface of the tea is colloidal and pekoe shows out. The method is simple, has low cost, increases the production of the green tea in hillside tea garden, obviously improves the quality of the tea in autumn and is conducive to conduct scale production of high quality green tea in autumn in the hillside area of Yangtze River.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI +1

Asparagus green tea processing making method

InactiveCN105394294AImprove utilization structureDoes not affect earningsTea substituesSocial benefitsFlavor

The present invention relates to an asparagus green tea processing making method, and belongs to the tea processing production field, the asparagus green tea processing making method comprises the following steps: 1) harvesting; 2) cleaning; 3) sorting; 4) tedding of fresh leaves; 5) cutting of asparagus; 6) deactivation of enzyme; 7) first cooling by spreading out; 8) first firing; 9) secondary cooling by spreading out; 10) final firing; 11) third cooling by spreading out; 12) flavor increasing; and 13) vacuum package; wherein before the tedding of fresh leaves, the asparagus is sorted, different types of the asparagus are tedded by different tedding methods, and two times of deactivation of enzyme can be performed, the retention of active ingredients in the asparagus is maximized, the taste of the asparagus tea is optimized, the developed product is emerald green and fresh and alive in appearance color, pure and rich in fragrance, mellow and sweet in taste, emerald green and bright in infused leaves and free of green flavor, and can be accepted by consumer groups. In addition, the asparagus tea improves the structure of the traditional use of the asparagus, the asparagus tea can take full advantage of older materials, the old asparagus raw material is turned into treasure from waste, and economic and social benefits are significant.

Owner:GUANGXI POLYTECHNIC

Preparation method of jasmine and cathaya argyrophylla green tea

InactiveCN105454522ASlightly flat shapeUnified specificationsPre-extraction tea treatmentFlavorThirst

The invention discloses a preparation method of jasmine and cathaya argyrophylla green tea, and belongs to the technical field of tea making. The jasmine and cathaya argyrophylla green tea is prepared through the steps of tea leaf selection, jasmine selection, fixation, cooling by spreading, tea strip tidying and rolling, thrice scenting, re-firing and drying, and the like. The jasmine and cathaya argyrophylla green tea prepared by the invention is slightly flat in appearance, indistinctly green in tomentum, constant in specification, verdant and bright in liquor color, heavily strong, durable and pure in fragrance and mellow, pure and cool in tea flavor, and is novel healthcare tea having the effects of clearing liver, improving vision, encouraging the production of body fluids to extinguish thirst, eliminating phlegm, treating dysentery, reducing blood fat, preventing arteriosclerosis, whitening and the like.

Owner:张莘蔓

Method for processing flat green tea by employing tea variety chuanmu No.28

InactiveCN104738231ASolve uneven and opaque finishingSolve quality problemsPre-extraction tea treatmentFlavorGreen tea

The invention discloses a method for processing a flat green tea by employing a tea variety chuanmu No.28. The method is characterized by comprising the following steps: (1) picking fresh leaves; (2) standing for green; (3) carrying out fixation; (4) tidying tea strips; (5) forming; (6) roasting and polishing; and (7) drying. Compared with the prior art, the flat green tea is prepared by adopting robust independent buds of the tea variety chuanmu No.28; through the process, the problems that the robust independent buds are not uneven or thorough in fixation, and the prepared tea is relatively poor in quality are solved; and the flat green tea which is flat, smooth and green in appearance, upright, forceful and full in buds after being brewed, green and bright in soup, light in fragrance, rich in flowery flavor, fresh in taste, fresh and alive, soft, uniform and regular in infused leaf, and excellent in quality can be produced.

Owner:SICHUAN AGRI UNIV +1

Method for producing pine leaf-shaped tea

InactiveCN101658223ABright green soupLong-lasting fragrancePre-extraction tea treatmentTea substituesBudCell budding

The invention discloses a method for producing pine leaf-shaped tea, which is produced by using single-bud tea leaves freshly expanded one bud one leaf and by fixing, twisting, shaping, spreading, cooking, drying and other processes. The tea leaf product has the unique characteristics that: the tea shape and appearance are uniform; the tea leaves soaked in hot water assume a needle shape and inversely fall down to bottom with an aesthetic effect; the color of the tea water is light green and bright; the fragrance of the tea water is fresh and long-lasting; and the stewed tea leaves are light green and complete; and the like. The tea meets the demands of customers for a noble, green, quick and fashion life.

Owner:宋百满

Processing method of green bud tea

InactiveCN103444920AImprove the effect of inner fragranceGuaranteed moisture contentPre-extraction tea treatmentTea leafHorticulture

The invention provides a processing method of green bud tea. The processing method comprises the steps of fresh bud picking, withering, steam deactivation, fine hair removing, shaping, final roasting and fragrance extracting with big fire, and then a green bud tea finished product is obtained. According to the processing method, the green bud tea processing steps are all optimized, the green bud tea deactivation method is especially renovated, mechanical degree is high, and tea leaf automatic production is facilitated. According to the green bud tea prepared by the method, buds are complete, leaf bottoms are emerald-green, tea color is light-green and bright, the specific fragrance and flavor of the steam-deactivation greed bud tea are achieved, and color, aroma and taste of the green bud tea are all great.

Owner:SICHUAN FULI TEA

Method for enhancing fragrance of green tea

InactiveCN108029795AGreen appearanceBright green soupPre-extraction tea treatmentUltravioletUltraviolet irradiation

The invention discloses a method for enhancing fragrance of green tea and belongs to the technical field of tea. The method comprises the steps of spreading, airing, killing out, cooling, rolling, drying and perfuming, wherein protective agent fine powder is uniformly sprayed onto the surface of a raw material, and intermittent ventilation is carried out in a cooling process; and ultraviolet irradiation is carried out in a perfuming process. A final product prepared by the method is green and moist in appearance, bright in soup color, persistent in fragrance, and mellow and normal in taste; leaf bases are yellow green and bright; and a loss of nutrients is low.

Owner:山东乡村之光农业科技发展有限公司

Health care wild tea

InactiveCN105875932AEmerald green colorAroma is mellowPre-extraction tea treatmentBitter gourdAllergy

The invention discloses health care wild tea, which is prepared from the following raw materials: wild tea leaves, honeysuckle flower, wild chrysanthemum flower, bitter gourd, mint, raw liquorice roots, radix sophorae flavescentis, rhizoma ligustici wallichii, radix angelicae, safflower, aloe, radix rehmanniae, herba houttuyniae, motherwort herb, colla corii asini, peach blossoms, fruit of Chinese wolfberry and honey. The health care wild tea provided by the invention has the advantages that the color and the luster are emerald green; the fragrance is mellow; the liquor color is green and bright; the mouthfeel is fresh; the efficacies of producing a refreshing effect to the mind, reaching health care and detoxication, clearing summer-heat, purging intense heat, nourishing blood, nourishing the liver, moistening the spleen, tonifying the kidney, clearing away the heart-fire, improving eyesight, tonifying qi and Yang, resisting allergy and cancer, regulating lipid, losing weight and enhancing the human immunity are achieved; the health care wild tea is suitable for being drunk for user groups in each stage.

Owner:周学付

Tea processing method

InactiveCN106035774AIncrease fresh and mellow tasteIncrease aromaPre-extraction tea treatmentFixation timeEmerald

The invention discloses a tea processing method in the field of tea processing technologies. The tea processing method includes the following steps that wilting is performed: indoor natural wilting is performed for 1.5-2.5 hours, and then hot-air wilting is performed for 20-35 minutes; fixation is performed: the temperature of a roller fixation machine is 295-310 DEG C, and the fixation time is 1-2 seconds; processing is performed: the temperature of a processing machine is 100 DEG C, and the processing temperature is 35-45 minutes; processes leaves obtained after processing are fed into a polishing and tomentum removing machine, and tomentum removing is performed at the temperature of 0-5 DEG C for 2 hours; shaping is performed: the shaping temperature is 70-80 DEG C, and the time is 3-5 minutes; drying is performed: the tea leaves are put into a dryer, the drying temperature is 70-80 DEG C, and the time is 2 hours; aroma raising is performed: the tea leaves are put into an aroma raising machine, the moisture content of the tea leaves undergoing aroma raising is 7%. The tea processing method integrates indoor natural wilting and hot-air wilting, effectively improves the aroma of finished tea to make the taste of the tea mellow and then is assisted by low-temperature and long-time tomentum removing, the problems of small aroma and slight taste brought by conventional low-temperature tomentum removing are avoided while the characteristics of emerald green color, bright tea water and little tomentum or tomentum absence are kept, and the tea processing method is suitable for production of brand-name and high-quality green tea.

Owner:正安县清新种养殖农民专业合作社

Production method for high-quality tea

InactiveCN105941679AImprove freshnessImprove quality foundationPre-extraction tea treatmentGreen teaAir temperature

The invention relates to a production method for high-quality tea. The method sequentially comprises the processing steps of selection and picking of a raw material, spreading, fixation, spread cooling, rolling, shaping, roasting and the like; it is strictly controlled that the variety Zaobaijian No. 5 of the raw material is selected; according to the requirements of raw material picking, the raw material is picked from a pollution-free ecological tea garden at the altitude of 550-650 m, the picking time is in the middle ten days of March, and the air temperature on a sunny day is required to range from 20 DEG C to 25 DEG C. The processing method is carried out from the perspectives of selection of the high-quality raw material, spreading optimization and other processing technologies, and the quality of green tea is improved.

Owner:CHONGQING YUNLING TEA IND TECH

Method for cultivating tea

InactiveCN100337526CImprove lighting conditionsEasy to synthesizeCultivating equipmentsDry seasonTea plantation

The invention discloses a method for cultivating tea comprising the steps of, tea plantation sun screening, planting deciduous arbor around the tea plantation and between the tea trees, covering the tea plantation through rice straw and planting bean green manure, applying special-purpose fertilizer for organic tea, inoculating beneficial soil organisms and soil creatures including right amount of earthworm, finally carrying out irrigation through mini- sprinkling irrigation system in high temperature dry seasons.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

Crescent formed green tea and preparation method

InactiveCN1759708AImprove qualityFully mechanized operationPre-extraction tea treatmentGreen teaEpigallo-catechin gallate

Owner:HUAZHONG AGRI UNIV

Orchid odor type ancient tea tree green tea and preparation method thereof

ActiveCN109198056AHigh orchid fragranceHigh water extract contentPre-extraction tea treatmentFlavorMicrowave

The invention relates to orchid odor type ancient tea tree green tea and a preparation method thereof. The preparation method comprises the steps of performing constant-temperature green leaf airing,performing sunlight sunning, performing green leaf airing for the second time, performing green leaf rocking, performing steam heat fixation, performing microwave tempering, performing rolling for thefirst time, performing baking for the first time, performing spreading for cooling for the first time, performing rolling for the second time, performing baking for the second time, performing spreading for cooling for the second time, and performing aroma increasing with full firing so that the orchid odor type ancient tea tree green tea is prepared. The prepared orchid odor type ancient tea tree green tea has high water extract content, high amino acid content and moderate tea polyphenols content, and the water extract content, the amino acid content and the tea polyphenols content are keysof forming unique quality flavor of the orchid odor type ancient tea tree green tea. The ancient tea tree green tea has excellent quality characteristics of being high and long in orchid odor, mellowand brisk in taste and green and bright in soup color.

Owner:HUNAN AGRICULTURAL UNIV

Jujube sprout tea and preparation process thereof

ActiveCN104054860AThe rope is tight and evenBright green colorPre-extraction tea treatmentTea leafAppetite

The invention discloses jujube sprout tea and a preparation process thereof, and relates to the field of tea. A formula of the jujube sprout tea comprises 3-5 parts of fresh tea leaves and 5-7 parts of winter jujube sprouts. The preparation process comprises four steps, namely tea base preparation, bud processing, fragrance absorption, and matching and packaging. The jujube sprout tea prepared by the formula and the process disclosed by the invention is tight, fine and uniform in strip, and green and fresh in color, and is interspersed by flower catkins; soup is green and bright; green leaves and flowers are beautiful; the tea can cultivate emotion and refine aspiration; tea aroma is clear and durable and the tea reserves refreshing flower fragrance; the tea soup is intense and fresh, is capable of promoting secretion of saliva on a tongue root after being drunk and is long in aftertaste. The tea has functions of clearing away heat and toxic materials, refreshing, tonifying spleen and stimulating appetite, inducing diuresis and relaxing bowels, reducing pressure and losing weight, and moistening and beautifying skin.

Owner:CHIBI ZHAOLI QIAODONGZHUANG TEA

Production method of green tea

InactiveCN107518098ABright green soupIncrease aromaPre-extraction tea treatmentCooking & bakingNational level

The invention mainly discloses a production method of green tea. Fresh leaves of all-round high-quality tea making varieties of national level tea trees, namely Lingyun pekoe tea, are used as raw materials, and through a series of processing and production method steps of tedding, fixation, rolling, baking and the like, new green tea products are processed. The new varieties of the deeply-processed Lingyun pekoe tea are enriched, the product quality of green tea is improved, upgrading of a traditional processing technology of green tea products is accelerated and promoted, and the processing scientific and technological content of new products is increased. The green tea product has the features of being tender green in shape, tender green and bright in liquor color, and delicately-fragrant, the fragrance lasts long, the mouth feel is fresh, mellow and soft, the green tea is tender, refreshing and fresh, the base color is bright and the buds are obvious, and the green tea is deeply loved by vast consumers. Besides, the economic and social benefits of tea leaves can be greatly increased after the technique is implemented, the progress of processing technologies of enterprises is greatly promoted, the production and the development are facilitated, the economic returns of tea growers and tea leaf manufacturing enterprises are increased, and the production method can well provide service for local economic construction.

Owner:广西正道茶业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com