Green tea and processing method thereof

A processing method and technology of green tea, which is applied in the field of green tea processing, can solve the problems of high-quality green tea soup, such as yellowing, difficulty in satisfying consumers, and low aroma, so as to maintain stable quality of green tea leaves, facilitate synthesis and transformation, and prevent dark green color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

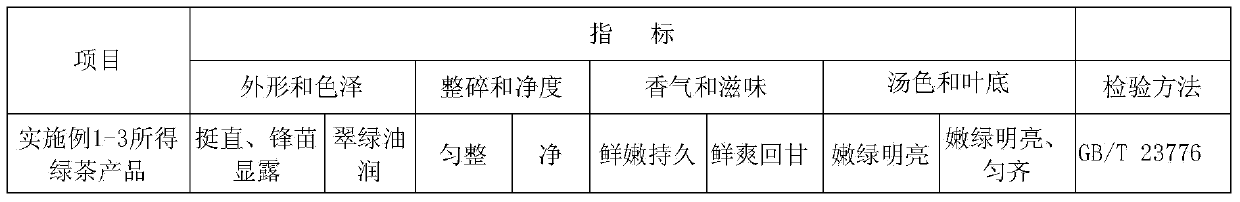

Examples

Embodiment 1

[0050] A kind of processing method of green tea, it comprises following concrete steps successively:

[0051] 1) Raw material selection and picking

[0052]The selected raw material variety is Fuding Dabai tea; the raw material is picked from a pollution-free ecological tea garden at an altitude of 550-650m. In this case, the raw material is produced in a 5A-level national forest park in Yongchuan District, Chongqing City - Chashan Bamboo Sea Scenic Area, Scenic Area It belongs to the subtropical monsoon humid climate, with an average temperature of 18.2°C, a maximum temperature of 39°C, and a minimum temperature of 2°C. The annual average rainfall is 1042.2mm, the average sunshine is 1298.5h, and the annual average frost-free period is 317 days. The scenic spot is rich in vegetation, with a forest coverage rate of 97%. The air is fresh and clean; the picking time is in mid-March, and the temperature on sunny days is required to be 20-25°C; the standard for picking fresh leave...

Embodiment 2

[0075] A kind of processing method of green tea, it comprises following concrete steps successively:

[0076] 1) Raw material selection and picking

[0077] The selected raw material variety is Zaobaijian No. 5; the raw material picking requirements are to be collected from pollution-free ecological tea gardens at an altitude of 550-650m. In this case, the raw materials are produced from the 5A-level national forest park in Yongchuan District, Chongqing City - Chashan Bamboo Sea Scenic Area. The scenic spot belongs to the subtropical monsoon humid climate, with an average temperature of 18.2°C, a maximum temperature of 39°C, and a minimum temperature of 2°C. The annual average rainfall is 1042.2mm, the average sunshine is 1298.5h, and the annual average frost-free period is 317 days. The scenic spot is rich in vegetation and the forest coverage rate reaches 97%. , the air is fresh and clean; the picking time is in mid-March, and the temperature on sunny days is required to be ...

Embodiment 3

[0100] A kind of processing method of green tea, it comprises following concrete steps successively:

[0101] 1) Raw material selection and picking

[0102] The selected raw material variety is Nanjiang No. 1; the raw material is picked from a pollution-free ecological tea garden at an altitude of 550-650m. In this case, the raw material is produced in the 5A National Forest Park in Yongchuan District, Chongqing City - Chashan Bamboo Sea Scenic Area, which belongs to Subtropical monsoon humid climate, with an average temperature of 18.2°C, a maximum temperature of 39°C, a minimum temperature of 2°C, an average annual rainfall of 1042.2 mm, an average sunshine of 1298.5 hours, and an average annual frost-free period of 317 days. The scenic spot is rich in vegetation, with a forest coverage rate of 97%. Fresh and clean; the picking time is in mid-March, and the temperature in sunny days is required to be 20-25°C; the standard for picking fresh leaves is one bud and one leaf at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com