High barrier food package coated membrane latexes by thermal sealing at low temperature and preparation method

A food packaging and low-temperature heat-sealing technology, which is applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of insufficient heat sealing and difficulty in fusion, and achieve the effect of extending shelf life and high barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

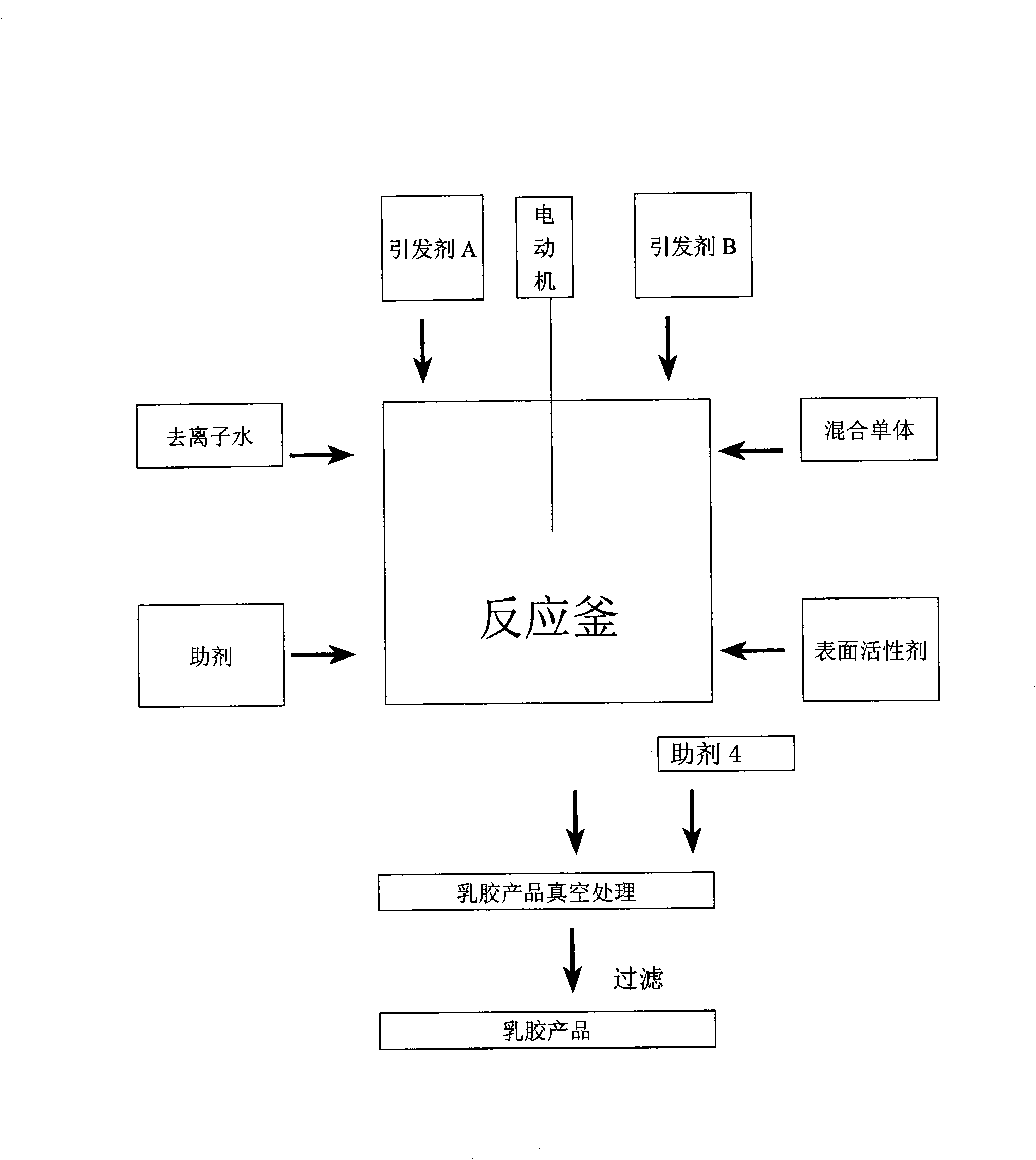

[0019] plan 1

[0020] Preparation: Add 0.02 parts of initiator A tert-butyl hydroperoxide to 8 kg of deionized water for later use;

[0021] 0.02 part of initiator B sodium formaldehyde sulfoxylate was added to 8kg of deionized water for subsequent use;

[0022] Kettle material: deionized water 82kg

[0023] Auxiliary 1 0.02kg

[0024] Auxiliary 2 0.002kg

[0025] Additive 3 0.04kg

[0026] Emulsifier: sodium paraffin sulfonate 1.4kg

[0027] Sodium lauryl sulfate 0.6kg

[0028] Mixed monomer vinylidene chloride 92.5kg

[0029] Acrylonitrile 7kg

[0030] Itaconic acid 0.5kg

[0031] Put the material into the 200-liter reactor, vacuum the nitrogen to replace it, and finally reduce the pressure of the reactor to -0.08~-0.095MPa, inhale the mixed monomer, cold disperse for half an hour, and when the temperature rises to 52°C, continue to add and configure. Initiator A tert-butyl hydroperoxide, initiator B sodium formaldehyde sulfoxylate, keep the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com