Patents

Literature

38results about How to "Solid appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron golf club

InactiveUS7338387B2Lower center of gravityHigh moment of inertiaGolf clubsRacket sportsHigh densityMetallic materials

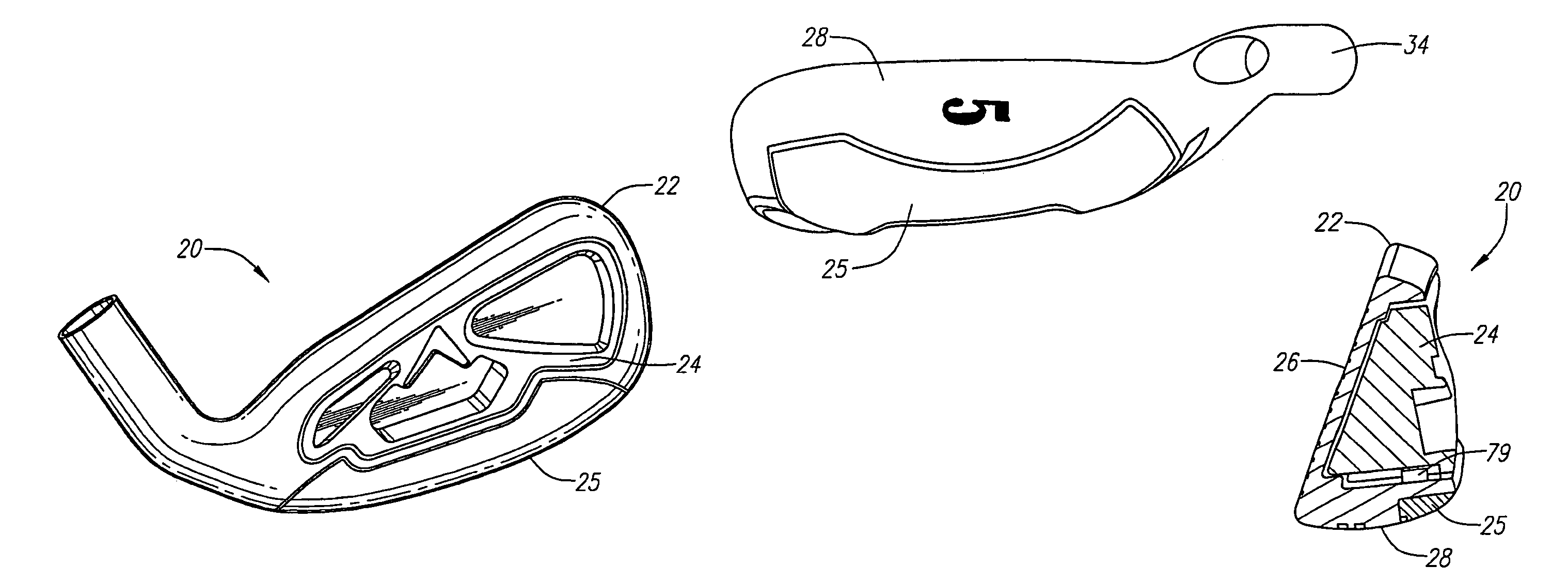

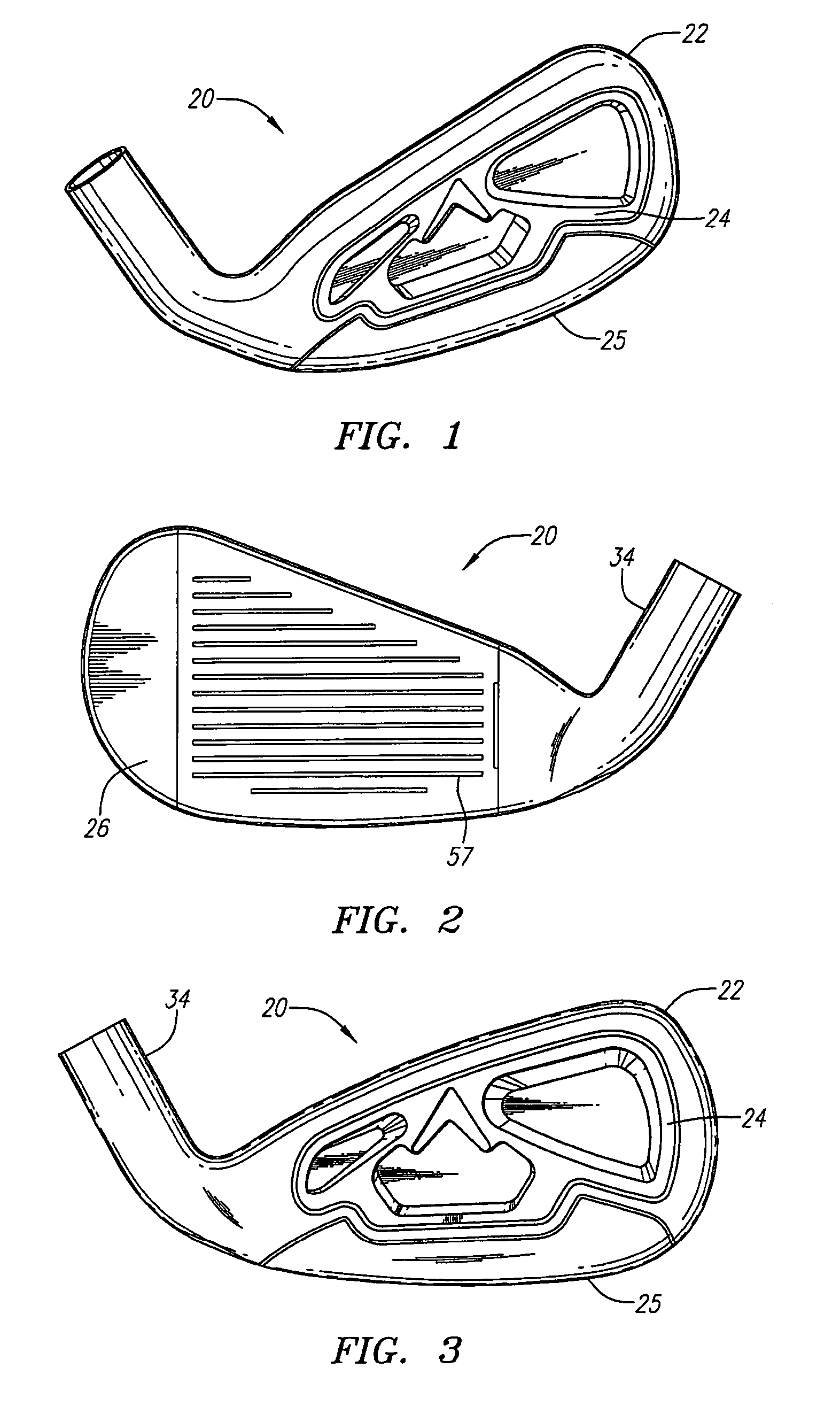

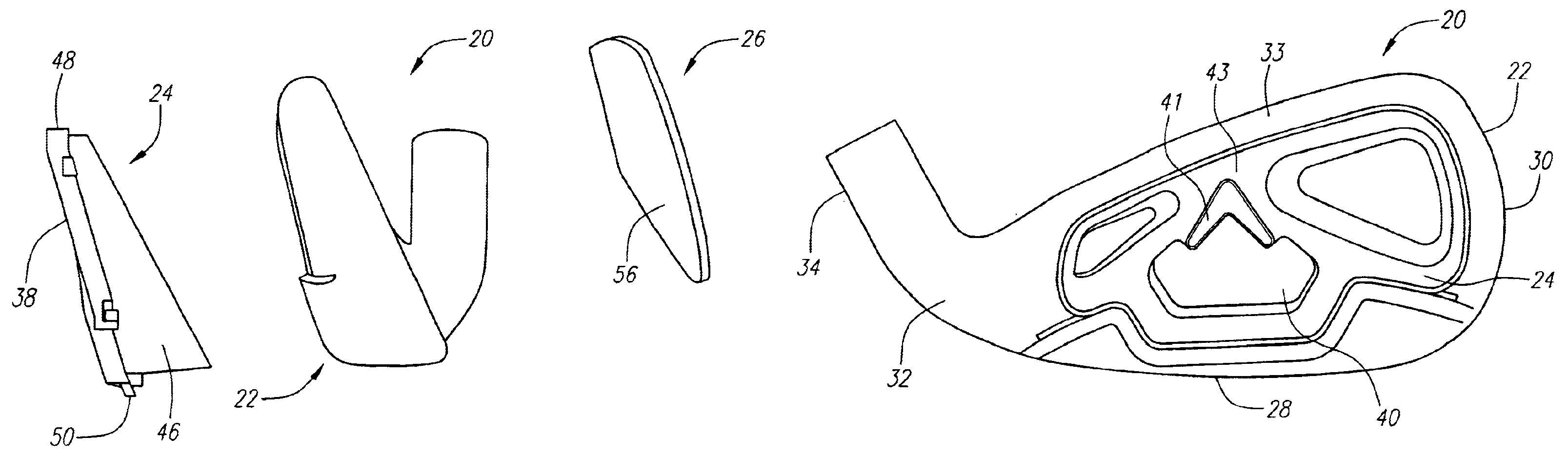

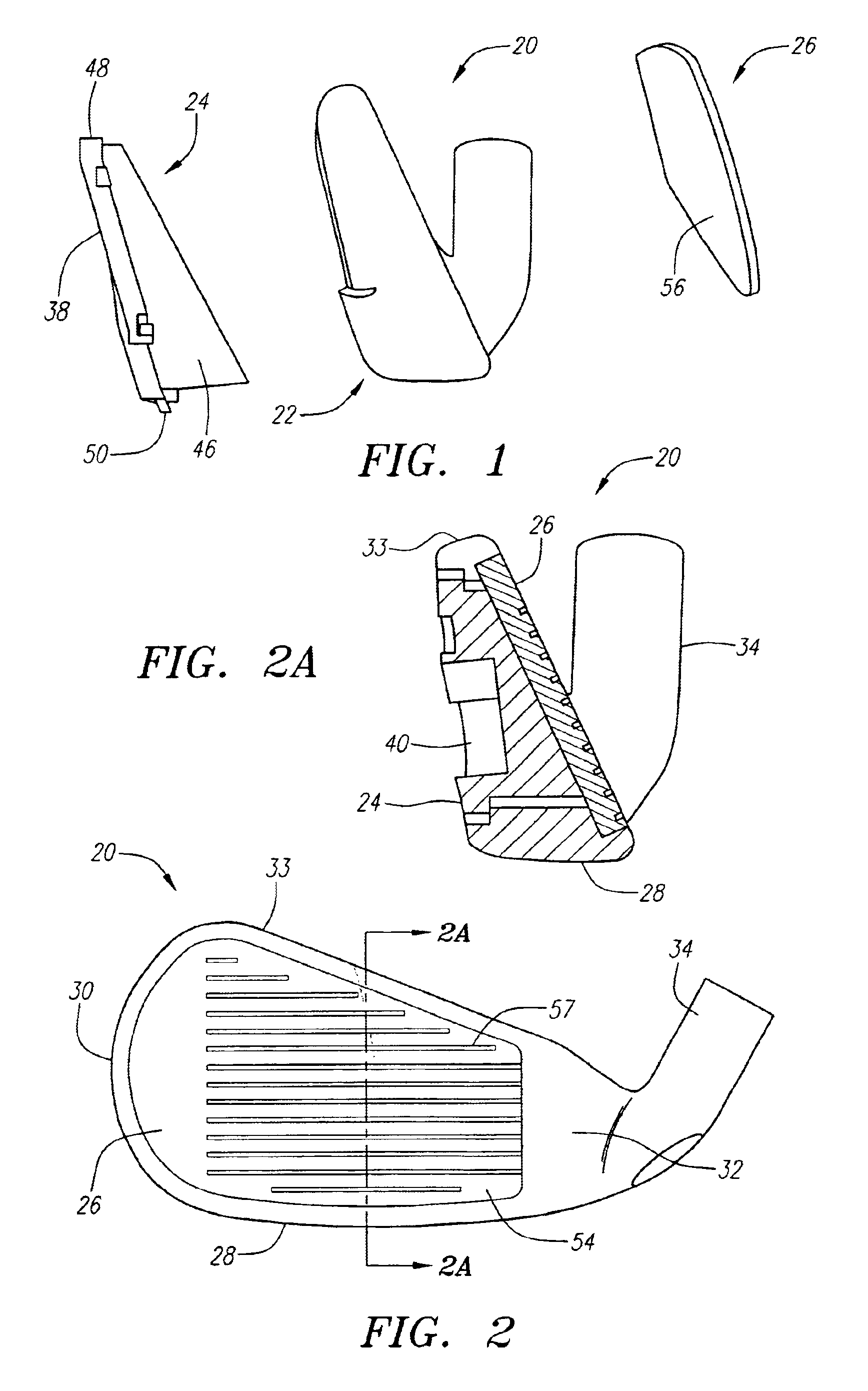

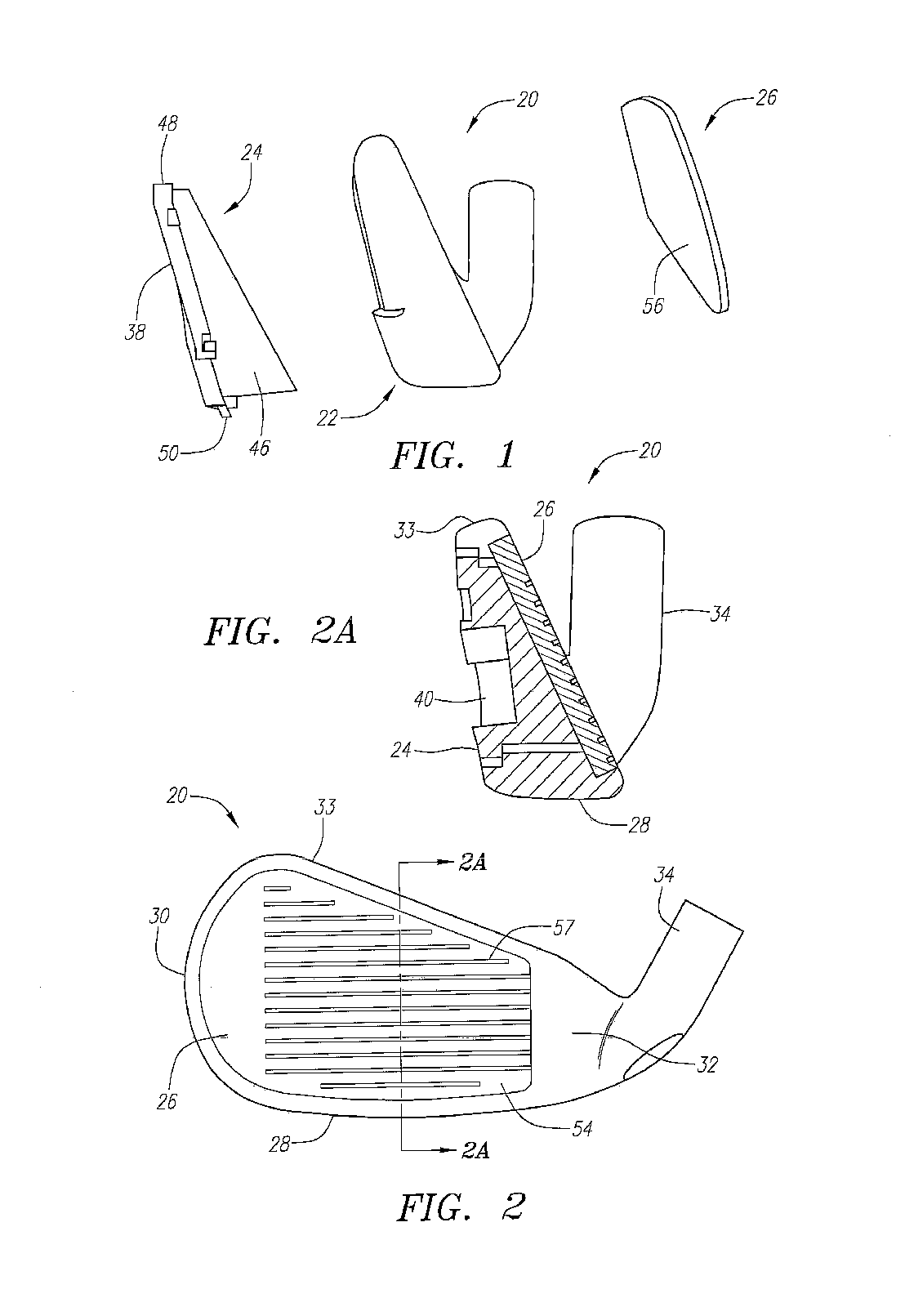

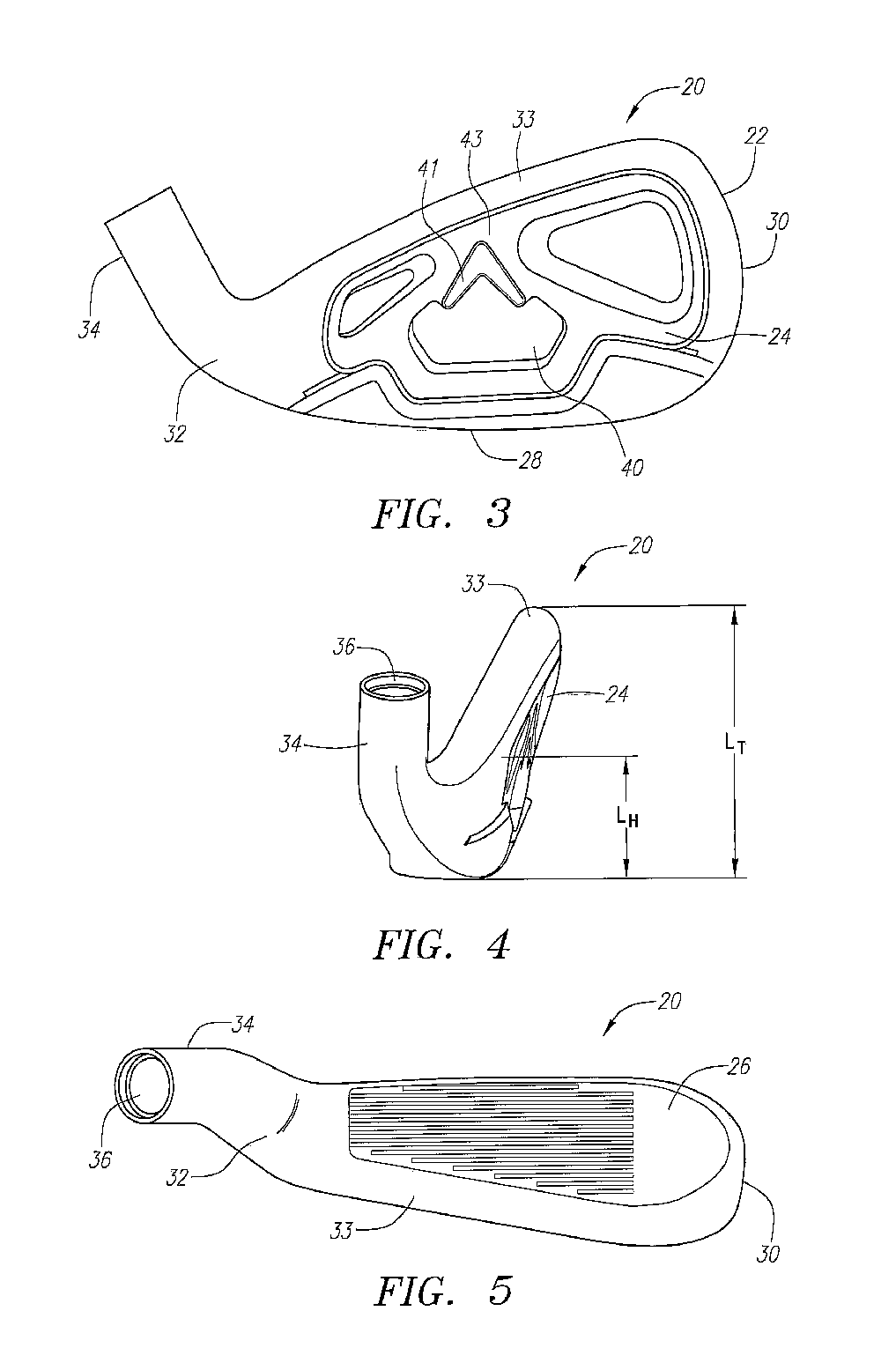

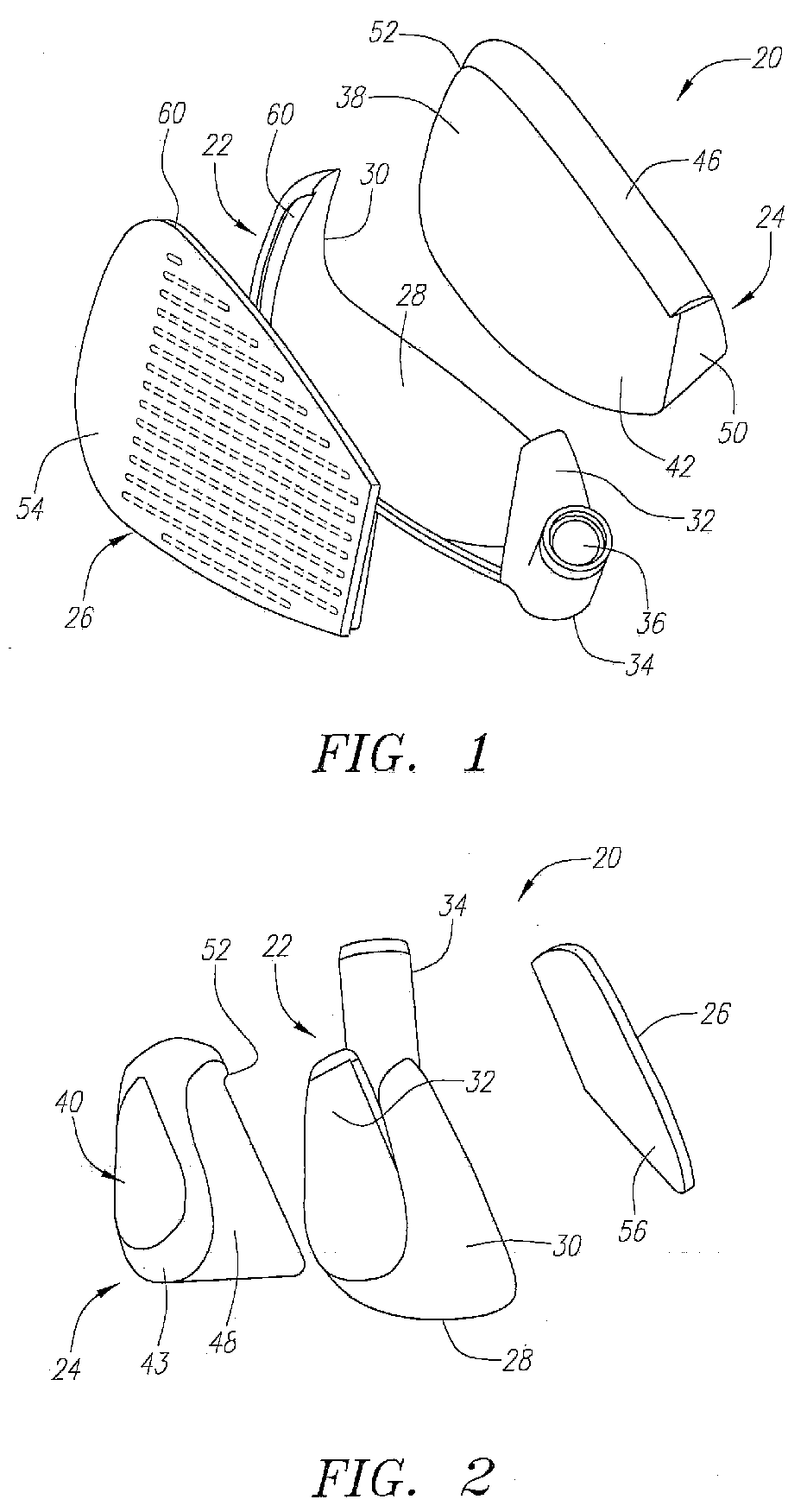

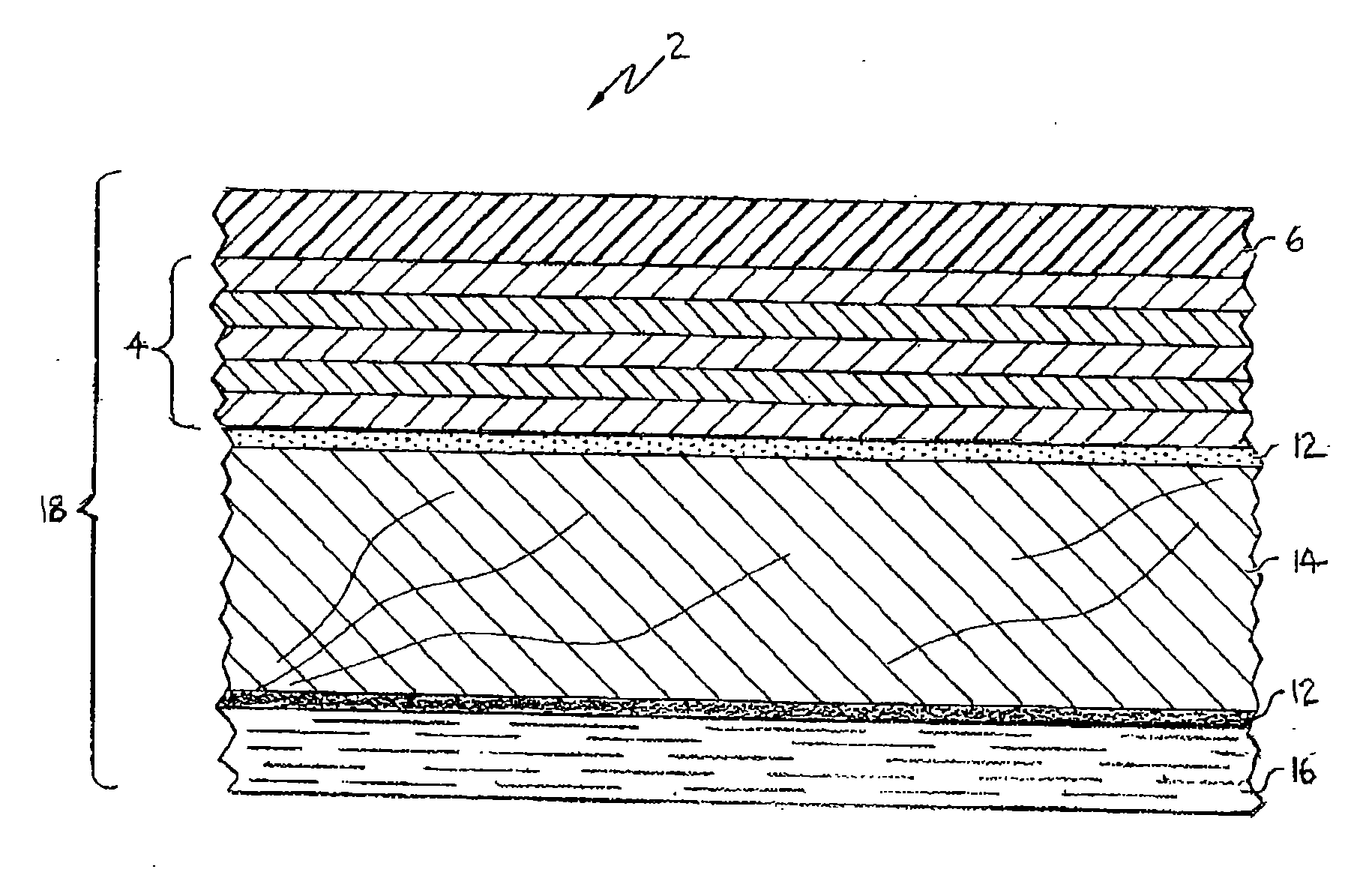

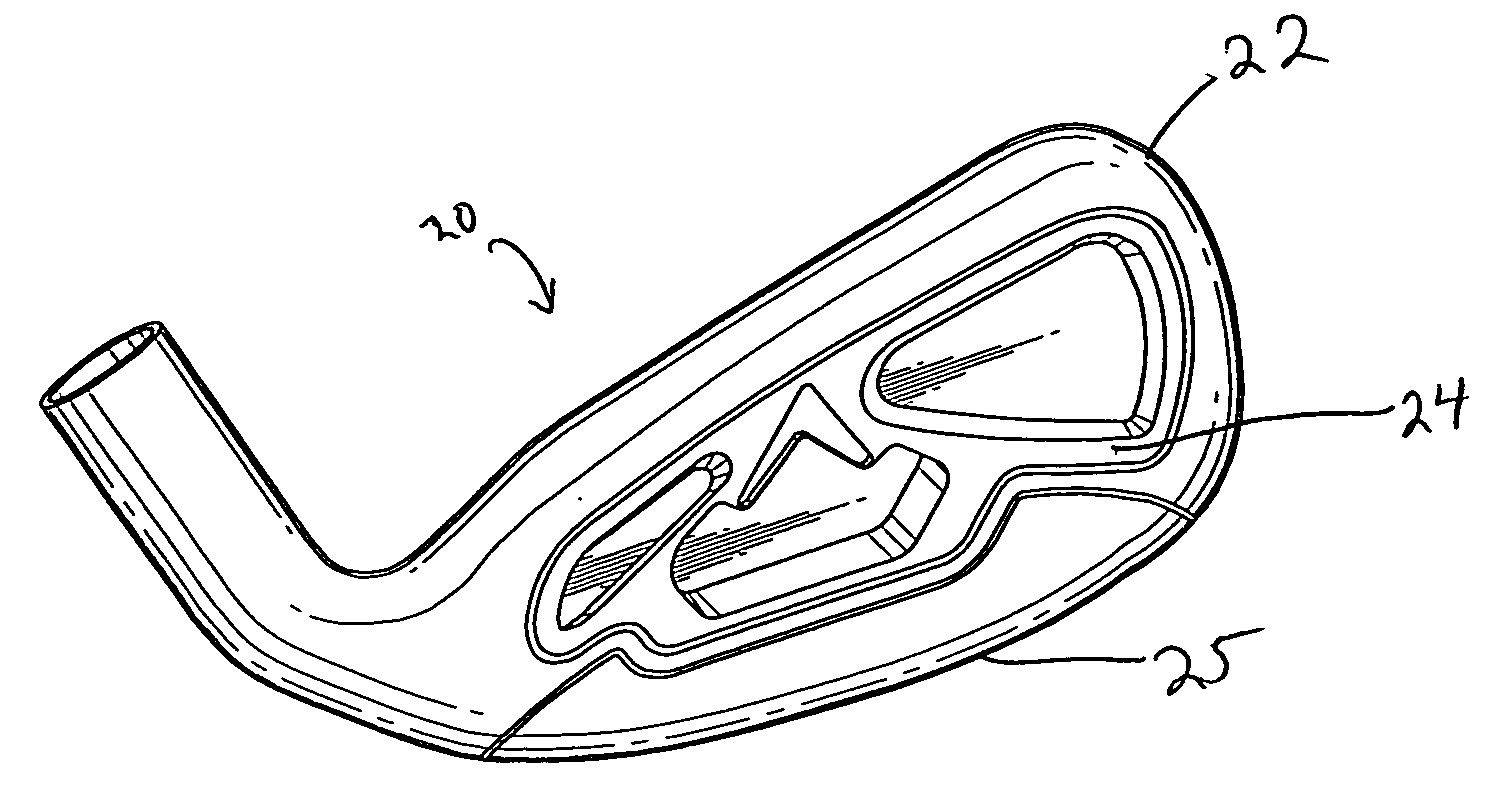

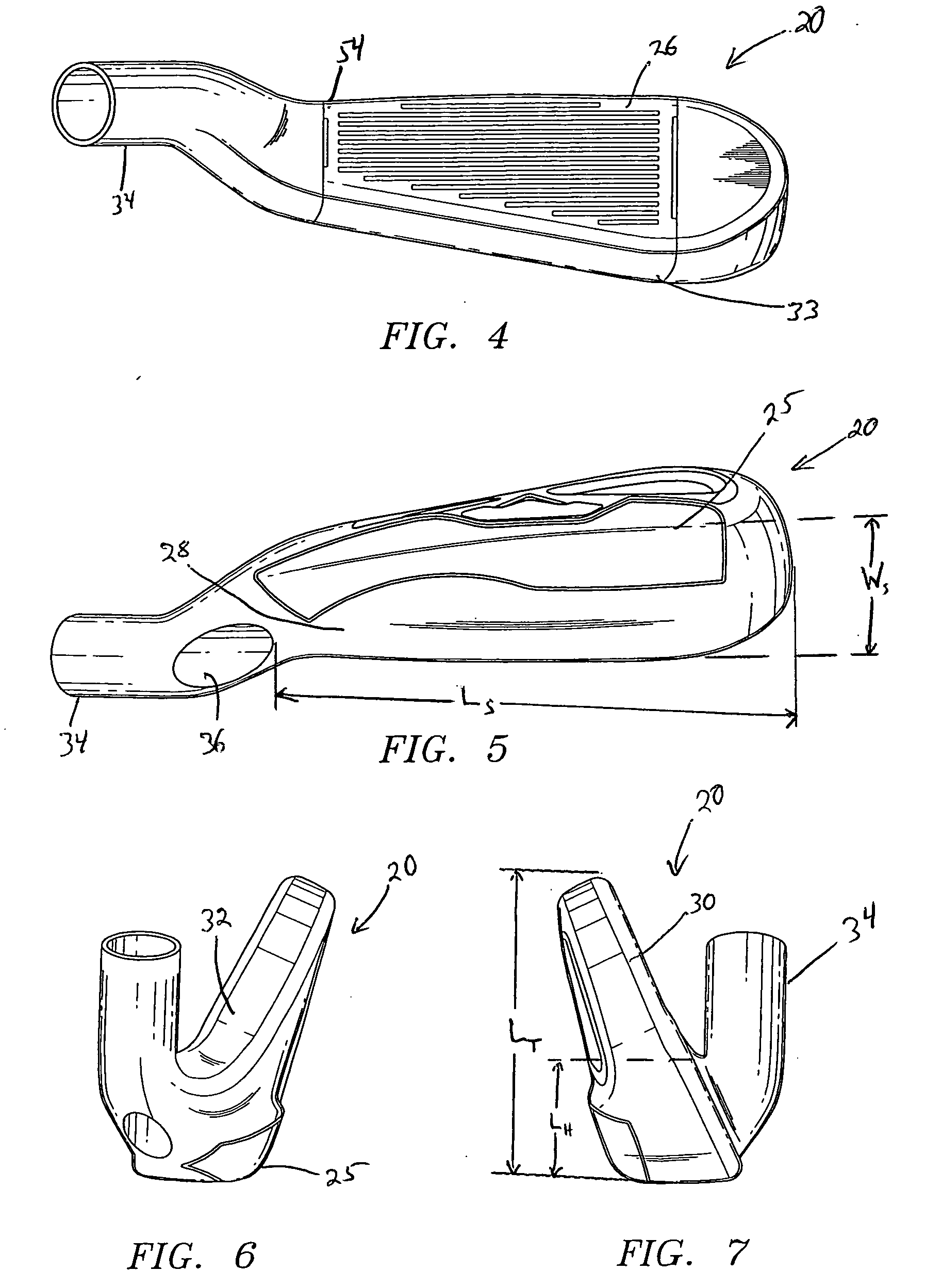

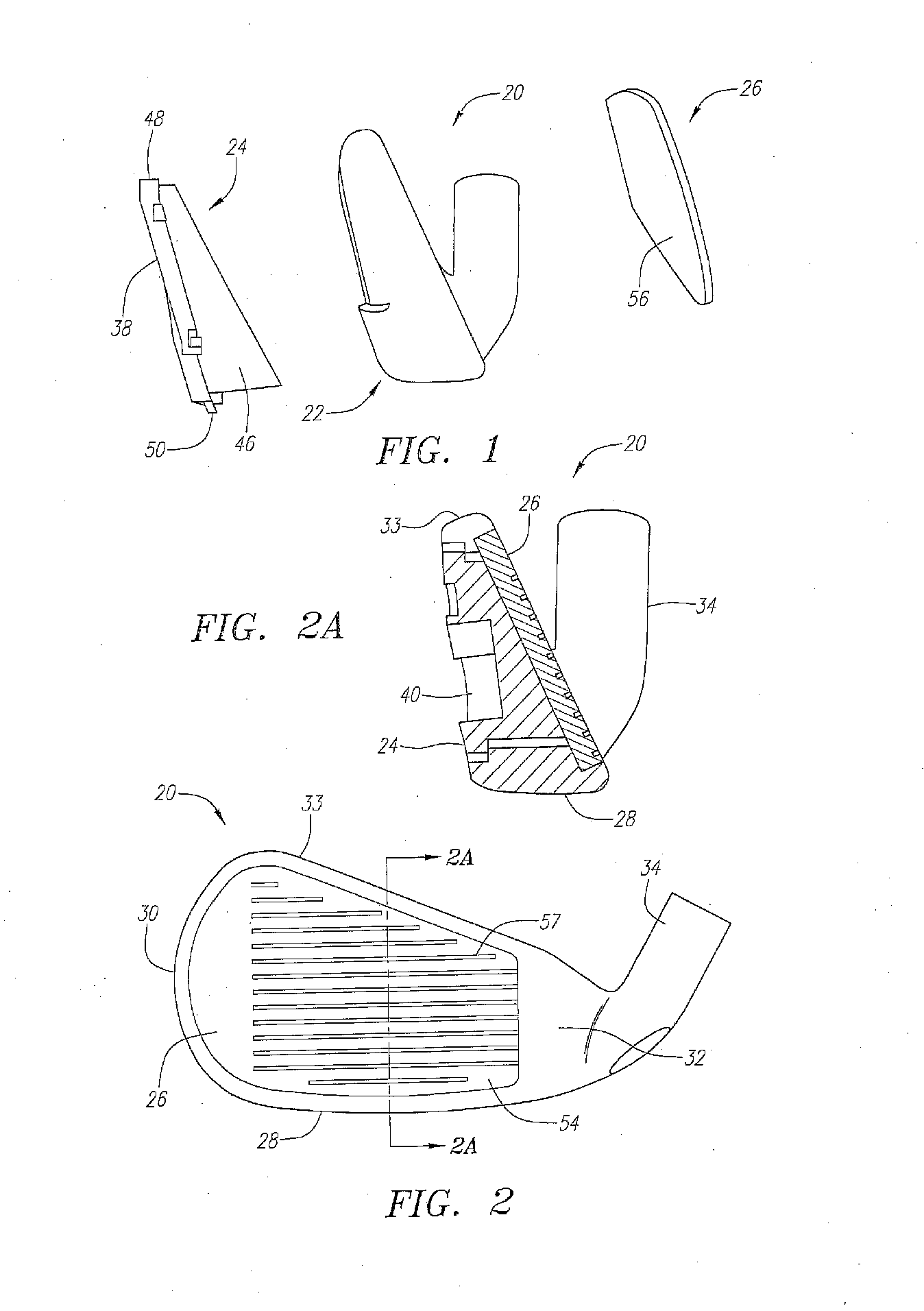

The iron golf club head (20) of the present invention is preferably composed of three main components: a main body (22), a central member (24) and a mass member (25). The Mass member (25) is preferably composed of a high density material such as a nickel-tungsten alloy. The central member (24) is preferably composed of a lightweight, non-metal material. The main body (22) is preferably composed of a titanium alloy material. The iron golf club head (20) preferably has high moments of inertia Izz and Ixx, and a low center of gravity.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Iron-type golf club

InactiveUS7083531B2Lower center of gravityHigh moment of inertiaGolf clubsRacket sportsEngineeringMoment of inertia

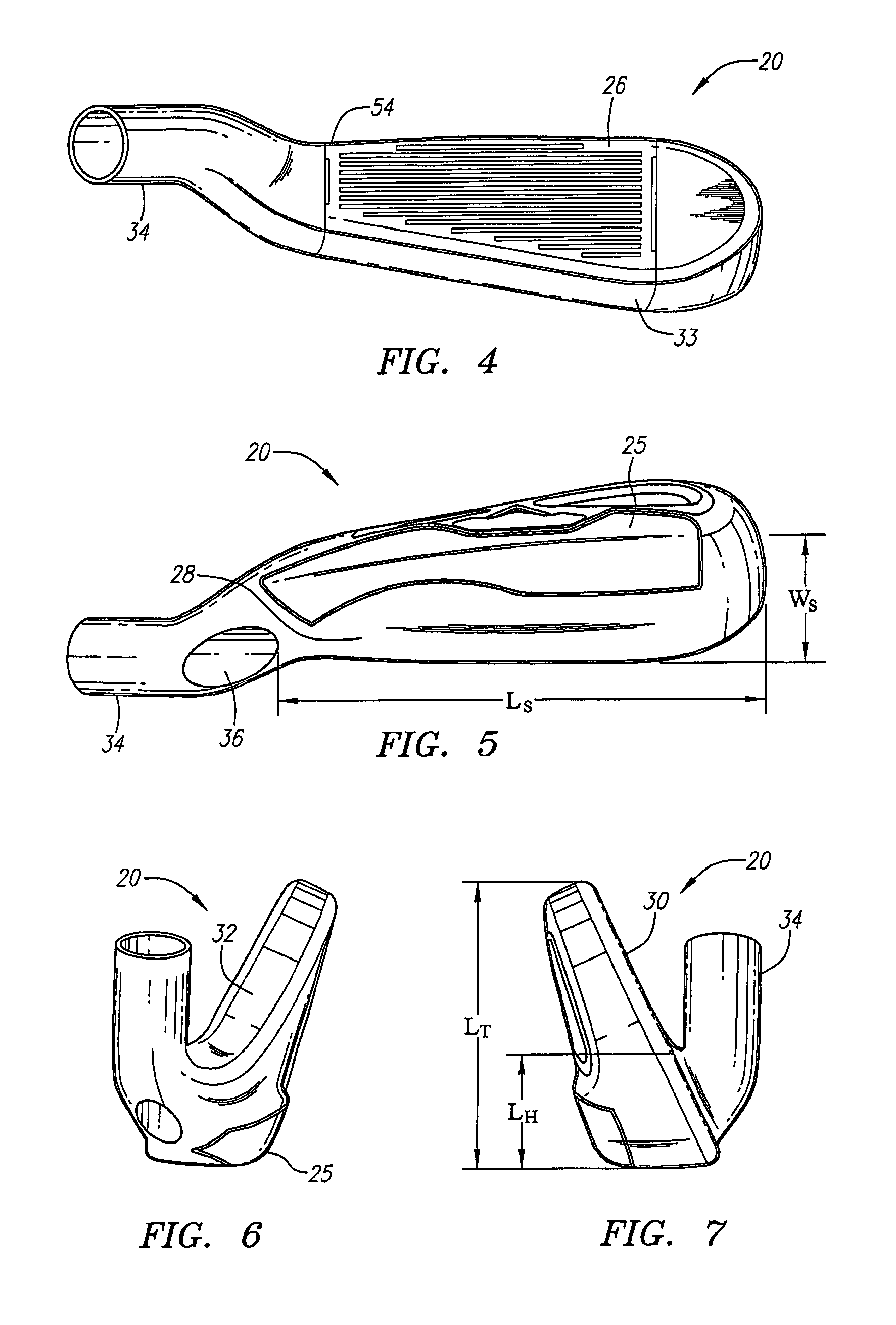

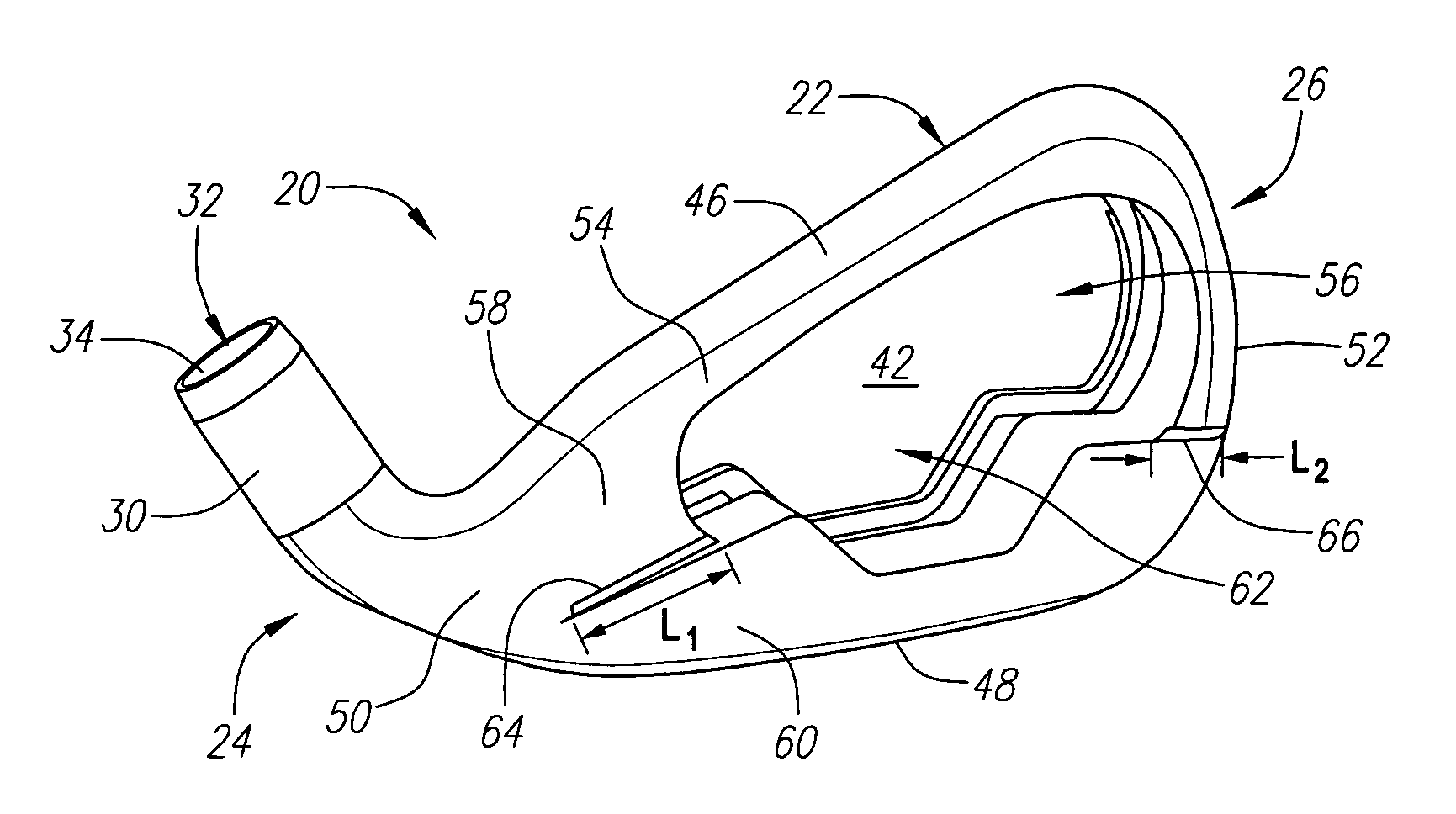

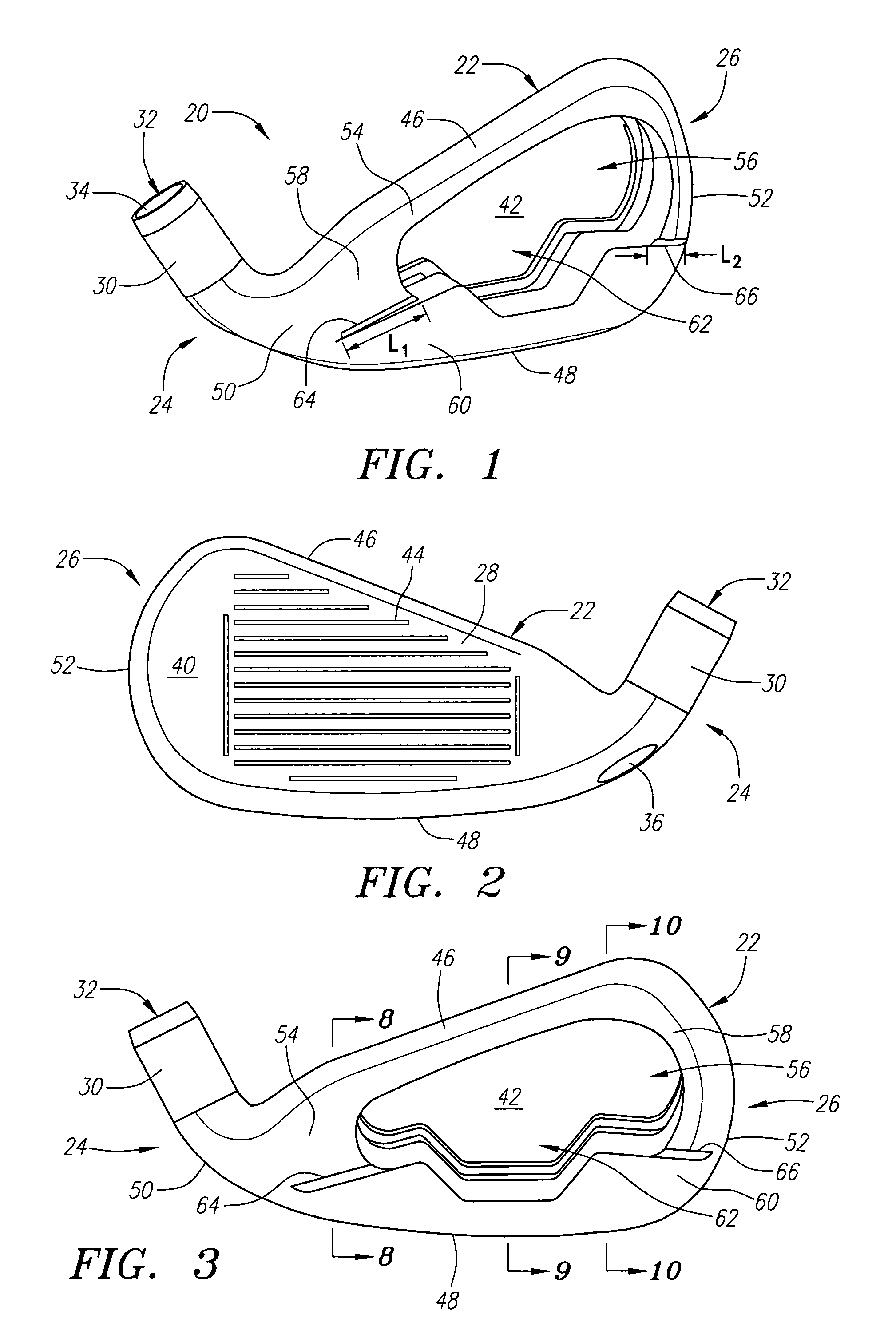

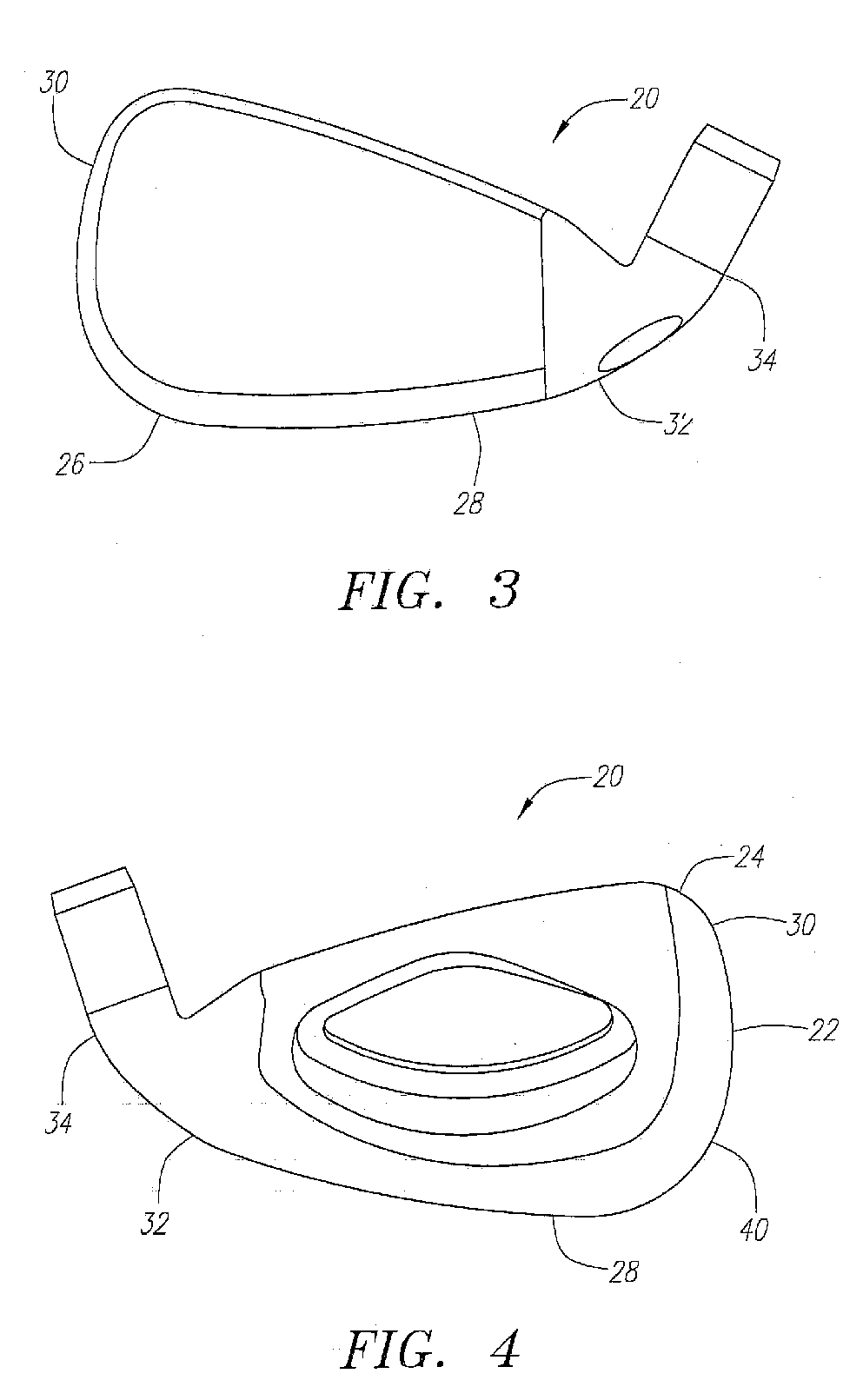

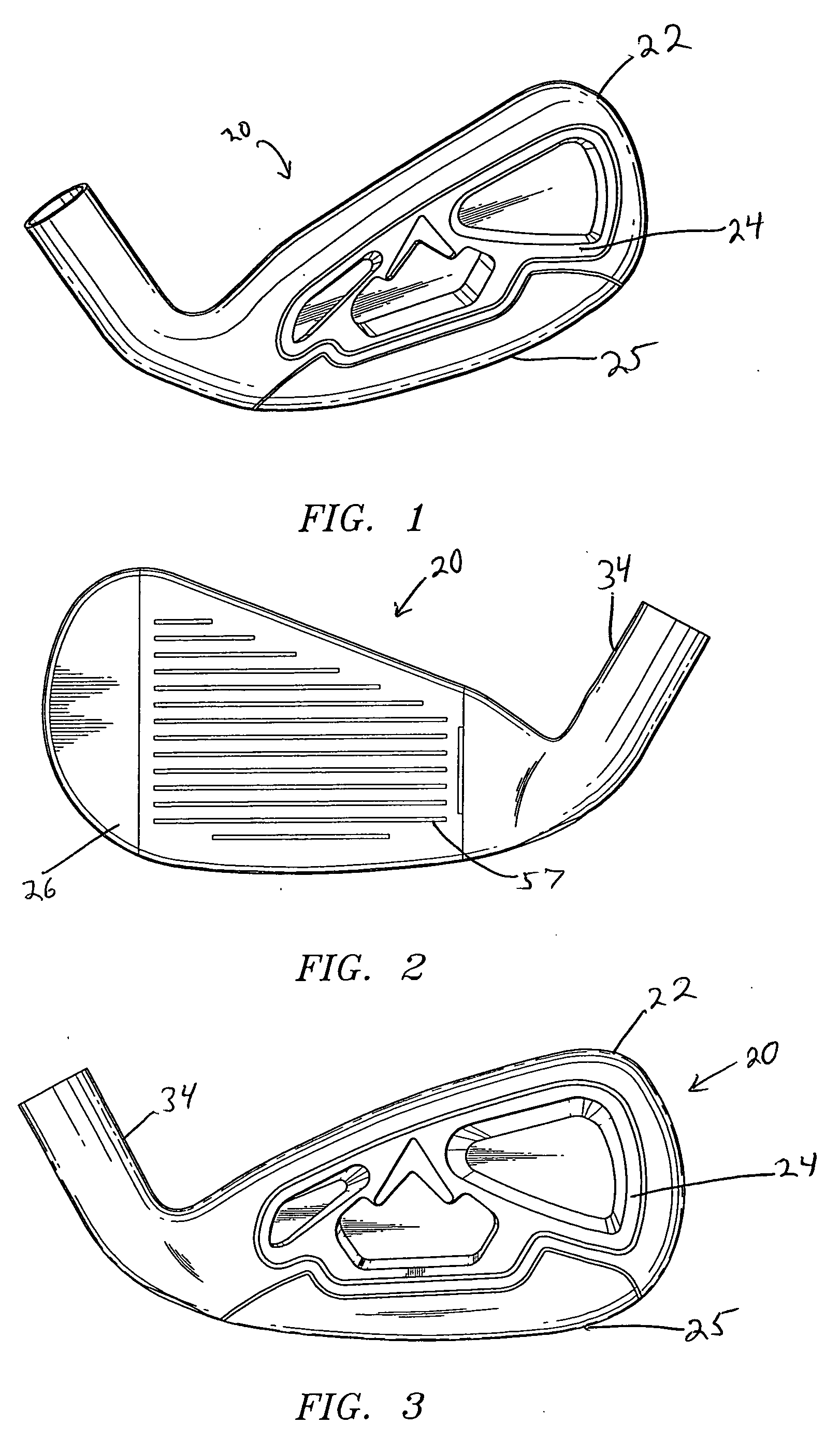

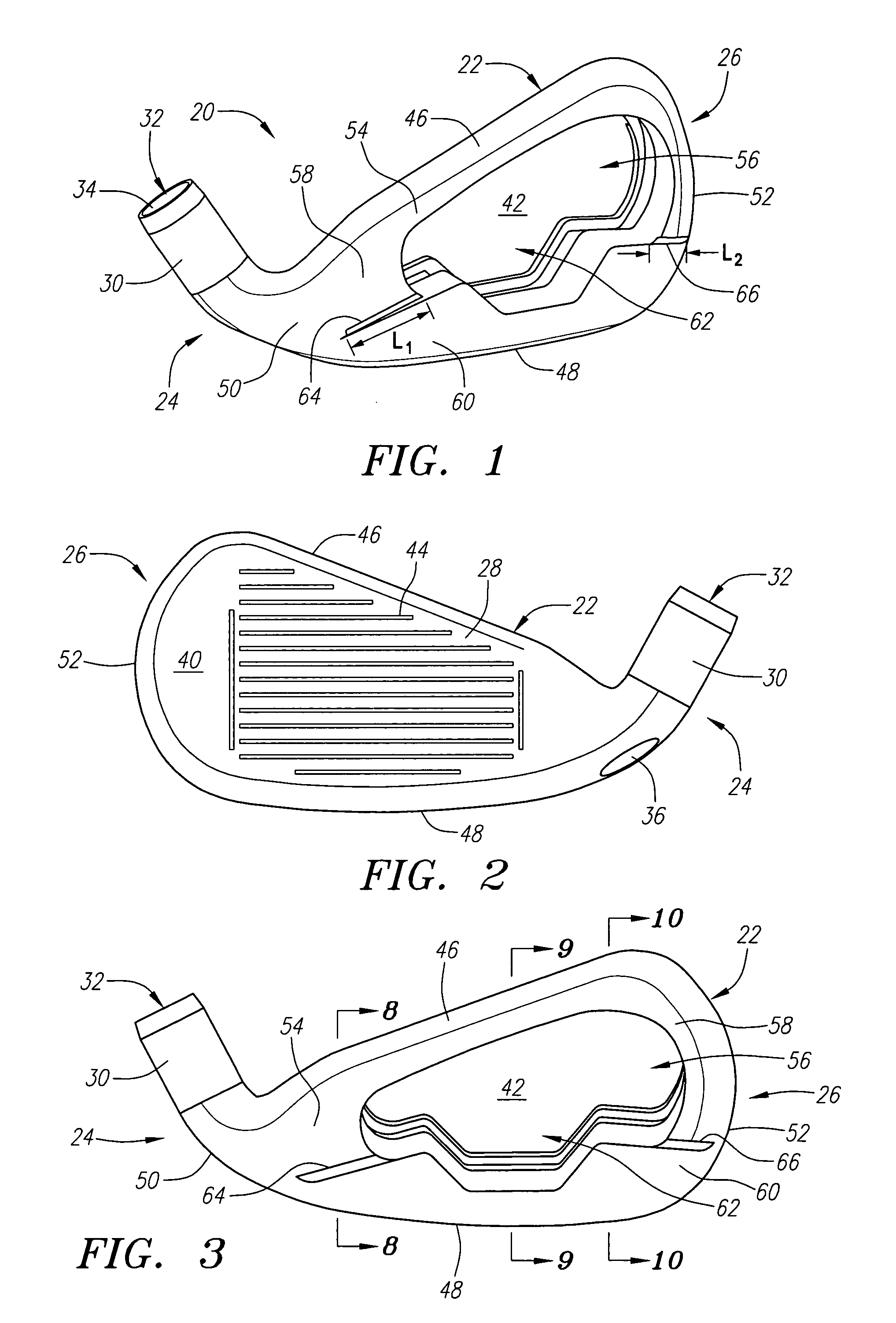

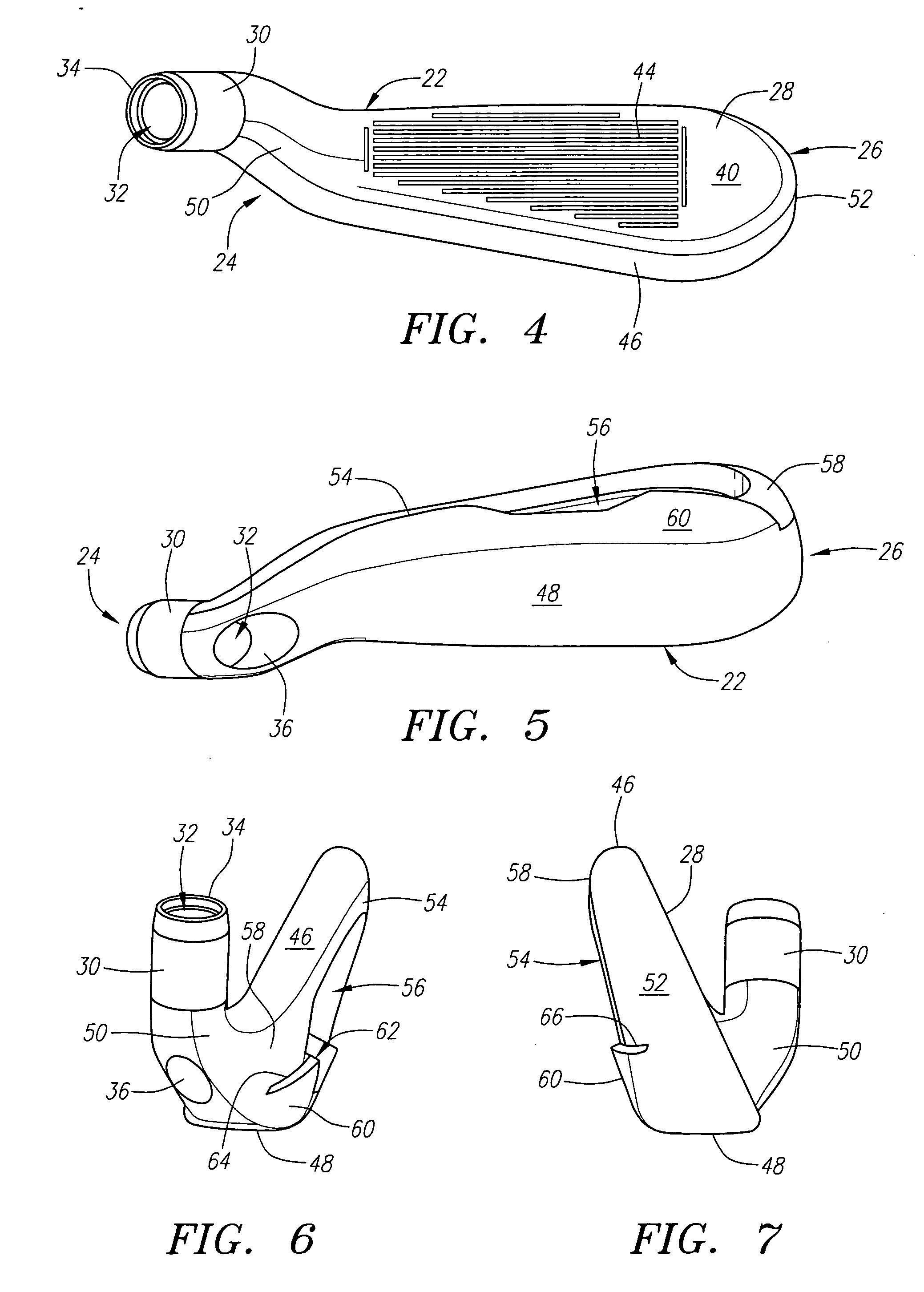

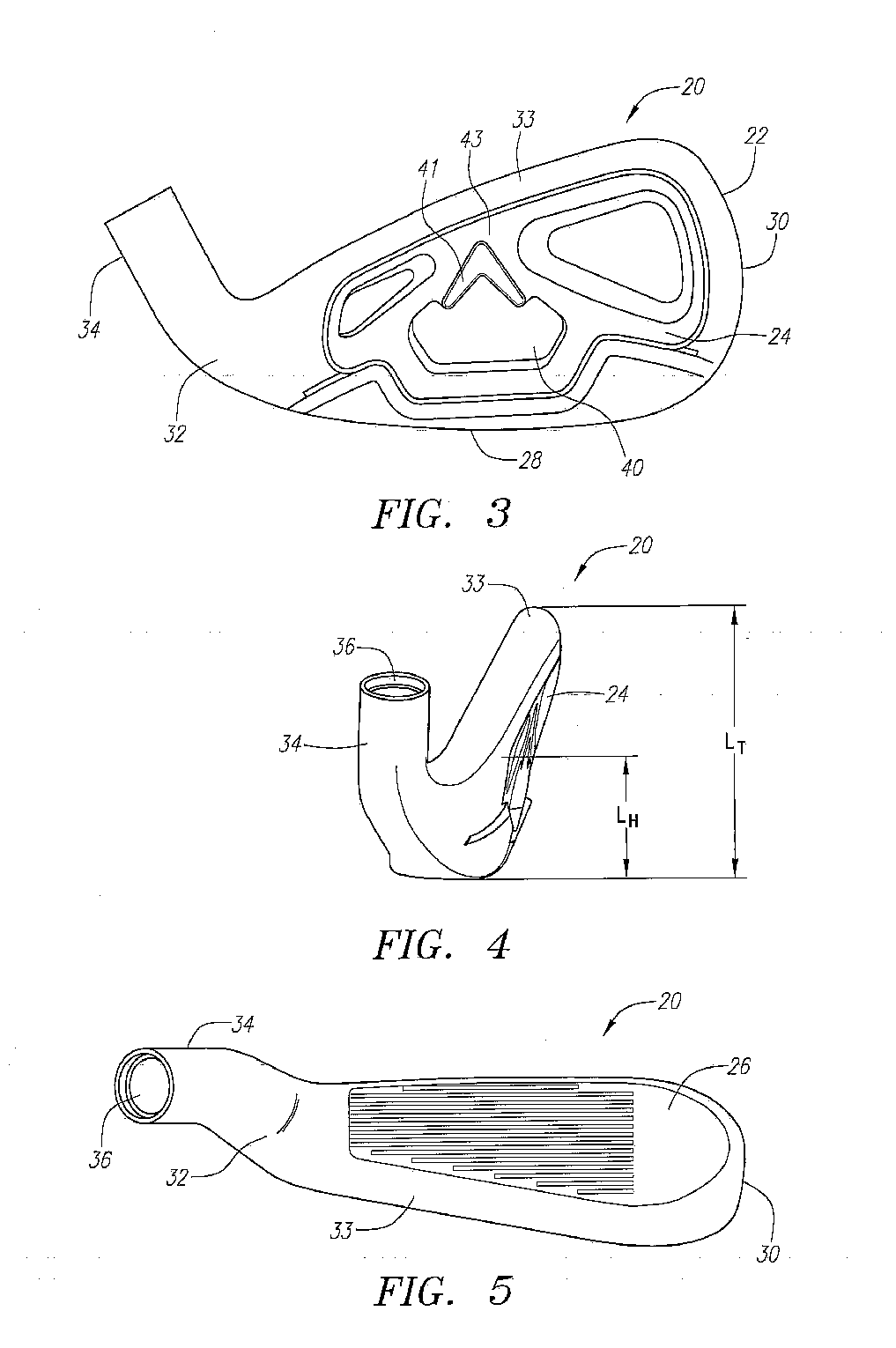

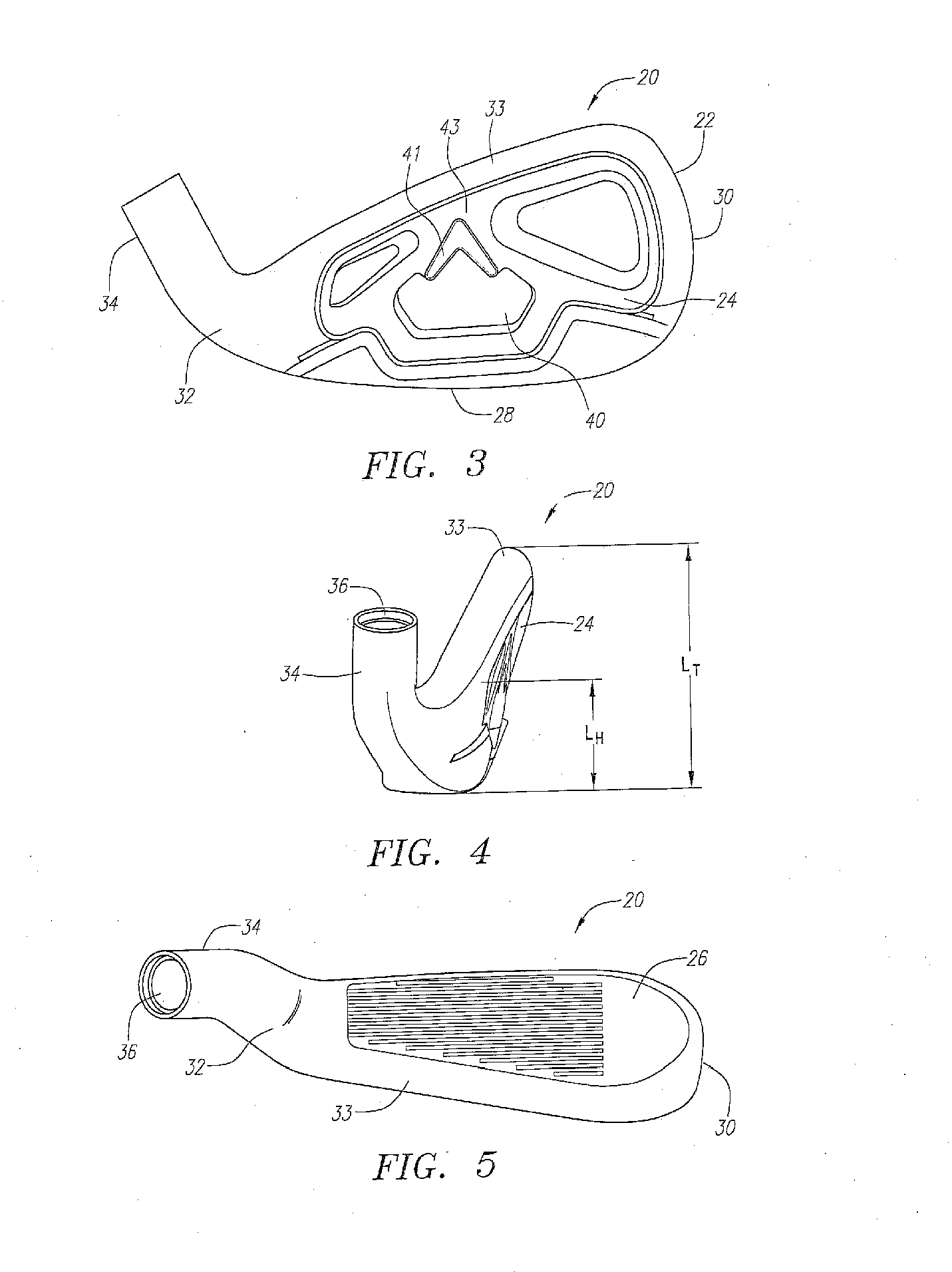

An iron-type golf club head (20) includes a body (22) having a front wall (28) with a ball-striking surface (40). The body (22) further includes a rear surface (54) that has external rear cavity (56) formed therein. The rear surface (54) includes an upper portion (58) and a lower portion (60). The upper portion (60) is separated from the lower portion (59) by the external rear cavity (56) and at least one groove (64, 66). The lower portion (60) of the rear surface (54) has a notch (62) formed therein, which communicates with the external rear cavity (56). The golf club head (20) preferably has high moments of inertia Izz and Ixx.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Iron golf club

InactiveUS6857973B2Lower center of gravityHigh moment of inertiaGolf clubsHigh densityMetallic materials

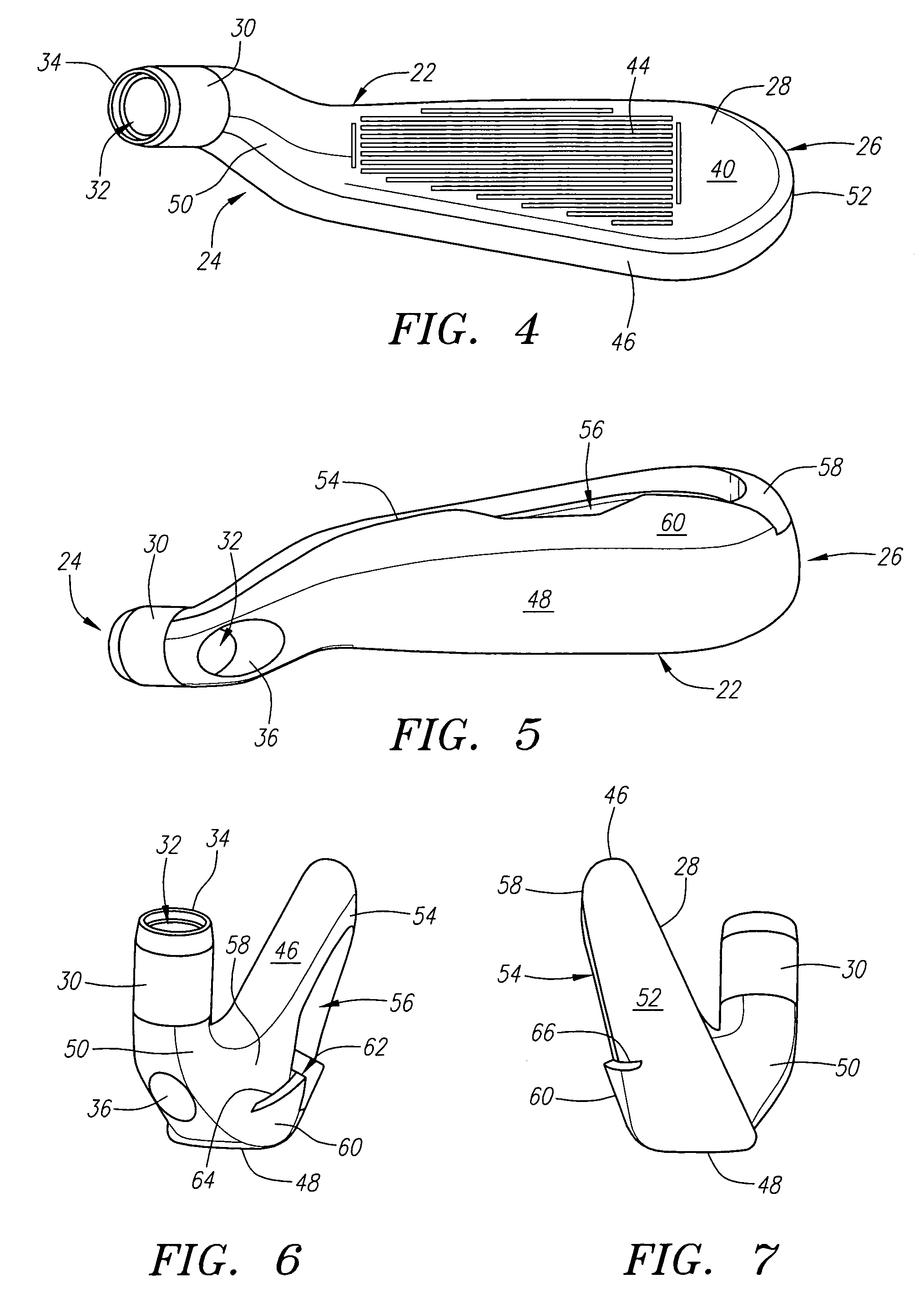

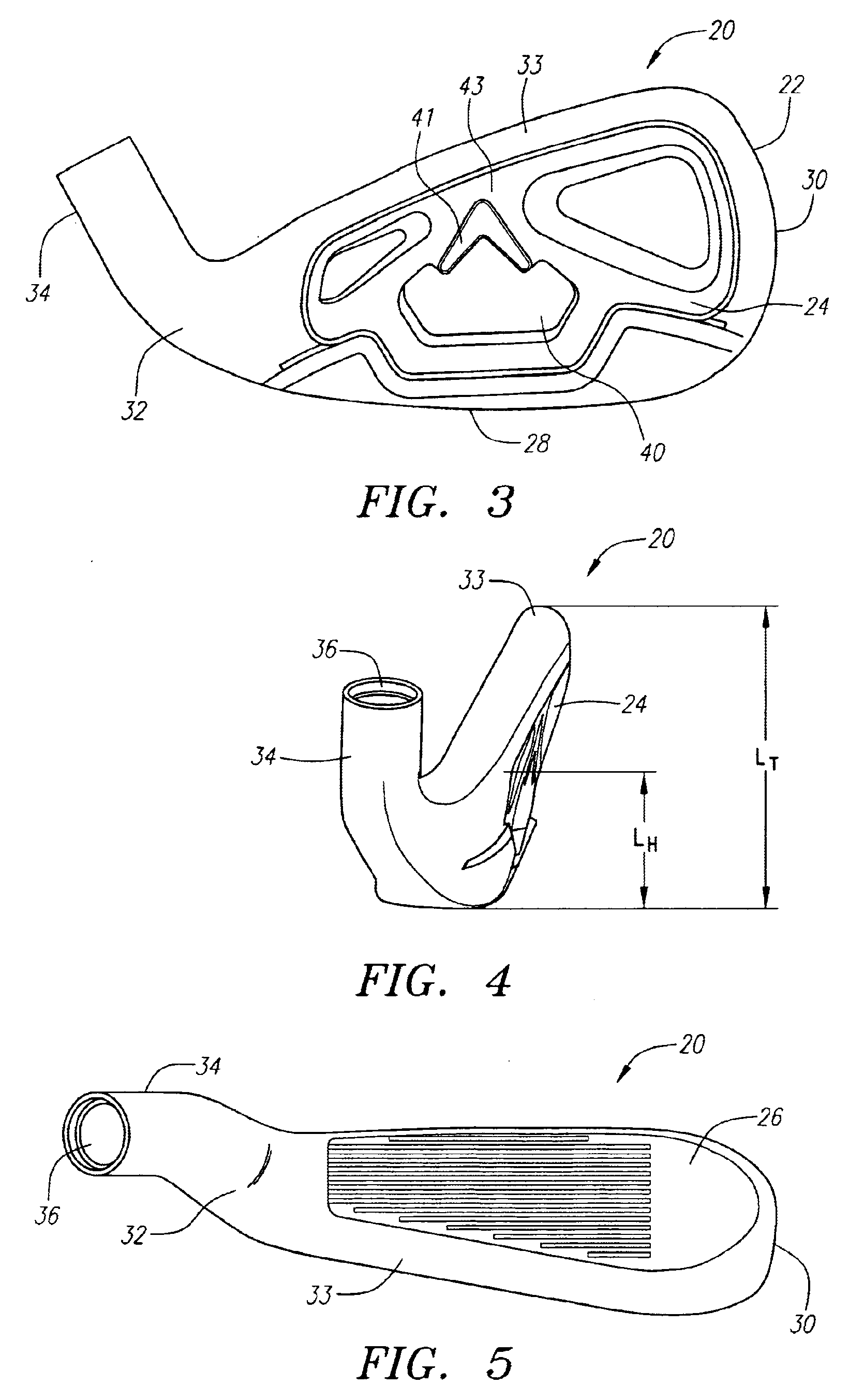

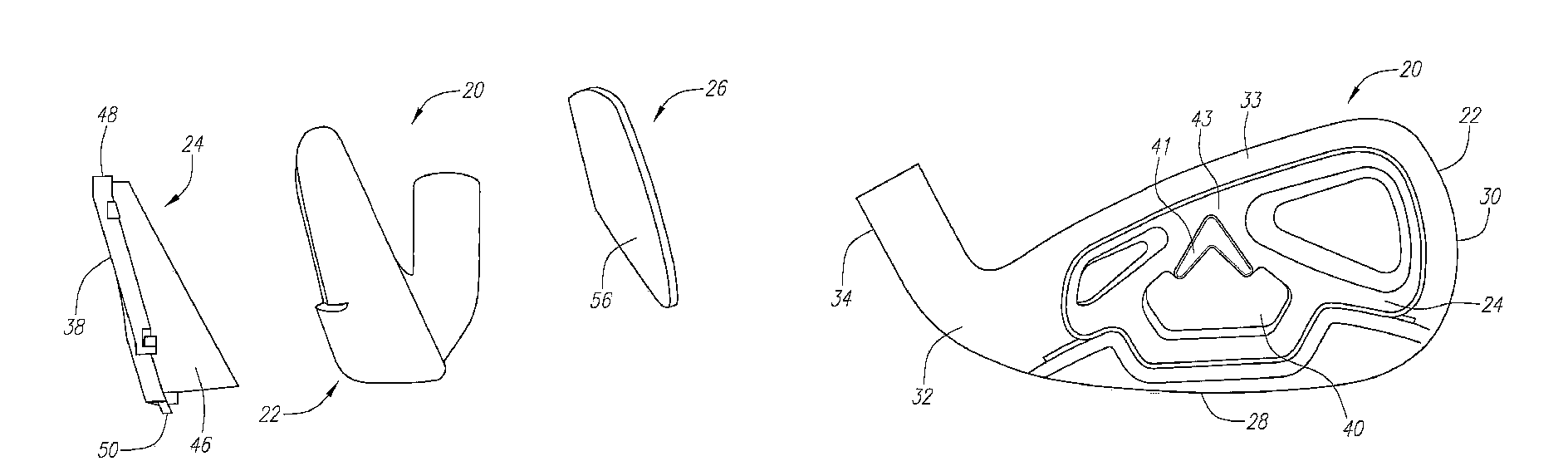

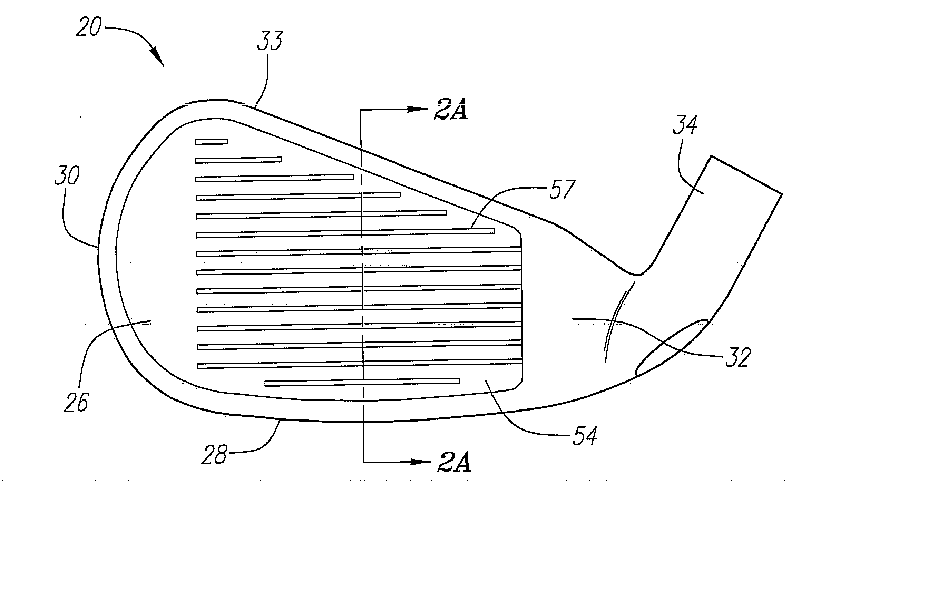

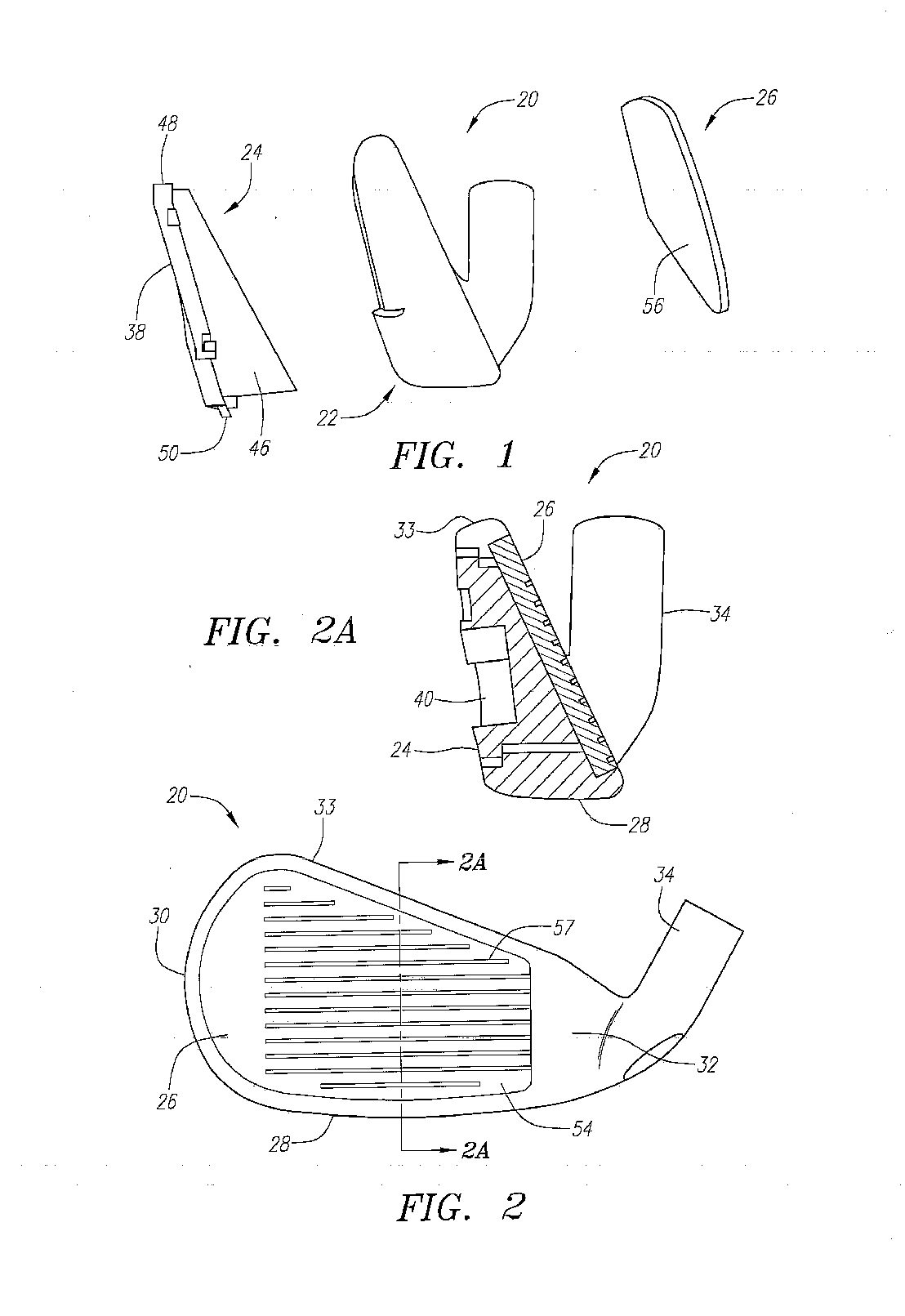

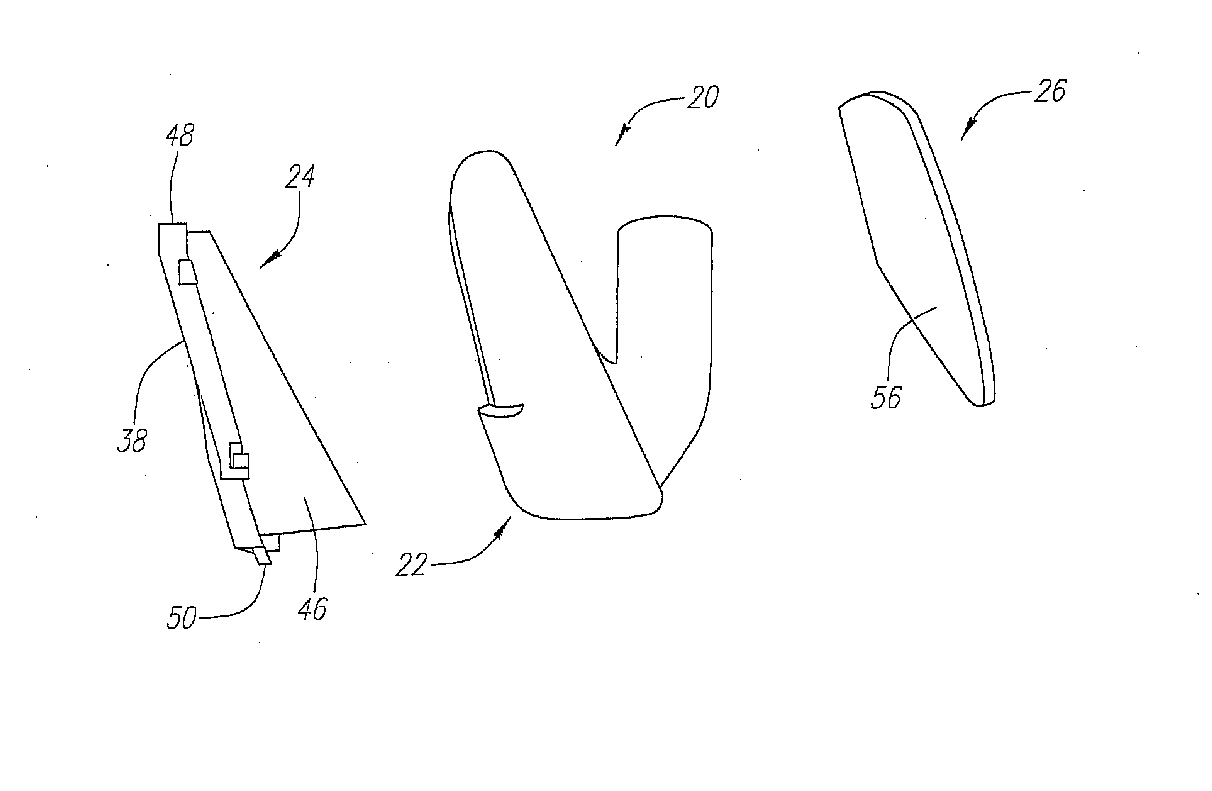

The iron golf club head (20) of the present invention is preferably composed of three main components: a periphery member 22, a central member 24 and a face plate 26. The periphery member (22) is preferably composed of a high density material such as a nickel-tungsten alloy. The central member (24) is preferably composed of a lightweight, non-metal material. The face plate (26) is preferably composed of a titanium alloy material. The iron golf club head (20) preferably has high moments of inertia Izz and Ixx.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Iron golf club

InactiveUS7220189B2Lower center of gravityHigh moment of inertiaGolf clubsRacket sportsHigh densityMetallic materials

The iron golf club head (20) of the present invention is preferably composed of three main components: a periphery member 22, a central member 24 and a face plate 26. The periphery member (22) is preferably composed of a high density material such as a nickel-tungsten alloy. The central member (24) is preferably composed of a lightweight, non-metal material. The face plate (26) is preferably composed of a titanium alloy material. The iron golf club head (20) preferably has high moments of inertia Izz and Ixx.

Owner:TOPGOLF CALLAWAY BRANDS CORP

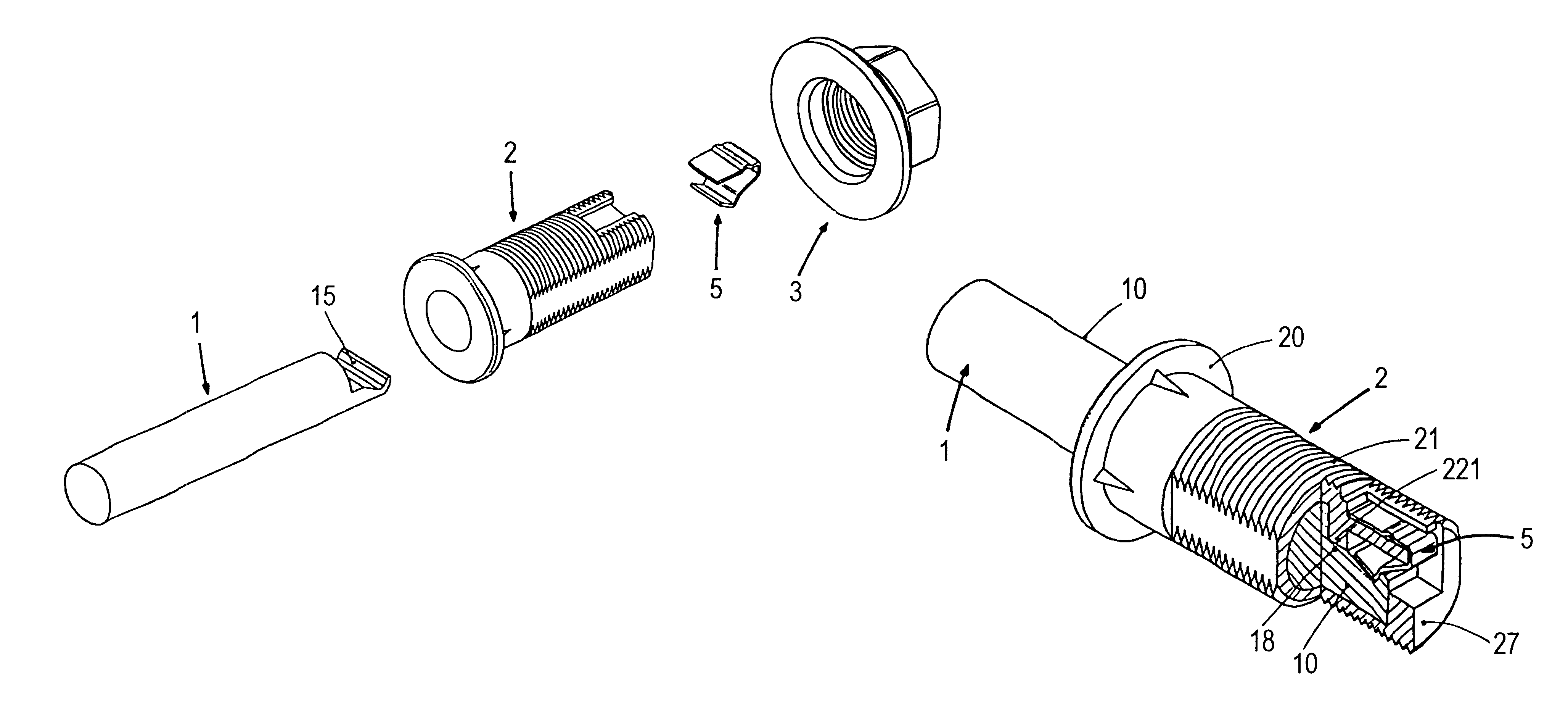

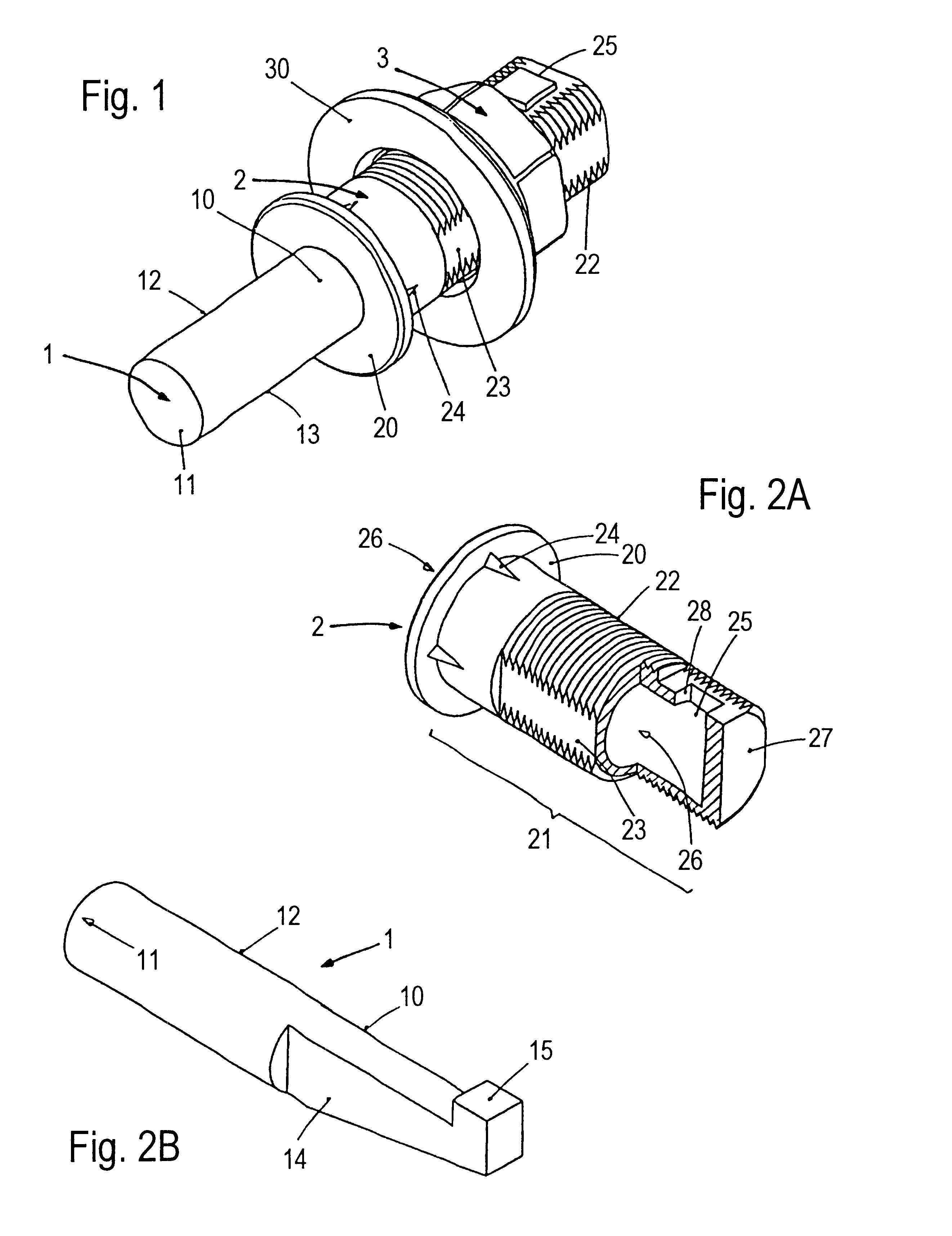

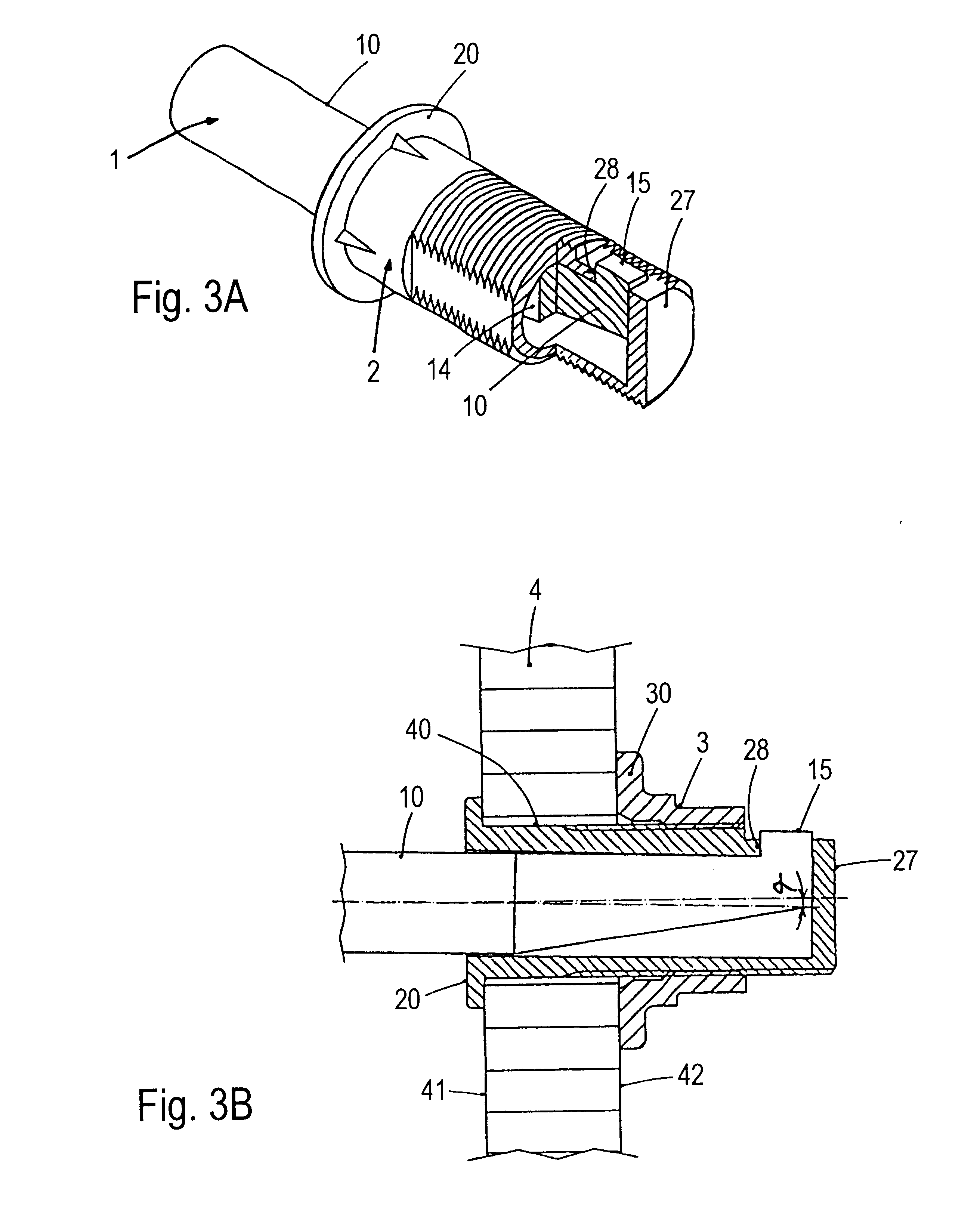

System of supporting bars for use in goods and services establishments

InactiveUS6371313B1Easy to fixSmall dimensionCandle holdersLighting support devicesEngineeringMechanical engineering

Owner:VISPLAY IP

Iron golf club

InactiveUS20050170908A1Lower center of gravityHigh moment of inertiaGolf clubsRacket sportsHigh densityEngineering

The iron golf club head (20) of the present invention is preferably composed of three main components: a periphery member 22, a central member 24 and a face plate 26. The periphery member (22) is preferably composed of a high density material such as a nickel-tungsten alloy. The central member (24) is preferably composed of a lightweight, non-metal material. The face plate (26) is preferably composed of a titanium alloy material. The iron golf club head (20) preferably has high moments of inertia Izz and Ixx.

Owner:TOPGOLF CALLAWAY BRANDS CORP

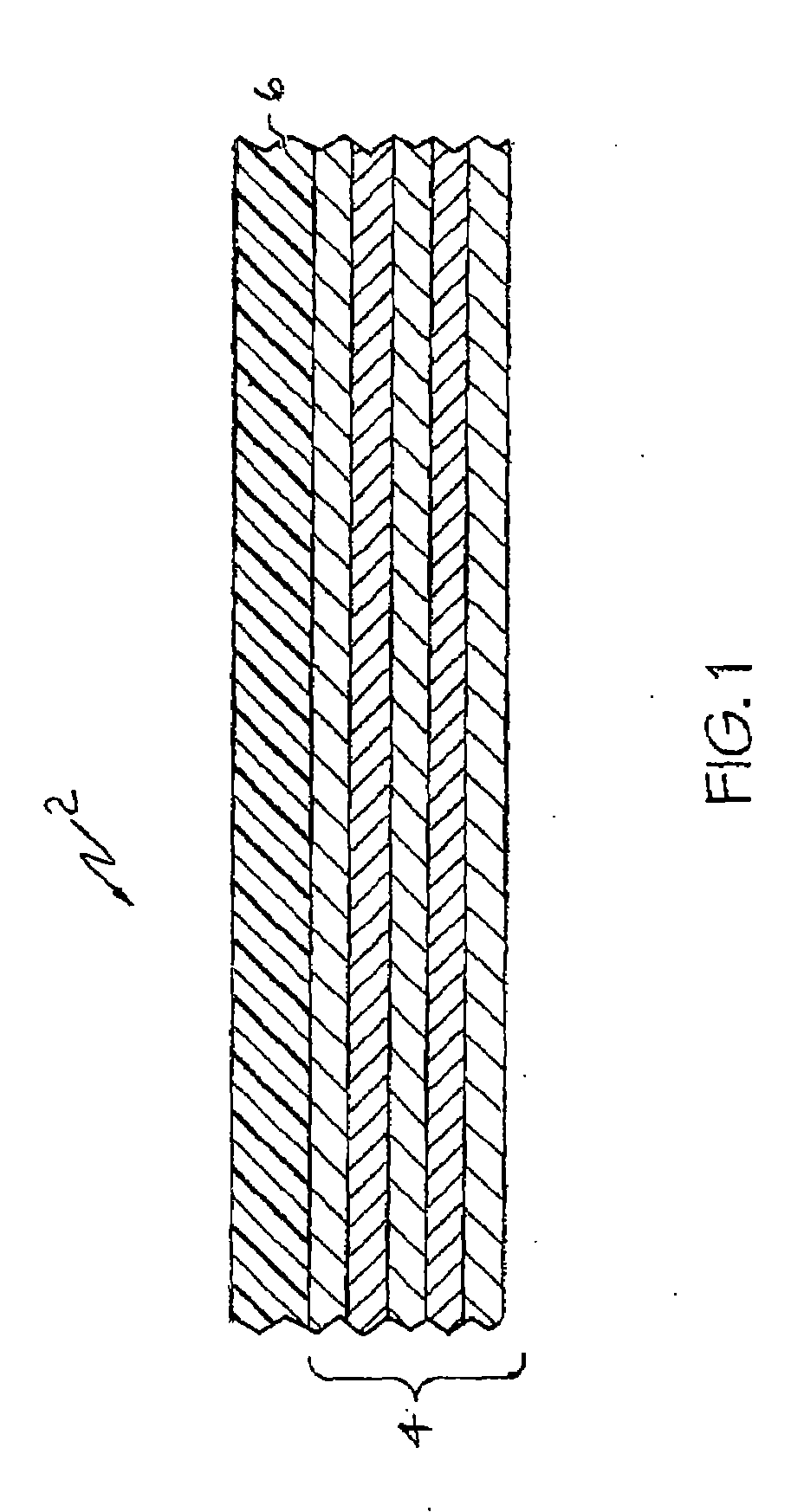

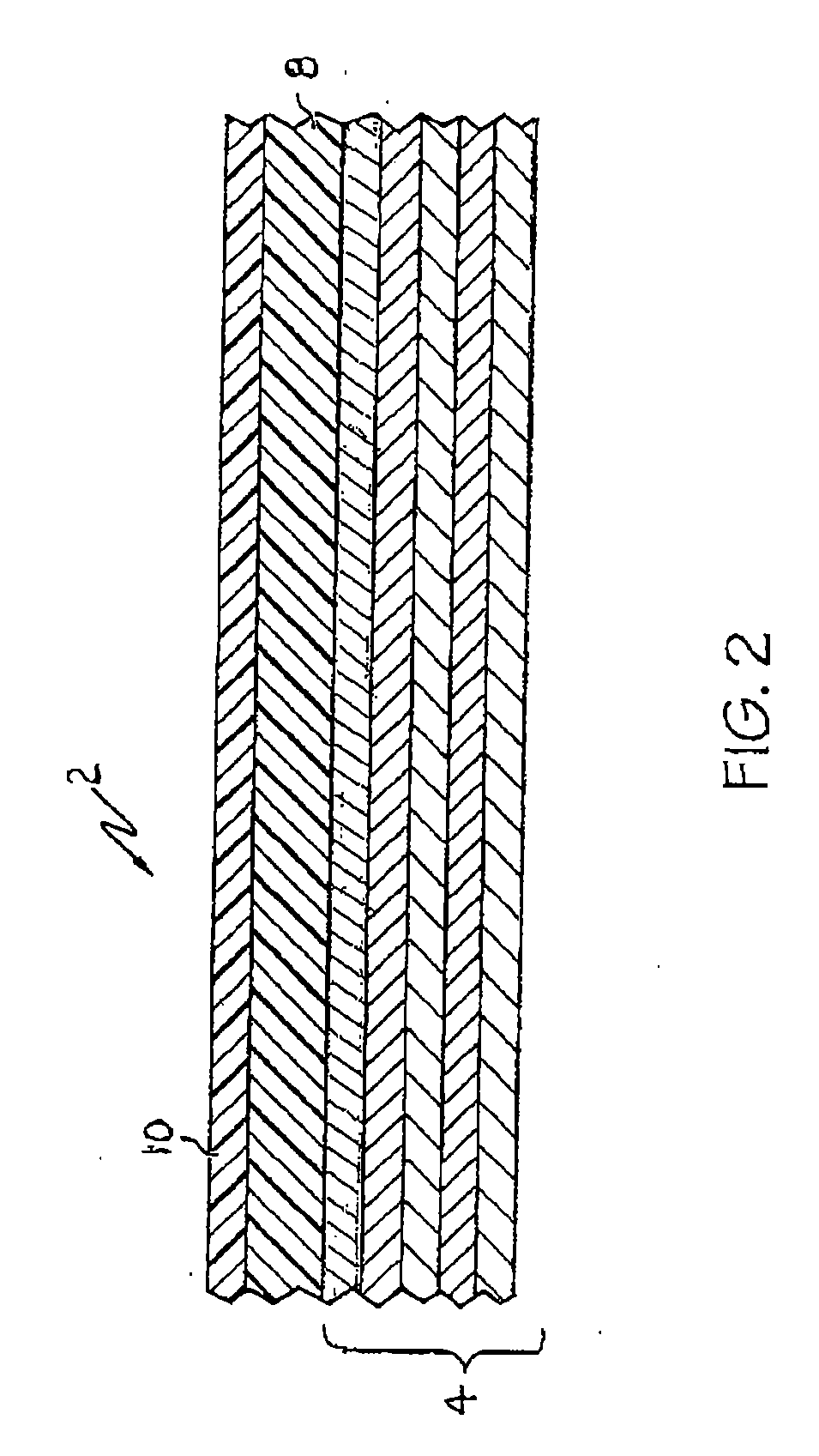

Through color high pressure decorative laminate and method of making same

InactiveUS20090155593A1Increase pressureAesthetically objectionableNon-fibrous pulp additionSpecial paperPolymer scienceFunctional monomer

A decorative laminate is provided and includes a core having a plurality of stacked paper sheets which are impregnated therein a melamine-formaldehyde resin and an internal plasticizer for the melamine-formaldehyde resin, the plasticizer comprising an amino-functional monomer; a decorative sheet overlying the core, the decorative sheet having impregnated therein a melamine-formaldehyde resin and an internal plasticizer for the melamine-formaldehyde resin; and, optionally, an overlay sheet on the decorative sheet. A combustion accelerant is also included in the resin.

Owner:THE DILLER

Iron golf club

InactiveUS20060084527A1Lower center of gravityHigh moment of inertiaGolf clubsRacket sportsHigh densityMoment of inertia

The iron golf club head (20) of the present invention is preferably composed of three main components: a main body (22), a central member (24) and a mass member (25). The Mass member (25) is preferably composed of a high density material such as a nickel-tungsten alloy. The central member (24) is preferably composed of a lightweight, non-metal material. The main body (22) is preferably composed of a titanium alloy material. The iron golf club head (20) preferably has high moments of inertia Izz and Ixx, and a low center of gravity.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Iron-Type Golf Club

InactiveUS20060025237A1Lower center of gravityHigh moment of inertiaGolf clubsRacket sportsEngineeringMoment of inertia

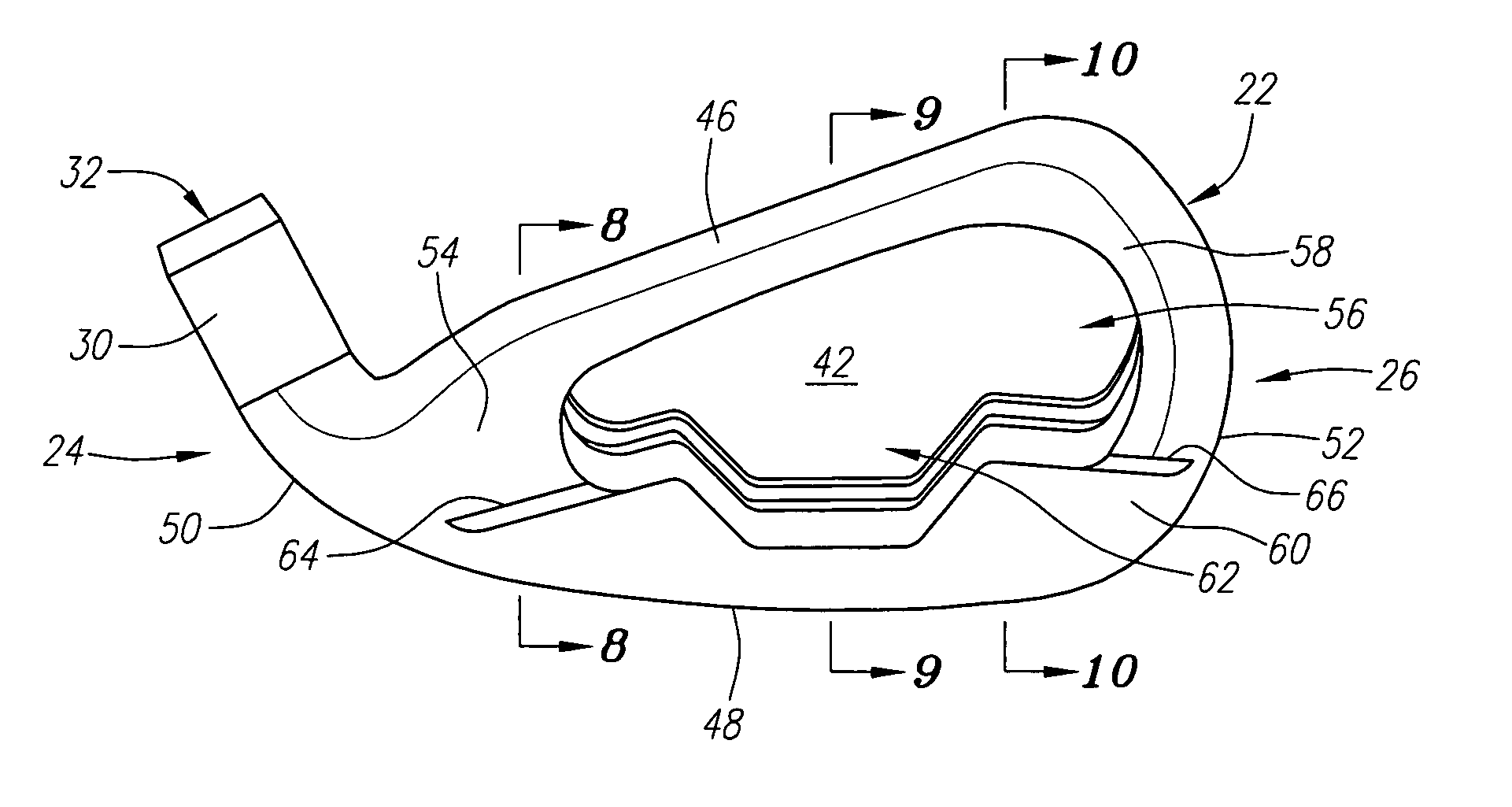

An iron-type golf club head (20) includes a body (22) having a front wall (28) with a ball-striking surface (40). The body (22) further includes a rear surface (54) that has external rear cavity (56) formed therein. The rear surface (54) includes an upper portion (58) and a lower portion (60). The upper portion (60) is separated from the lower portion (59) by the external rear cavity (56) and at least one groove (64, 66). The lower portion (60) of the rear surface (54) has a notch (62) formed therein, which communicates with the external rear cavity (56). The golf club head (20) preferably has high moments of inertia Izz and Ixx.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Method of improving black tea quality

InactiveCN103053716AStrong stress resistanceSolid appearancePre-extraction tea treatmentDiagnostic Radiology ModalityBlack tea

The invention relates to a method of improving black tea quality, in particular to a method and a production technique of utilizing optimizing raw materials combination and polymorphic biological enzymes to improve the quality of the traditional black tea. Production cycle is reduced and the quality of the black tea can be improved. Geoherbalism and functionality of black tea products can be guaranteed. Applicability of the black tea products can be enlarged. A defect of similar product modality can be overcome.

Owner:贺志弘 +2

Iron Golf Club

InactiveUS20050130765A1Lower center of gravityHigh moment of inertiaGolf clubsRacket sportsHigh densityMoment of inertia

The iron golf club head (20) of the present invention is preferably composed of three main components: a periphery member 22, a central member 24 and a face plate 26. The periphery member (22) is preferably composed of a high density material such as a nickel-tungsten alloy. The central member (24) is preferably composed of a lightweight, non-metal material. The face plate (26) is preferably composed of a titanium alloy material. The iron golf club head (20) preferably has high moments of inertia Izz and Ixx.

Owner:TOPGOLF CALLAWAY BRANDS CORP

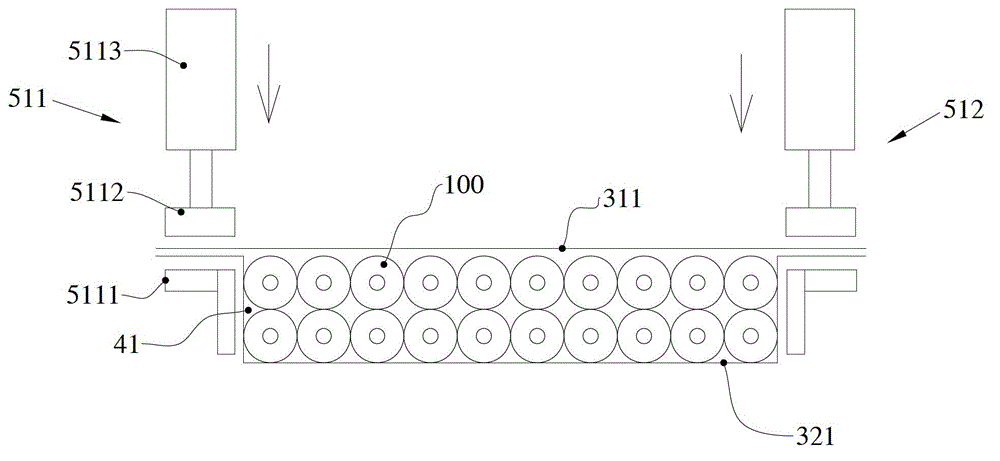

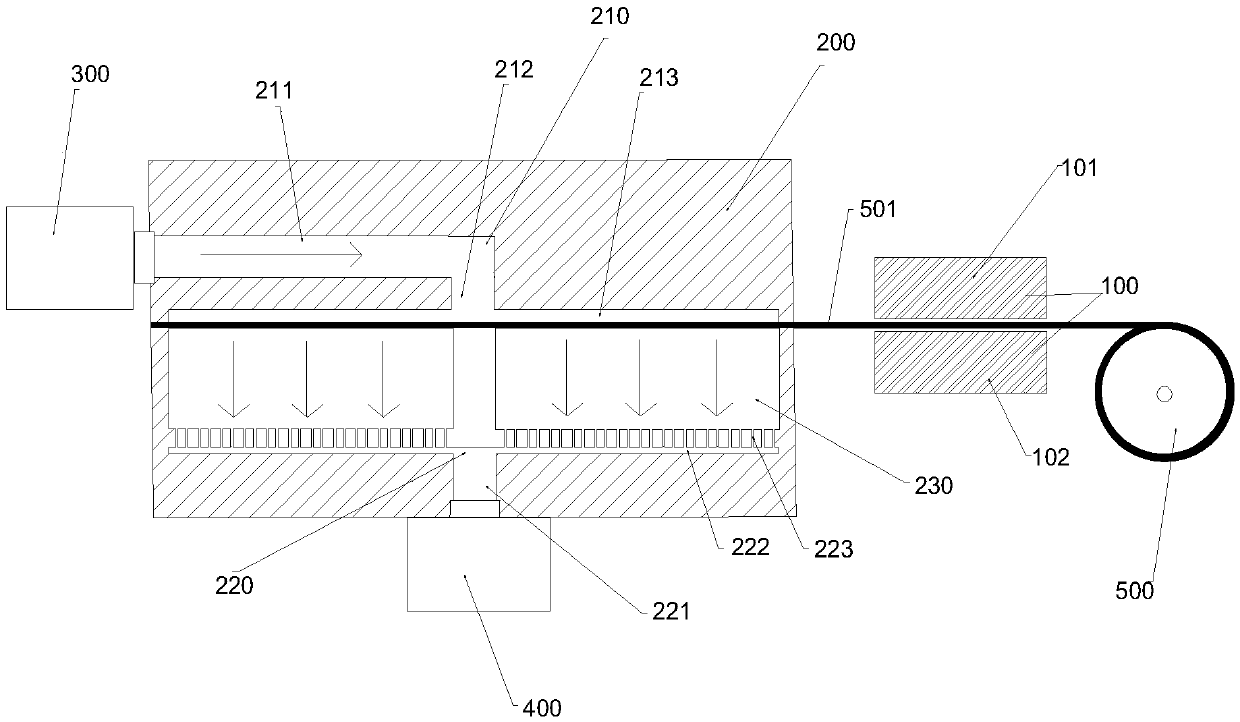

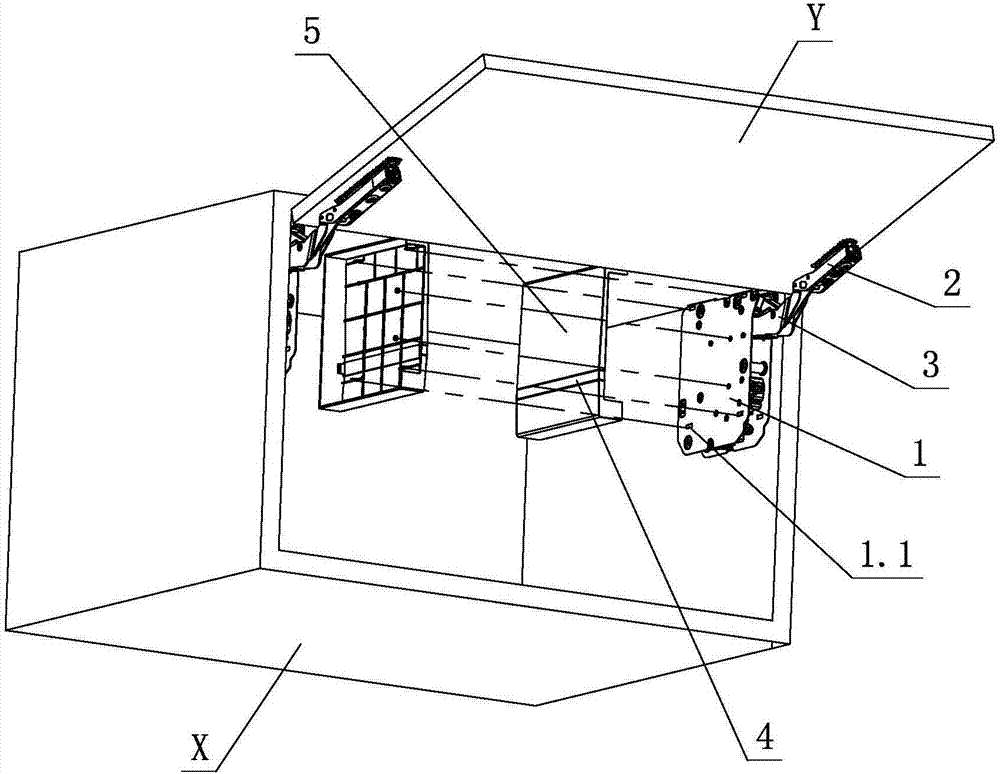

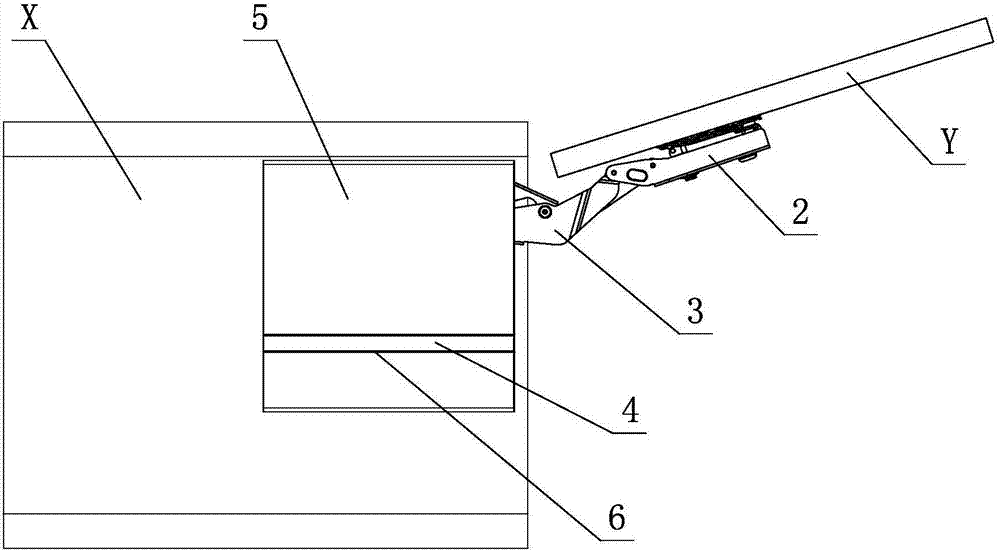

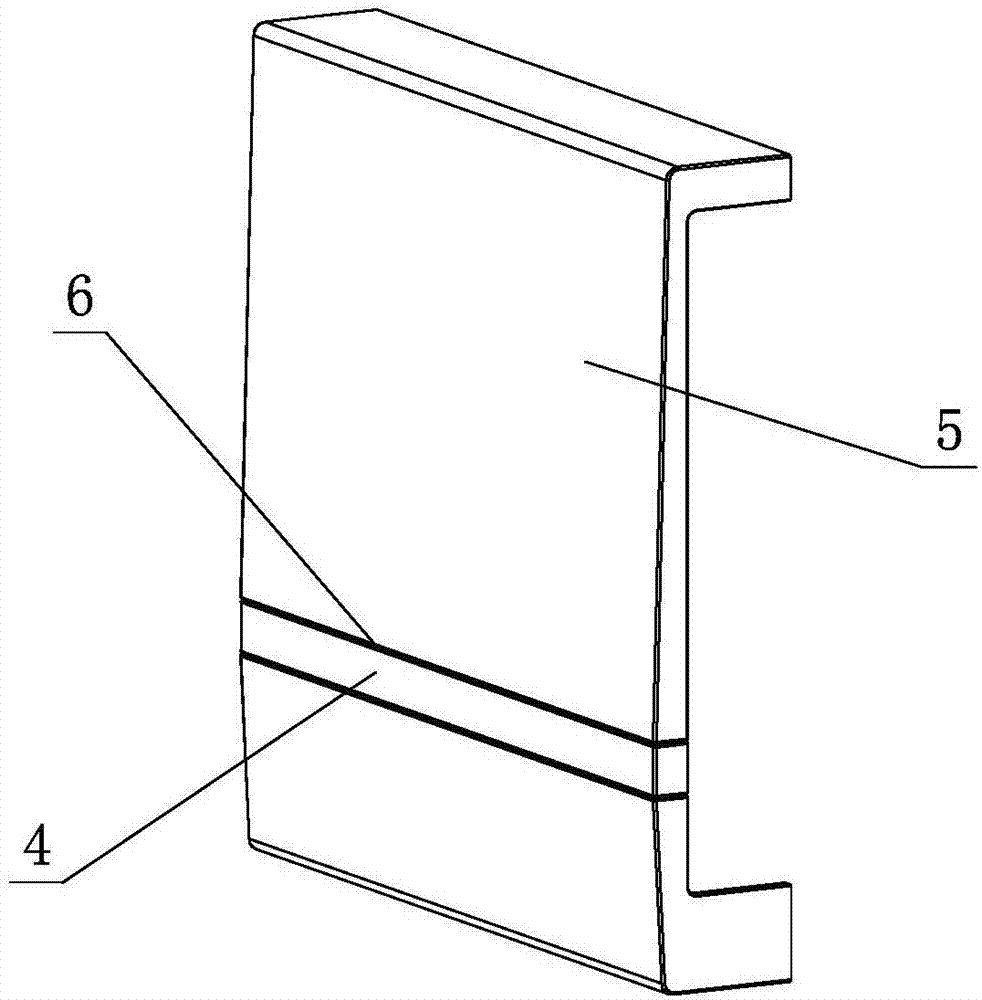

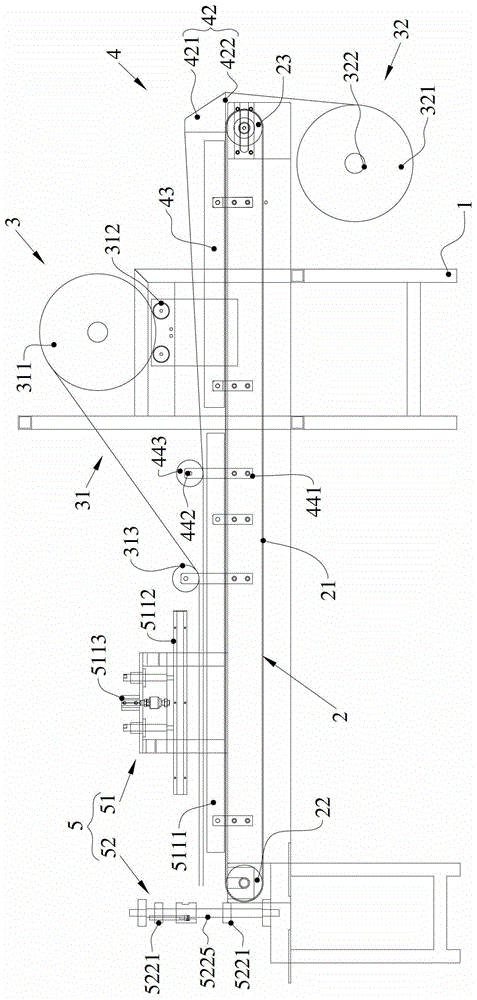

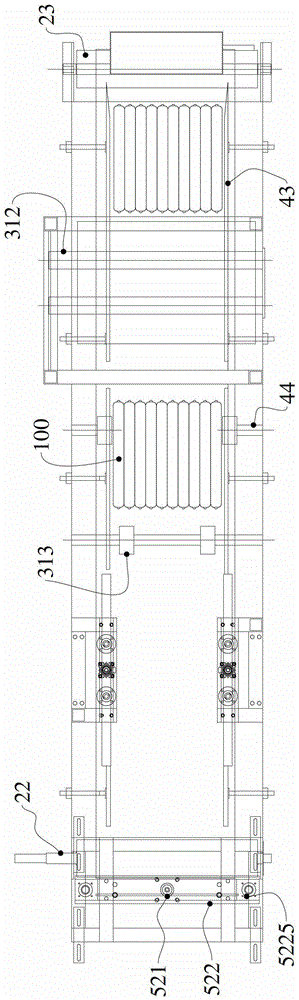

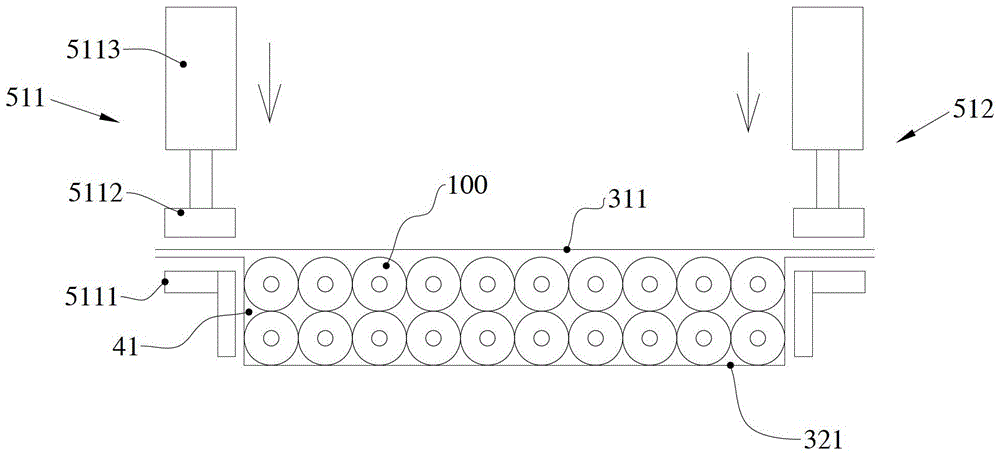

Belt medium package machine

ActiveCN104029842AReduce gapSolid appearanceWrapping material feeding apparatusWrapper twisting/gatheringVertical edgeEngineering

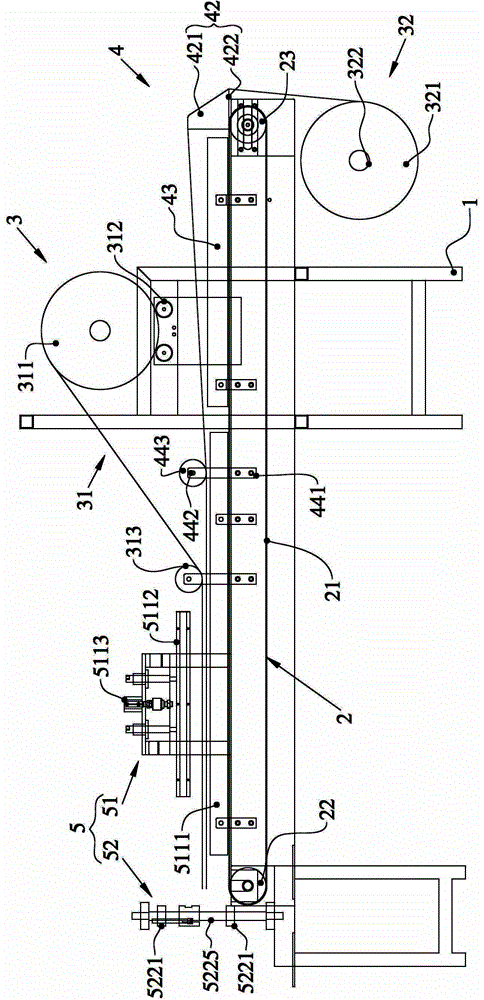

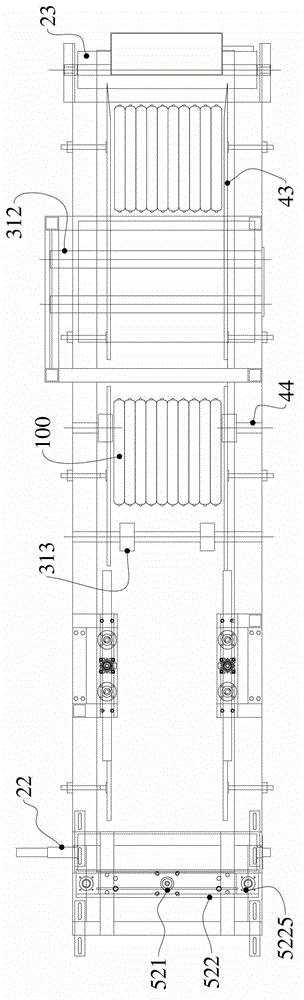

The invention belongs to the field of columnar explosive package and particularly relates to a belt medium package machine which comprises a machine frame, a conveying mechanism arranged on the machine frame and used for conveying columnar explosives, a film supply mechanism used for supplying an upper film and a lower film, a film bending mechanism arranged at the output end of the film supply mechanism and used for bending the lower film to form a containing groove for containing the columnar explosives and an edge sealing mechanism arranged above the conveying mechanism and used for sequentially sealing the corresponding transverse edges and the corresponding vertical edges of the upper film and the lower film to package the columnar explosives. The conveying mechanism is adopted to convey the columnar explosives between the upper film and the lower film, the bending mechanism is utilized to bend the lower film to form the containing groove to locate the columnar explosives, and the edge sealing mechanism is utilized to seal the corresponding transverse edges and the corresponding vertical edges of the upper film and the lower film sequentially to form a columnar explosive package. The package efficiency is high, gaps between the columnar explosives in each columnar explosive package is small, mutual movement cannot happen easily, the whole columnar explosive package is stable in appearance, and the package and shaping effects are good.

Owner:江苏天明化工有限公司

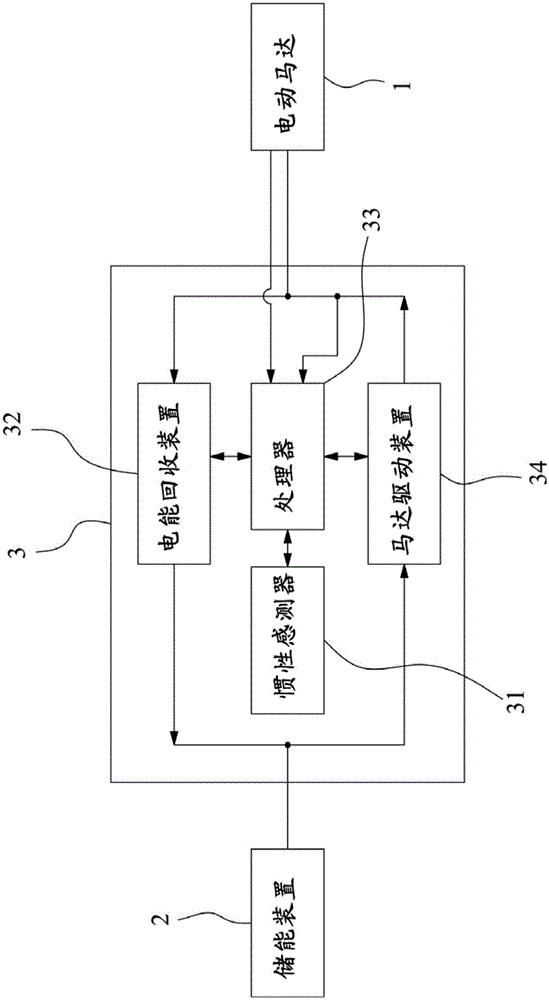

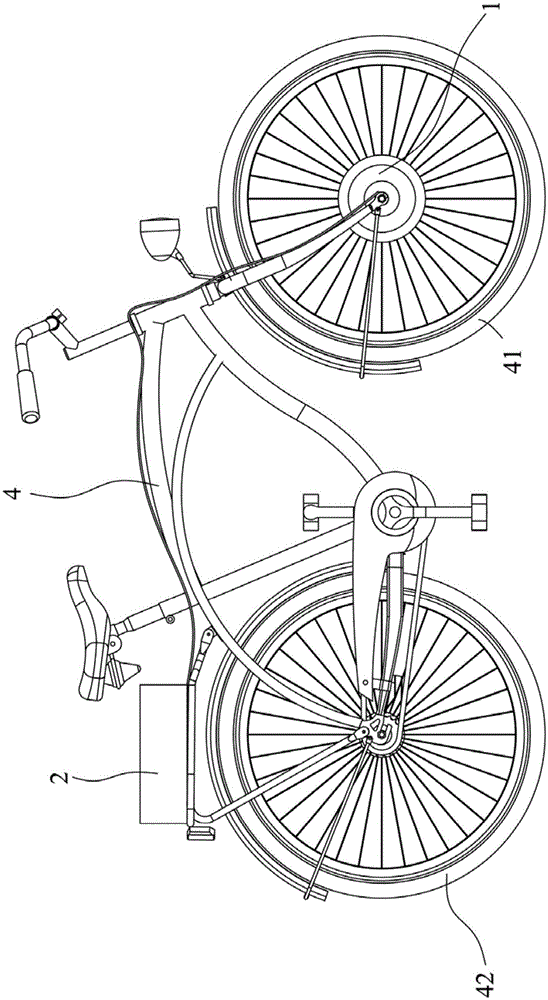

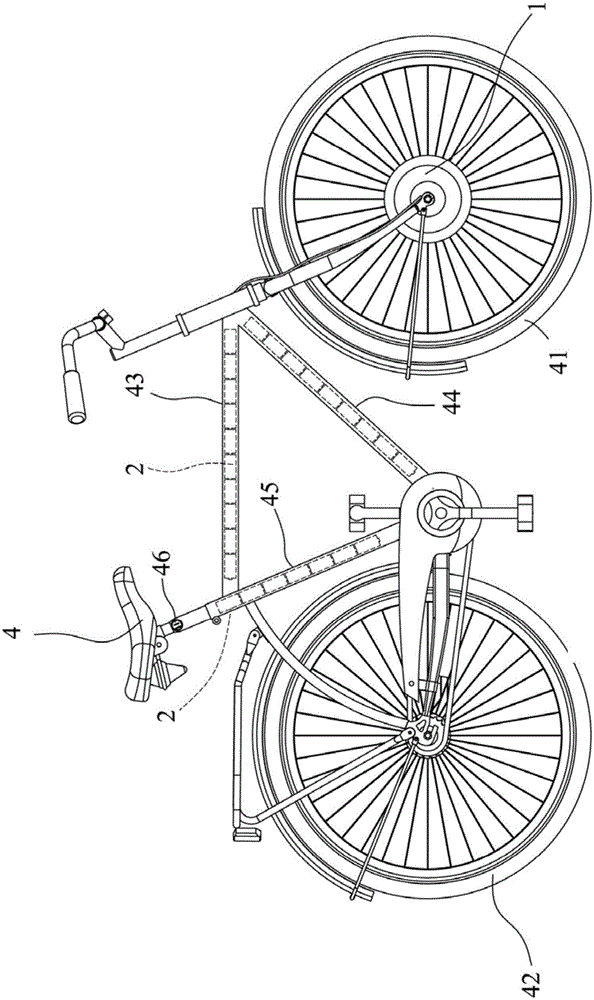

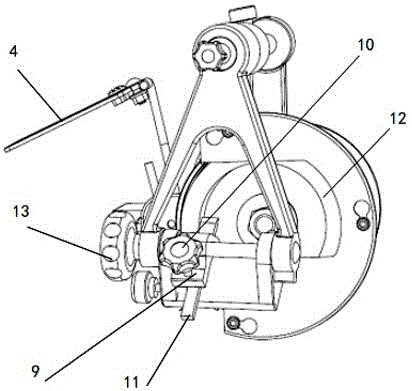

Intelligent auxiliary power system of bicycle

An intelligent auxiliary power system of a bicycle includes an electric motor, an electric auxiliary drive module and an energy storage device; the electric motor is arranged on a wheel drum of a wheel of the bicycle; the energy storage device is coupled to the electric motor through the electric auxiliary drive module; the electric auxiliary drive module includes an inertia sensor, an electric energy recovery device, a processor, and a motor drive unit; the processor receives information including a forward momentum and a vehicle attitude, of the bicycle, acquired by the inertia sensor, and acquires the revolution speed and the torque of the electric motor through operation; and the processor performs operation through a control algorithm according to all the information, and then the motor drive module drives the electric motor, or the electric energy recovery device charges up the energy storage device with electric energy generated by the electric motor. Accordingly, when a rider rides the bicycle, the intelligent auxiliary power system can control output of auxiliary power in a self-adaption manner according to the forward momentum and the vehicle attitude of the bicycle and the revolution speed and the torque of the electric motor.

Owner:TRITAN TECH INC

Method for fruiting and breeding needle mushrooms on flat plate through multi-spore self-breeding

The invention discloses a method for fruiting and breeding needle mushrooms on a flat plate through multi-spore self-breeding. The method comprises the steps of: collecting spores, mixing monospores for self breeding, fruiting on the flat plate, selecting self-breeded dikaryon colonies and cultivating and screening. The method can be used for greatly increasing the working efficiency and the breeding quality, and the obtained strains have definite target properties and have the characteristics of high growth speed, high yield, attractive appearance, stable heredity, strong stress resistance and the like.

Owner:SHANGHAI ACAD OF AGRI SCI

Production method for linen-cotton slubbed sofa fabric

InactiveCN104562375AStatic freeFast moisture absorption and heat dissipationWoven fabricsYarnFiberMoisture absorption

The invention relates to the technical field of textile fabrics, in particular to a production method for a linen-cotton slubbed sofa fabric. According to the production method, due to the addition of natural linen fibers, the fabric is cool, air-permeable, antistatic, high in moisture absorption and radiation speed, soft and comfortable, and does not stick to the skin; the linen fibers have the effect of inhibiting the growth of bacteria, and are lethal to insects, so that human skin can be effectively prevented from being damaged by bacteria and mites; the fabric produced by the method is produced by interweaving high-strength warp and weft twines, so that the fabric is high in strength and wear resistance; a plain structure production mode is adopted, so that warp and weft yarns can be most closely intertwined, most firm texture and most appearance flatness of the fabric are achieved, and the strength and the wear resistance of the fabric are further enhanced; slubbed twines with extremely high thickness contrast are adopted as the weft yarns, so that the fabric is highly layered, and unique visual effects and texture effects are achieved.

Owner:HUNAN GUANGYUAN HEMP IND CO LTD

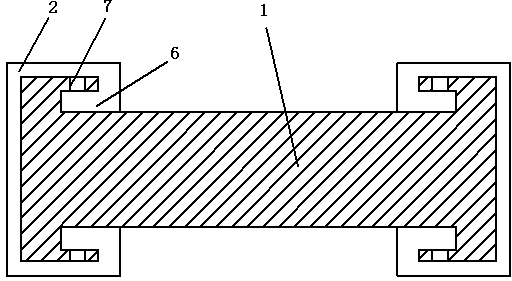

Crystal embroidery ornament and manufacturing method thereof

InactiveCN102632761ARealize the framed effectBreakthrough cannot promote corporate cultureSpecial ornamental structuresPaperhangingEngineeringMechanical engineering

The invention relates to a manufacturing method of an embroidery ornament, which comprises the following steps of: firstly, paving a prefabricated embroidery on an embroidery containing cavity (2) of a mounting outer frame (1) of the ornament, and aligning the position of embroidery in the embroidery containing cavity (2); secondly, aligning, gluing and fixing an upper frame board (11) and a lower frame board (12) which are form the mounting outer frame (1); and thirdly, cutting and edging the glued upper frame board (11) and the lower frame board (12) to form the embroidery ornament. The embroidery ornament manufactured by using the manufacturing method provided by the invention has better sealing performance and can ensure that the embroidery is not corroded and damped, thus greatly prolonging the service life of the embroidery.

Owner:孙正德

Iron golf club

InactiveUS20050187032A1Lower center of gravityHigh moment of inertiaGolf clubsRacket sportsHigh densityEngineering

The iron golf club head (20) of the present invention is preferably composed of three main components: a periphery member 22, a central member 24 and a face plate 26. The periphery member (22) is preferably composed of a high density material such as a nickel-tungsten alloy. The central member (24) is preferably composed of a lightweight, non-metal material. The face plate (26) is preferably composed of a titanium alloy material. The iron golf club head (20) preferably has high moments of inertia Izz and Ixx.

Owner:TOPGOLF CALLAWAY BRANDS CORP

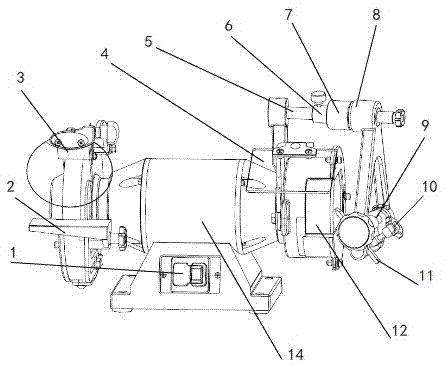

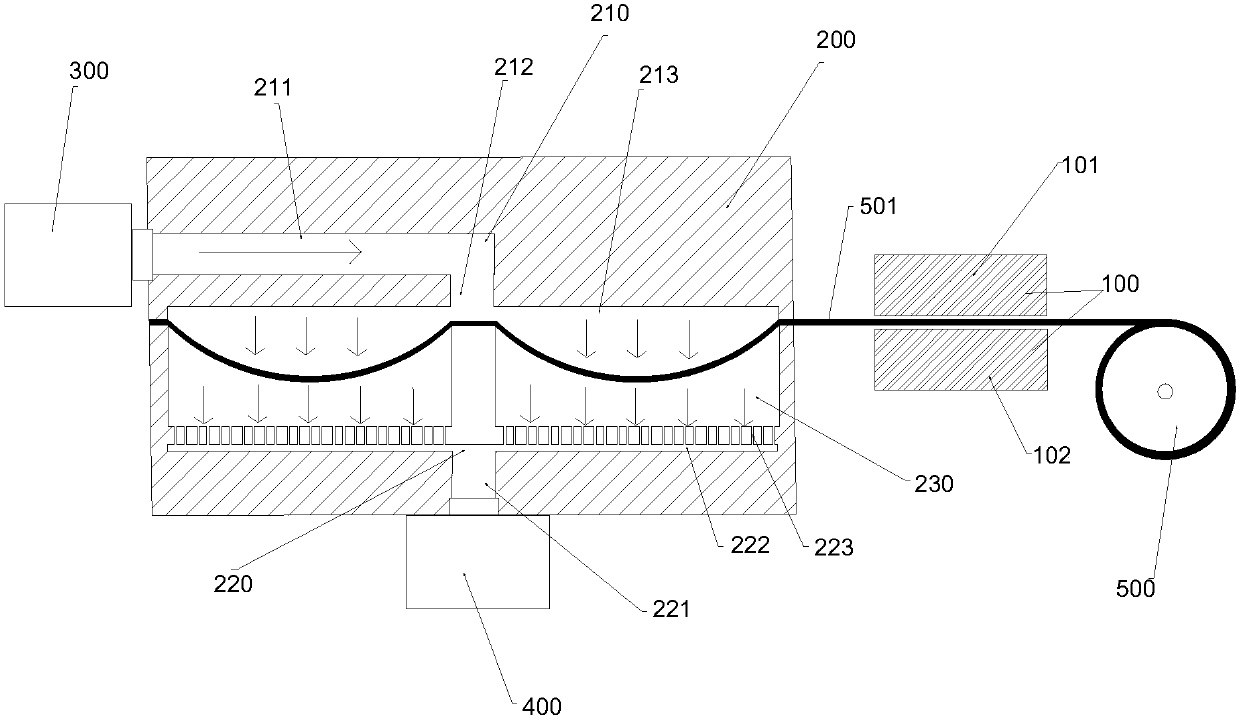

Pendulum tool grinding machine

InactiveCN106914798AReduced sources of drive failureBeautiful appearanceGrinding drivesOther manufacturing equipments/toolsBlade plateChisel

The invention relates to the field of machines, in particular to a pendulum tool grinding machine used for narrow and long tools such as the kind of woodworking chisels. The pendulum tool grinding machine is composed of a motor and a tool grinding cup type grinding wheel and is characterized in that the tool grinding cup type grinding wheel is installed on a main shaft on the right side of the motor; a lifting shaft, an adjusting seat, an adjusting nut and a swing seat are installed on the upper face of the right side; a tool pressing plate and a tool clamping handle are installed on the lower face of the swing seat; and a bracket and a left protection lens are installed on the left side of the motor. The pendulum tool grinding machine has the beneficial effects that the novel tool grinding machine is provided, rough grinding of a common grinding wheel machine and finish grinding of a pendulum mechanism are integrated, the motor is arranged in the middle and is used for driving a grinding wheel piece and the cup type grinding wheel to rotate at the two ends; and a transmission mechanism is relatively simple, transmission fault sources are reduced, and products are attractive in appearance, compact and stable.

Owner:WENDENG ALLWIN MOTORS MFG

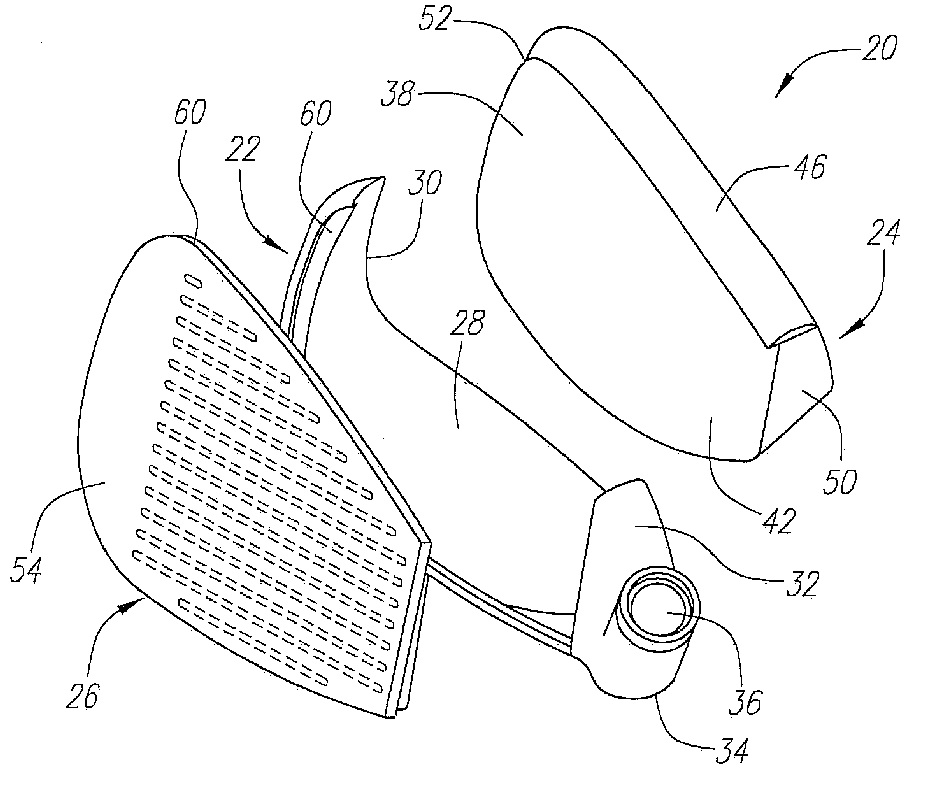

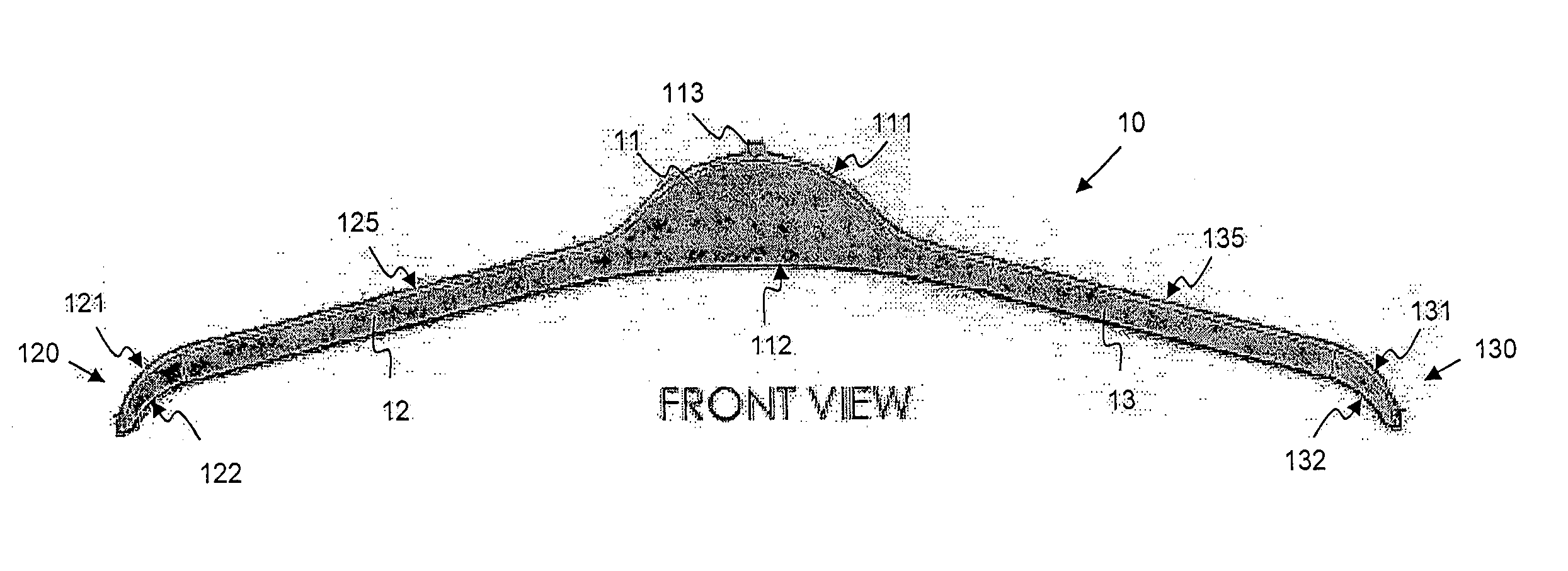

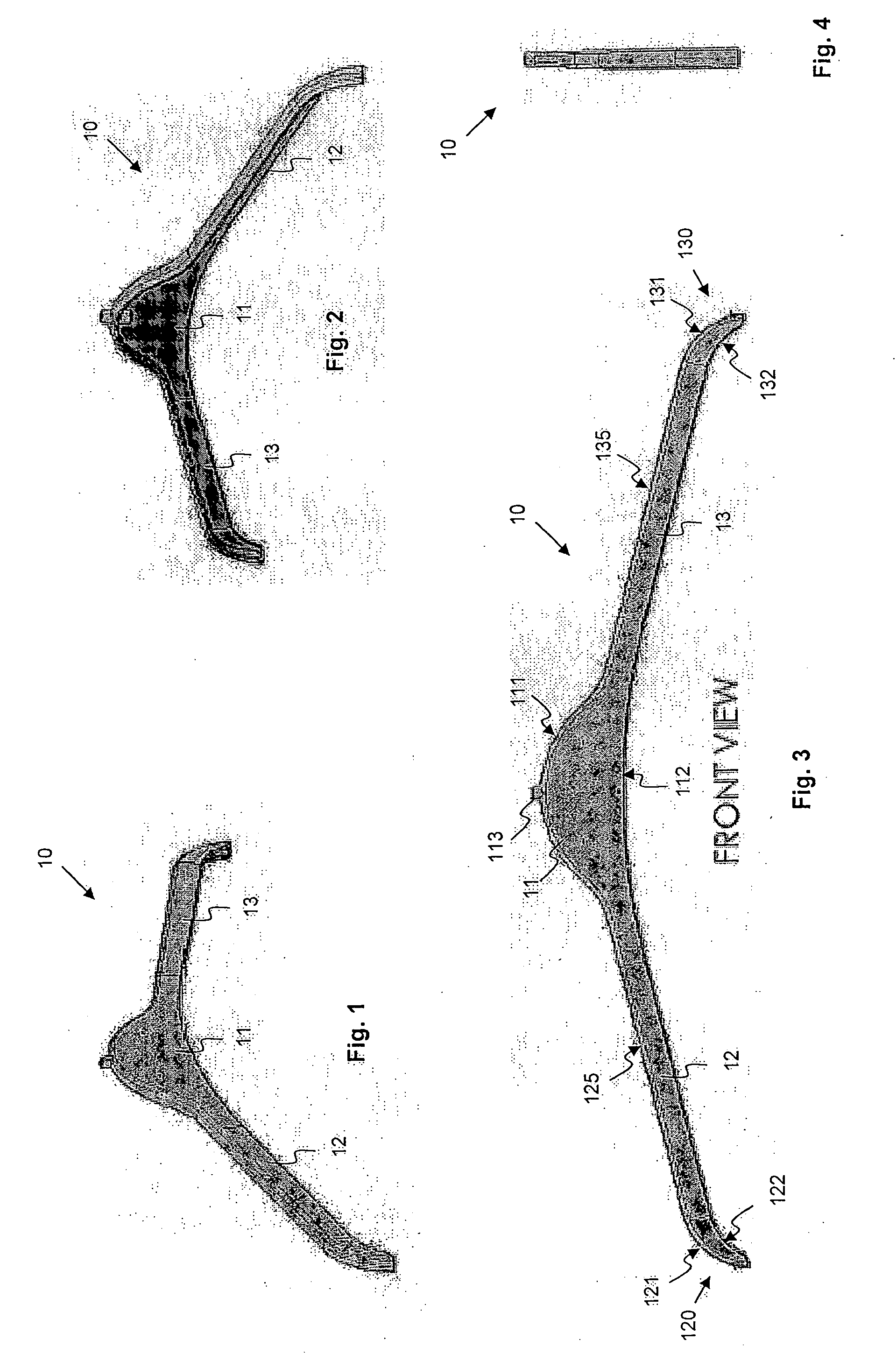

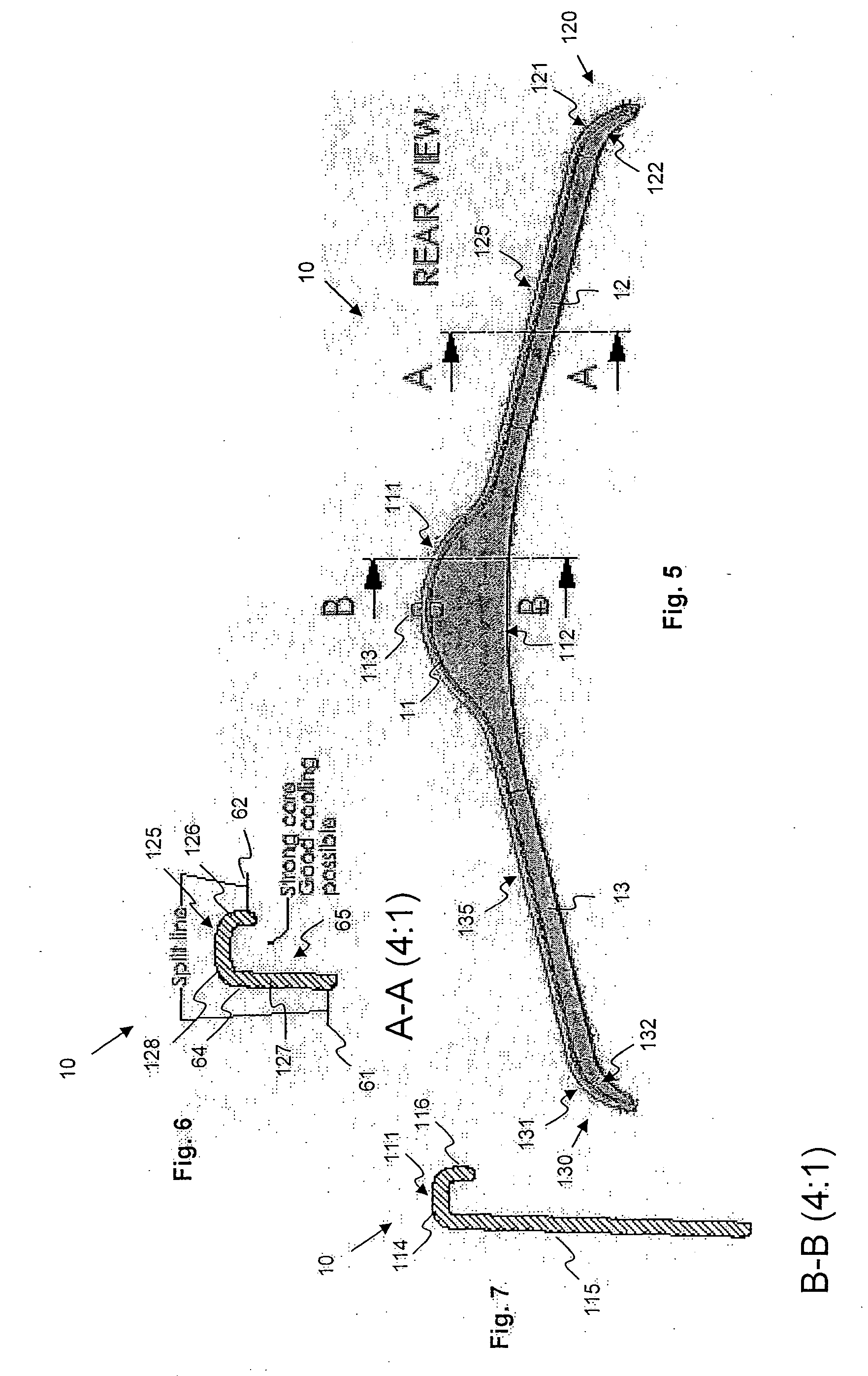

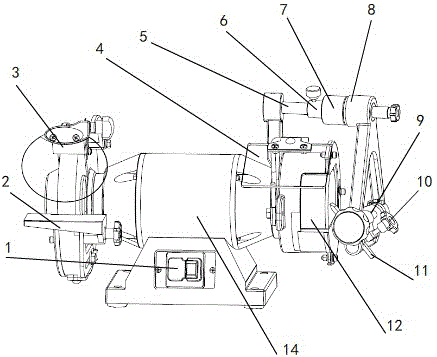

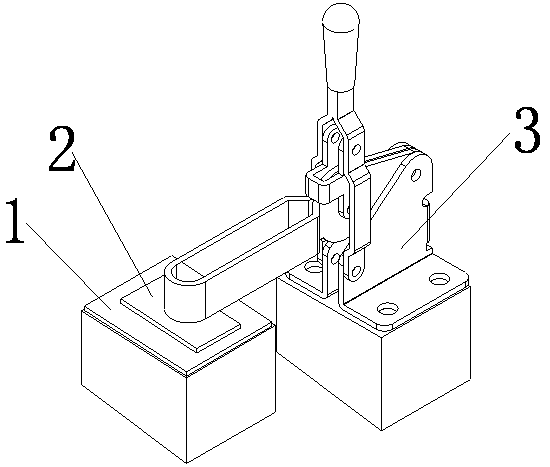

Garment hanger and molding apparatus

InactiveUS20060278672A1Solid appearanceLow production costApparel holdersGarmentsClothes hangerEngineering

Owner:BRAITRIM U K

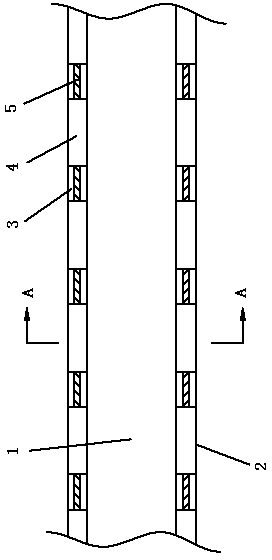

Improved color band structure

The invention discloses an improved color band structure. The structure comprises a color band body, wherein two sides of the color band body are provided with outer wrapping layers respectively, the outer side of the outer wrapping layer is provided with concave areas and convex areas which are arranged at intervals, the surface of the concave area is provided with a reflective layer, the upper end and the lower end of the inner side of the outer wrapping layer are provided with L-shaped fixing grooves respectively, and the L-shaped fixing groove is internally provided with a plurality of fixing teeth. The improved color band structure can improve deficiencies of the prior art, and improves the tolerance of a color band in use.

Owner:广州盈科新材料科技有限公司

Thermal-forming vacuum stretching packaging machine

The invention provides a thermal-forming vacuum stretching packaging machine comprising a heating plate, a vacuum forming chamber, an air blowing device and an air sucking device. Thermoplastic materials on a transmission device are heated by the heating plate and then enter the vacuum forming chamber. The vacuum forming chamber comprises an upper ventilating opening, a lower ventilating opening and a model chamber communicating with the two ventilating openings, wherein the upper ventilating opening is connected with the air blowing device, the lower ventilating opening is connected with theair sucking device, airflow generated by the air blowing device enters the model chamber through the upper ventilating opening to act on the thermoplastic materials, the lower ventilating opening communicates with micro holes distributed in the bottom of the model chamber, and the air sucking device enables the thermoplastic materials to be evenly stressed through the micro holes so as to reach the bottom of the model chamber. According to the thermal-forming vacuum stretching packaging machine, through a stretching technology that positive pressure and negative pressure are conducted simultaneously, the thermoplastic materials can be automatically formed on equipment, the forming rate is high, and the box form is stable.

Owner:上海金硕实业有限公司

A method for embedding lactic acid bacteria using Maillard products as wall material

ActiveCN104531664BImprove survival rateImprove stabilityMicroorganism based processesOn/in organic carrierBiotechnologyEgg White Proteins

Owner:SICHUAN GAOFUJI BIOLOGICAL TECH

Method for manufacturing ping-pong table

The invention discloses a preparation method of a table tennis table. Firstly, the front and side surfaces of the mold are polished, and a layer of release wax is coated on the mold, and then polished; secondly, the billet shape is heat-treated, and the surface of the wooden core board is placed on the edge of the back surface of the table tennis table. The wooden strips after nailing treatment are reinforced; the third is to paint the table mold with resin, mix the unsaturated polyester resin and talcum powder in proportion, and then paint; the fourth is to wash and brush the wooden core table surface, and add peroxide Bad acetone and accelerator, brush on the table surface, and fix the table mold; the fifth is to paint the table surface, use fiberglass cloth to spread the brush, and then perform hydraulic pressure; the sixth is to remove the film from the table surface, after a certain period of time Remove the film and paint the surface of the ball table with unsaturated polyester resin and talcum powder. The process of the invention is simple and convenient, the table does not deform or crack in harsh environments, and has a long service life.

Owner:王少虎

Method for manufacturing ping-pong table

A technology for making the ping-pong table includes polishing the front surface and side surface of mould, coating demoulding wax, polishing, thermally treating the raw table, reinforcing edges withstrips, coating the mixture of unsaturated polyester resin and talc powder on mould, coating the mixture of cycloethaneone peroxide and promoter on table, fixing in mould, spreading glass fibre fabric on surface of table, hydraulic pressing, demoulding, and brushing the mixture of unsaturated polyester resin and talc powder. Its advantages are no deformation and cracking and long service life.

Owner:王少虎

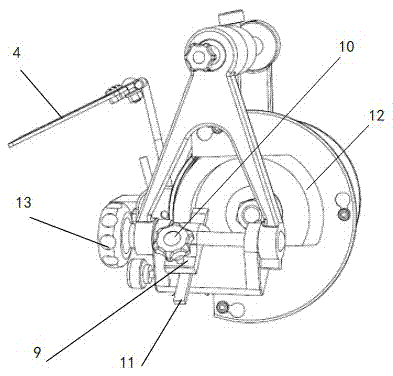

Motor double-shaft-extension cutter sharpener

InactiveCN105965327AReduced sources of drive failureBeautiful appearanceOther manufacturing equipments/toolsGrinding machinesBench grinderEngineering

The invention provides a motor double-axis extension knife grinder, which includes a motor. The motor has shaft extensions at both ends. One end of the motor is installed with a common knife grinder for rough grinding of knives. The other end of the motor is equipped with a pendulum sharpening device. The device includes a sharpening cup-shaped grinding wheel, a suspension shaft, an adjustment seat, an adjustment nut, a swing seat, a knife presser, a knife clamp handle and an M8 locking handle. The sharpening cup-shaped grinding wheel is installed on the main shaft of the motor and is driven by the motor to rotate. The suspension shaft is located on the upper part of the motor and is fixed on the motor casing; the suspension shaft is provided with an adjustment seat, an adjustment nut and a swing seat in sequence, and a horizontal shaft is set at the bottom of the swing seat, and the horizontal shaft is equipped with a pressure plate and a knife clamp handle Lock the handle with M8, the pressure knife plate is put on the horizontal axis, the knife clamp handle is set on the pressure knife plate through threaded connection, and it is used to fix the tool to be sharpened by screwing operation. A pendulum knife sharpening device is installed at one end of the motor, which swings when sharpening the knife, which is similar to a pendulum, smaller than the conventional knife sharpener, and increases the function of the conventional grinder.

Owner:WENDENG ALLWIN MOTORS MFG

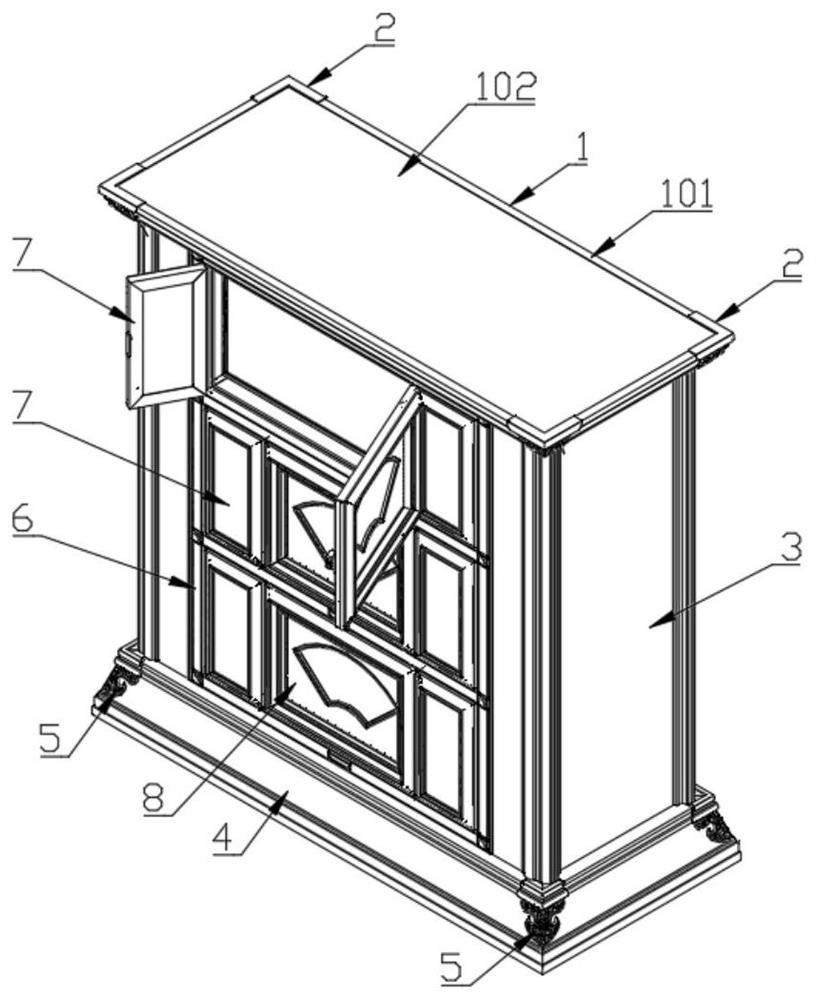

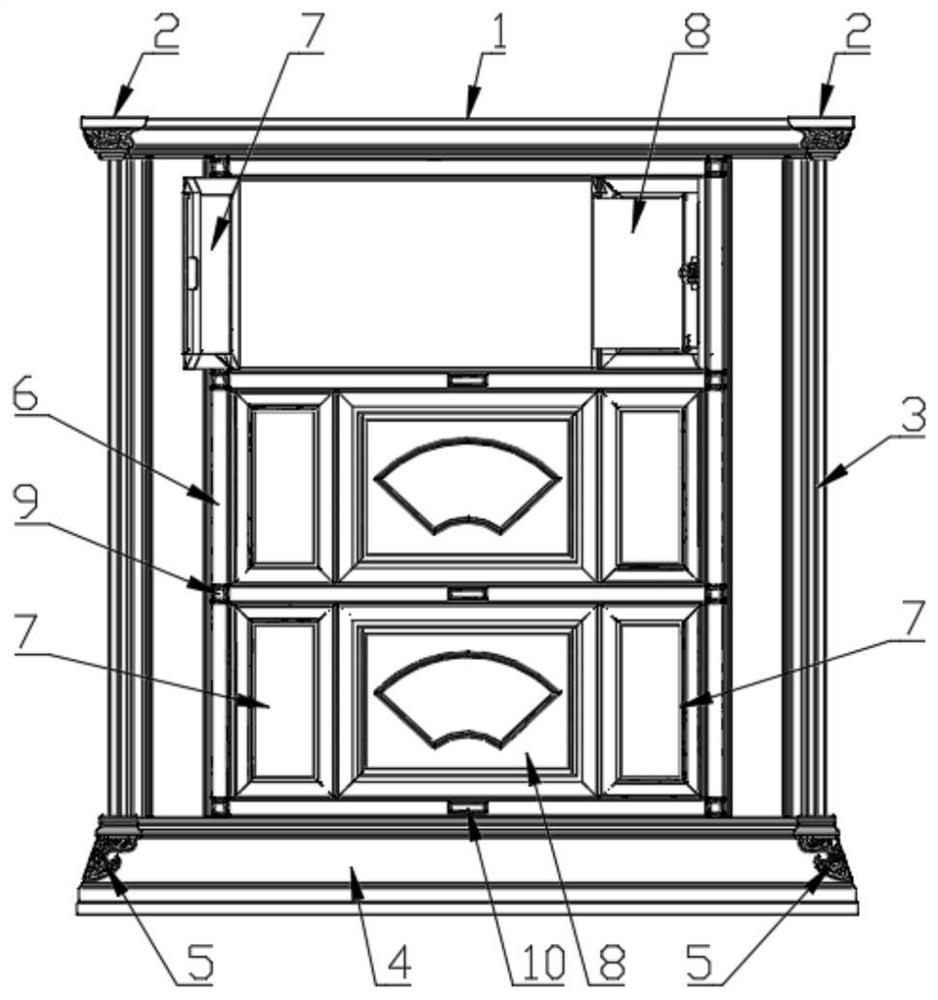

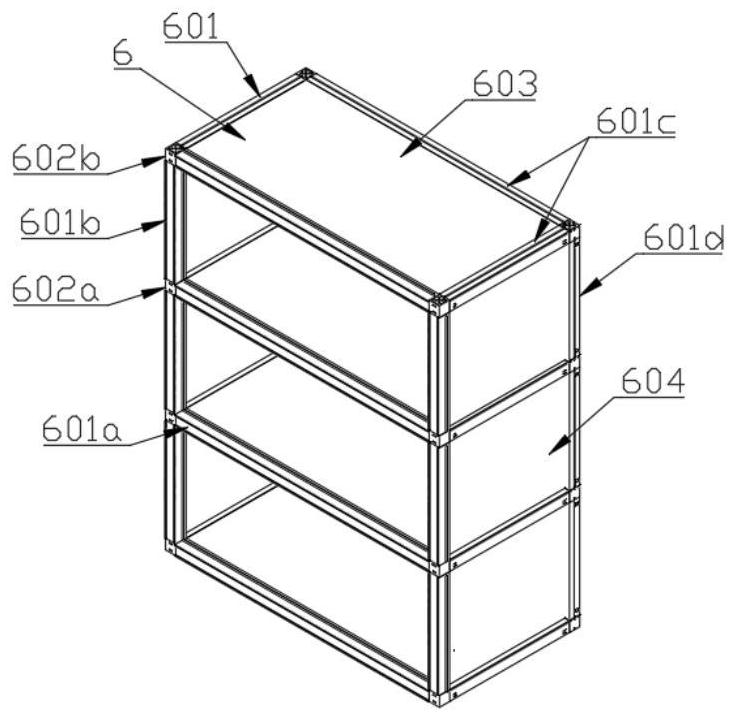

A combined urn storage rack

ActiveCN110872912BHigh strengthEasy to plug inBurial vaultsMonumentsMortise and tenonStructural engineering

The invention discloses a combined type cinerary casket storing frame. The combined type cinerary casket storing frame comprises a storing box and is characterized in that a top cover is arranged at the upper end of the storing box, a base is arranged at the lower end of the storing box, side protecting frames are arranged on the left side and the right side correspondingly, the storing box comprises a skeleton, side doors and main doors, the skeleton is provided with a plurality of layers, the layers are inserted and connected into a cuboid framework structure through general tenon parts, each layer of the skeleton is provided with side doors and one main door, two side doors are arranged on each layer and are symmetrically arranged on the left side and the right side of the storing box,the main door is arranged between the two side doors, the side door on the left side and the main door are arranged to be of an opposite opening structure, and an interlayer is arranged between the side protecting frame and a sealing plate of the side face of the storing box. According to the frame, the skeleton is made of profiles, the profiles are inserted and connected through the general tenonparts and mortise and tenon joints to be mutually connected fixedly, the sealing plate, layer plates and the skeleton are inserted and connected, the side doors and the main doors are inserted and connected, inserting and connecting are easy, screws, rivets, connectors and gaps cannot be seen from inside to outside, assembling and disassembling are convenient, and appearance is attractive.

Owner:江西元宗科技有限公司

Belt packing machine

ActiveCN104029842BReduce gapSolid appearanceWrapping material feeding apparatusWrapper twisting/gatheringMechanical engineering

The invention belongs to the field of packing of columnar explosives, in particular to a belt-type tucking machine. A belt-type tundish machine, including a frame, a conveying mechanism placed on the frame and used for conveying columnar explosives, a film feeding mechanism used to supply the upper film and the lower film, placed at the output end of the film feeding mechanism and the lower film is bent to form a film-folding mechanism for holding the columnar explosive, placed above the conveying mechanism and sequentially seal the corresponding transverse edges and longitudinal edges of the upper film and the lower film to seal the The edge sealing mechanism of the columnar explosive package. The present invention adopts the conveying mechanism to transport the columnar explosive placed between the upper film and the lower film. The film folding mechanism bends the lower film to form a receiving groove to position the columnar explosive. The edges are sealed to form a columnar explosive package, so that the packaging efficiency is high, the gaps between the columnar explosives in the columnar explosive package are small, and it is not easy to move each other, the appearance of the entire columnar explosive package is stable, and the packaging effect is good.

Owner:江苏天明化工有限公司

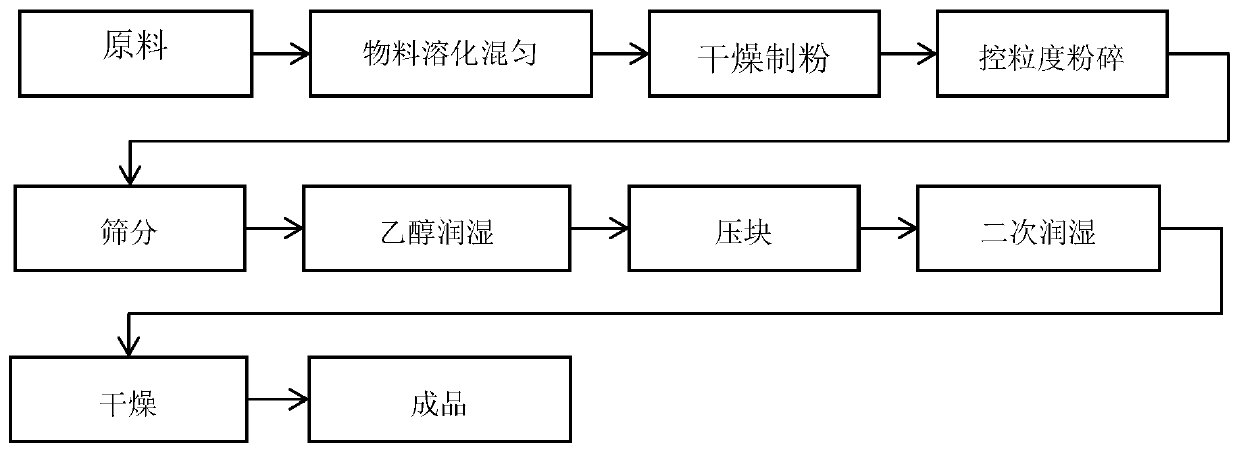

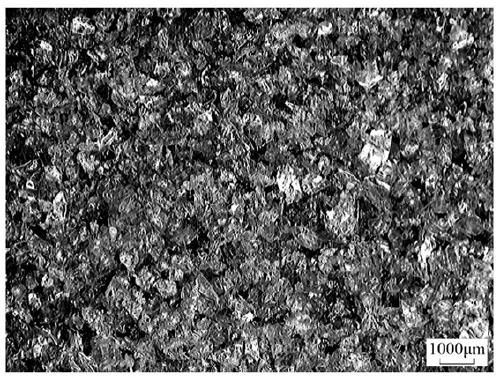

A kind of glue product instant block and preparation method thereof

ActiveCN108926524BSolve technical problems that cannot be quickly resolvedGuaranteed liquidityDispersion deliveryUnknown materialsPolymer scienceHoneycomb

The invention relates to a new instant dosage form of glue products, in particular to an instant block of glue products and Soluble Cube Compressing (SCC) Technology. The raw materials are dissolved in water and concentrated to obtain a glue solution; the glue solution is dried to obtain an irregular honeycomb colloid; the colloid is crushed and sieved to obtain a rubber powder with a particle size of not less than 80 mesh; use 85-95% After the rubber powder is wetted with alcohol, it is compressed into a block with a compression ratio of 30% to 60%, and the obtained pressed block is an instant block of a rubber product. The instant block of the glue product of the present invention has a loose pore structure inside, a high surface area / volume ratio, and a product density of 0.4 to 0.8 g / cm 3 , can be quickly dissolved in hot water within 2 minutes, and has a crisp taste, which can be taken orally directly, which can meet the convenience of consumers in different situations.

Owner:东阿阿胶保健品有限公司

Method for solder welding

The invention discloses a solder welding method, which comprises the following steps: step 1: preparing tin, a solvent, a terminal plate and a base frame; step 2: skimming the terminal block and hanging the tin; step 3: skimming the bottom frame joint and melting tin at the joint; step 4: terminal block and bottom frame solder welding; step 5: washing the solvent attached to the terminal block andbottom frame by hot water. Compared with the prior art, the solder welding method effectively solves the welding of stainless steel and copper plate, and the products after welding are beautiful andfirm in appearance; the solder welding method has the advantages of simple process and high production efficiency.

Owner:南通舟舰钣金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com